– 5 –

Operating haracteristics

Note:

Refer to Component Locator Views.

Refer to Schematics.

Component Description

The compressor and dryer are located in the

machine compartment at the bottom, rear of the

unit. The condenser is located under the unit. The

evaporator is located in the freezer compartment

on the back wall.

The capillary is soldered to the compressor

suction line. The capillary is also taped to the

suction line near the dryer. This arrangement

serves as a heat exchanger.

The temperature control and defrost control are

located in the control console. The control

console is located in the top of the fresh food

compartment. The evaporator fan is located in the

freezer compartment behind the air tower.

Electric l Oper tion

The power source provides 115 VAC to the

temperature control. The temperature control is a

thermostatic switch that closes when the fresh

food compartment temperature is higher than the

control setting. When closed, the temperature

control provides 115 VAC to the defrost control.

The defrost control contains a motor/cam

mechanism that switches the defrost control

between defrost mode and cooling mode. When

in cooling mode, the defrost control provides

115 VAC to the compressor, condenser fan, and

evaporator fan. The compressor, condenser fan,

and evaporator fan should always operate at the

same time.

Defrost Oper tion

The automatic defrost function is controlled by the

defrost control. The defrost control contains a

motor/cam mechanism that switches the defrost

control between defrost mode and cooling mode.

The defrost control motor/cam mechanism

operates only when the temperature control

(switch) is closed. After 8 hours of motor/cam

mechanism runtime in cooling mode, the defrost

control switches to defrost mode. The defrost

control will stay in defrost mode, providing 115 VAC

to the heater for 30 minutes of motor/cam

mechanism runtime. The defrost thermostat

switch is mounted on the evaporator and, when

closed, completes the neutral side of the defrost

heater circuit. The defrost thermostat switch

opens when the evaporator temperature raises to

58 °F and closes when the evaporator temperature

lowers to 28 °F. The defrost thermostat switch

typically opens during the defrost cycle, preventing

the heater from defrosting for the full 30 minutes.

The purpose for the 30 minute defrost mode at the

defrost control is to prevent the compressor from

operating and refreezing any water that may be

dripping from the evaporator.

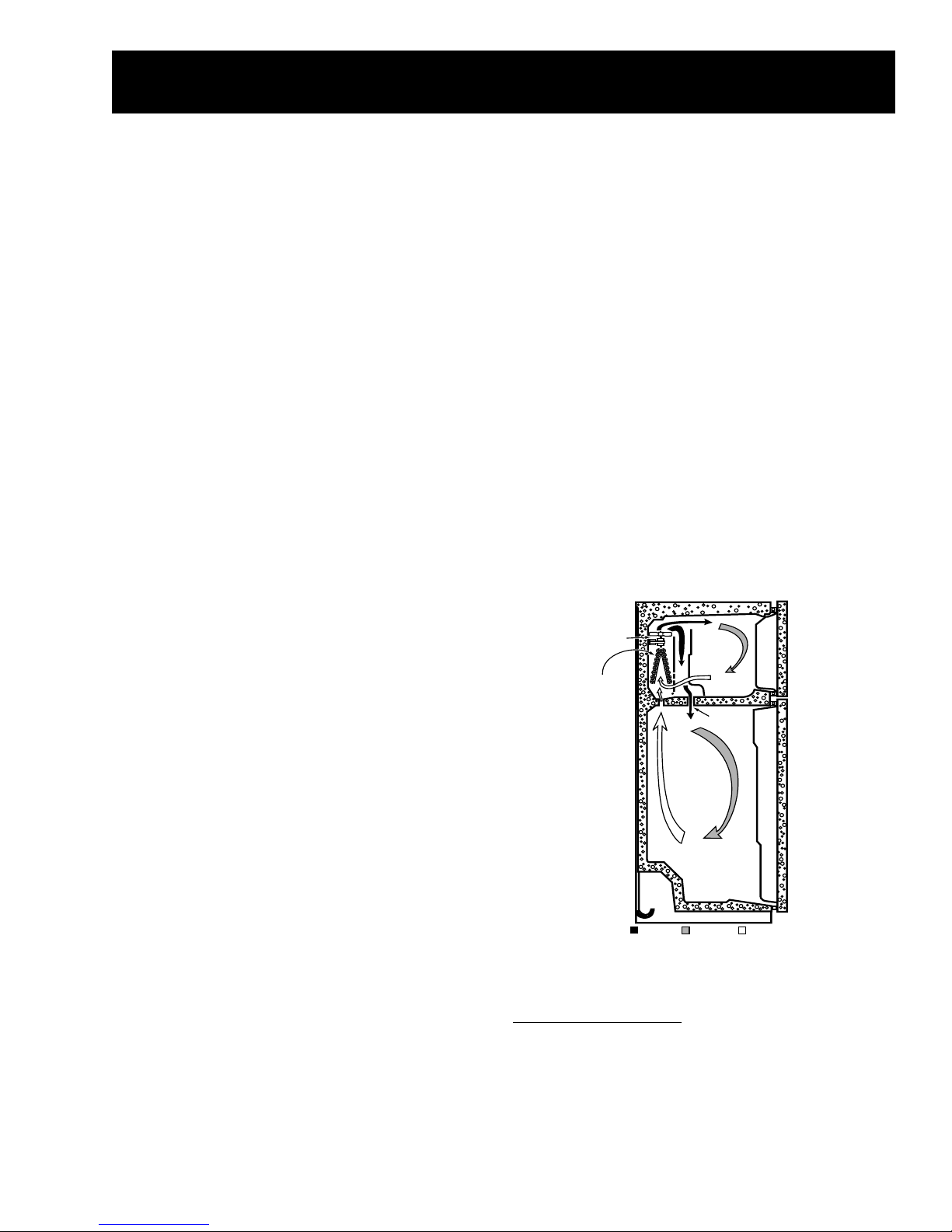

ND103-02B

WARMER AIRMIXED AIR

COLD AIR

DAMPER

FAN

EVAPORATOR

Airflow

Freezer Compartment

Cold air from the evaporator is forced up against

the top of the freezer and the back of the

evaporator cover. It is then discharged through