IMPORTANT SAFETY NOTICE: This information is intended for use by individuals

possessing adequate background of electrical, electronic and mechanical experience.

Any attempt to repair a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection with its use.

DISCONNECT POWER BEFORE SERVICING.

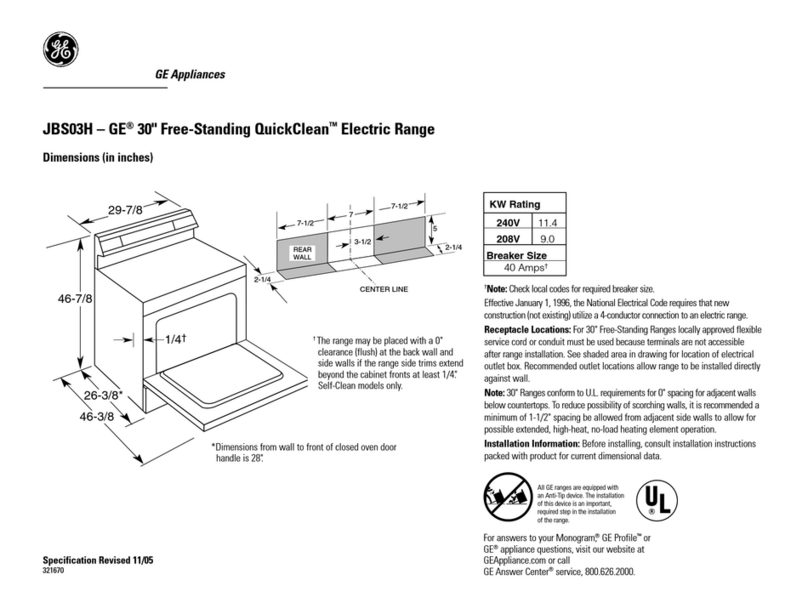

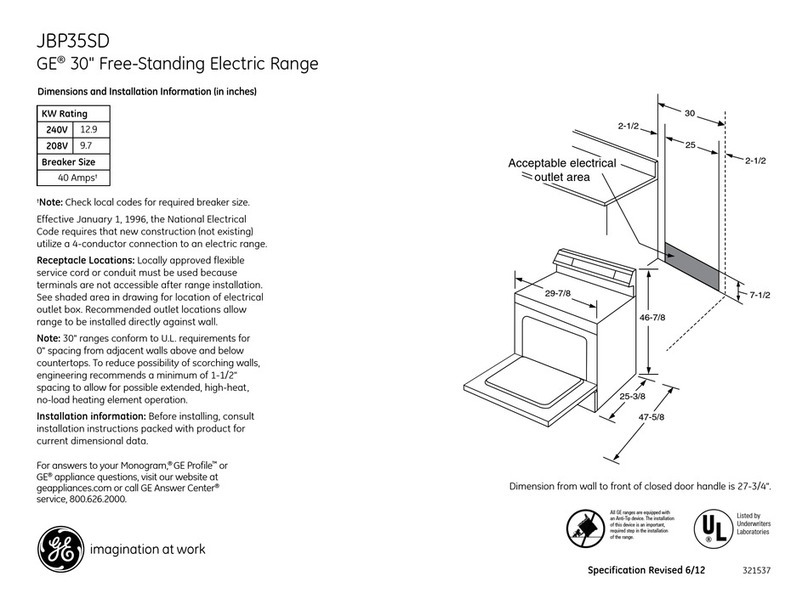

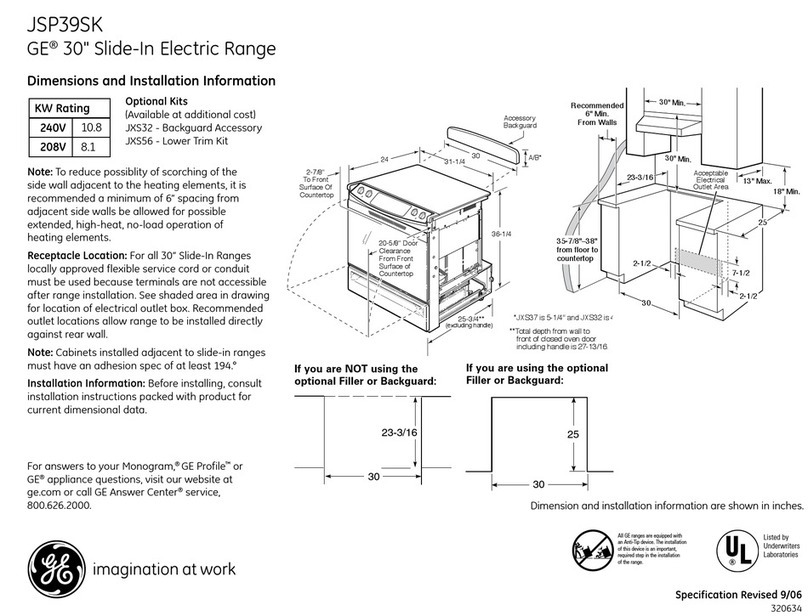

MODEL NUMBER

PGS908

IMPORTANT SERVICE INFORMATION

DO NOT DISCARD

30" SLIDE-IN NON-CONVECTION

GAS SELF-CLEAN RANGE

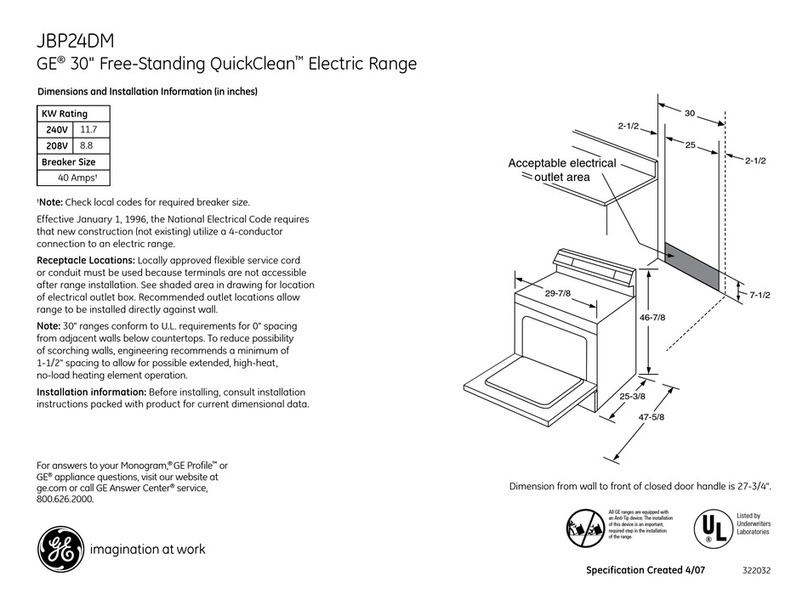

Gas Inlet

Shut-Off Lever

Shown in the

Open Position

Gas Supply

to Oven

Gas Supply to

Top Burner

Pressure Regulator

as see from Front of

Range

OVEN GAS SHUT-OFF VALVE

The gas shut-off valve is located on the side of the

pressure regulator which is mounted to the back of

the range. Access to the shut-off lever is obtained

by removing the storage drawer and reaching

through the opening on the right side of the control box.

NOTE: The oven shut-off valve shuts off the gas to

the oven only and has no effect on the top burners.

