– 3 –

Table of Contents

Air Temperature Thermistors....................................................................................................................................35

Center Mullion and Heater ........................................................................................................................................43

Components.....................................................................................................................................................................28

Components Locator Views......................................................................................................................................22

Compressors and Inverters.......................................................................................................................................62

Condenser Fans..............................................................................................................................................................61

Control Board Connector Locator..........................................................................................................................26

Control Features.............................................................................................................................................................16

Customer Control...........................................................................................................................................................34

Dead Unit Diagnostics.................................................................................................................................................63

Diagnostic Mode ............................................................................................................................................................64

Door Gaskets....................................................................................................................................................................32

Drawers..............................................................................................................................................................................42

EMI Filter.............................................................................................................................................................................56

Evaporator ......................................................................................................................................................................52

Extended Diagnostic Codes......................................................................................................................................68

Filter Head.........................................................................................................................................................................56

Freezer Evaporator Components ...........................................................................................................................49

Freezer Evaporator Cover..........................................................................................................................................47

Freezer Fan Motor .........................................................................................................................................................51

Fresh Food Evaporator Components ...................................................................................................................39

Fresh Food Evaporator Cover ..................................................................................................................................35

Fresh Food Fan Motor..................................................................................................................................................41

Fresh Food/Wine Reserve Door ..............................................................................................................................33

Icemaker ............................................................................................................................................................................44

Icemaker and Water Valve Control Diagnostics .............................................................................................81

Icemaker Fill Tube Heater..........................................................................................................................................45

Icemaker Inlet Tube ......................................................................................................................................................46

Initial Diagnostic Codes ..............................................................................................................................................65

