GE Profile PFSS5NJWSS User manual

Other GE Refrigerator manuals

GE

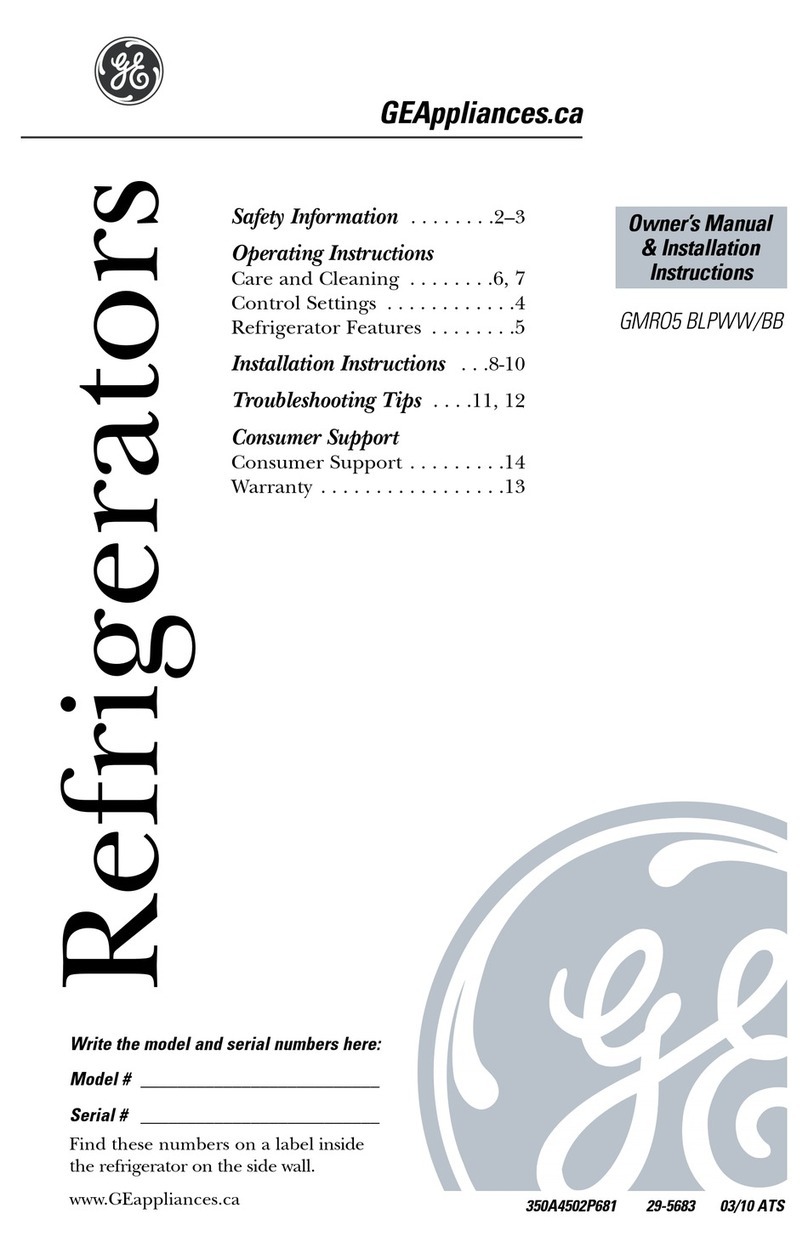

GE GMRO5 BLPWW Original instructions

GE

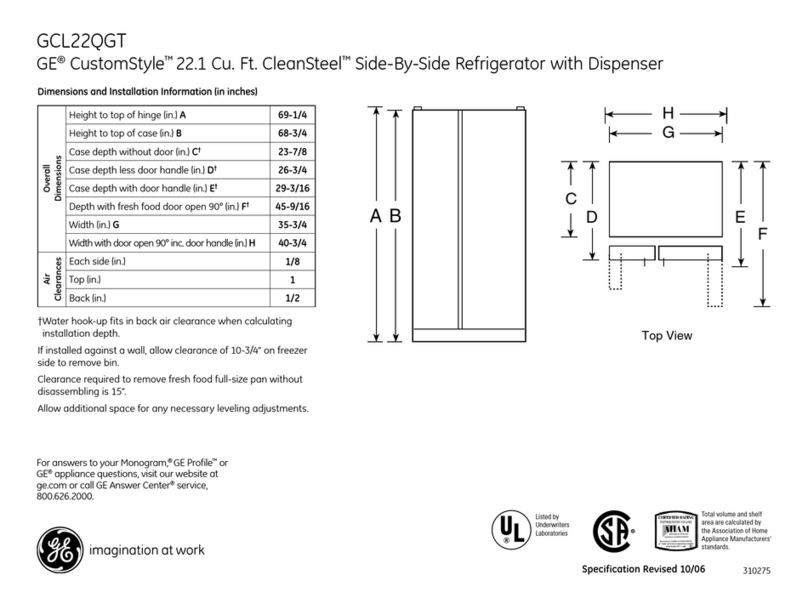

GE CustomStyle GCL22QGT Manual