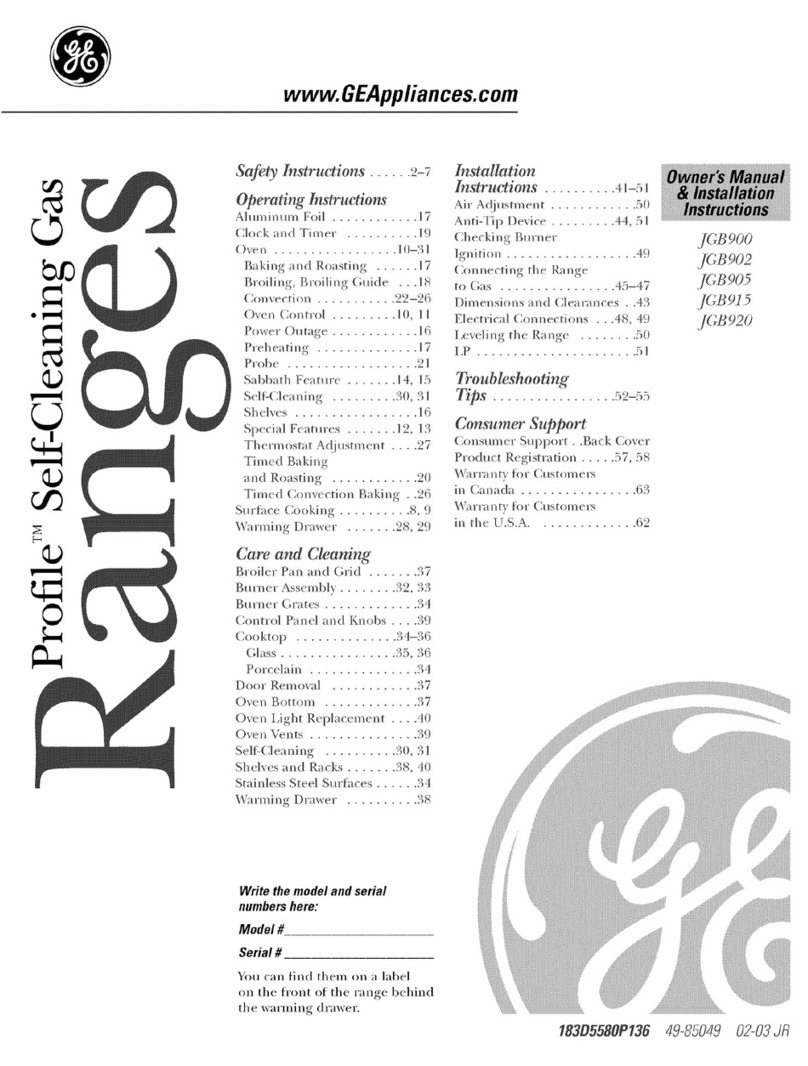

Removal position

3. Firmly grasp both sides of the door at the top.

4. Close door to the door removal position, which

is halfway between the broil stop position and

fully closed.

5. Lift door up until the hinge arm is clear of the slot.

REMOVABLE OVEN DOOR

The door is very heavy. Be careful when removing and lifting the door.

Do not lift the door by the handle.

TO REMOVE:

1. Fully open the door.

2. Push the hinge locks down toward the door frame, to the unlocked

position. A tool, such as a small flat-blade screwdriver, may be required.

Slot

Hinge

Lock

Pull hinge locks

down to unlock

Pressure Regulator as Seen

from Front of Range

TO REPLACE:

1. Firmly grasp both sides of the door at the top.

2. With the door at the same angle as the removal

position, seat the indentation of the hinge arm into the

bottom edge of the hinge slot. The notch in the hinge

arm must be fully seated into the bottom of the slot.

Push hinge locks up to lock

3. Fully open the door. If the door will not fully open, the

indentation is not seated correctly in the bottom edge

of the slot.

4. Push the hinge locks up against the front frame of the

oven cavity, to the locked position.

5. Close the oven door.

Bottom Edge

of Slot Hinge Arm

Indentation

Hinge Arm

Hinge Lock

MAINTOP REMOVAL AND ACCESS TO SPARK MODULE

1. Cut off gas supply to range.

2. Cut off electrical supply to range.

3. Remove the control panel as follows:

a) Remove knobs.

b) Unscrew and remove hexagonal control panel fasteners.

c) Remove control panel faceplace.

d) Remove hex head screws from metal insert.

e) Lift off insert/clock assembly.

f) Remove the 5 amp connectors from the electronic clock.

g) Disconnect the 12 pin amp connector.

h) Remove the upper hex head screws holding the control panel to the maintop frame.

i) Remove the lower screws holding the control panel to the maintop baffle.

(NOTE: These are accessed through the top of the oven cavity behind the door.)

j) Remove the control panel.

