Before you begin - Readthese instructions completely and carefully.

IMPORTANT- Savethese instructions for local inspector's use.

iMPORTANT- OBSERVEALL GOVERNINGCODESAND ORDINANCES.

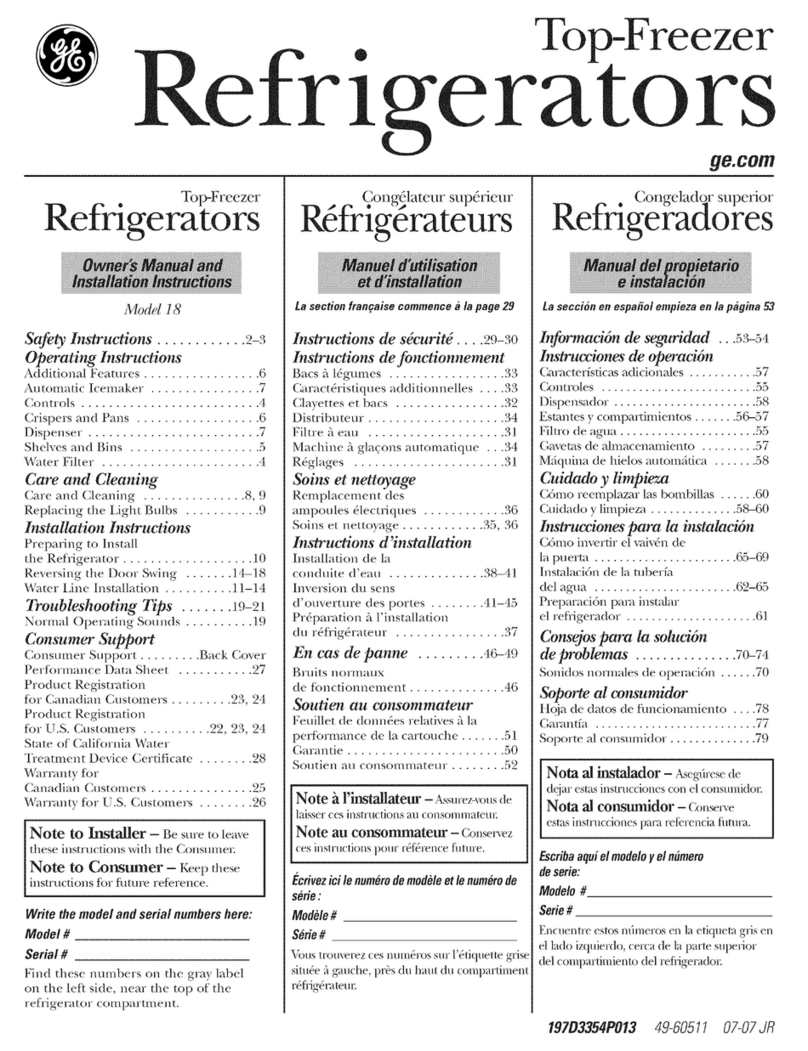

Note to Installer - Be sure to leave these instructions with the Consumer.

Note to Consumer - Keep these instructions with your Use and CareBook for future reference.

:t I This appliance musthe properlygrounded.See "Grounding the Refrigerator,"page12.

p_j._l_ Cet appareil dolt_tre correctementmisa la terre.

Consulter. Mise aterre de re_frige_rateerii, page12.

Ifyou have a question concerning the installation of this

product, call the GEAnswer Center® Consumer

Information Service at 800.626.2000,24hours a day,

7 days aweek.

ifyou received a damaged refrigerator, you should

immediately contact your dealer or builder.

Proper installation is the responsibility ofthe installen

Product failure dueto improper installation is not

covered under the GEAppliance Warranty. Seethe

Use & CareGuide for warranty information.

ForMonogramlocal service in yourarea,

1-800-444-1845.

ForMonogramservice in Canada,

1-888-880-3030

ForMonogramParts andAccessories, call

1-800-626-2002.

