30″ELECTRIC TRIVECTION™WALL OVEN

IMPORTANT SAFETY NOTICE: This information is intended for use by

individuals possessing adequate backgrounds of electrical, electronic and

mechanical experience. Any attempt to repair any major appliance may

result in personal injury and property damage. Neither the manufacturer nor

the seller can be responsible for the interpretation of this information or

assume any liability in connection with its use. THIS BOOKLET PROVIDES

BASIC INFORMATION INTENDED TO ASSIST A KNOWLEDGEABLE

TECHNICIAN IN TROUBLESHOOTING PROBLEMS WITH THE OVEN. FOR

DETAILED INFORMATION ON SERVICING THIS OVEN, REFER TO SERVICE

GUIDE 31-3115.

DISCONNECT POWER BEFORE SERVICING

IMPORTANT: RECONNECT ALL GROUNDING DEVICES. All parts of this

appliance capable of conducting electrical current are grounded. If

grounding wires, screws, straps, clips, nuts or washers used to complete a

path to ground are removed for service, they must be returned to their

original position and properly fastened.

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY.

A. A MICROWAVE EMISSION CHECK SHOULD BE PERFORMED PRIOR TO

SERVICING IF THE OVEN IS OPERATIVE.

B. DO NOT OPERATE OR ALLOW THE OVEN TO BE OPERATED WITH THE

DOOR OPEN.

C. IF THE OVEN OPERATES WITH THE DOOR OPEN:

1. INSTRUCT THE USER NOT TO OPERATE THE OVEN.

2. CONTACT THE MANUFACTURER AND THE CENTER FOR DEVICES

AND RADIOLOGICAL HEALTH IMMEDIATELY.

D. MAKE THE FOLLOWING SAFETY CHECKS ON ALL OVENS TO BE

SERVICED BEFORE ACTIVATING THE MAGNETRON OR OTHER

MICROWAVE SOURCE, AND MAKE REPAIRS AS NECESSARY:

1. INTERLOCK OPERATION

2. PROPER DOOR CLOSING

3. SEAL AND SEALING SURFACES (ARCING, WEAR AND OTHER

DAMAGE)

4. DAMAGE TO OR LOOSENING OF HINGES AND LATCHES

5. EVIDENCE OF DROPPING OR ABUSE

E. BEFORE TURNING ON MICROWAVE POWER FOR ANY TEST OR

INSPECTION WITHIN THE MICROWAVE GENERATING

COMPARTMENTS, CHECK THE MAGNETRON, WAVE GUIDE OR

TRANSMISSION LINE AND CAVITY FOR PROPER ALIGNMENT,

INTEGRITY AND CONNECTIONS.

F. ANY DEFECTIVE OR MISADJUSTED COMPONENTS IN THE INTERLOCK

MONITOR, DOOR SEAL AND MICROWAVE GENERATION AND

TRANSMISSION SYSTEMS SHALL BE REPAIRED, REPLACED OR

ADJUSTED BY PROCEDURE DESCRIBED IN THIS MANUAL BEFORE

THE OVEN IS RELEASED TO THE OWNER.

G. A MICROWAVE LEAKAGE CHECK TO VERIFY COMPLIANCE WITH THE

FEDERAL PERFORMANCE STANDARD SHOULD BE PERFORMED ON

EACH OVEN PRIOR TO RELEASE TO THE OWNER.

GROUNDING SPECIFICATIONS

Ground Path Resistance 0.10 ΩMax.

Insulation Resistance 250 KΩMin.

