2

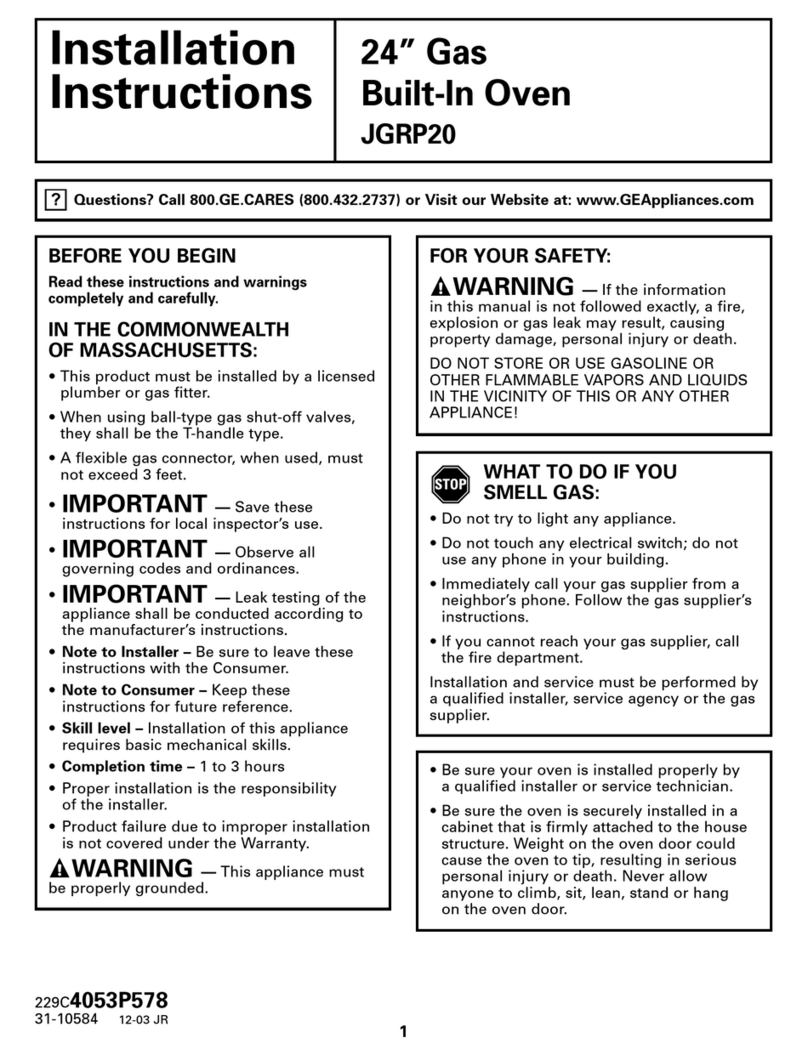

IMPORTANT SAFETY INSTRUCTIONS

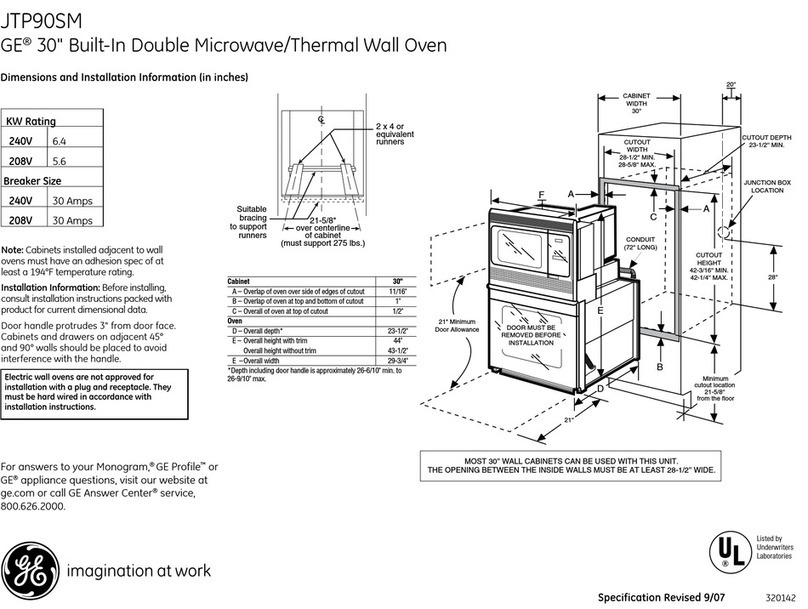