GE

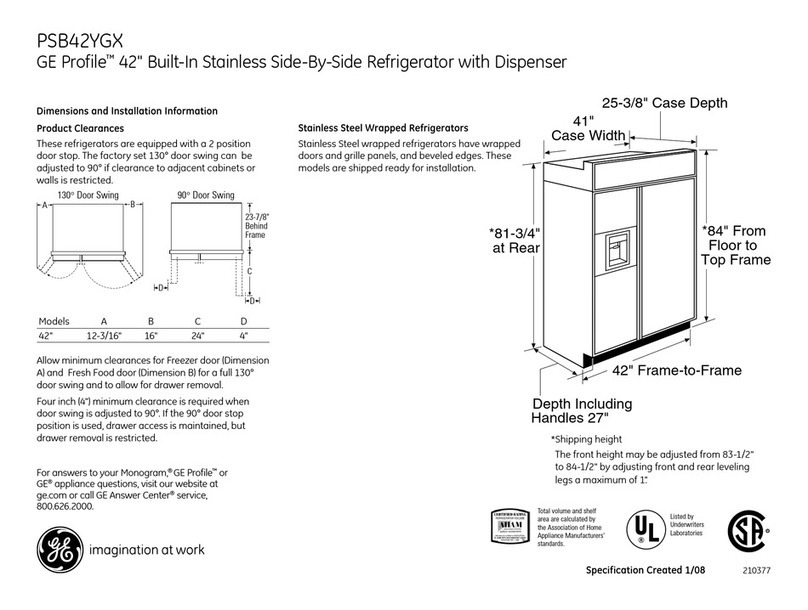

GE Profile PSB42YGXSV User manual

GE

GE Monogram Refrigerator User manual

GE

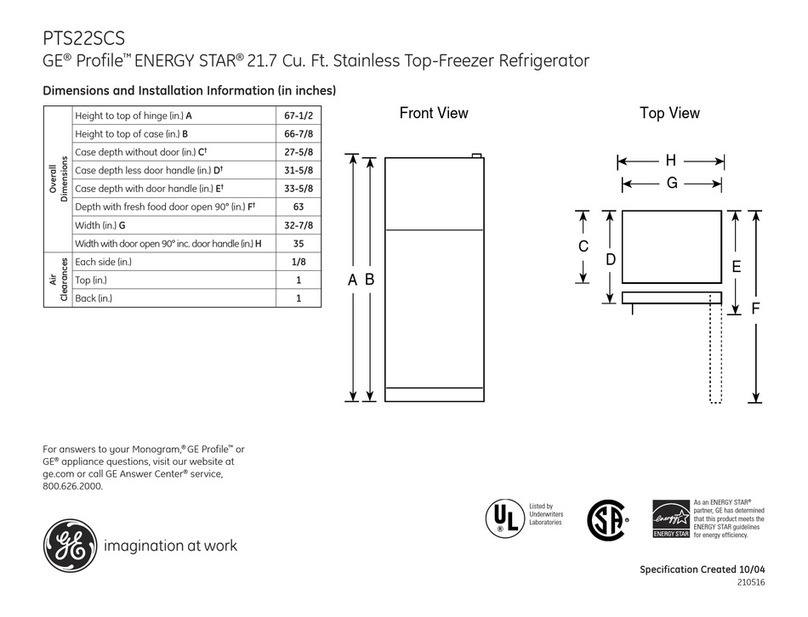

GE Profile PTS22SCSSS Manual

GE

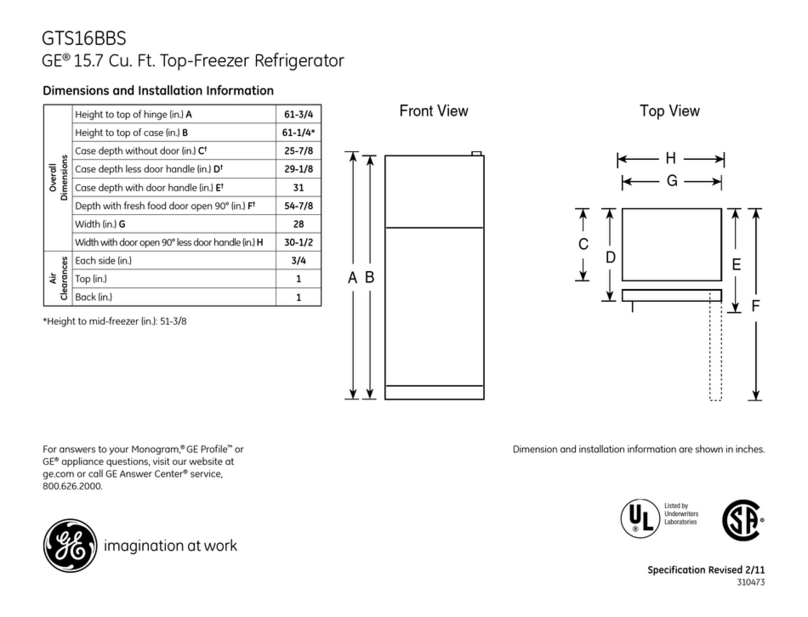