4. Remove the gas fitting (right side) connecting the gas manifold to the gas supply line.

5. Remove two screws, one right, one left, holding the maintop to the range frame.

6. Unscrew and remove the oven cavity vent using a 1/2 inch socket and turn counterclockwise.

7. Lift off the maintop by sliding forward. NOTE: Take care to miss the oven cavity vent when

sliding forward.

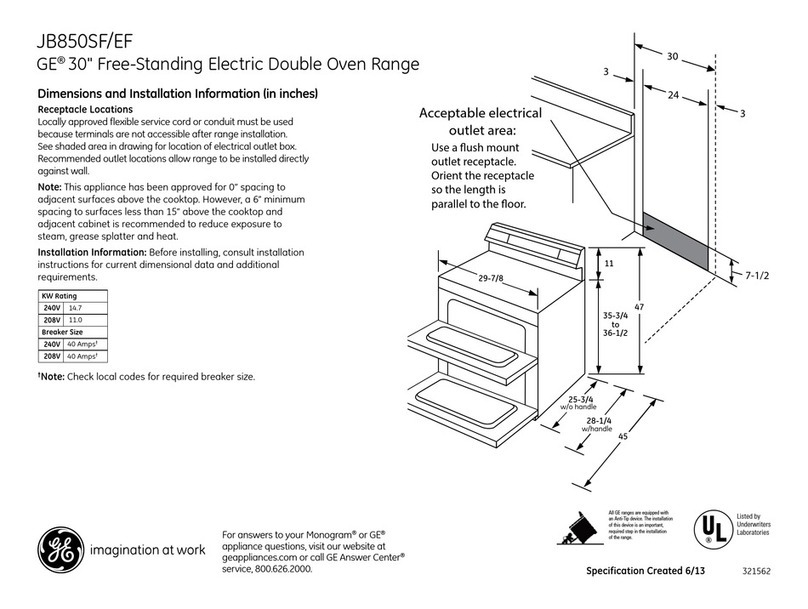

SEALED SURFACE BURNER

Burner Cap

Burner Head

Burner Base

Burner Cap

Burner Head

Burner Base

Front Right

(on some models)

Electrode

Front Right (on some models)

Front Left

Back Right

Back Left

Electrode

Stability

Chamber

SURFACE BURNER ADJUSTMENTS

Standard adjustments to the air shutter and gas metering orifices are not possible on sealed burners.

If burner flames appear to be abnormal, check the following:

•Check gas pressure available to the burners. The required operating pressure is 5" W.C.P. Natural

Gas or 10" W.C.P. LP (Propane) Gas. The pressure reading can be taken at the BROIL, BAKE or

TOP burner orifices.

•Check for drafts entering the burner box from behind the range. Strong drafts beneath the maintop

can extinguish the burner and/or cause erratic burner flames.

•Check for blockage or partial blockage of the orifice. Inspect the orifice to be sure it has been

drilled on center and is free of debris or burrs.

•Check the burner alignment per the “Burner Alignment” section of this manual.

•If the flames blow and lift off the burner and the cause of the problem cannot be found, installing

an orifice with smaller diameter openings may solve the problem. In high altitude (above 6000 ft.)

installation, the orifices will usually have to be downsized.

MAINTOP BURNER ALIGNMENT

For proper operation of the burner, alignment of the orifice holder, orifice and air/gas mixer tube

must be correct. The alignment can be checked by placing 7mm or 9/32" nutdriver over the orifice to

exaggerate the angle. The nutdriver should stand straight, indicating the alignment and gas injection

angle is correct. Aslight downward pressure may be necessary to seat the nutdriver over the “Orifice

Retainer Ring.”

If an angle adjustment is necessary, remove the burner cap, head and bowl to inspect the orifice

holder and the brackets that hold them in place. Adjust as necessary. A misaligned burner may

result in uneven flames around the burner head.

LOW FLAME SIMMER ADJUSTMENTS

Remove the surface control knob and locate the adjustment screw on the valve body at about the

6 o’clock position.

NOTE: Low setting adjustments must be made with two other burners in operation on a

medium setting. This procedure prevents the low flame from being set too low, resulting in

the flame being extinguished when other burners are turned on.