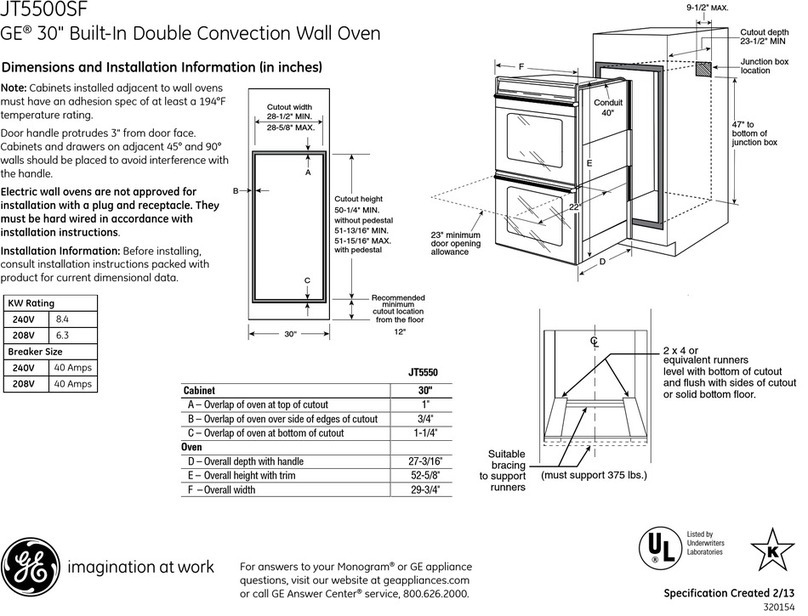

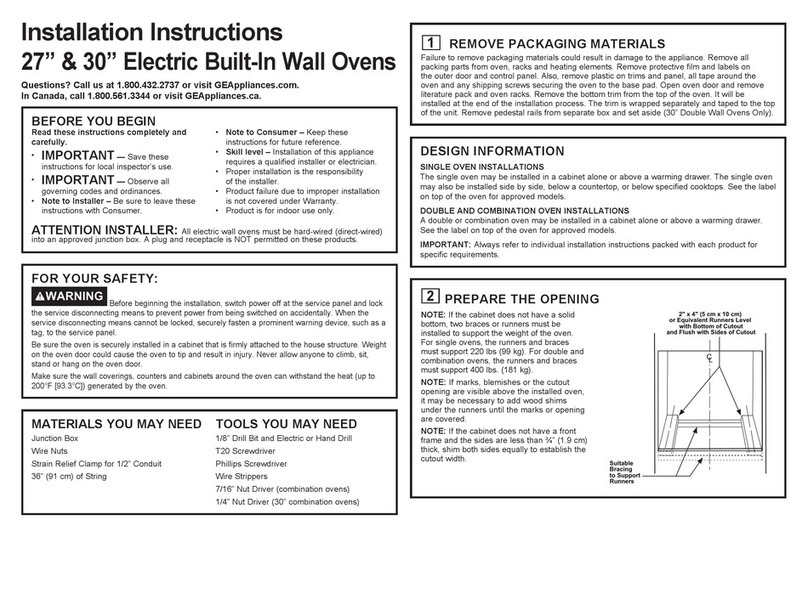

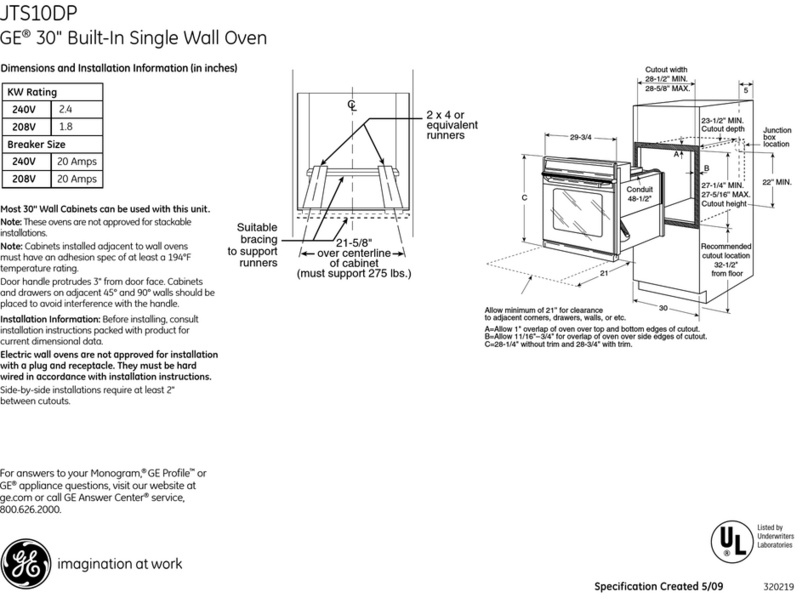

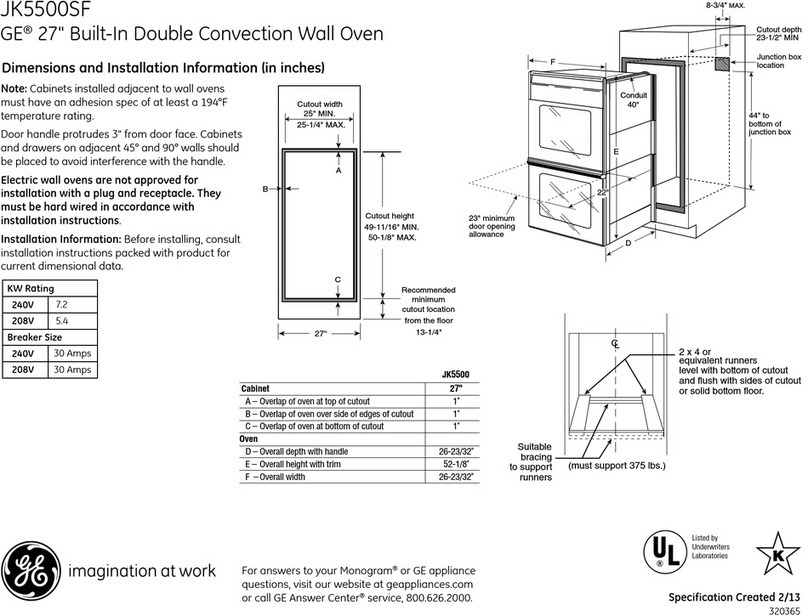

INSTALLATION POWER REQUIREMENTS

Power Supply: This appliance must be be supplied with proper voltage and

frequency and connected to an individual, properly grounded branch circuit

breaker or time-delay fuse as noted on the rating plate. Wiring must conform to the

National Electrical Code. The rating plate is located on the lower front frame

behind the oven door.

CAUTION: This oven power supply cable is recognized for copper wire only,

NOT ALUMINUM WIRE. Refer to the Installation Instructions for additional details.

OVERCURRENT PROTECTION—

WALL-MOUNTED OVEN

NEC FUSE MAXIMUM KILOWATT RATING

RATING 208V 236V 240V

20 Amp 4.2 4.7 4.8

30 Amp 6.2 7.1 7.2

35 Amp 7.3 8.3 8.4

40 Amp 8.3 9.4 9.6

50 Amp 10.4 11.8 12.0

SERVICE MODE

This electronic control features a service mode to help diagnose a problem caused

by a particular load. To enter Service Mode, disconnect main power to the oven for

at least 15 seconds. Reconnect power and enter ‘0803’ on the keypanel within 5

minutes after the control initializes. Select SERVICE from the SPECIAL MODES