GE GTS16BBSRWW - 15.7 cu. Ft. Top-Freezer... Manual

GE

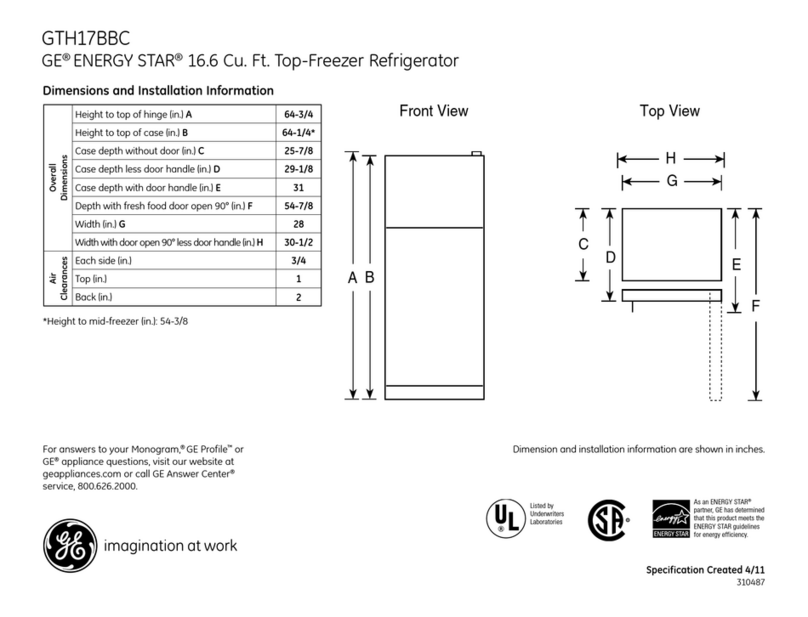

GE GTH17BBCRWW Manual

GE

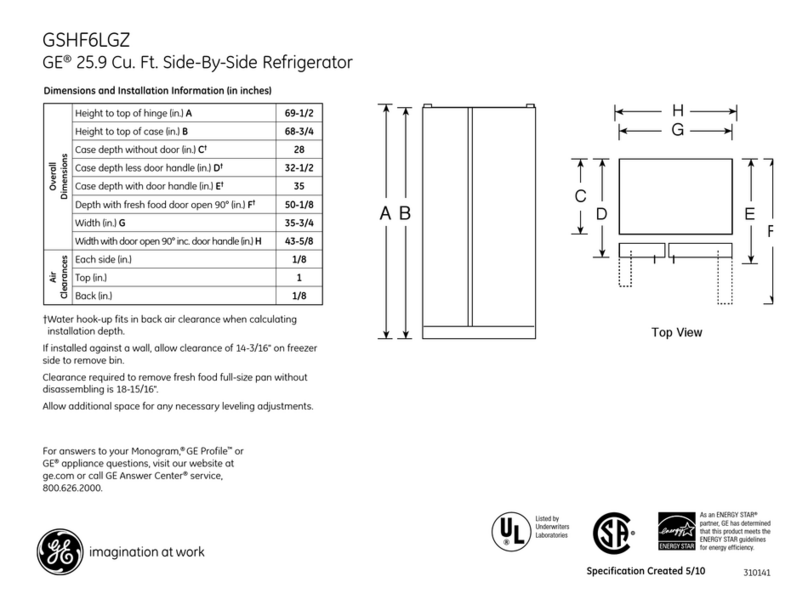

GE Profile GSH6LGZ Manual

GE

