JGB650 SINGLE OVEN

31-17081 06-13 GE

OVEN TEMPERATURE CALIBRATION

The bake temperature can be adjusted from its factory calibration (+or -)

35˚F in 1˚ increments.

1. Press and hold both the BAKE and BROIL pads for about 2 seconds

until the display shows SF.

2. Press the BAKE pad. The current offset setting is in the display.

3. Enter the desired temperature offset using the number pads.

4. Use the BAKE pad to toggle between +/-.

5. Press START key. The display will return to Time or Day Clock.

BAKE BURNER REMOVAL

• Remove oven door and drawer.

• Remove the screws on the oven oor at the back of the oven cavity and

remove oven oor/deector.

• Remove 1/4” hex head screws from the bracket holding the burner to

the back wall of the range.

• Remove the screw at the front of the burner.

• Disconnect the igniter wires.

• Remove the Bake Burner.

BACKGUARD DISASSEMBLY

• Remove screws located on the back of the backguard. (There is a set of

screws on each side.)

• Remove the torx screw on the front inside corner of backguard (1 on

each side).

• Gently lift backguard off.

• Be sure to reassemble rear cover and backguard per original assembly.

OVEN BURNER IGNITION SYSTEM

The ignitor is a “Norton” style rectangular glowbar. The ignition circuit

consists of the electronic control, the igniter, and the oven safety valve

(gas valve). The three components are wired in series.

The most important points to know about the ignition system are:

1. THE IGNITOR RESISTANCE DECREASES AS THE IGNITER SURFACE

TEMPERATURE INCREASES.

2. THE SAFETY VALVE OPERATES BY CURRENT, NOT VOLTAGE.

From a cold start, the ignitor needs 30-60 seconds, with voltage applied, to

reduce the electrical resisteance enough to provide a minimum of 2.9 amps

of current ow in the series circuit. This is the required current ow needed

for the safety valve to open to supply gas to the burner. The glowbar should

provide a steady current ow of between 3.2 to 3.6 amps owing in the circuit.

The igniter will remain energized at all times during burner operation. If the

igniter glows red but does not draw at least 2.9 amps, the fault is usually with

the igniter, not the valve. Always check the oven shut-off valve for a “No Oven”

condition.

