– 5 –

Technical Data

Important Safety Notice:

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic, and mechanical experience.Any

attempt to repair a major appliance may result in

personal injury and property damage. The

manufacturer or seller cannot be responsible for

the interpretation of this information, nor can it

assume any liability in connection with its use.

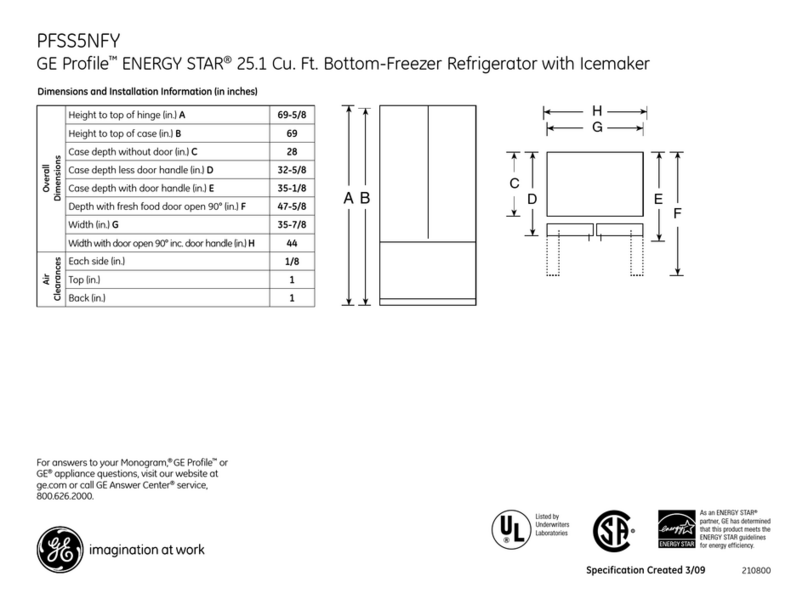

Compressor ...............................................833 Btu/hr

MinimumCompressorCapacity

Vacuum .......................................... 22 inches

MinimumEqualizedPressure

@ 70 °F...........................................65/65 PSIG

@ 90 °F...........................................79/80 PSIG

Refrigerant Charge (R134a) .............................12.50 oz

HMI Temperature Control..........................................**

OvertemperatureThermodiscLight..........WR50X10035

OvertemperatureThermodiscEvaporator ..WR50X10036

Defrost Heater ....................................... WR51X10065