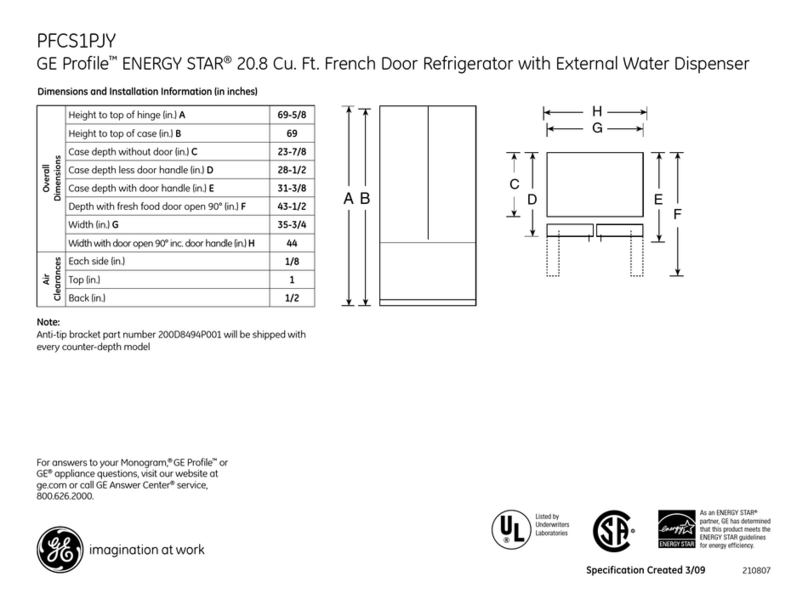

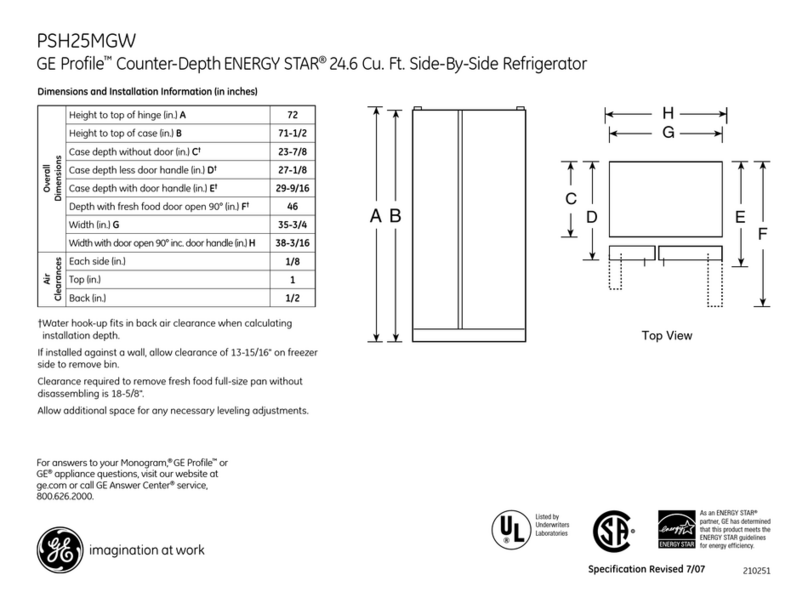

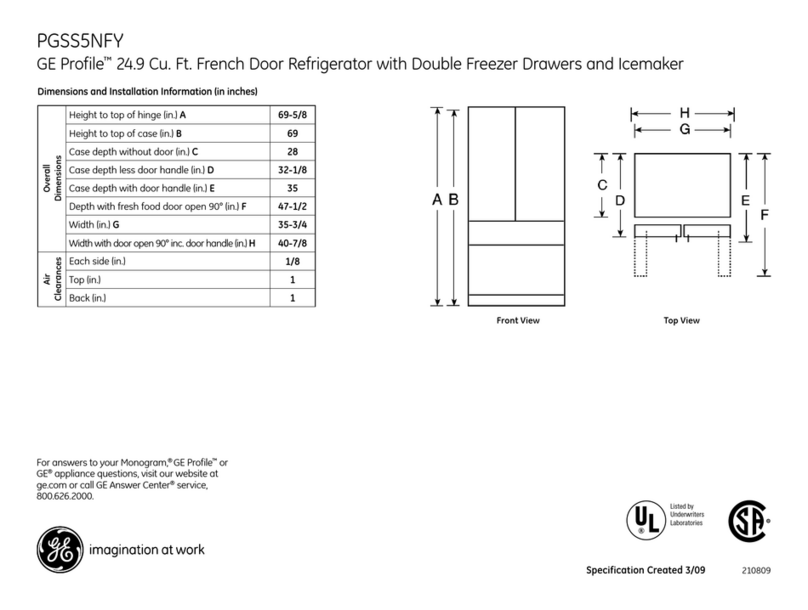

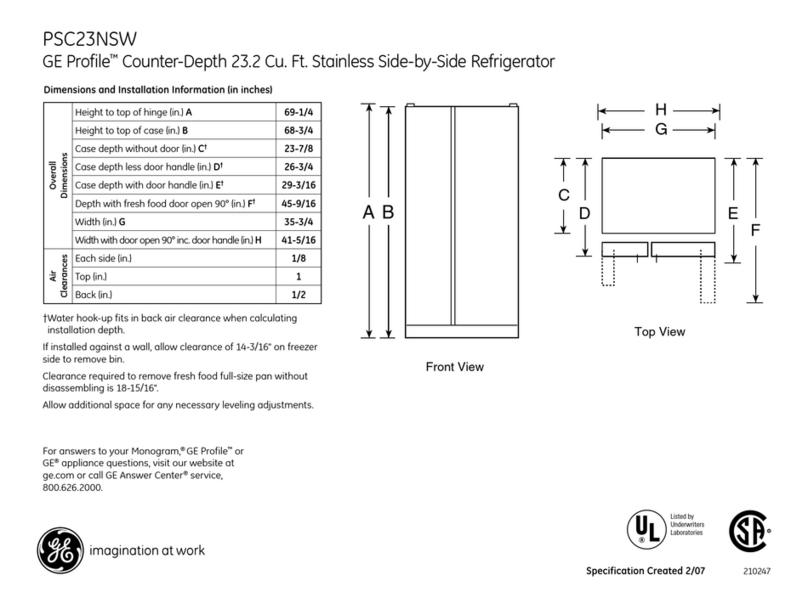

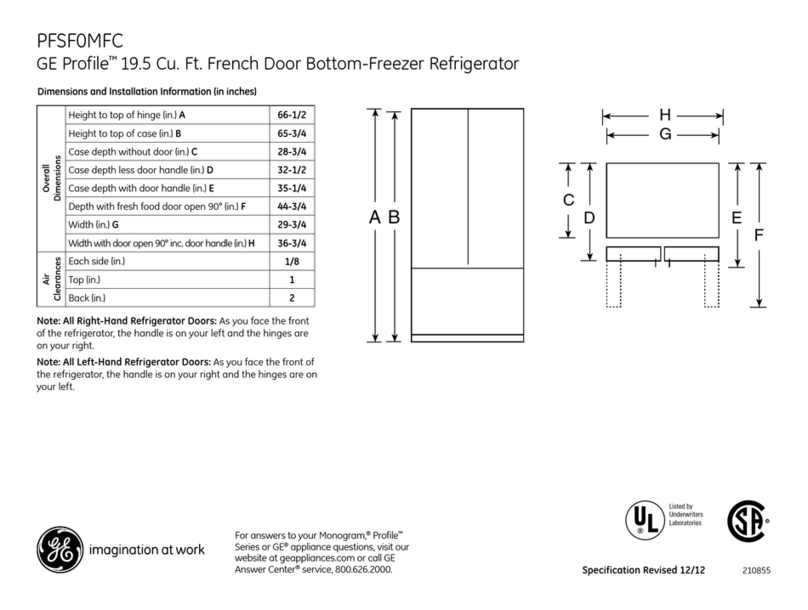

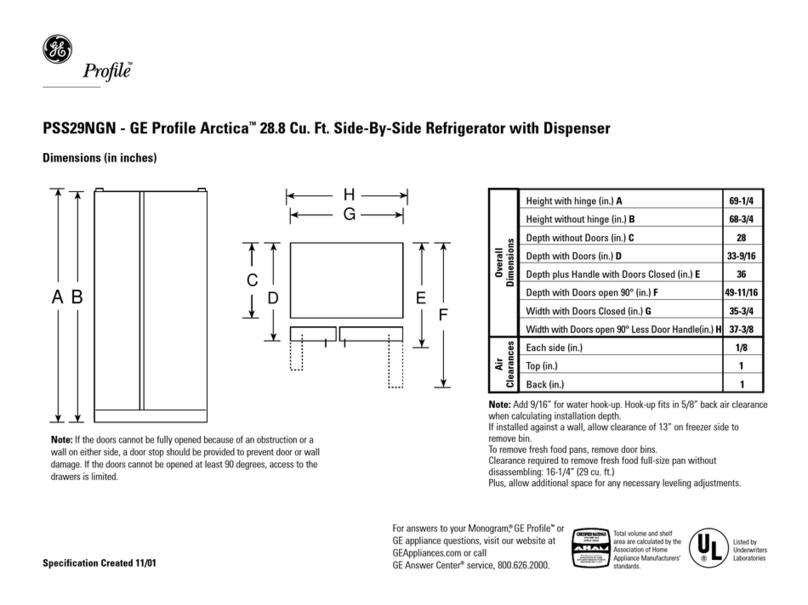

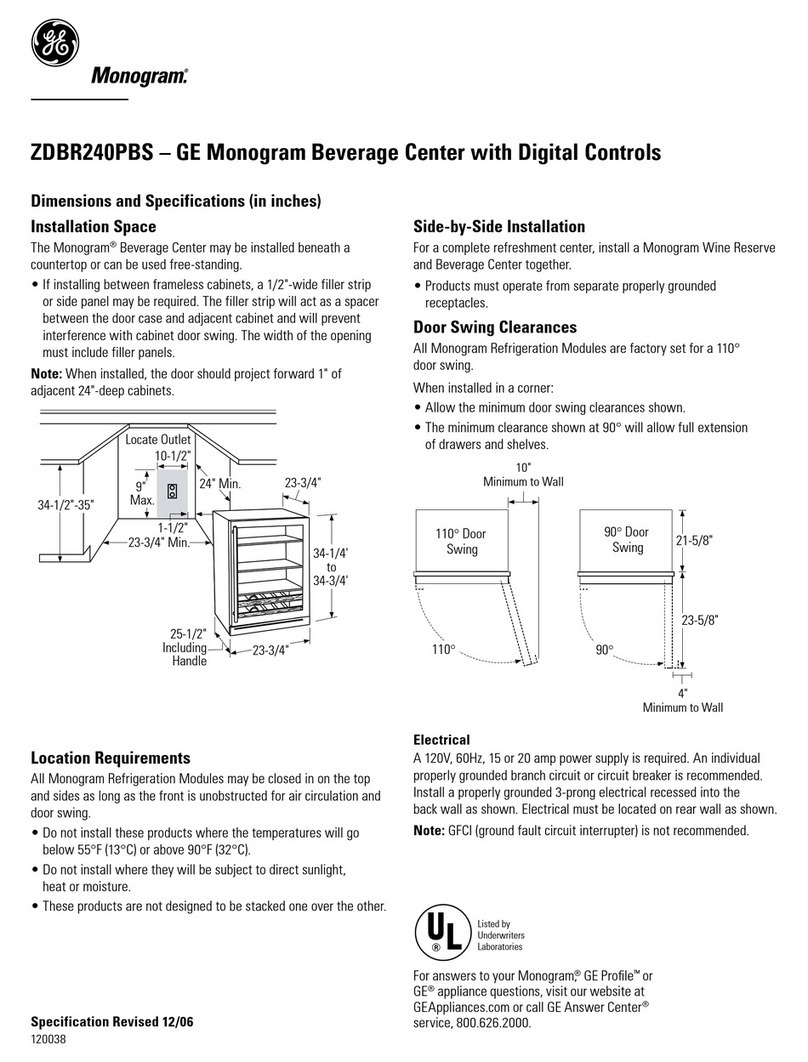

Installation......................................................................................................................................................................... 9

Installation Instructions ..............................................................................................................................................10

Interior Lights...................................................................................................................................................................31

Interior Shelves, Drawers, and Bins.......................................................................................................................28

Introduction...................................................................................................................................................................... 5

Nomenclature.................................................................................................................................................................. 6

Power Supply and Main Control Board Assembly..........................................................................................57

R600a – Isobutane Refrigerant ............................................................................................................................... 8

Safety Information........................................................................................................................................................ 4

Schematic..........................................................................................................................................................................82

System Tray .....................................................................................................................................................................58