•Use this appliance only for its intended purpose,

• Immediately repair or replace electric service

cords that have become frayed or damaged,

• Unplug the refrigerator before cleaning or making

repairs.

• Repairs should be made by a qualified service

technician.

• II nefaat utiliser cet appareil que pour I'usage

pour leqael il a 6t6 constrait,

• IIfaut rGparer oa remplacer immGdiatementtout

cordon d'alimentation 61ectrique effiloch6 ou

endommag&

• OGbrancher le rGfrigGrateur avant le nettoyage ou

route intervention,

• Les rGparations doivent _tre faites par un

technicien qualifi&

Contents DesignInformation

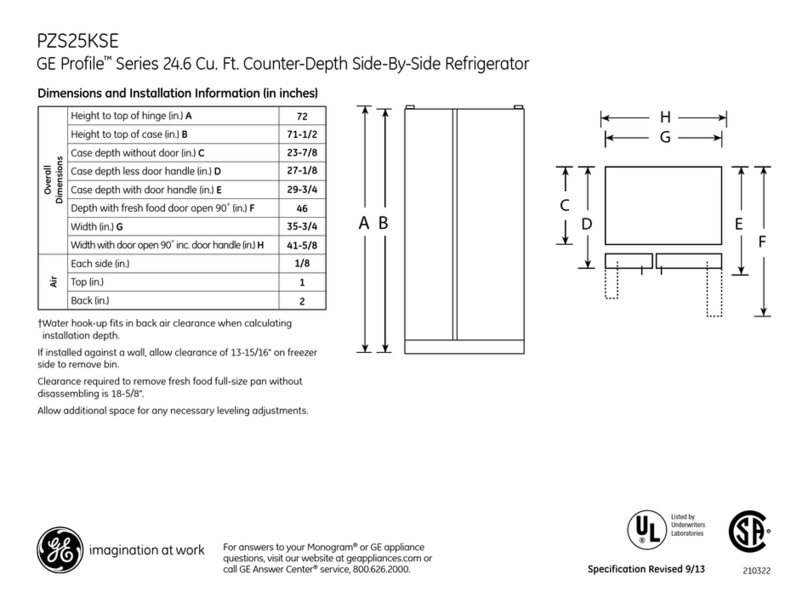

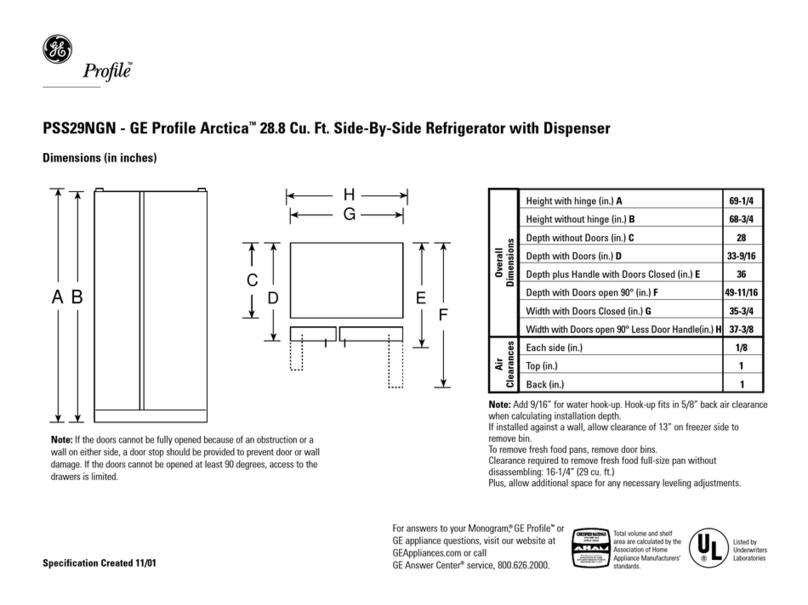

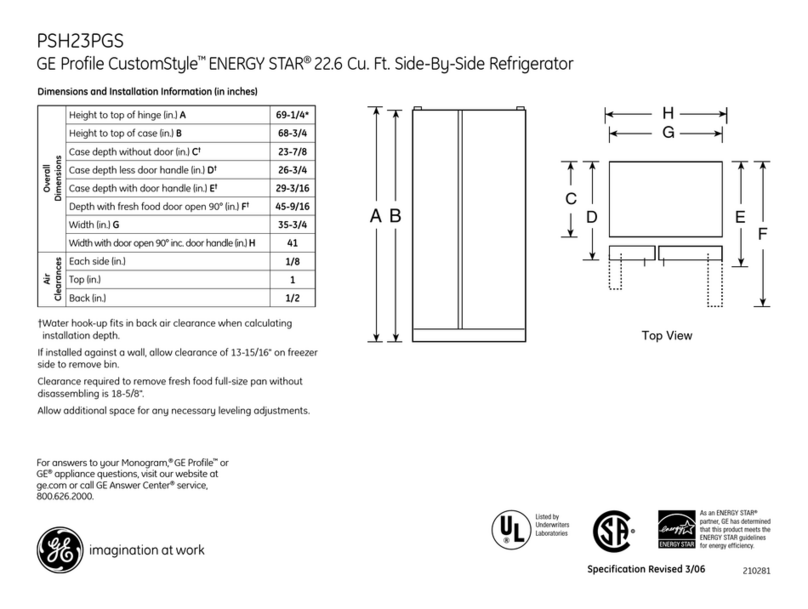

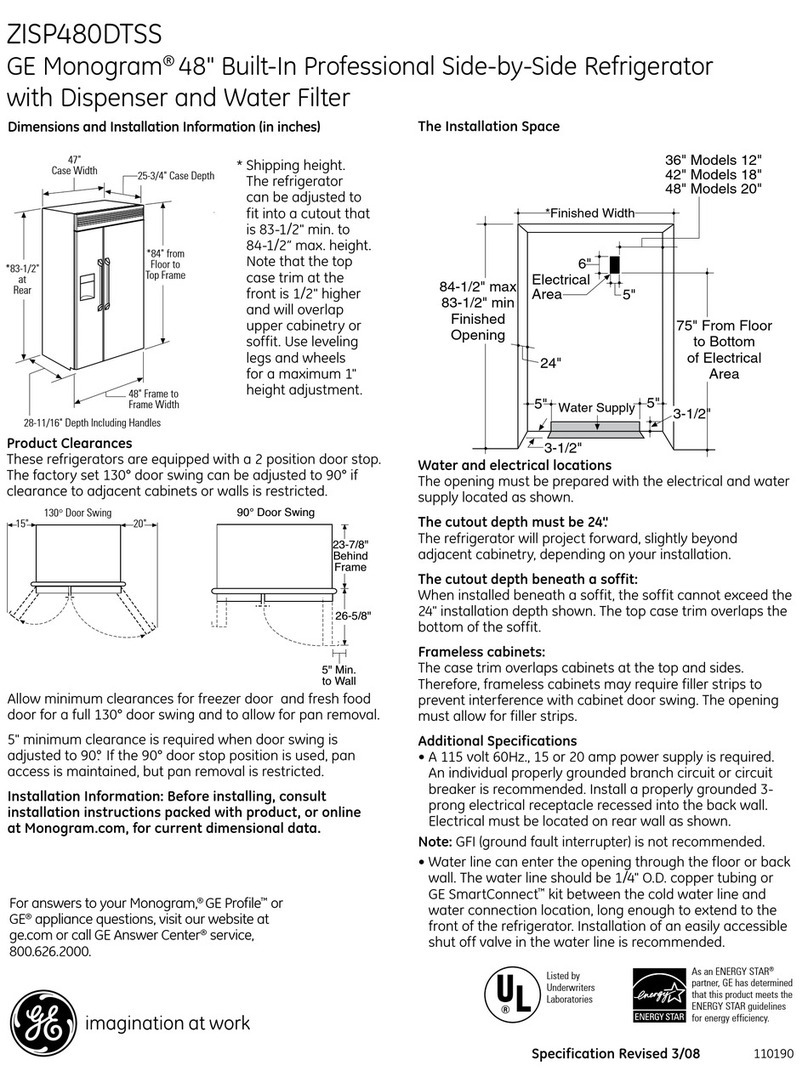

Flushor Semi-FlushEnclosure Installations ...............................................................................................................................3