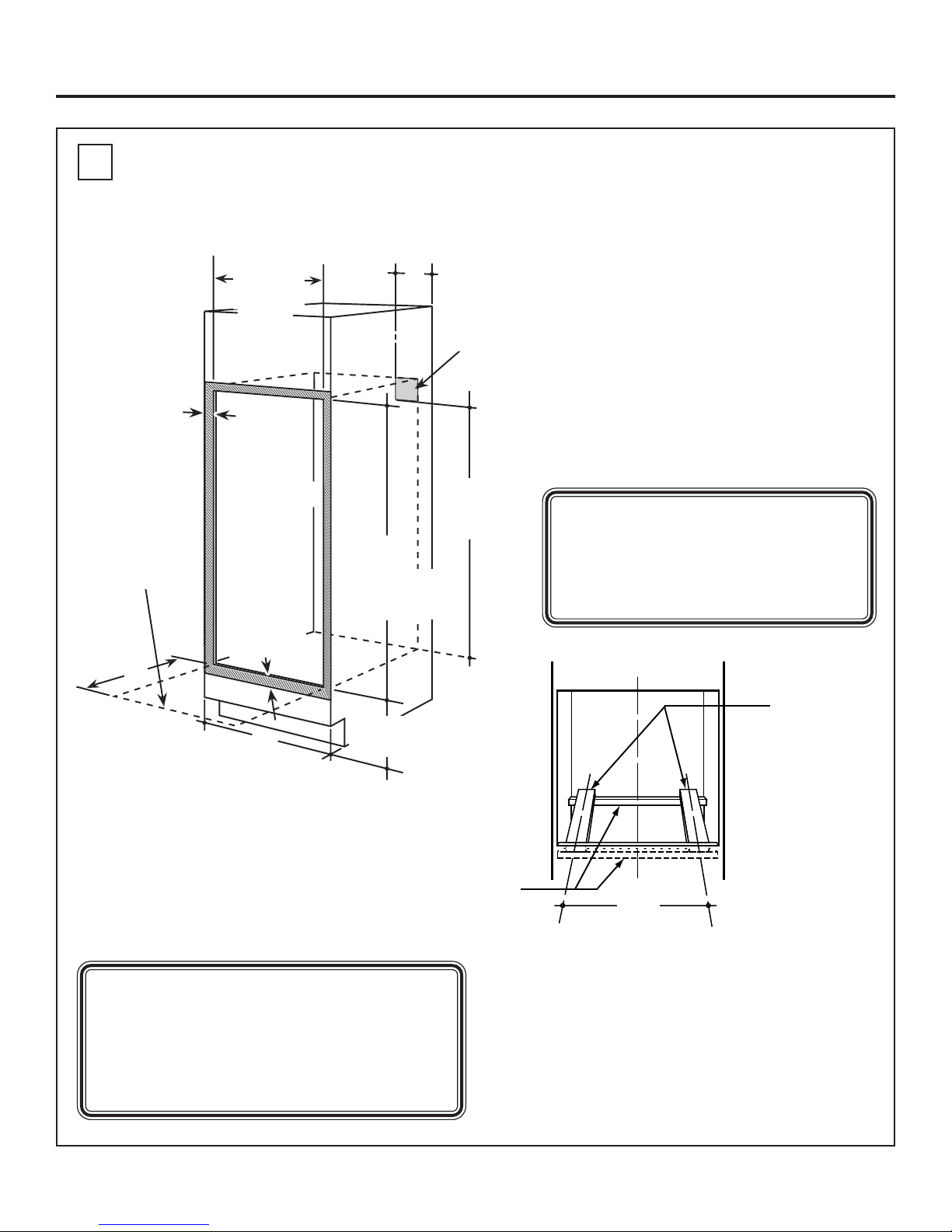

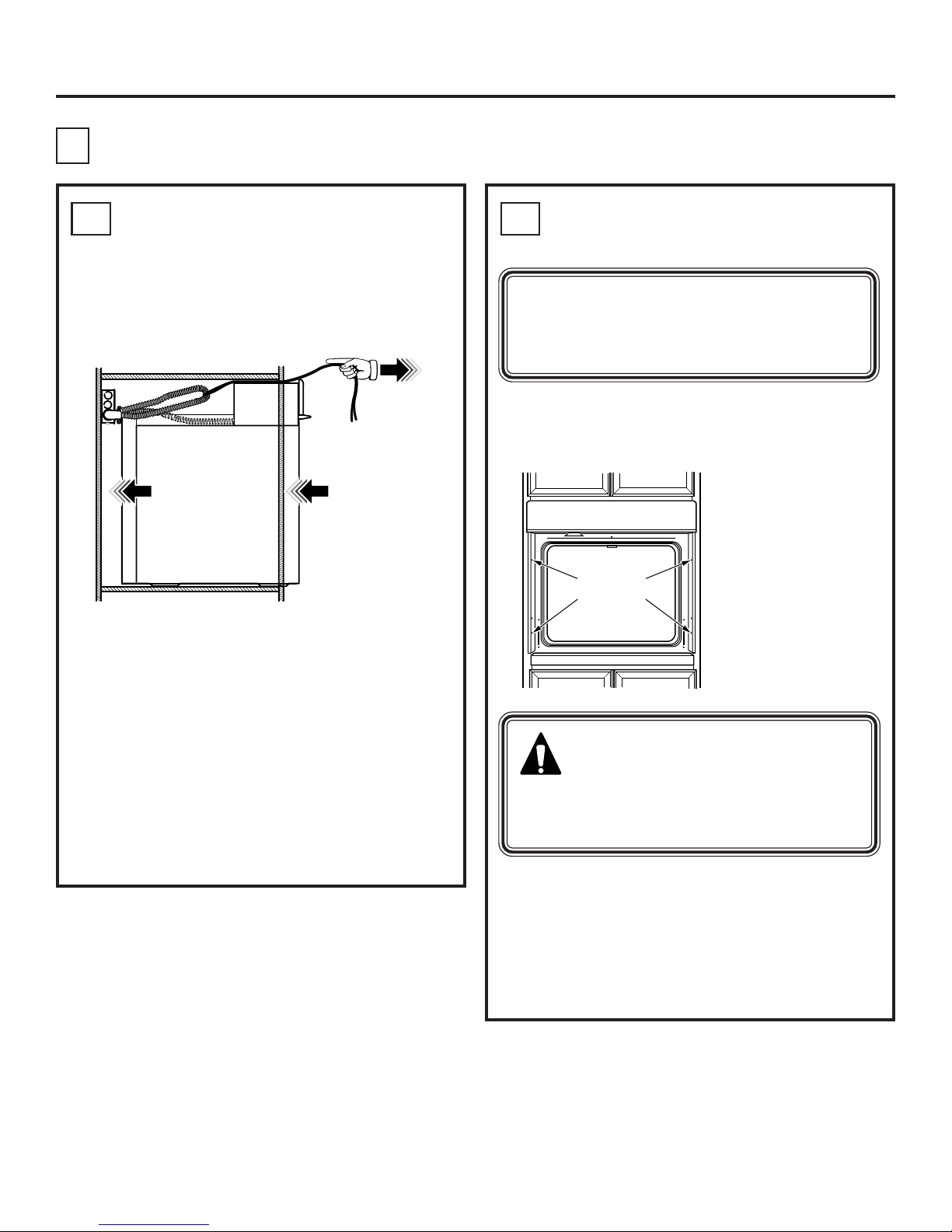

Installation Instructions

For Your Safety

• Be sure your oven is installed properly by

a qualified installer or service technician.