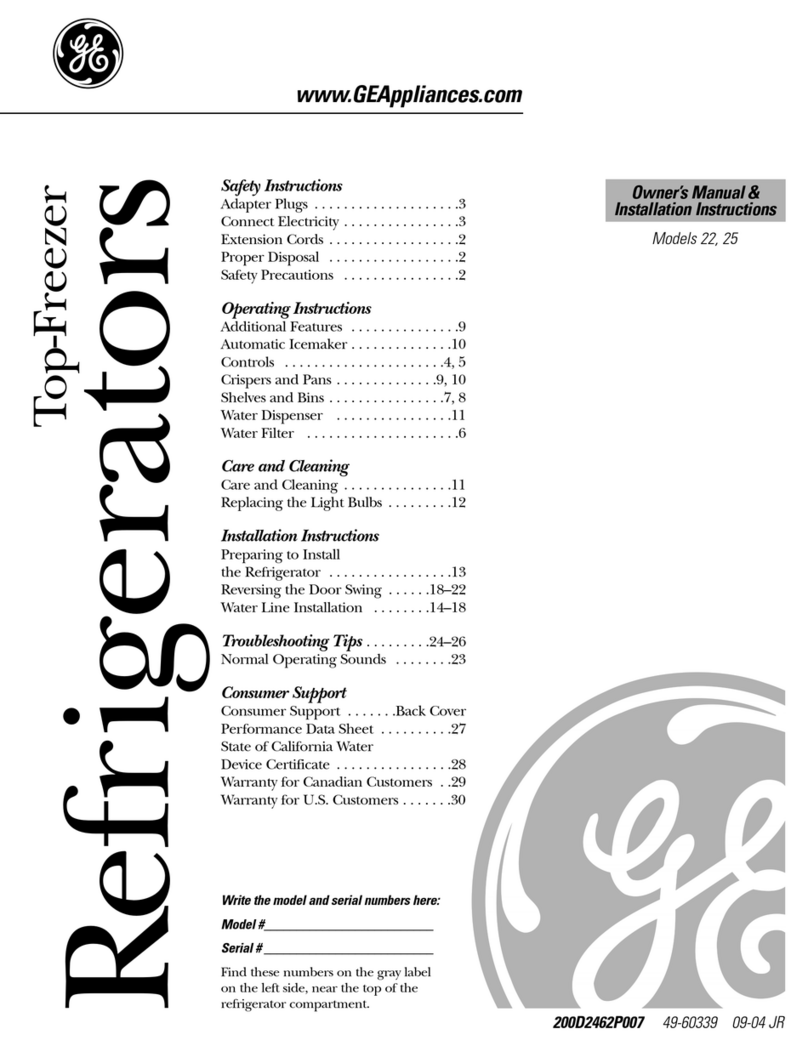

GE SIDE-BY-SIDE REFRIRATOR 22 Service manual

GE

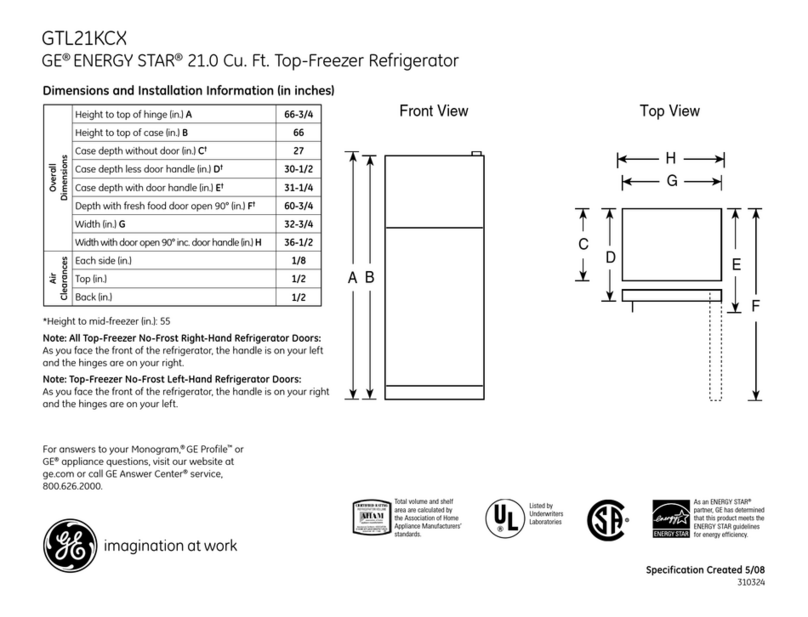

GE GTL21KCXBS - R 21.0 Cu. Ft. Top-Freezer... Manual

GE

GE Profile PYE22PSKSS Operating instructions

GE

