Safety Information

Skill Level —Installation of this refrigerator requires

basic mechanical, carpentry and plumbing skills

Proper installation is the responsibility of the installer

Product failure due to improper installation is not

covered under the GE Appliance Warranty See the

Owner’s Manual for warranty information

WAR I G:

• These refrigerators are top-heavy and must

be secured to prevent the possibility of tipping

forward Anti-Tip protection is required See page 11

for details

• Use this appliance only for its intended purpose

• Immediately repair or replace electric service cords

that become frayed or damaged

• Unplug the refrigerator before cleaning or making

repairs

• Repairs should be made by a qualified service

technician

AVERTISSEME T

• Ces réfrigérateurs sont lourds en haut et il faut

les arrimer pour éviter leur basculement Il faut avoir

un système de protection contre le renversement

Voir les détails page 11

• Il ne faut utiliser cet appareil que pour l’utilisation

appropriée

• Réparer ou remplacer immédiatement tout cordon

électrique effiloché ou endommagé

• Il faut débrancher le réfrigérateur avant le nettoyage

ou toute intervention

• Les réparations doivent être faites par un technicien

qualifié

For Monogram local service in your area, call

1.800.444.1845.

For Monogram service in Canada, call

1.800.561.3344

For Monogram Parts and Accessories, call

1.800.626.2002.

www. monogram.com

2

BEFORE YOU BEGI

Read these instructions completely and carefully.

• IMPORTA T —Save these instructions

for local inspector’s use Observe all governing codes

and ordinances

• ote to Installer —Be sure to leave these

instructions with the Consumer

• ote to Consumer —Keep these instructions

with your Owner’s Manual for future reference

WAR I G:

This appliance must be properly grounded See

“Grounding the Refrigerator,” page 9

AVERTISSEME T

Cet appareil doit être correctement mis à la terre

Consulter « Mise à la terre du réfrigérateur », page 9

If you received a damaged refrigerator, you should

immediately contact your dealer or builder

CAUTIO :

