JGBP86WEA JGBP85WEA JGBP79WEA JGBP35WEA

JGBP86AEA JGBP85AEA JGBP79AEA JGBP35AEA JGBP30WEA JGBP26WEA

JGBP90MEA JGBP86BEA JGBP85BEA JGBP79BEA JGBP35BEA JGBP30AEA JGBP30BEA JGBP28BEA JGBP27BEA JGBP26AEA JGBP26BEA JGBP24BEA

Capacity

Extra-large oven l lll l l ll l ll l

Features

Oven cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning Self-Cleaning

Cooktop burners Sealed Sealed Sealed Sealed Sealed Sealed Sealed Sealed Sealed Std./Twin Std./Twin Std./Twin

Maximum Output burner (2) 12,000/ (2) 12,000/ (2) 12,000/ (2) 12,000/ (1) 12,000/ (1) 12,000/ (1) 12,000/

(Nat.) 1,000 BTU 1,000 BTU 1,000 BTU 1,000 BTU 1,000 BTU 1,000 BTU 1,000 BTU

(1) 5,000/ (1) 5,000/ (1) 5,000/ (1) 5,000/ (1) 5,000/ (1) 5,000/ (1) 5,000/

Precise Simmer burner (Nat.) 600 BTU 600 BTU 600 BTU 600 BTU 600 BTU 600 BTU 600 BTU

(1) 9,500/ (1) 9,500/ (1) 9,500/ (1) 9,500/ (2) 9,500/ (2) 9,500/ (2) 9,500/ (4) 9,500/ (4) 9,500/

All-purpose burners (Nat.) 850 BTU 850 BTU 850 BTU 850 BTU 850 BTU 850 BTU 850 BTU 850 BTU 850 BTU

Valves (degree of turn) 270 270 270 270 270 270 270 140 140 270 270 270

TrueTemp™ System l lll l l l ll

SmartLogic™ controls l lll l l l ll

QuickSet oven controls QuickSet V QuickSet V QuickSet V QuickSet IV QuickSet IV QuickSet III QuickSet III QuickSet II QuickSet II QuickSet III QuickSet III QuickSet II

Auto Self-Clean l lll l l ll l ll l

Electronic oven control l lll l

Hi/Low broil l lll l

Electronic clock and timer l lll l l ll l ll l

Automatic oven timer l lll l l l ll

Audible preheat signal l lll l l ll l ll l

Auto oven shut-off l lll l l ll l ll l

One-piece upswept cooktop BC Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam.

Lift-up cooktop ll l

Easy-clean porcelain-

enameled subtop ll l

Grey Grey Grey Grey

Porcelain-enameled Taupe Taupe Taupe Taupe Grey

one-piece drip pans Black Black Black Black Black Taupe Black Opt. Access. Opt. Access. Chrome Black Opt. Access.

Profes. Grates Grey Dxe. Cast Grey Dxe. Cast Grey Std. Cast Grey Dxe. Grey Std.

Grey Taupe Taupe Taupe Porc. Steel Black Porc. Steel

Profes. Taupe Deluxe Cast Deluxe Cast Std. Cast Taupe Deluxe Deluxe Black Std. Black Std. Taupe Std. Black Std. Black Std.

Removable square grates Grates Black Black Dxe. Cast Black Dxe. Cast Black Std. Cast Porc. Steel Porc. Steel Porc. Steel Porc. Steel Porc. Steel Porc. Steel Porc. Steel

Ignition system Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic

Oven racks 3 3 3 3 2 2 2 2 2 2 2 2

Six embossed rack positions l lll l l ll l ll l

Extra-large broiler pan/grid l lll l l ll l ll l

Scratch-resistant backguard Mirrored Glass Glass Glass Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam. Porc.-Enam.