GE Monogram ZIC360N RH Guide

GE

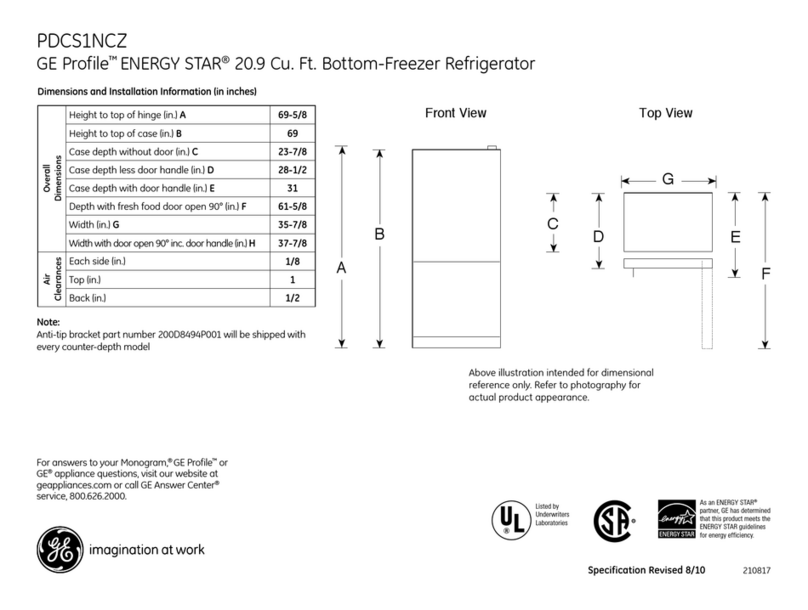

GE Profile PDCS1NCZ Manual

GE

GE GDE03GMKED Original instructions

GE

GE Profile PSW26PSSSS Operating instructions

GE

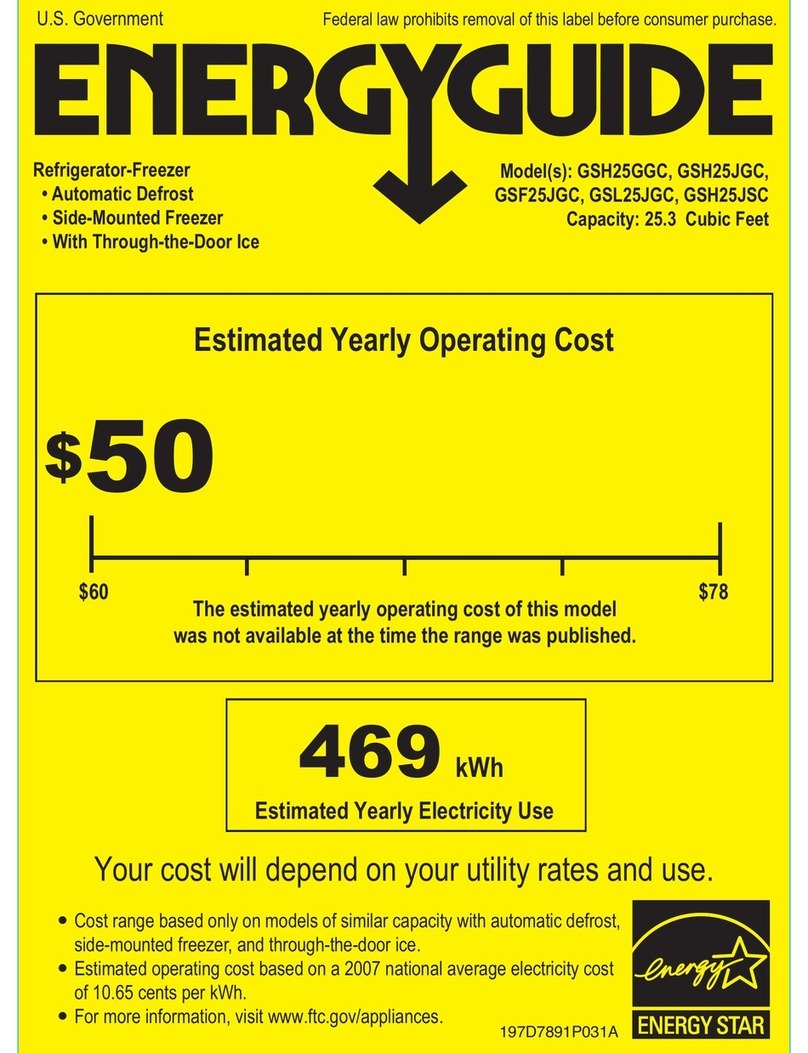