Drain Trough ASM .................................. WR17X11194

Condenser Fan Motor ............................ WR60X10083

Condenser Fan Blade ............................ WR60X10049

Evaporator Fan Motor ............................ WR60X10043

Evaporator Fan Blade ............................ WR60X10050

Main Board ........................................... WR55X10400

Thermistors(2-FF, 1-FZ, 1-EV)...............WR55X10025

DamperAssembly Fresh Food ............... WR60X10085

Evaporator ............................................ WR84X10038

Compressor .......................................... WR87X10064

Condenser............................................. WR84X10037

Filter Drier ............................................. WR86X0096

Inverter ................................................ WR55X10155

Accumulator ......................................... WR02X11264

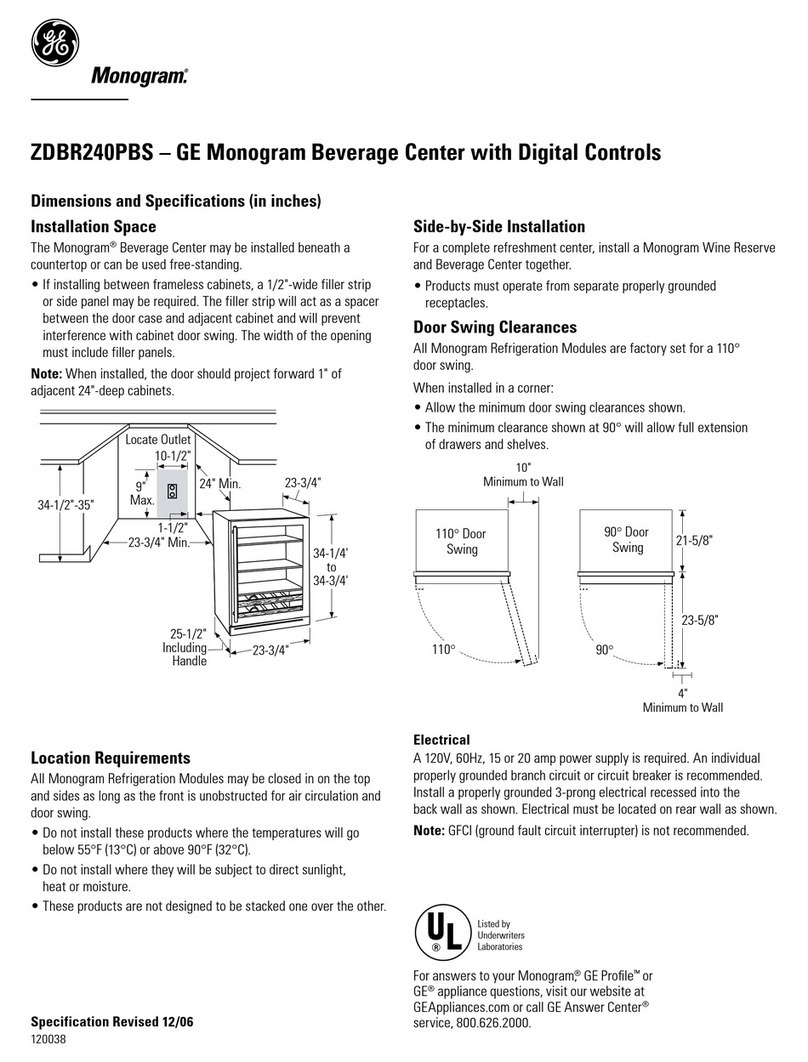

REPLACEMENT PARTS

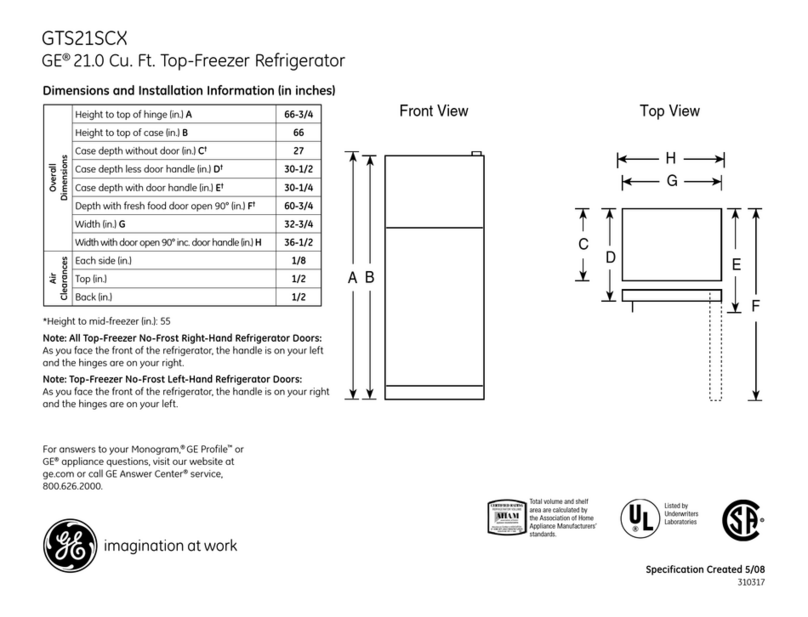

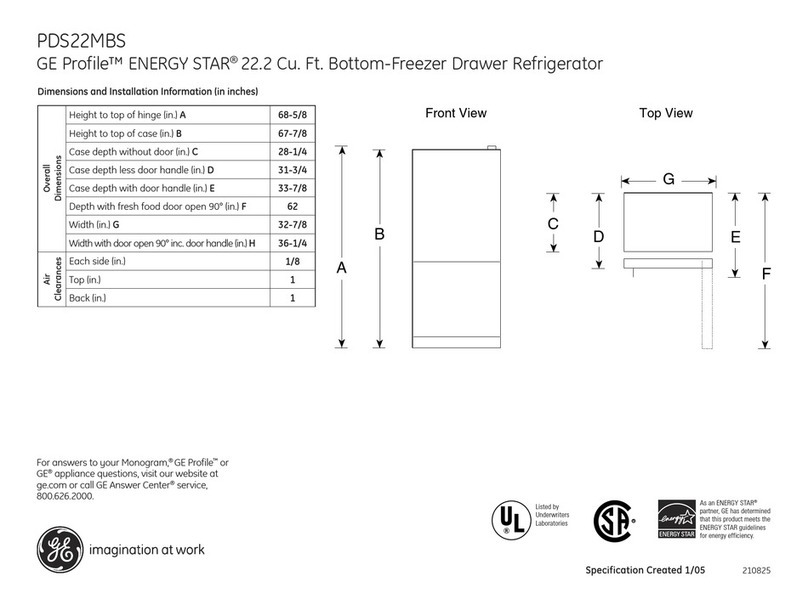

TO CABINET

WIRING