menu. *SERVICE MODE* menu appears. Navigate through SERVICE MODE

menu by pressing the pads next to the NEXT and BACK keys. Available

troubleshooting modes are:

• COOKING LOADS (Verify proper operation of cooking elements, microwave and

convection fan. See troubleshooting section below.)

• DOOR LATCH (Verify proper operation of door lock motor and switches)

• DOOR POSITION (Verify proper operation of door sense switch)

• RTD (Displays oven sensor temperature in red on right display)

• VENT FAN (Verify proper operation of ventilation fan)

• R COOLING FAN (Verify proper operation of cooling fan)

• L COOLING FANS (Verify proper operation of mag cooling fan, HVT fan

and mag stirrer fan)

• OVEN LIGHT (Verify proper operation of oven lights)

• OFFSET (Oven calibration offset in non-microwave modes)

• DISPLAY (Verify operation of display segments by allowing all of them to be

turned on and off. Press CLEAR/OFF key to return display to normal)

• KEYS (Verify proper operation of keypanel)

• LINE VOLT(AGE) (Displays line voltage L1-L2 in the upper temperature display)

• F CODES (Displays up to last 7 ERC Failure Codes)

NOTE: Always check failure codes and then clear them.

• COSENSOR (KENMORE ONLY)

Press EXIT to return to normal cooking mode.