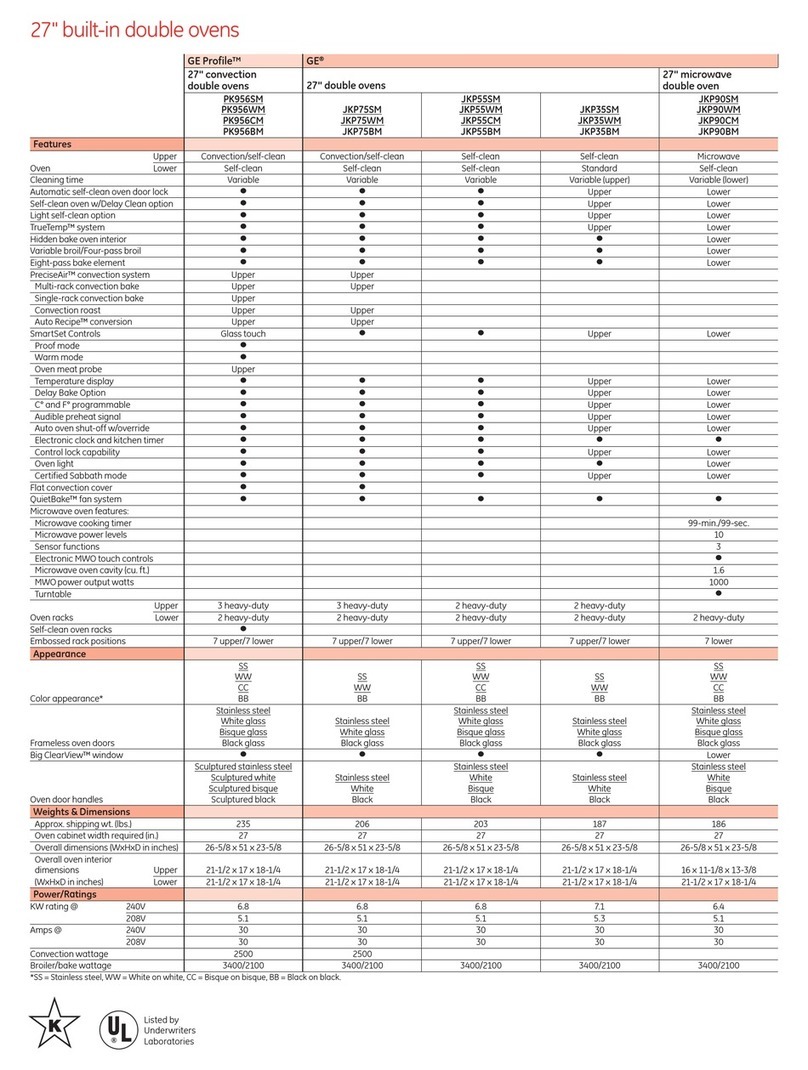

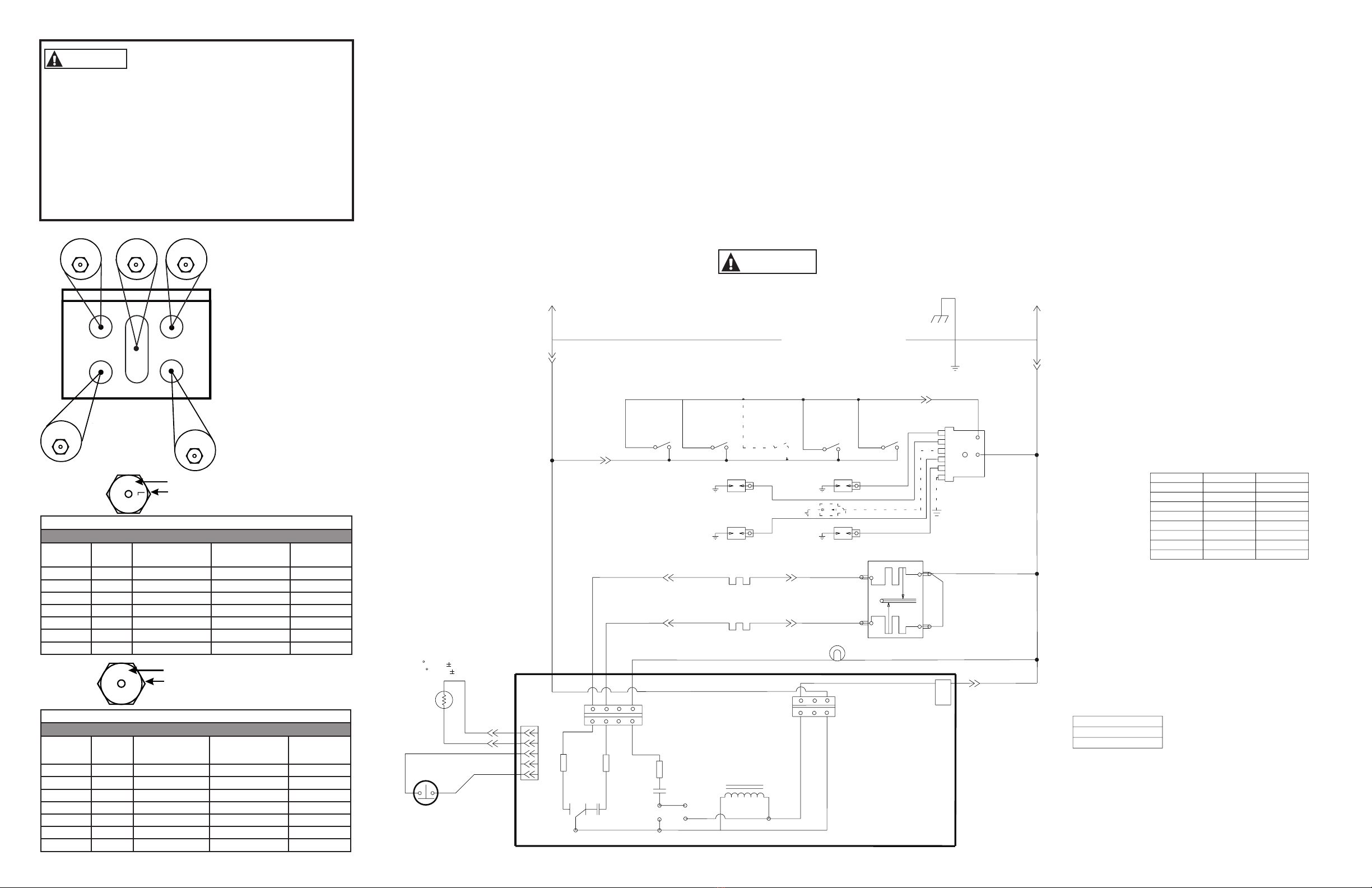

CONTROL SYSTEMS

There are three versions of the control used on gas ranges. Versions 1, 2 and

3. Features and appearance will vary by model:

Version 1

Has Delay Start and Cook Time features.

Version 2

Has Delay Start, Cook Time and Self Clean features.

Version 3

Has Delay Start, Cook Time, Self Clean and Convection Bake features.

GLOWBAR IGNITION CIRCUIT

L1 N

120 V

T´STAT

T1 to 1.2 Ohms

GLOW BAR

IGNITER OVEN

VALVE

IGNITER GLOWBAR REPLACEMENT

The igniter glowbar and its protective cage are one assembly on

this Norton style igniter. The round Carborundum igniter CANNOT be

substituted for the rectangular Norton Igniter.

• Remove the burner from

the oven. See Bake Burner

Removal in this manual.

• Remove the 1/4” hex head

screws securing the igniter

to the burner.