COMMUNICATION

SIGNAL

COMPRESSOR

GROUND

GREEN/YELLOW

GROUND

RED

ORANGE

BLACK

BLACK GREEN/YELLOW

BLUE

BROWN

WHITE

INVERTER

*

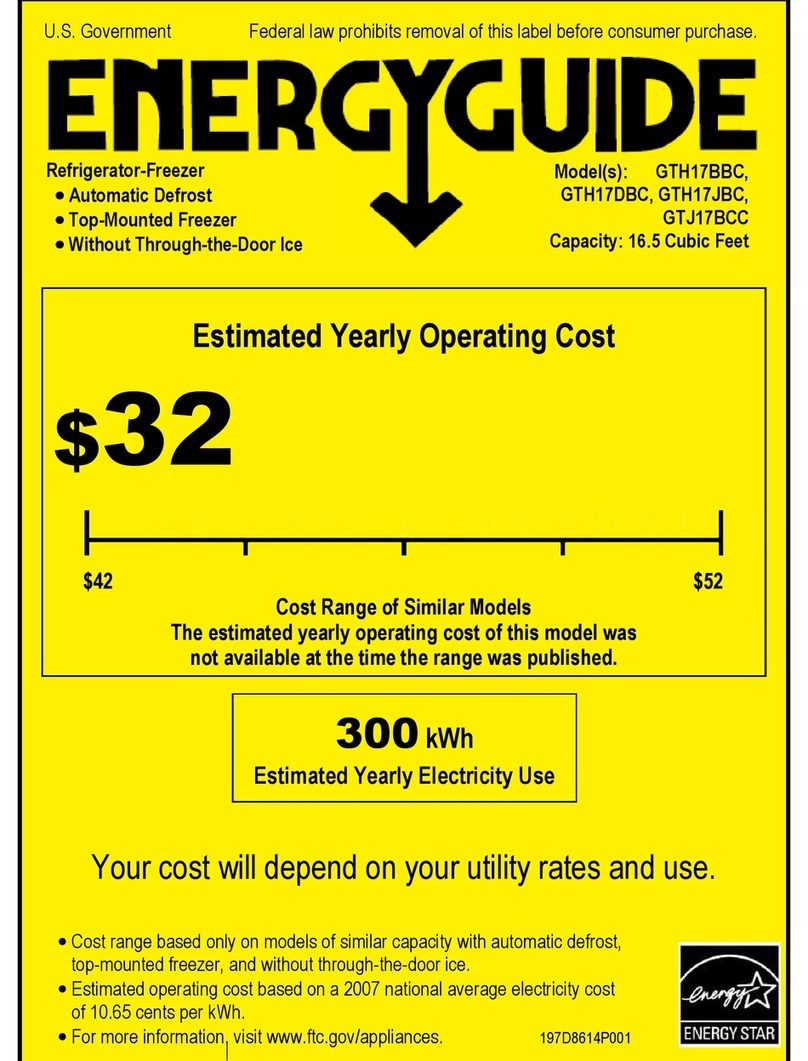

Models ZIS360 - 45.58 kWh/mo. ZIS 360D - 48.67 kWh/mo. ZIS 420 - 47.08

kWh/mo. ZIS 420D - 51.83 kWh/mo. ZIS 480 - 49.33 kWh/mo. ZIS 480D -

56.50kWh/mo.

**

ModelsZIS360 -WR55X10166.ZIS 360D-WR55X10165. ZIS 420-

WR55X10164.ZIS 420D-WR55X10163. ZIS480- WR55X10162. ZIS480D -

WR55X10158.

WARNING: Disconnect power cord before

servicing.

Note: Reconnect all grounding devices.

All parts of this appliance capable of conducting

electrical current are grounded. If grounding

wires, screws, straps, clips, nuts, or washers

used to complete a path to ground are removed

for service, they must be returned to their

original positions and properly fastened.

Caution: To avoid personal injury when

servicing the condensing unit, stand on a ladder

which will give enough support to allow removal

of the top panel and safely allow access to

service the unit.