• Be sure the oven is securely installed in a

cabinet that is firmly attached to the house

structure. Weight on the oven door could

cause the oven to tip and result in injury.

Never allow anyone to climb, sit, stand or

hang on the oven door.

• Make sure the cabinets and wall

coverings around the oven can withstand

the temperatures (up to 200°F [93.3°C])

generated by the oven.

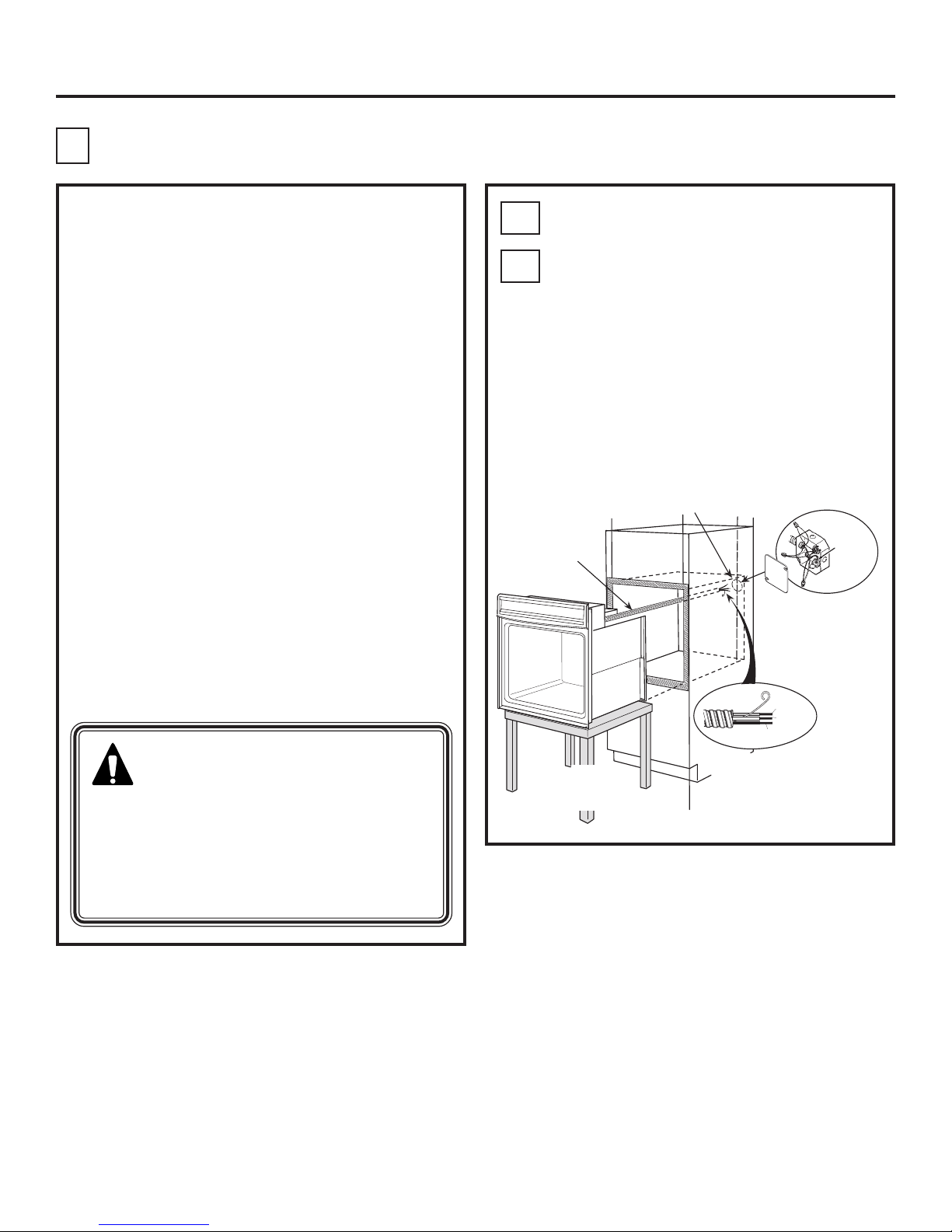

Electrical

Requirements cont.