TEST THE FLAME STABILITY

Test 1: Turn the knob from “HI” to “LOW” quickly. If the low flame goes out, increase the flame size

and test again.

Test 2: With the burner on “LOW” setting, open and close the oven door quickly. If the flame is

extinguished by the air currents created by the door movement, increase the flame height and

test again.

ACCESS TO CONTROL VALVE:

The control valve for this product is not front serviceable. There is a test loop available through the

control panel that will allow a continuity check to determine the integrity of the control valve.

NOTE: Make sure the anti-tip bracket is installed correctly when pushing the range back into place.

SMALLER ORIFICES ARE AVAILABLE AS LISTED BELOW:

Smaller Orifices for Natural Gas:

Burner

RF

RR

LF

LR

Size

No. 53

No. 56

No. 53

No. 54

Part Number

WB28T10091

WB28K10085

WB28T10014

WB28T10017

Smaller Orifices for LP Gas:

Burner

RF

RR

LF

LR

Size

No. 60

No. 70

No. 64

No. 66

Part Number

WB28T10086

WB28K10085

WB28K10087

WB28T10017

GLOWBAR IGNITION CIRCUIT

WARNING: The “Norton” glowbar ignitor is NOT INTERCHANGEABLE with the

“Carborundum” glowbar ignitor. The two types of glowbar ignitors operate at different

amperages and use different gas valves.

NOTE: Check system with clamp-on ammeter. If ignitor glows red but circuit does not draw at least

2.9 amps, the fault is likely with the ignitor, not the valve.

NOTE: If ignitor glows, but ignition does not occur, be sure the oven shut-off valve is in the open position.

SLOW IGNITION CAN BE CAUSED BY ONE OR MORE OF THE FOLLOWING CONDITIONS:

1. Blockage of primary air intake: Hole beneath the bake orifice hood must be open and free

of insulation.

2. Blockage of secondary air intake holes: Examine oven burner box (galvanized box surrounding

oven burner) and inspect the single row of secondary air holes beneath the bake burner for signs

of blockage.Also, be sure items in the storage drawer do not push against the ceiling of the drawer

area. If pushed hard enough, the ceiling will flex upward, closing

off

the secondary air holes.

3. Improper alignment of orifice hood and burner: Orifice must be pointing straight into burner venturi.

4. Improper air/gas adjustment.

5. Blockage of burner crossover slots: Crossover slots must be open and free of burrs.

6. Improper installation: Failure to seal all openings in the wall behind and floor below range may

permit substantial drafts which can affect ignition.

7. The gas control valve should draw 5 amps when operating. This can be checked by measuring

the amperage in L1 to the oven control. This can be done by removing the control panel glass

and clock/insert assembly.

OVEN BURNER IGNITION SYSTEM

The oven burners are ignited by a glowbar ignition system. The ignitor is a “Norton” style rectangular

glowbar.The bake and broil ignition circuits consist of the electronic control, an ignitor and an oven

safety valve (gas valve). The three components are wired in series for each cooking function.

The most important points to know about the ignition system are:

1. THE IGNITOR RESISTANCE DECREASES AS THE IGNITOR SURFACE TEMPERATURE

INCREASES.

2. THE SAFETY VALVE OPERATES BY CURRENT, NOT VOLTAGE.

From a cold start, the ignitor needs 30–60 seconds, with a minimum of 116 volts applied, to reduce

its electrical resistance enough to provide a minimum of 2.9 amps of current flow in the series circuit.

This is the required current flow needed for the safety valve to open and supply gas to the burner.

The glowbar should provide a steady current flow of between 3.4 to 3.6 amps in the circuit. At that

point the ignitor temperature is between 1800 to 2500 degrees F. The ignitor will remain energized

at all times during burner operation. If the ignitor glows red but does not draw at least 2.9 amps,

the fault is usually with the ignitor, not the valve. Always check the oven shut-off valve for a

“Not On” condition.