ACRONYM TABLE

CAP = capacitor

COM = common

CO Sensor (on some models) = carbon monoxide sensors

for Sens-a-Clean (on some models)

ERC = engineering range control

F codes = ERC failure codes

HVT = high voltage transformer

J = jumper/connector on a PCB

K = relay on a PCB

MAG = magnetron

MLB = main logic board

MPB = main power board

MW = microwave

NC = normally closed

NO = normally opened

PCB = printed circuit board such as MLB or MPB

RTD = resistive thermal device (oven temperature sensor)

TCO = thermal cutout

TROUBLESHOOTING COOKING LOADS IN SERVICE MODE

CAUTION: TO PREVENT ELECTRICAL SHOCK, USE EXTREME CAUTION

WHEN DIAGNOSING OVEN WITH OUTER COVERS REMOVED AND POWER

“ON”. THE HIGH VOLTAGE CIRCUIT OF THE MAGNETRON POWER

SECTION (HVT, CAPACITOR, DIODE, MAGNETRON) IS 4400 VOLTS

POTENTIAL WITH RESPECT TO GROUND.

WAIT AT LEAST 5 MINUTES AFTER POWERING DOWN BEFORE

SERVICING THE MAGNETRON POWER SECTION.

CAUTION: HEATSINKS ON MAIN POWER BOARD ARE ELECTRICALLY

LIVE. TAKE SPECIAL PRECAUTIONS WHEN TROUBLESHOOTING THE

MAIN POWER BOARD WITH POWER “ON”. WAIT AT LEAST 5 MINUTES

AFTER POWERING DOWN BEFORE SERVICING THE MAIN POWER BOARD.

Cooking loads (bake, broil, convection elements and convection fan) can be

energized individually through SERVICE MODE (Press key next to COOKING

LOADS, then appropriate load.) When the appropriate load is turned on in

SERVICE MODE, first verify that the element is heating or the fan is turning.

If load is not energized, check AC relay voltages according to the second column

in the following table:

SERVICE MODE (CONT.)

RELAY CONTROL TABLE

Note: To turn off all loads that are energized in COOKING LOADS, press the

CLEAR/OFF key or exit the COOKING LOADS menu. If load is not turned off,

additional loads can be turned on at the same time.

If AC voltage measures OK, then check the load (element, fan, lock motor, HVT, etc.)

and/or wiring to the load and repair/replace as required. If there is no AC voltage

supplied to the load through the power relays per the wiring schematic, then check

the DC power supply voltages from the Main Power Board (MPB-J3 connector) to

the Main Logic Board (MLB-J5 connector) according to the following table:

If voltages do not measure according to the table above, replace Main Power

Board. If voltages measure OK, then measure DC voltages according to the

previous relay control table (relay control signals columns 3, 4 and 5). If the MLB-

J3 pins do not provide the correct DC voltages, then replace the Main Logic Board.

SERVICE MODE (CONT.)

If display is blank, oven light does not operate when the oven door is opened and

keypanel does not respond, first check DC power supply voltages. Next, check DC

voltages at MLB J2: J2-2, J2-4, J2-6, J2-8 should be +12VDC. If not, replace Text

Display and/or Time/Temp Display.

If DC power supply voltages are OK:

If display is blank and keyboard is not responding, replace MLB.

If just the display is blank, replace the display.

If just the keyboard is not responding, check glass touch display. If OK, replace MLB.

If oven light does not turn on when door is opened, check oven light relay per

relay troubleshooting table. If relay voltages are OK, check door sense switch per

DOOR SWITCH section.

MICROWAVE

a. Microwave Leakage Test

Place 275mL of water in a 600mL beaker.

Place beaker in center of oven shelf.

Set meter to 2450Hz scale.

Enter SERVICE MODE, press COOKINGLOADS, then MW.

Time for 5 minute test.

Hold probe perpendicular to surface being tested and scan surface at rate

of one inch/sec.

Test following areas:

Entire perimeter of door and control panel.

Viewing surface of door window.

Exhaust vents.

Maximum leakage not to exceed 4 mW/cm2.

Record Data on service invoice and microwave leakage report.

NOTE: Maximum allowable leakage is 5 mW/cm2. 4 mW/cm2is used to

allow for measurement and meter accuracy. Inform manufacturer of any

oven found to have emissions in excess of 5 mW/cm2. Make repairs to

bring the unit into compliance at no cost to the owner and try to determine

cause. Instruct owner not to use oven until it has been brought into compliance.

b. Performance Testing

Standard test load will be 1 liter (1000mL) of water with an initial

temperature 59° ~ 75°F in a 1000mL beaker (PN WB64X73).