Fluorescent backguard light ll l

Interior oven light l lll l l ll l ll l

Storage drawer Easy Glide Easy Glide Easy Glide Easy Glide l l ll ll

In-oven broiling l lll l l ll l ll l

Appearance WW WW WW WW

AA AA AA AA WW WW

Color appearance* BC BB BB BB BB AA WH/AD WH/AD WH/AD AA WH/AD WH/AD

White Glass White Glass White Glass White Glass

Frameless removable Almond Glass Almond Glass Almond Glass Almond Glass White Glass Solid White Glass Solid

oven door Mirrored Glass Black Glass Black Glass Black Glass Black Glass Almond Glass Black Glass Black Glass Black Glass Almond Glass Black Glass Black Glass

Oven door with window Big View Big View Big View Big View Big View Big View Big View lll

Professional-

Designer-style handle Style Sure Grip Sure Grip Sure Grip lll l l l l l

Professional-

Designer-style control knobs Style lll

Four leveling legs l lll l l ll l ll l

Weights & Dimensions

Overall oven interior

dimensions (WxHxD in inches) 24 x 17 x 19

Approx. shipping weight (lbs.) 230 220 220 210 210 210 210 210 210 200 200 200

Power/Ratings (2) 12.0/11.0 (1) 12.0/11.0

Top burners (1) 5.0/5.0 (1) 5.0/5.0 (4) 9.5/9.5 (4) 9.0/8.0

(000's BTU?s) Nat/LP (1) 9.5/9.5 (2) 9.5/9.5

Oven/broiler burners 16.0/16.0 Oven

(000's BTU's) Nat/LP 13.5/12.0 Broil

Gas range electrical rating 120V, 60Hz, 5A

LP conversion kit (included) l lll l l ll l ll l

*BB = Black on black, WW = White on white, AA = Almond on almond, WH = White, AD = Almond, BC = Brushed-Chrome, CM = Color-matched indicates color of oven door matches cooktop (either White or Almond).

Factory set for Natural Gas. A set of LP orifices is included with each XL44TM range for LP conversion.