ACCESS TO BAKE AND BROIL BURNERS AND

BAKE AND BROIL BURNER IGNITORS:

1. Remove oven door.

2. Remove oven racks.

FOR BAKE BURNERS AND BAKE BURNER IGNITORS:

1. Remove oven bottom by lifting at front and sliding forward.

2. Remove flame spreader by unscrewing four hex head screws.

3. Remove air shutter shield for access to air shutter and bake orifice, if needed.

FOR BROIL BURNERS AND BROIL BURNER IGNITORS:

1. Remove lower burner shield by unscrewing two hex head screws.

NOTE: Make sure the ignitor wires are pushed back into and through the insulation to prevent

touching the oven cavity back.

When maintenance and/or adjustments are completed, reverse the assembly process prior to range use.

ELECTRONIC OVEN CONTROL (B)

CAUTION: Components are electrically HOT on control when voltage is connected to range.

The Electronic Oven Control system consists of the control, key panel, oven sensor, door and

lock assembly.

The key panel (control panel) and electronic control are separate components but must be tested

together.

KEY PANEL TEST

Press each pad on the key panel followed by the start pad. If the key panel is functioning properly,

the following should occur:

• BAKE, BROIL, CLEAN, TIMER, CLOCK, STOP TIME, COOK TIME, PROOF, PROBE and RANGE

LOCKOUT Modes – Audible tone plus display showing mode of operation selected.

• CLEAR/OFF –Audible tone and display shows time of day.

• PROBE –Audible tone and response if meat probe is plugged in.

• Numerical Pads –Audible tone. Can only be used after another function has been selected.

See section on sensor and lock switch connector

RELAY CONTACTS OPERATION TEST AND

CONTROL VOLTAGE CHECK

DOOR MOTOR TO N

L1- TO N

TERMINALS

SWITCH CONTACTS

BROILTO N

BAKE TO N

120 VAC locking or unlocking

120 VACALL THE TIME

120 VAC when in BAKE mode

VOLTAGE

120 VAC when in BROIL mode

NOTE: Temperature/Mode Selection Necessary for operation of Relay contacts.

NOTE: Voltage must be present across terminals L1 to N for control to operate. Transformer

primary is 150 to 200Ωmeasured “L1” to “N” with power removed.

OVEN SENSOR AND DOOR SWITCH OHMMETER TEST

(See “Motorized Door Lock Operation”for door switch function explanation.) Remove power from

oven. Make resistance measurement from side of sensor and lock switch connector, with

exposed terminals disconnected from control.

OVEN SENSOR AND LOCK SWITCH CONNECTOR

L1

BLACK N

L1

BAKE AND TIME BAKE

BAKE RELAY

BROIL RELAY

L1

BR

BK

L1

BLACK N

BROIL & CLEAN UNTIL/AFTER 750˚F IS REACHED

BROIL RELAY

L1

Bake & Broil relays cannot be on at same time.

1

2

3

5

7

OVEN TEMP

SENSOR 1100Ω@ ROOM TEMP

2650Ω@ CLEAN TEMP

UNLOCK

SW 2

LOCK SW 1

CONTROL

CONNECTOR

PLUG

THERMAL SWITCH

OPENS @275˚F

CLOSES @205˚F

NOTE: When door is

either being locked or

unlocked, both lock

switches will be in the

open position.

OVEN SENSOR AND DOOR LOCK SWITCH

MOTORIZED DOOR LOCK

The motorized door lock assembly is located above the oven. The assembly consists of a lock motor

cam and switch assembly, lock hook and mounting plate.

MOTORIZED DOOR LOCK OPERATION

The lock motor is energized when the control is set for Clean and Clean Time is selected. The K4

Relay contacts will close and complete the circuit that supplies the voltage to the lock motor.

HTI

HTITech & Ind

HTSYG048B002FL45

-0001

Date:

Made in China

LOCK SW.

N.O. CONTACT

CLOSED

UNLOCK SW.

N.O. CONTACT

OPEN CAM IN

LOCK POSITION

LOCKED

HTI

HTITech & Ind

HTSYG048B002FL45

-0001

Date:

Made in China

LOCK SW.

N.O. CONTACT

OPEN

UNLOCK SW.