Rating plate is located on oven side trim,

side front frame or lower front frame.

We recommend you have the electrical wiring

and hookup of your oven connected by a qualified

electrician. After installation, have the electrician

show you where your main oven disconnect is

located.

Check with your local utilities for electrical codes

which apply in your area. Failure to wire your oven

according to governing codes could result in a

hazardous condition. If there are no local codes,

your oven must be wired and fused to meet the

requirements of the National Electrical Code,

ANSI/NFPA No. 70–Latest Edition. You can

get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Effective January 1, 1996, the National

Electrical Code requires that new, but not existing,

construction utilize a four-conductor connection to

an electric oven. When installing an electric oven

in new construction, a mobile home, recreational

vehicle or an area where local codes prohibit

grounding through the neutral conductor,

follow the instructions in the section on NEW

CONSTRUCTION AND FOUR-CONDUCTOR

BRANCH CIRCUIT CONNECTION.

You must use a three-wire, single-phase A.C.

208Y/120 Volt or 240/120 Volt, 60 hertz electrical

system. If you connect to aluminum wiring,

properly installed connectors approved for

use with aluminum wiring must be used.

WARNING:

The electrical

power to the oven supply line

must be shut off while line

connections are being made. Failure

to do so could result in serious injury

or death.

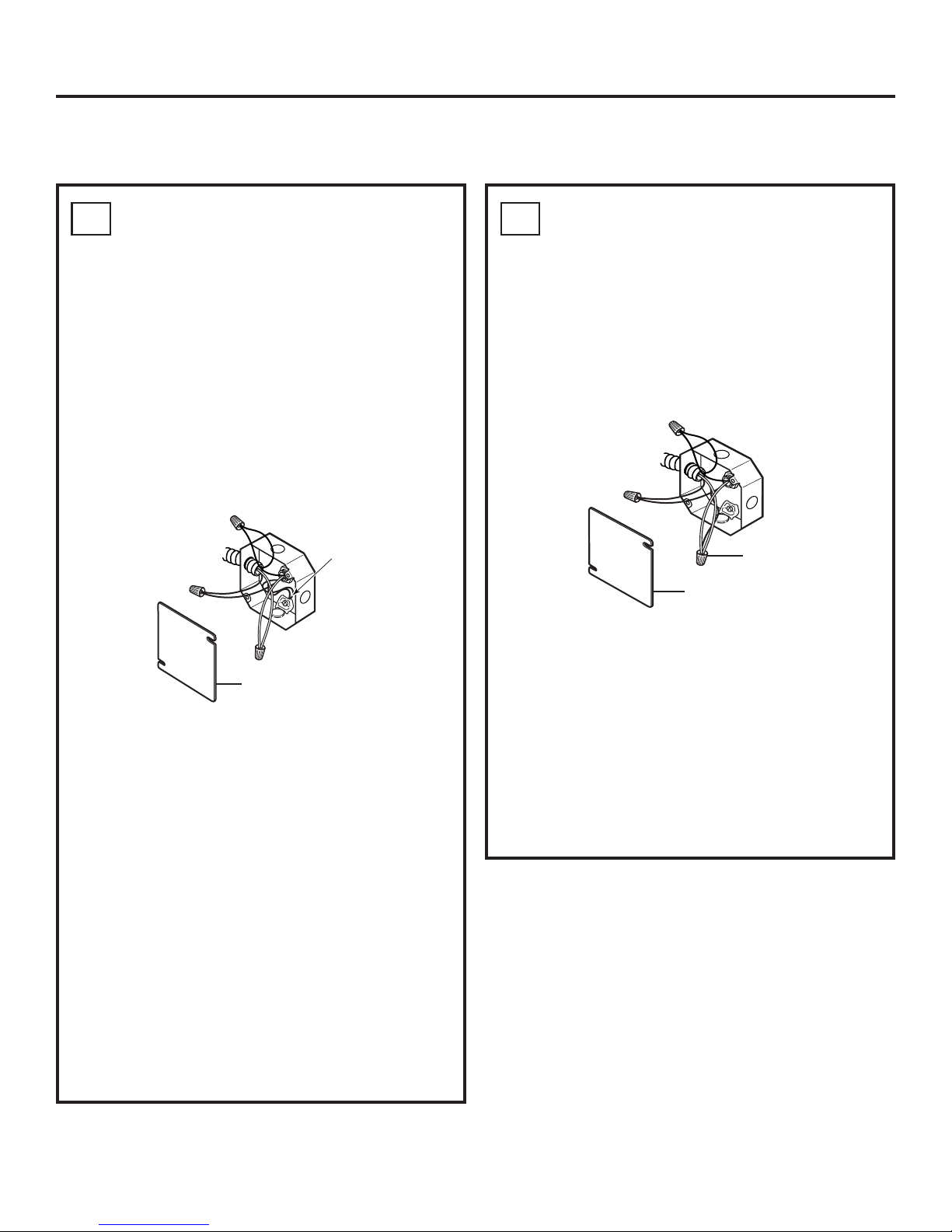

Rating Plate

Location

Electrical

Requirements

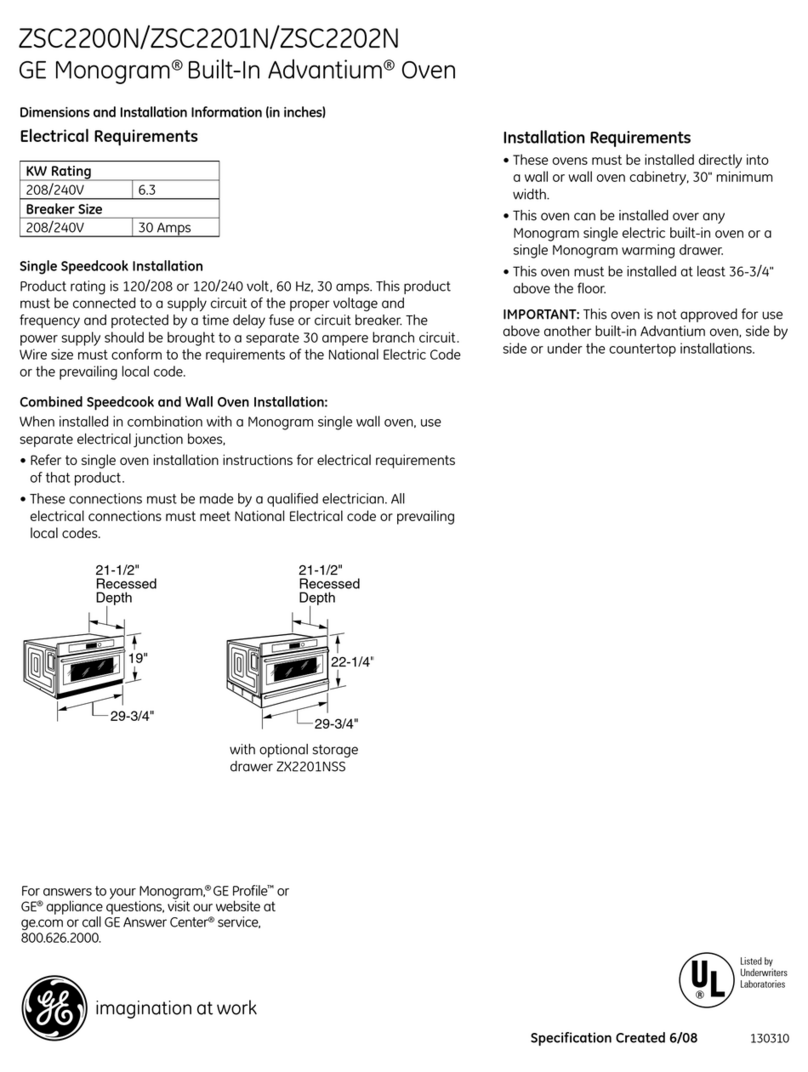

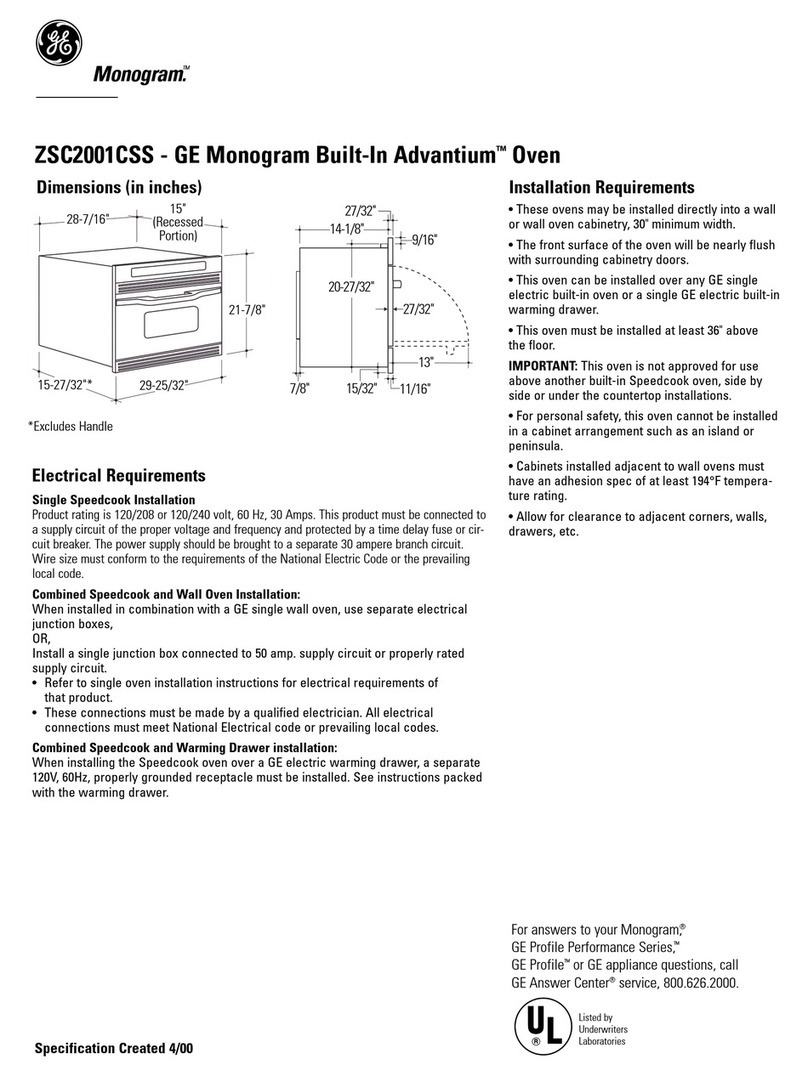

This appliance must be supplied with the proper

voltage and frequency, and connected to an

individual, properly grounded branch circuit,

protected by a circuit breaker or fuse. See the

rating plate located on the oven frame to determine

the rating of the product. Use the chart below to

determine the minimum recommended dedicated

circuit protection.

Recommended

KW Rating KW Rating Circuit Size

240V 208V (Dedicated)

≤4.8 KW ≤4.1 KW 20 Amp

4.9 KW–7.2 KW 4.3 KW–6.2 KW 30 Amp

7.3 KW–9.6 KW 6.3 KW–8.3 KW 40 Amp

9.7 KW–12.0 KW 8.4 KW–10.4 KW 50 Amp