Sealed Burner Models Sealed Burner Models Standard Burner Models

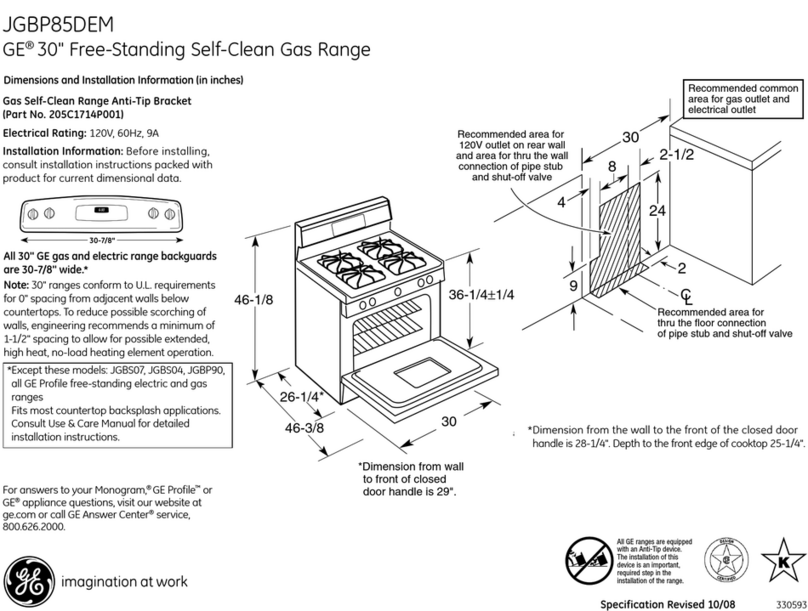

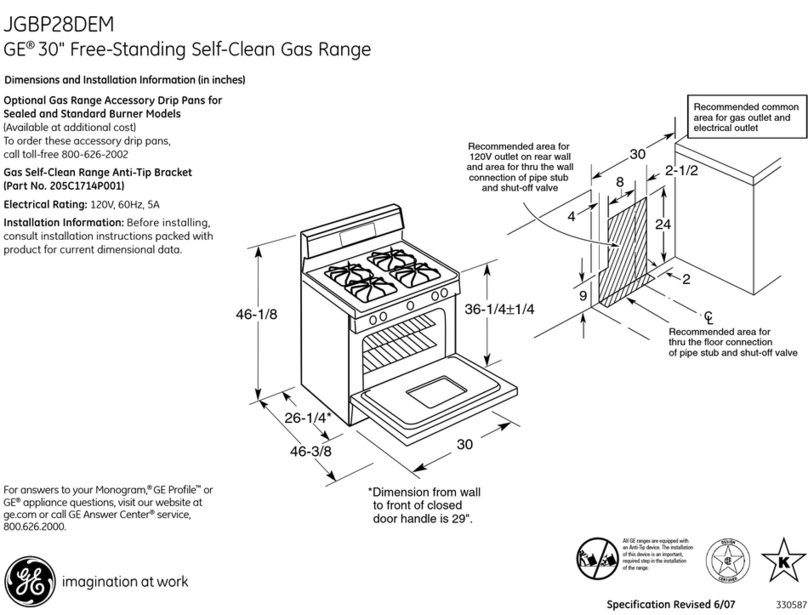

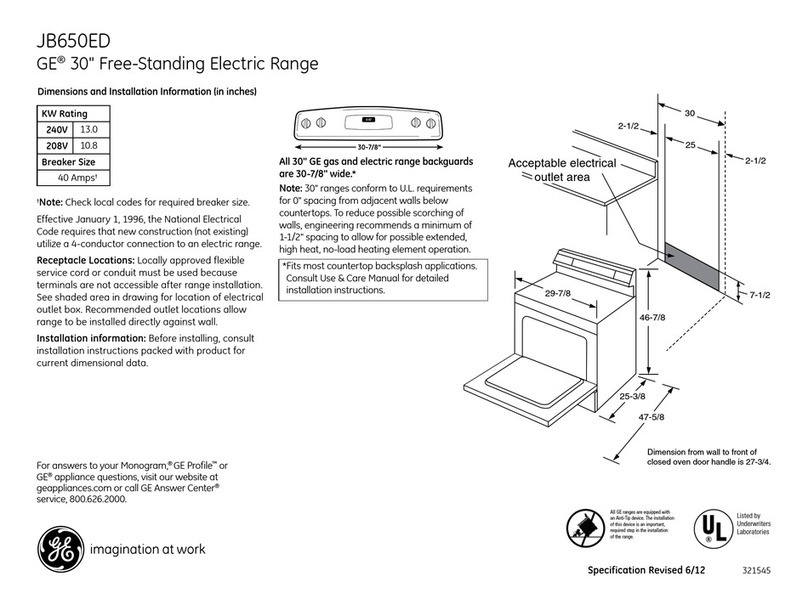

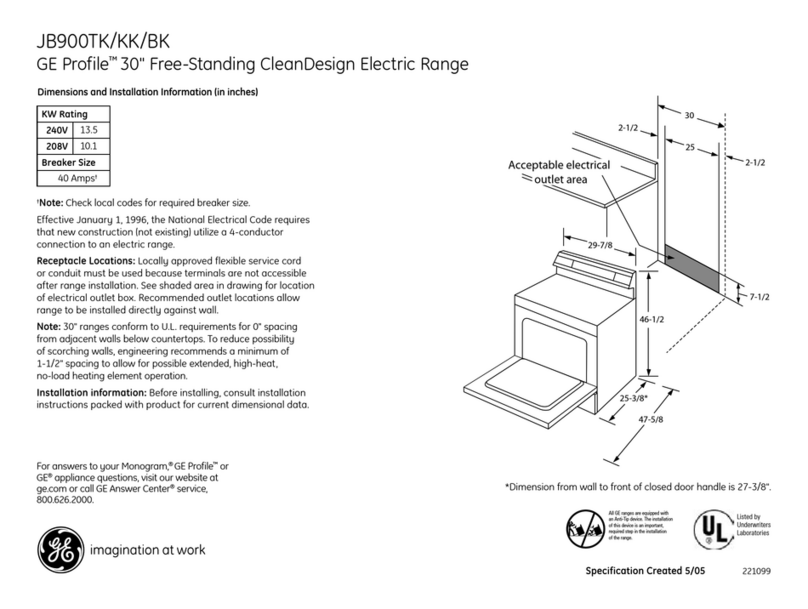

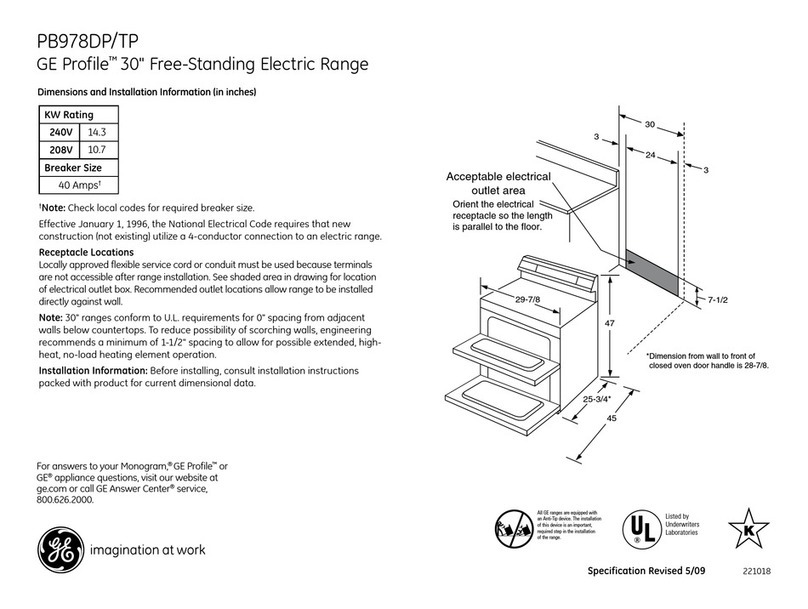

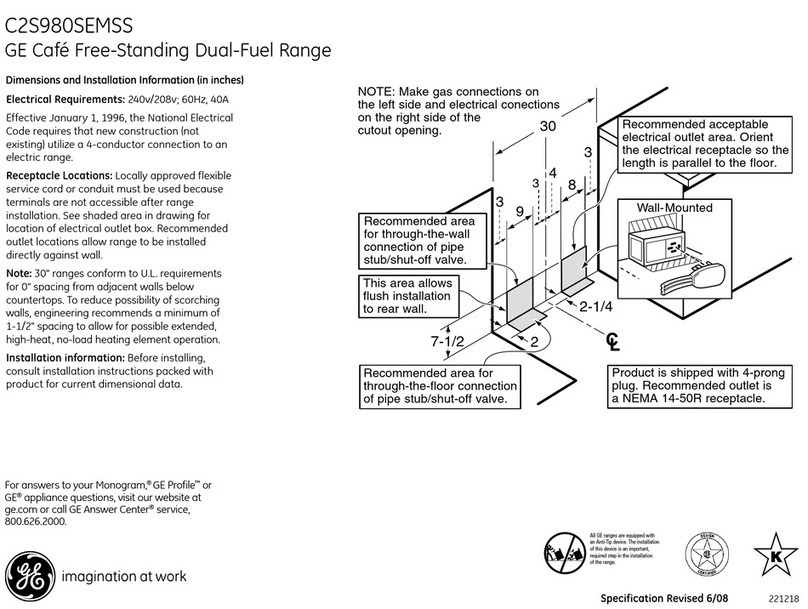

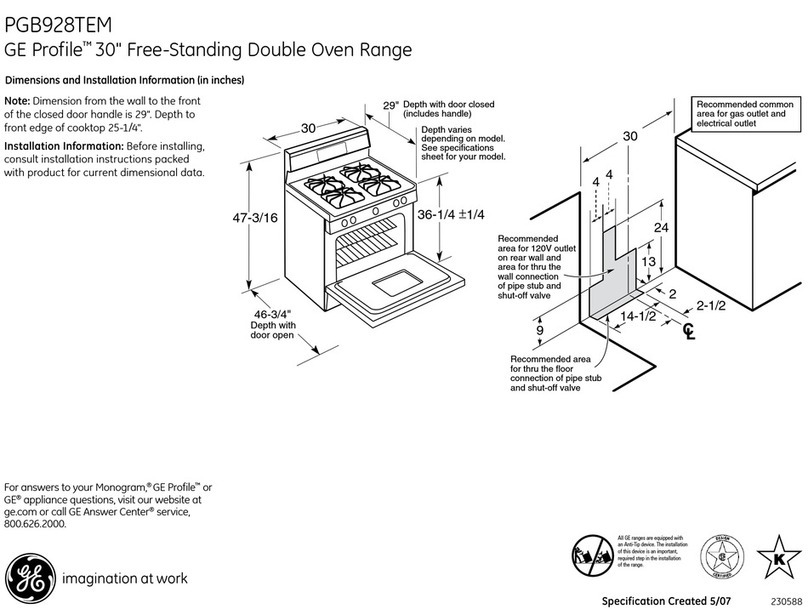

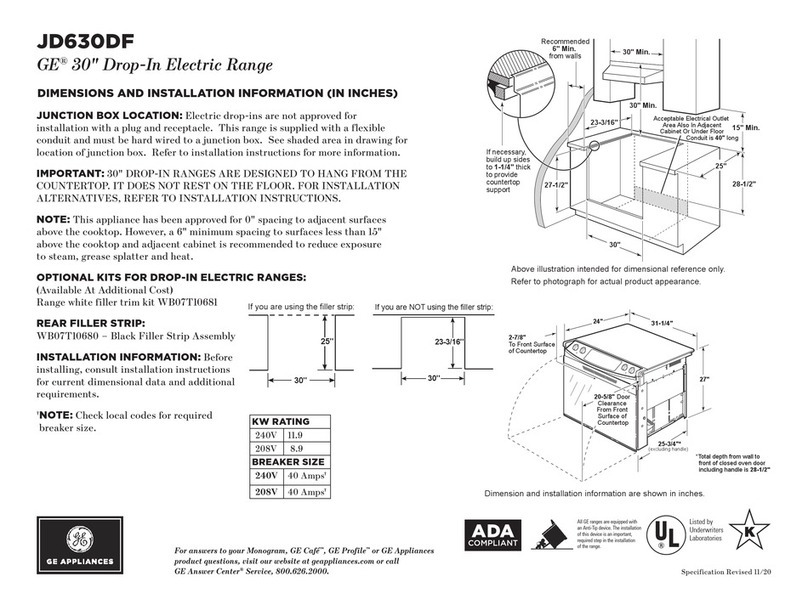

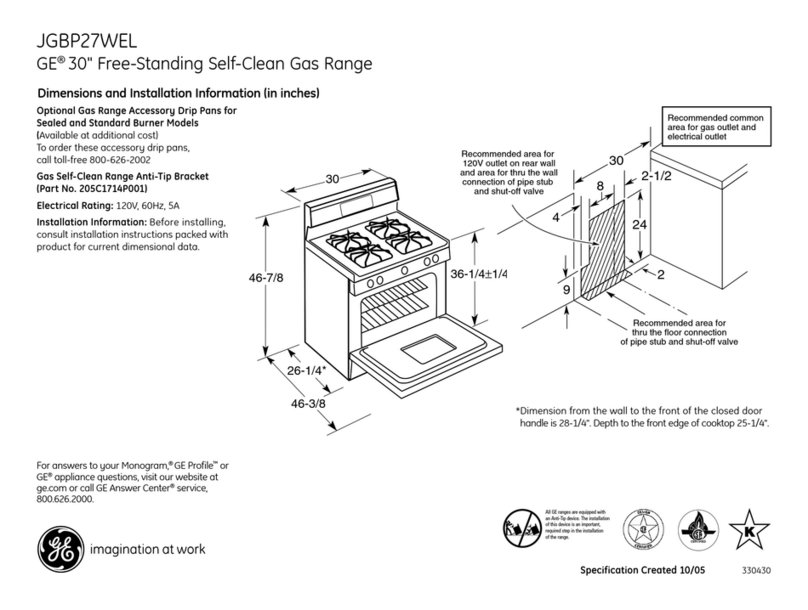

Model A B C* D E

JGBP90MEA 30 47-3/4 26-1/4 46-3/8 36±1/4

JGBP86BEA/WEA/AEA 30 47-3/4 26-1/4 46-3/8 36±1/4

JGBP85BEA/WEA/AEA 30 47-3/4 26-1/4 46-3/8 36±1/4

JGBP79BEA/WEA/AEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP35BEA/WEA/AEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP30BEA/WEA/AEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP28BEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP27BEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP26WEA/AEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP26BEA 30 46-1/2 26-1/4 46-3/8 36±1/4

JGBP24BEA 30 46-1/2 26-1/4 46-3/8 36±1/4

*Dimension from wall to front of closed door handle is 29" on models JGBP86/85/79

and 28-1/4" on models JGBP90/35/30/28/27/26/24.

25-1/4"—Depth to front edge of cooktop.

All GE ranges are equipped

with an Anti-Tip device.

The installation of this

device is an important,

required step in the

installation of the range.

GE Profile™GE