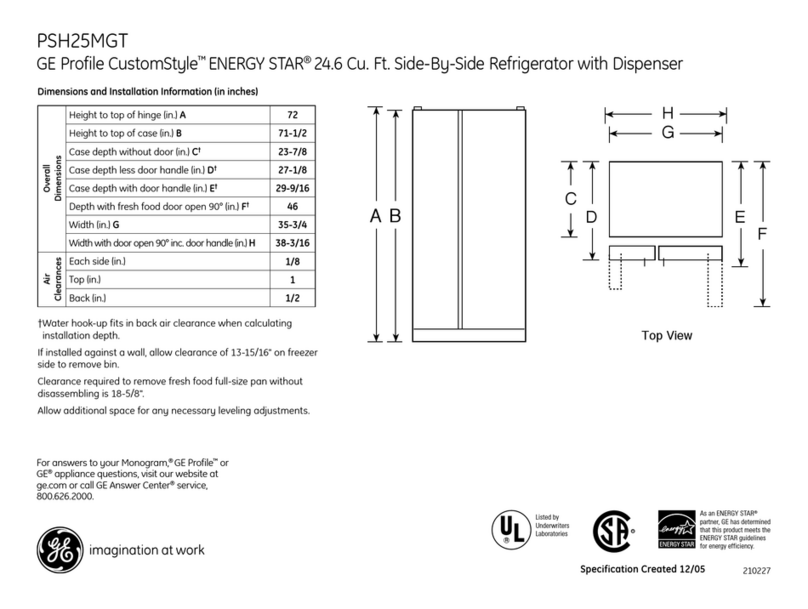

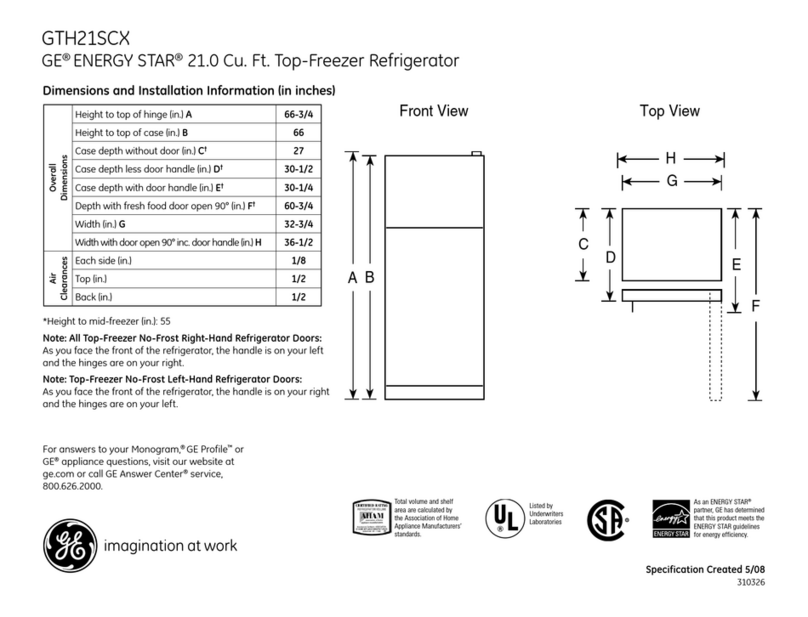

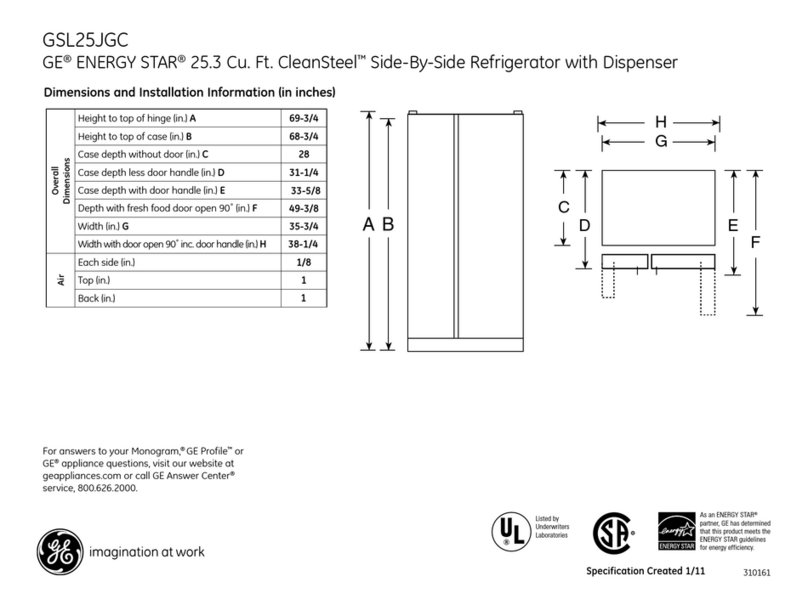

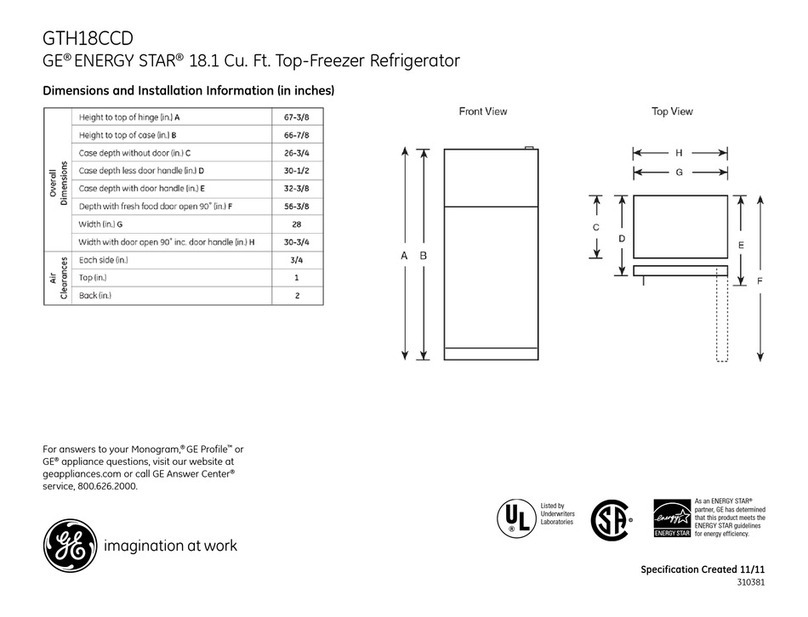

Enclosure Cutout and ProductDimensions .................................................................................................................................3

Installation Examples,Between Base & Wall Cabinets ...........................................................................................................4

Installation at End-of-Run ...............................................................................................................................................................4

FramelessCabinets ..........................................................................................................................................................................4

Accessory PanelKits .......................................................................................................................................................................4

Models Available ..............................................................................................................................................................................5

Advance Planning Exterior Appearance Options.......................................................................................................................5

Trim KitDescriptions ........................................................................................................................................................................6