N.O. CONTACT

CLOSED

CAM IN

UNLOCK POSITION

UNLOCKED

3

2

1

5

7

DOOR LATCH OUTPUT PIN 5, -25VDC

AT ALL TIMES MEASURED TO GROUND

DOOR UNLATCHED INPUT PIN

DOOR LATCHED INPUT PIN

SENSOR AND LOCK

SWITCH CONNECTORS

LOCK SW. #2

LOCK

SW. #1

LOCK SW. CIRCUIT

LOCKED

THERMAL SWITCH

NOTE: Control display will flash “LOCK DOOR”

if the door switch is in the “C”to “NC”position

(door open).

•The words “LOCK DOOR”will flash on and off

in the display while the lock motor is in motion.

When the door is locked, the words “LOCKED

DOOR”remain illuminated in the display.

•CAM –The cam on the motor performs two

functions:

1. Positions the lock hook in the door to

prevent opening during clean operation.

2. Operates the lock switches which tell the

control if the door is unlocked or locked

and ready for Clean operation.

3

2

1

5

7

DOOR LATCH OUTPUT PIN 5, -25VDC

AT ALL TIMES MEASURED TO GROUND

DOOR UNLATCHED INPUT PIN

DOOR LATCHED INPUT PIN

SENSOR AND LOCK

SWITCH CONNECTORS

LOCK SW. #1

LOCK

SW. #2

LOCK SW. CIRCUIT

UNLOCKED

THERMAL SWITCH

SPECIAL FUNCTIONS

The control has a section that can be entered to change how the control will work. To enter this section:

Press and hold BAKE and BROIL pads for 2 (two) seconds and “SF”appears in the display. Select

the area to change. When the change has been made, press START to return toTime of Day.

•End-of-Cycle Tone –Press TIMER pad. Display shows “Con Beep”when control is set for

continuous End-of-Cycle Tone or “Beep”when set for noncontinuous.

•°F or °C –Press BROIL pad. Display will show either “F°”or “C°.”Press BROIL pad again to

change.

•12-Hour, 24-Hour or blank out Time-of-Day Clock –Press CLOCK pad. Display will show

“12 hr,”“24 hr,”“OFF”for blank clock. Press again to change.

•12-Hour Shutdown comes set to shut down after 12 hours of continuous operation; this can be

eliminated—press DELAY START pad. Display will show “No Shdn.”To turn back on, press

DELAY START pad again and display will show “12 Shdn.”

•Sales Mode (special feature for sales floor demonstration) –Press CLOCK and TIMER pads

at the same time. Display will start to cycle through the different modes of operation.

•Sabbath Mode –This feature disables all but Bake and Timed Bake, overrides 12-Hour

Shutdown, disables beeps and puts symbols in the display during Bake. Access by pressing

DELAY START pad until display shows “SabbAtH.”Exit by pressing DELAY START until

“No Shdn”or “12 Shdn”shows.

THERMAL SWITCH

The thermal switch is located on the floor of the component compartment in front of the fan

motor. The thermal switch is wired in series with the lock motor switches. The limit switch

opens at 275°F and closes when temperatures cool below 205°F. If the thermal switch opens during:

1. Oven Temperature Below 600°F, program is cancelled when thermal switch opens. Lock motor

will run and the words “LOCK”and “DOOR”will be flashing in the display.

2. Oven Temperature Above 600°F, any mode of operation control will go to -F2- failure code. When

this condition exists, check the fan operation (look for obstructions), inspect oven installation

(make sure grille areas are not blocked), oven insulation and lock circuit.

RF 15,000 —No. 49

RR 5,000 —No. 56

LF 11,000 —No. 52

LR 9,100 —No. 54

BAKE 15,000 ——

BROIL 12,000 ——

KWBURNER BTU RATE

BURNER OUTPUT RATING:

NATURAL GAS 5" W.C.P.

ORIF. SIZE REPAIR PART

RF 13,000 —No. 59

RR 5,200 —No. 69

LF 11,000 —No. 63

LR 8,000 —No. 65

BAKE 15,000 ——

BROIL 12,000 ——

KWBURNER BTU RATE

BURNER OUTPUT RATING:

L.P. (PROPANE) GAS 10" W.C.P.

ORIF. SIZE REPAIR PART

229C4059P559