GE GSH25JSCSS Assembly instructions

GE

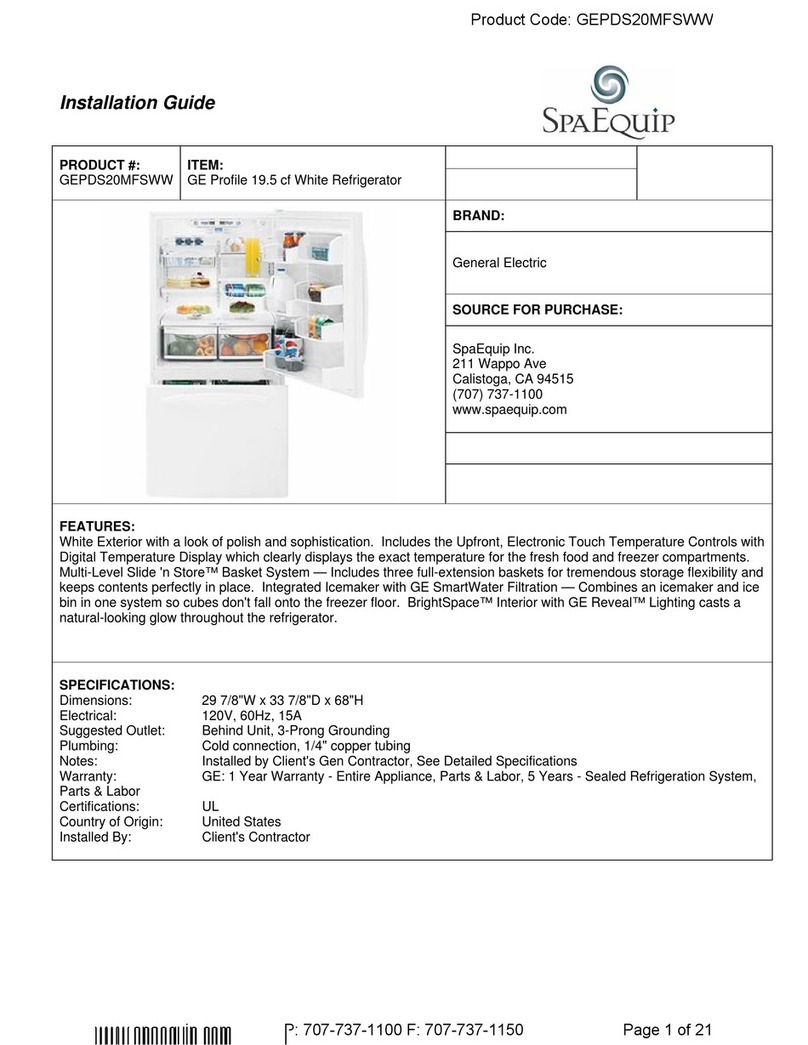

GE GEPDS20MFSWW User manual

GE

GE GPE12FGKWW Original instructions

GE

GE Profile PSC25PSTSS Manual

GE

GE 20 Original instructions