• Remove the old igniter.

• Install the new igniter and

re-install the two 1/4” hex

head screws to secure the

igniter.

• Reinstall the burner.

WIRING DIAGRAM

WARNING Power must be

disconnected before servicing this

appliance.

222D8441P002

FAILURE MEANING CORRECTION

CODE

SHORTED

CANCEL/OFF KEY

Power down then power up the range. If the fault

condition reappears within 15 minutes–REPLACE

CONTROL.

OVEN

OVERTEMPERATURE

CONDITION

• Door unlocked–oven

exceeded ~620°F

• Door locked–oven

exceeded ~930°F

• Door latch unlocked

while oven in excess

of ~620°F

1. If no overtemperature condition occurred–check all

contacts and connections in sensor circuit. Eliminate

excessive resistance in sensor circuit due to increased

contact/connector resistance.

2. If overtemperature condition occurred–look for

welded relay contacts on bake, broil, or double-line-

break relays. If relay contact welding is confirmed–

REPLACE CONTROL.

3. Ensure Door Latch stays locked for duration of CLEAN

cycle.

F2

OPEN OVEN SENSOR

Sensor resistance

>2900 ohms

Disconnect sensor/latch connector from the control.

Measure sensor circuit resistance at sensor/lock switch

connector (should be ~1100 ohms at room temperature).

Ensure each sensor lead to chassis ground resistance is

infinitely high.

If open or short circuit is detected:

1. Look for cut or pinched sensor harness wire.

2. Look for sensor leads shorted to chassis ground.

3. Look for loss of terminal contact in the harness and at

the control.

4. Check sensor resistance directly at sensor harness

connector (away from the control). If reading is

abnormal–REPLACE OVEN SENSOR.

If sensor circuit appears to be normal:

1. Reinstall sensor/lock switch connector on the control

and measure sensor resistance at solder joints on

the back of the control circuit board. If abnormal

resistance reading is observed–RESTORE CONTACT

PRESSURE OR SENSOR/LOCK SWITCH CONNECTOR.

If corrective actions above do not eliminate the

problem–REPLACE CONTROL.

F3

SHORTED OVEN

SENSOR

Sensor resistance

<950 ohms

F4

SHORTED MATRIX

KEY

Power down then power up the range. If the fault

condition reappears within 15 minutes–REPLACE

CONTROL.

F7

EEPROM ERROR Power down then power up the range. If the fault

condition reappears within 5 minutes–REPLACE

CONTROL.

F8

CONTROL

SUPERVISORY

CIRCUIT FAILURE

REPLACE CONTROL.

F5

F0

T09 FAULT CODES

1100 OHMS@ROOM TEMP

2650 OHMS@CLEAN TEMP

OVEN SENSOR

PINS 4 & 5

DOOR LOCK CIR.

PINS 1 & 3

DOOR LOCK CIR.

PINS 1 & 3

PIN 2 BLANK

CNC

LATCH

BI-METAL

(THERMAL

LOCK

SWITCH

UNLOCK

LOCK

LOCK

COLOR SYMBOL

LAST

NUMBER USED

RED R3

WHITE W10

ORANGE O2

YELLOW Y2

VIOLET V2

BLUEN 2

GRAY S-

BROWNC -

BLACK B-

BLACK/WHITE B/W -

200 C

200 C

R

ELECTRONIC CONTROL

COM

150 C

150 C

MD

SW

V

150 C

V

V

150°C W-7

VALVE

CONTROL

IGNITOR

BAKE

R150 C

RF

SW

150 C

V

V

BROIL

IGNITOR

R

SENSOR

OVEN

150 C

1

2

D

LF

SW

NC

LR

150 C

LR

SW

V

V

ELECTRODE

MD

Y-2 250 C

200 C

IGNITION

MODULE

ELECTRODE

LCH SW

LF

O-2

1

250 C

1

W-9

5

W-8

5

150 C

150 C

N-2

W-6

Y-1

2

1

E

W-8

W-9

200 C

200 C

150 C R

R-3

V-2

C1

N-1

150 C W-2 125 C

150° C N-2

W-5

O-1

LIGHT

OVEN

150 C

150 C

W-3 125 C

V-1

R-2 125° C

125 C

2

R-2

W-4 125°C

125 C

B/W

N

A

2

L1

1B

G

Y-1 150°C

R-1 125°C

W-1 125°C

N-1 150°C

W-1

125 C

NO

F

B

W-10

0-1 150°C

125 C

R-1

150 C

GND

GND

L

BR

BA N

OL

W-1

W-2

W-6

W-5

150 C

RR

SW

V

RR 200 C

ELECTRODE

RF 200 C

NOTES:

ALL LEADS WITH DESIGNATION

NUMBERS THAT ENTER COMMON

LEAD PATH( ) MUST BE

TRACED TO THEIR TERMINATIONS.

- - - -THIS CIRCUIT NOT IN ALL MODELS.

W-3 125°C

V-1

N

L

125°C