Due to the weight and size of this refrigerator, and to

reduce the risk of personal injury or damage to the

product—THREE PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION

PRUDE CE

À cause du poids et de la taille de ce réfrigérator et pour

réduire le risque de blessure et de dommages, IL FAUT

TROIS PERSONNES POUR FAIRE L’INSTALLATION

CORRECTEMENT

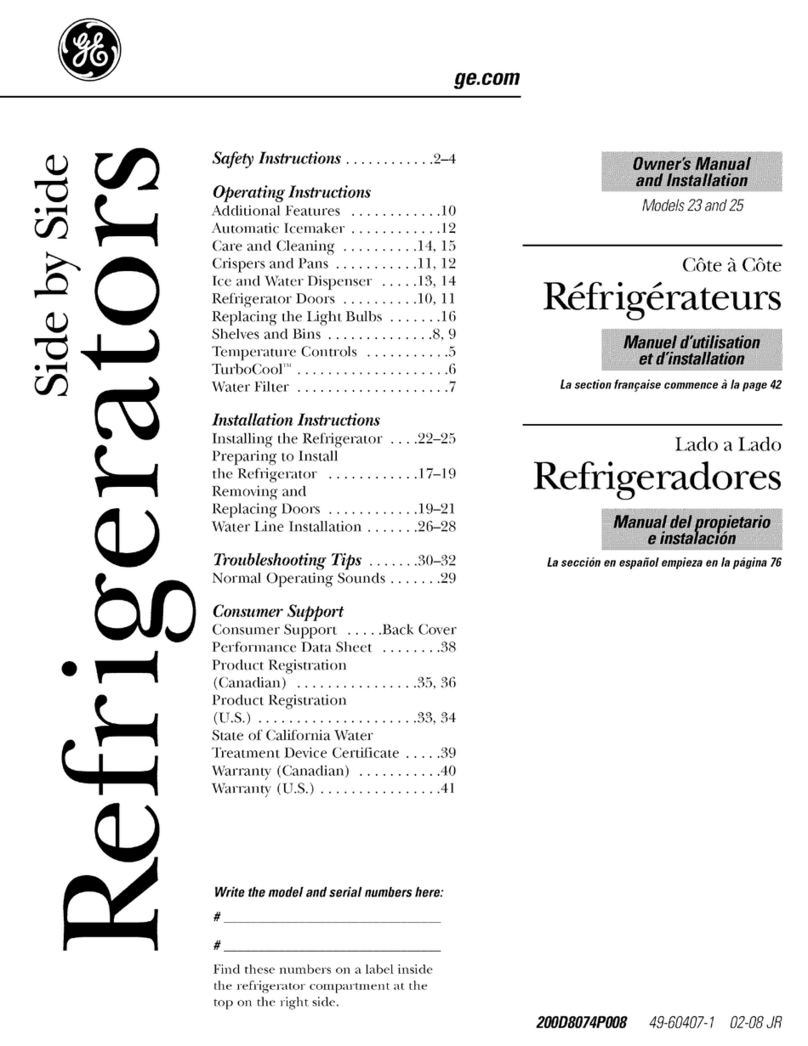