CustomPanel Dimensions

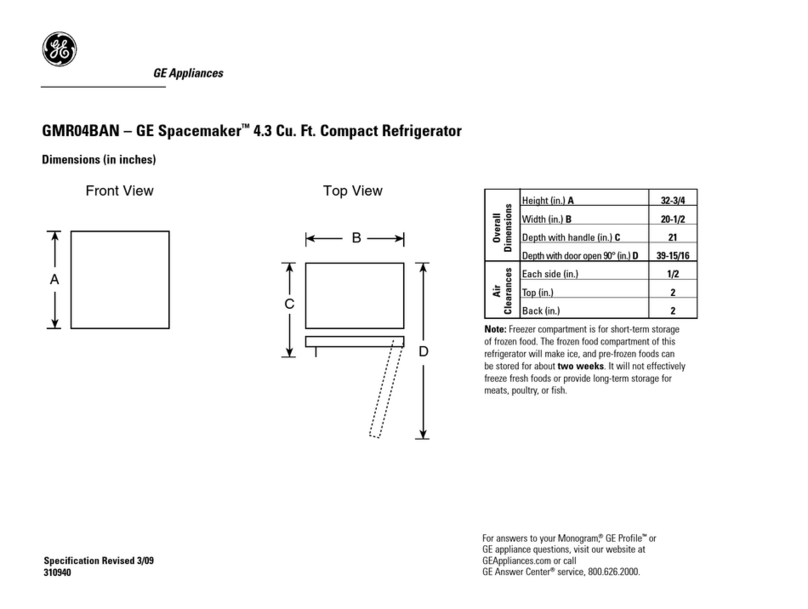

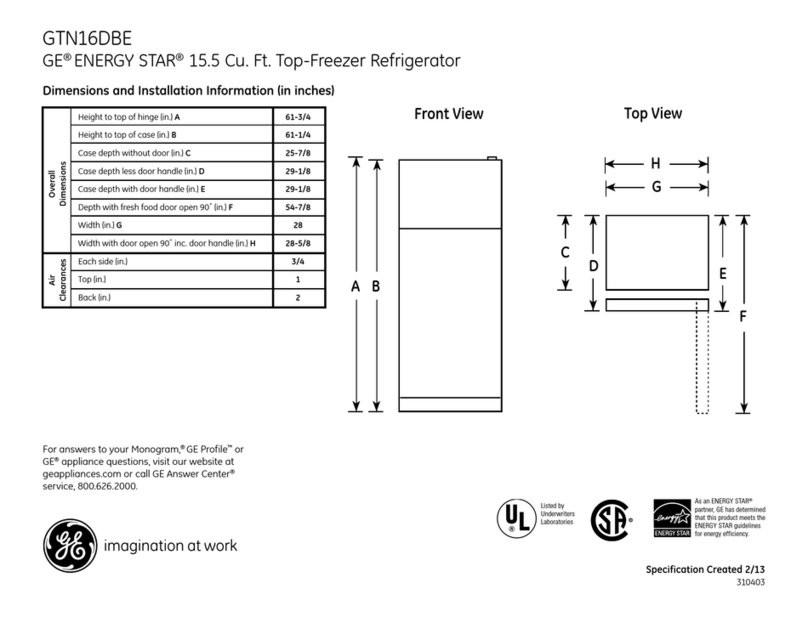

Product and Cutout Information ....................................................................................................................................................7

1/4"Thick CustomPanels or Panels Secured to 1/4"thick backing ........................................................................................8

3/4"Thick Panels with Supplied Handle, ZKTC36Lor ZKTC36R..............................................................................................9

3/4"Thick Panels with CustomHandle .......................................................................................................................................10

Side Panel or Filler Options ..........................................................................................................................................................11

Installation Instructions..........................................................................................................................................................12-17

TrimKits

ZGC2Trim Kit,Grille PanelFrame Adjustment ..........................................................................................................................18

ZKHC1Trim Kit(for 1/4"Panels), Support for CustomHandles.........................................................................................19-21

ZKTC36L/ZKTC36RTrim Kit,3/4"Custom Panels..................................................................................................................22-27

ZKHTClTrim Kit (for 3/4" Panels), Support for Custom Handles ......................................................................................28-31

ZKHCSS1Trim Kit(for 1/4"Panels), Tubular Stainless Steel Handles .............................................................................32-35

ZKHTCSS1Trim Kit (for 3/4" Pane]s),Tabular Stainless Steel Handles ...........................................................................36-38

ZFClTrim Kit, for side to side installation ..................................................................................................................................39