ELECTRICAL SPECIFICATIONS

NO LOAD PERFORMANCE

REFRIGERATION DIAGNOSIS

MaxDefrostControl

W/No Door Openings ............60 hrs @ 35 min

Evap.OvertemperatureThermodisc..............60 °F - 45

°F

Light Thermostat .....................................140 °F - 90 °F

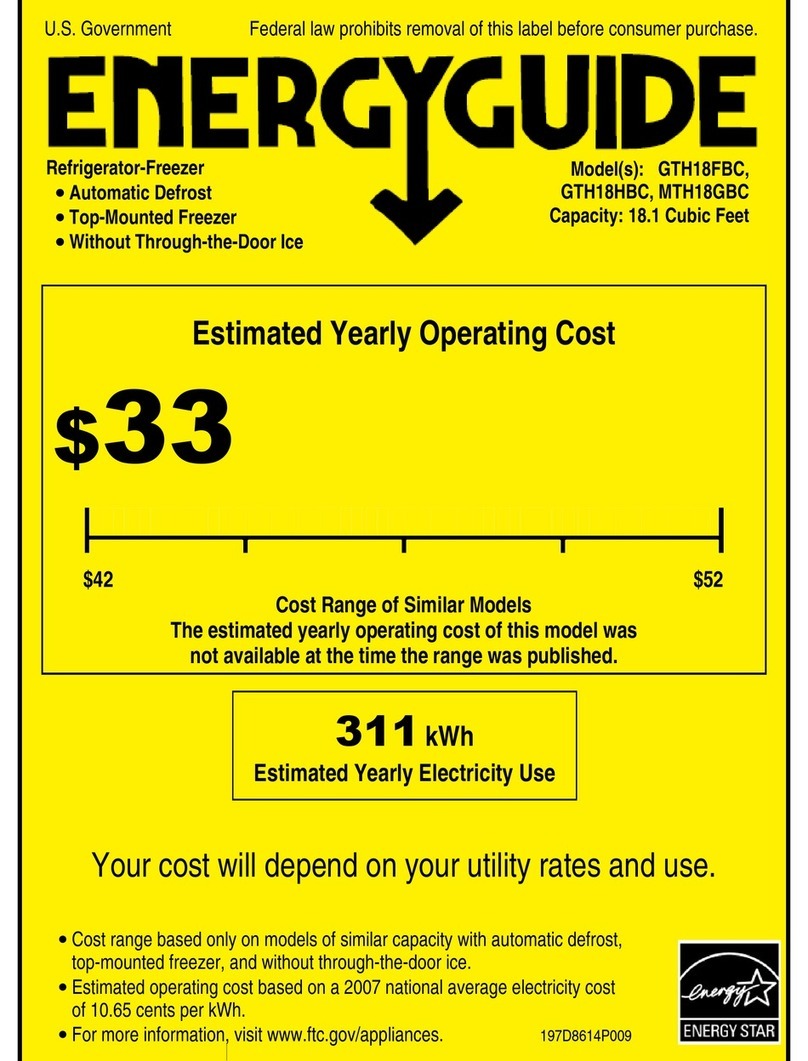

Electrical Rating: 115 VAC 60 Hz.....................9.0 amp

Maximum Current Leakage............................ 0.75 mA

Maximum Ground Path Resistance ............ 0.14 ohms

Energy Consumption (HUMID) ................................. *

To access the low-pressure side of the system,

install a WR86X0097 valve only on the process

tube extending from the compressor case.