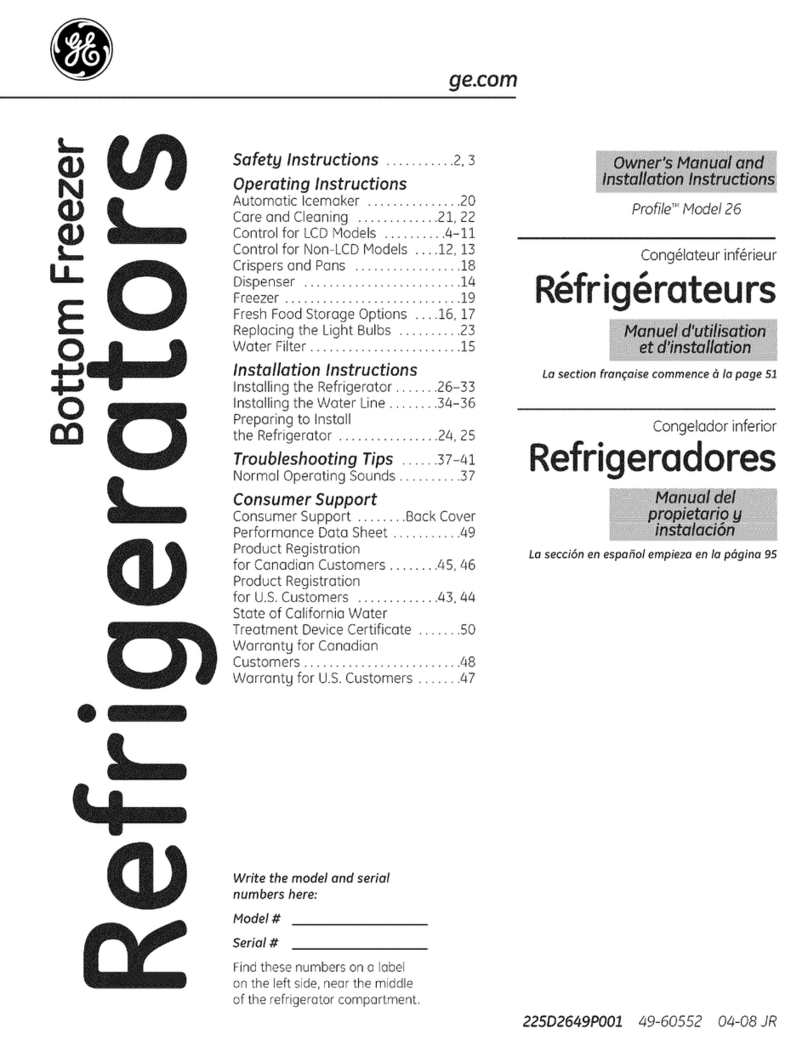

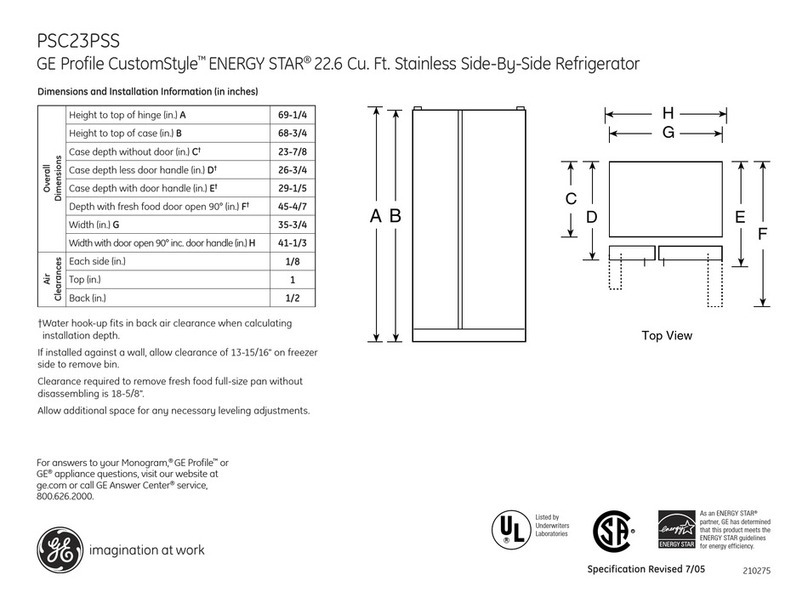

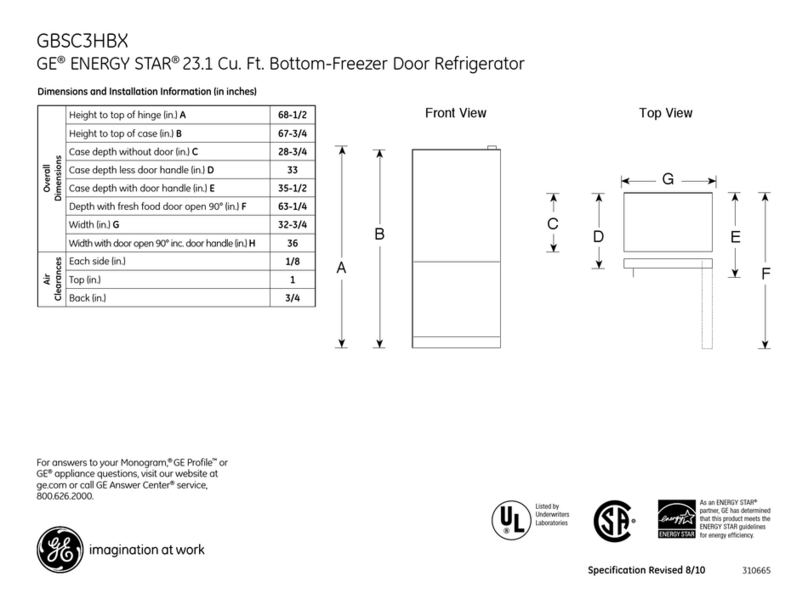

CO TE TS

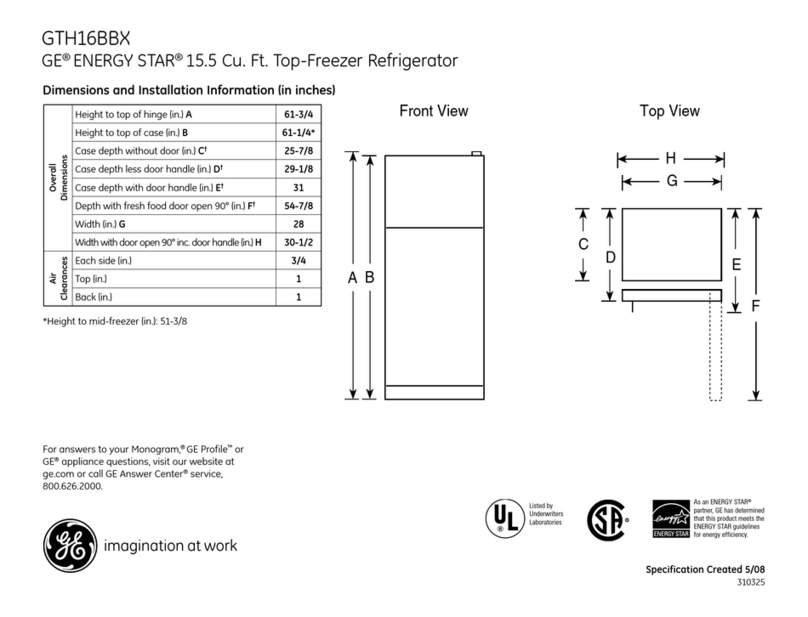

Planning Guide

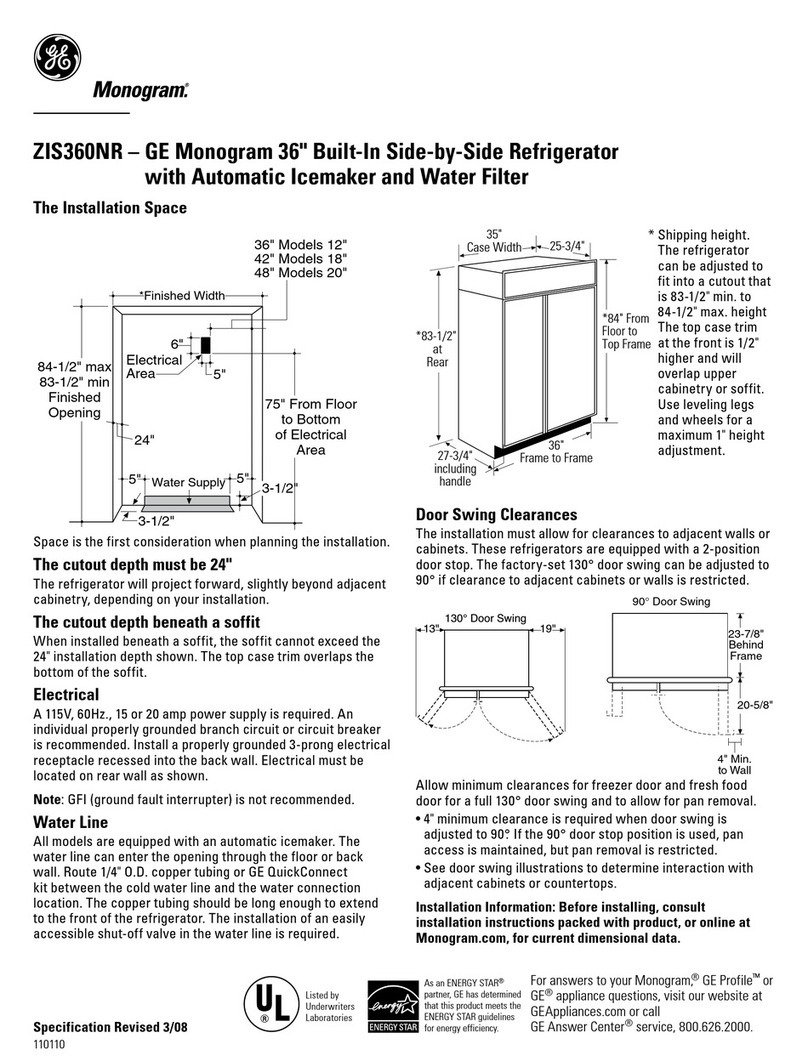

The Installation Space 3

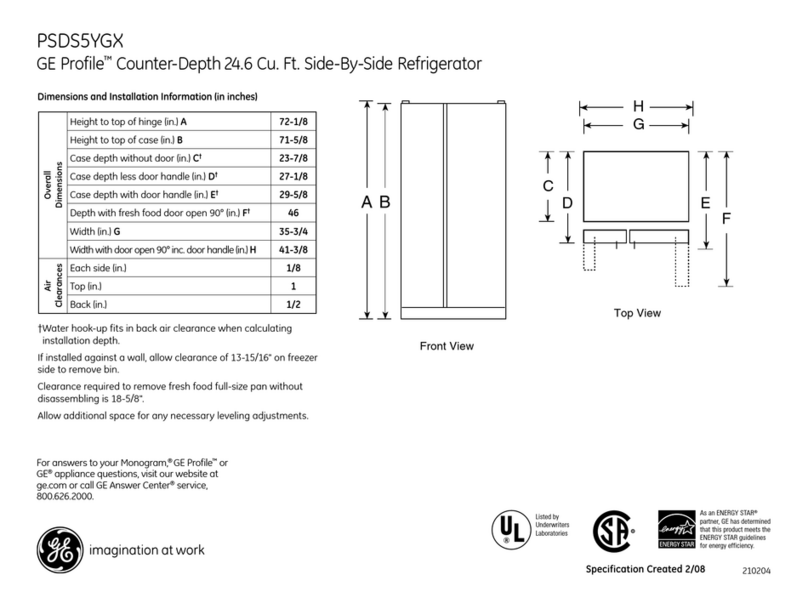

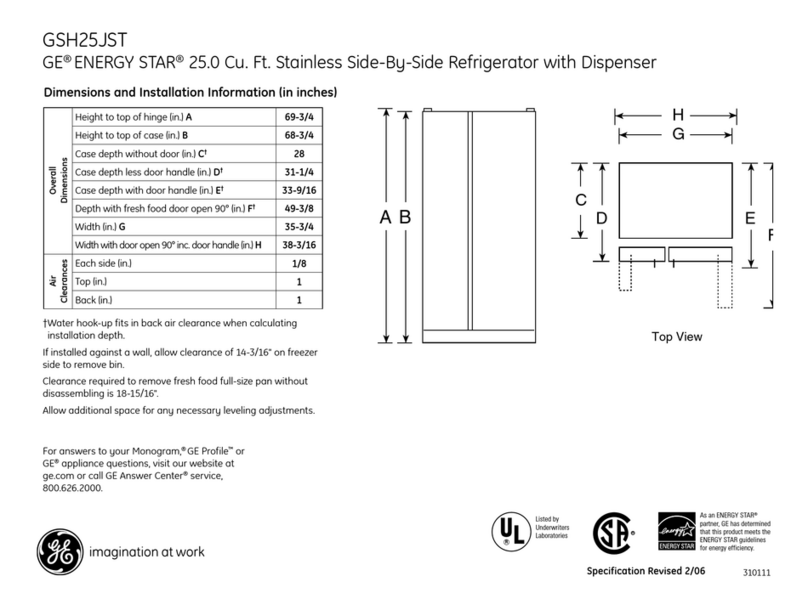

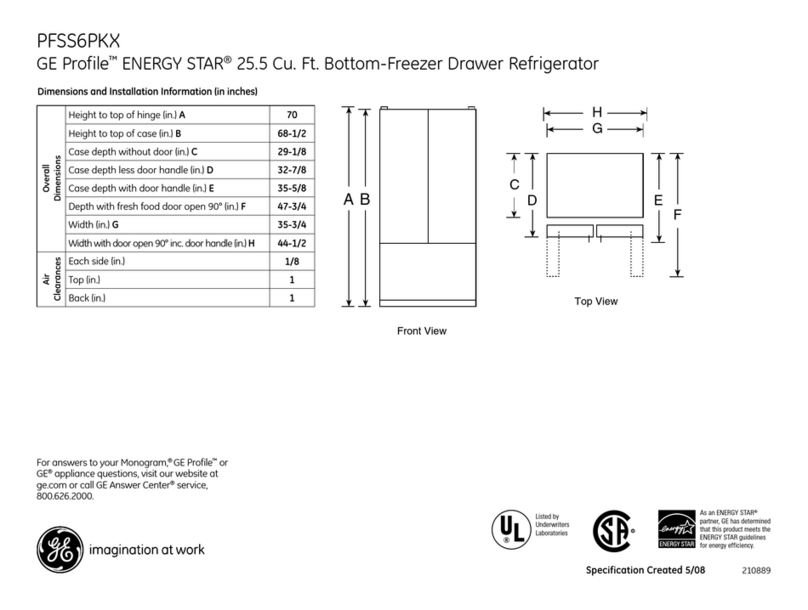