Record initial water temperature.

Place beaker in center of middle oven shelf.

Enter SERVICE MODE, press COOKINGLOADS, then MW.

Time for 2 minutes, then open door.

Record end water temperature.

The difference between the initial and ending temperature should be 12°F

minimum at 240VAC.

NOTE: Standard sparkle blocks are not applicable for testing of the

microwave assist mode in this oven.

c. High-Voltage Capacitor

WARNING: The capacitor holds its 4400V charge for at least 2 minutes

after power is removed. Always be certain that the capacitor is discharged

before servicing. Mechanically discharge by placing an insulated handle

screwdriver between the diode connection of the capacitor and oven

chassis ground.

d. Magnetron

The magnetron cannot be serviced from the component compartment;

the unit must be removed from the wall. Be sure to replace the ground

wire under the screw head when installing. Make sure that the magnetron

is seated flat against the mounting surface.

e. Special assembly note

Elements, convection fan and oven light contain special radiation screens

and chokes. Be sure to replace these in the oven cavity. Take special care

not to strip any screws when replacing these components.

229C4059P444-1

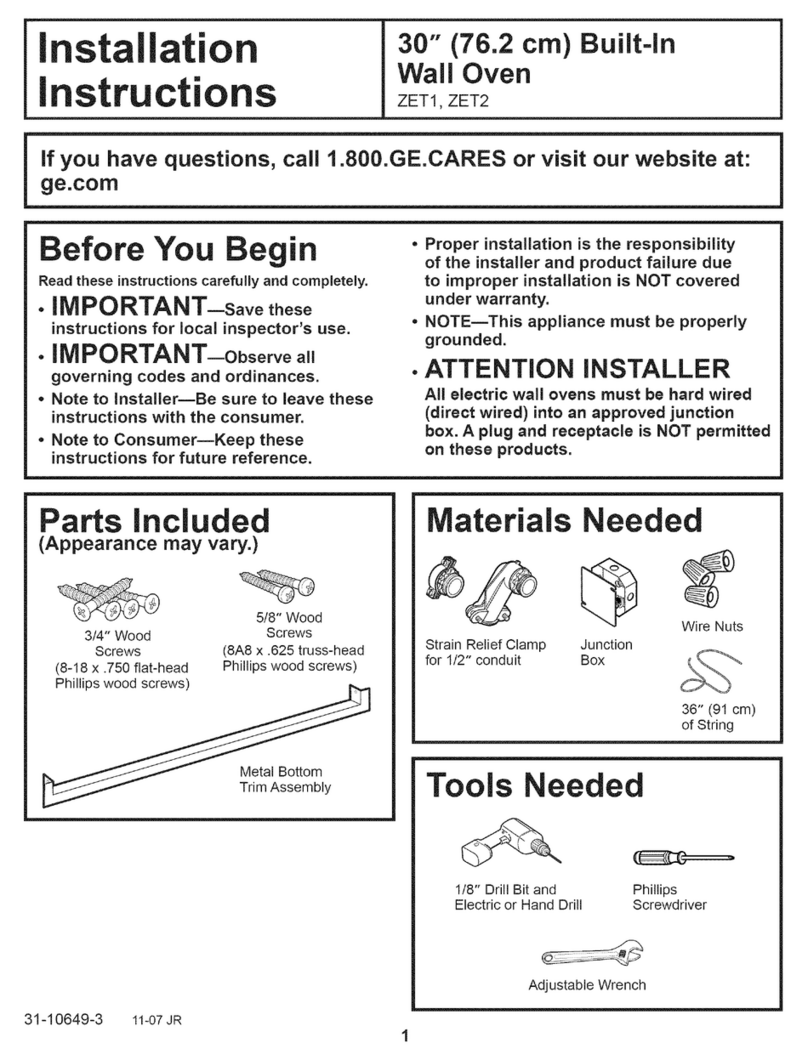

The branch circuit load for one

wall-mounted oven or one

counter-mounted cooktop is the

rating on the nameplate of the

appliance. The branch circuit

load for a counter-mounted

cooktop and not more than

two wall-mounted ovens – all

supplied from a single branch

circuit and located in the same

room – shall be computed by

adding the nameplate ratings of

the individual appliances and

treating this total as equivalent

to one range.