CONTROL POSITION 37-0 °F and

AMBIENT TEMPERATURE OF

70 °F 90 °F

Fresh Food, °F ....................... 35–39 .............. 37–48

Frozen Food, °F ..................... (-4)–4 .............. (-4)–4

Percent Running Time............. 60 .................... 80

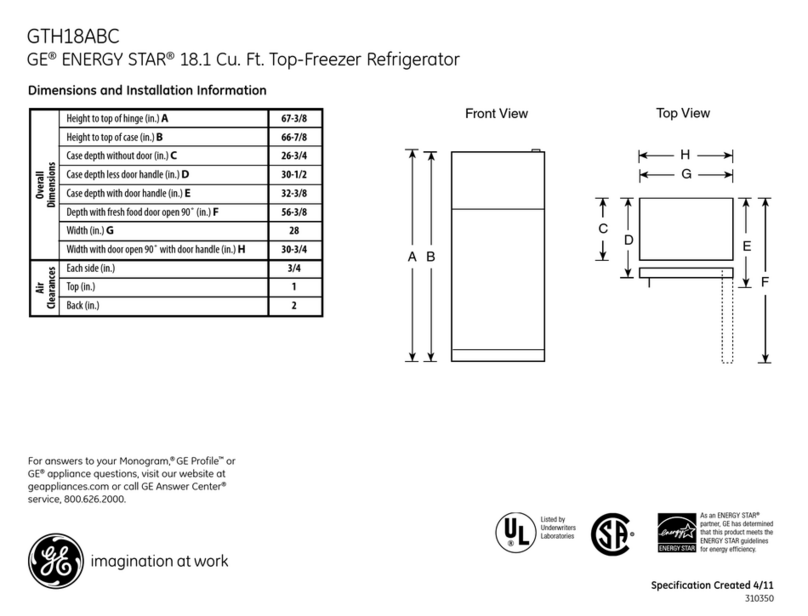

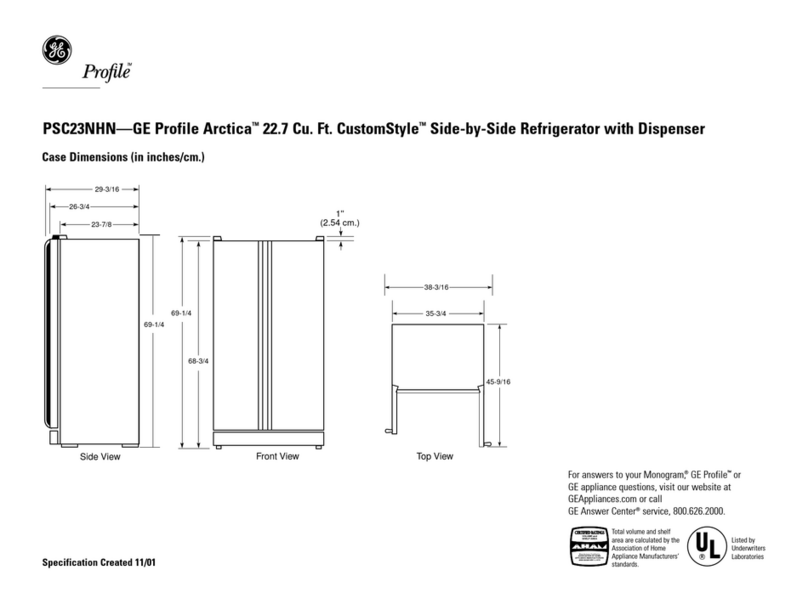

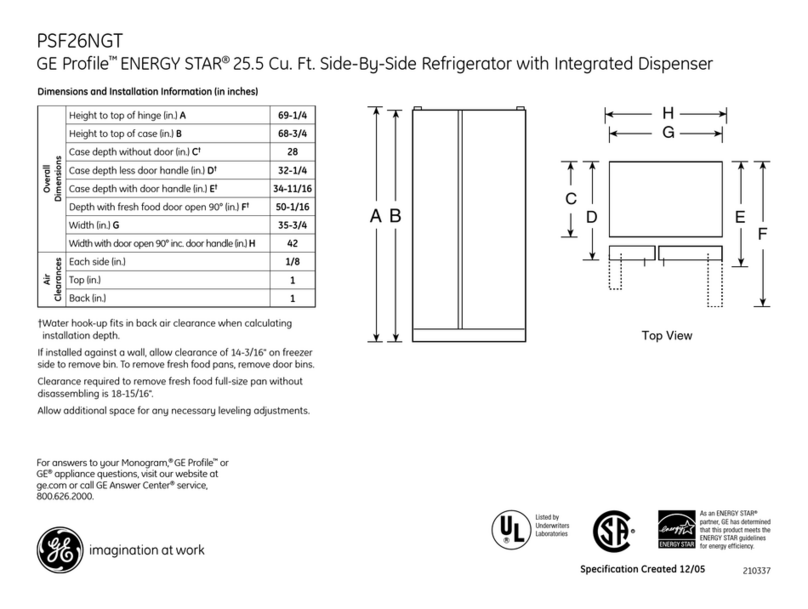

CONDENSER

LOOP

PROCESS

TUBE

COMPRESSOR

*ACCUMULATOR

CONDENSER

HEAT EXCHANGE

EVAPORATOR

HIGH PRESSURE

(DO NOT USE)

*INVERTER

DRYER

CONDENSER FAN

(SEE NOTE)

Note: Fan blade mounted for maximum airflow with 1/2" of shaft exposed.

*Approximate location (Inverter and Accumulator).

REFRIGERATION SYSTEM