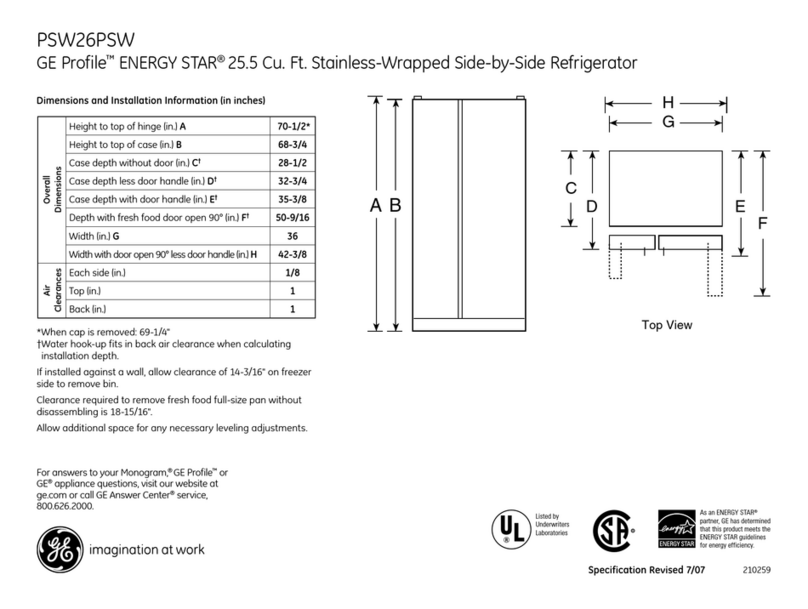

Dimensions and Clearances 3

130° Door Swing 4

90° Door Swing 5

Customization Basics 6

Panel Dimensions 7

Side Panels 8

ZUG2 Grille Panel Dimensions 8

Installation Instructions

Tools, Hardware, Materials 9

Grounding the Refrigerator 9

Step 1, Remove Packaging 10

Step 2, Install Water Line 10

Step 2A, RO Water Line 11

Step 3, Install Side Panels 11

Step 4, Install Anti-Tip Brackets 11

Step 5, Level Refrigerator 12

Step 6, Alternate Anti-Tip Procedure 12

Step 7, Secure Refrigerator to

Cabinetry 12

Step 8, Adjust Door Swing 13

Step 9, Install Grille Panel 13

Step 10, Install Framed Panels 14

Step 10A, Install Overlay Panels 15

Step 11, Connect Water Supply 16

Step 12, Connect Power 16

Step 13, Start Icemaker 16

Step 14, Install Toekick 17