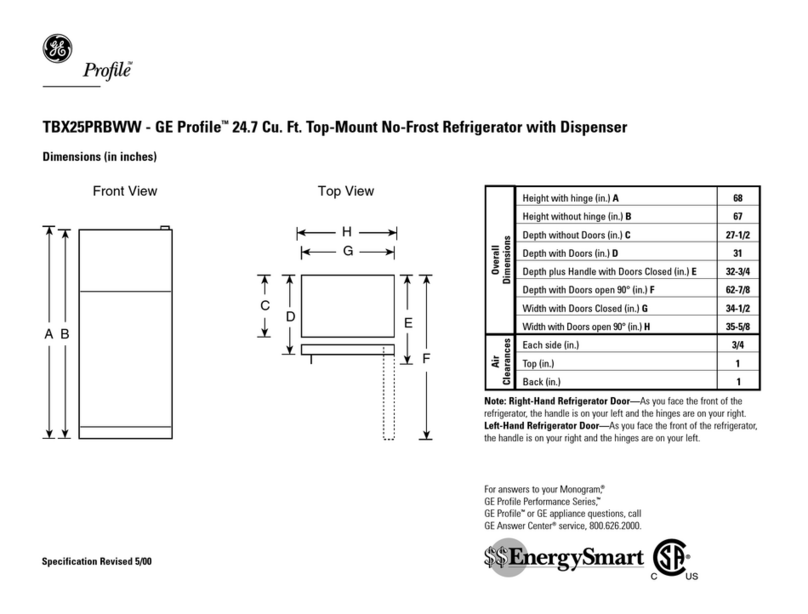

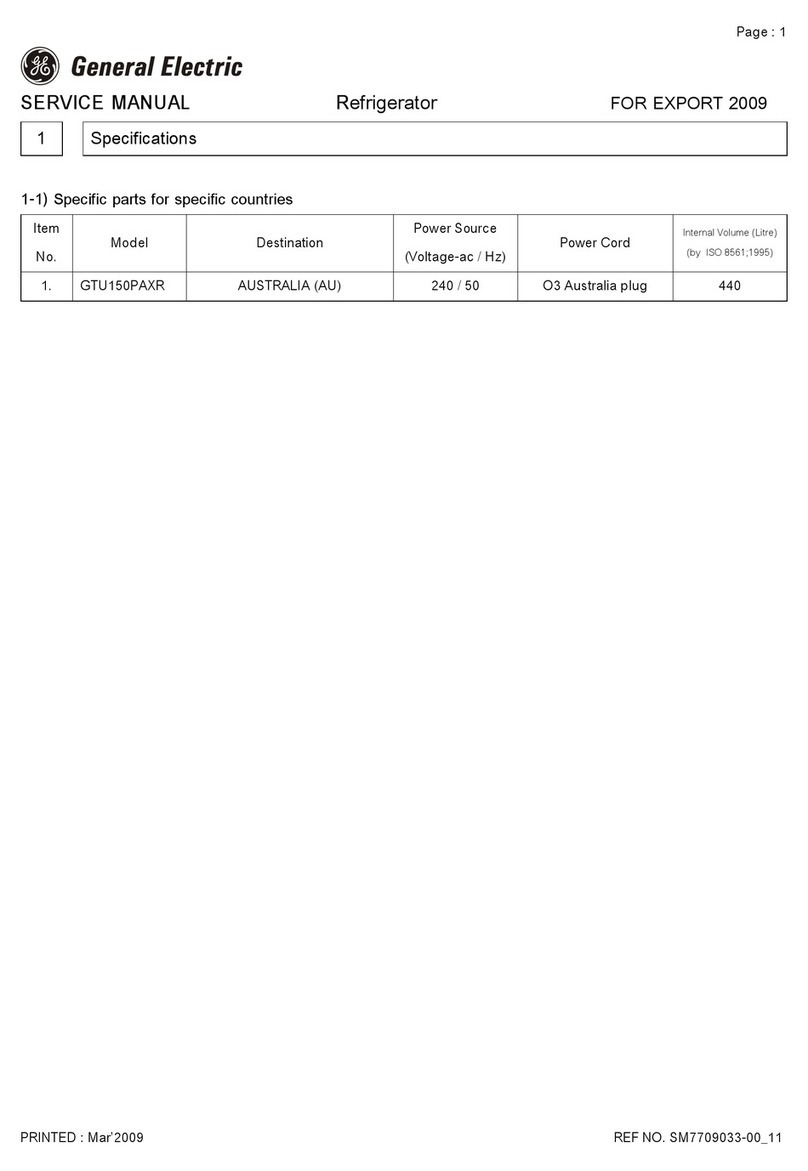

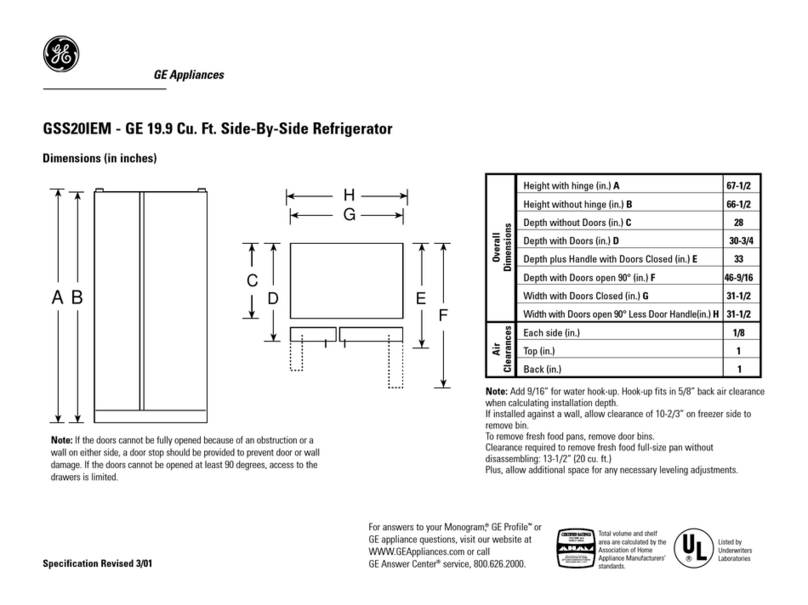

Technical Data................................................................................................................................................................. 7

Toekick and Vent Panel................................................................................................................................................54

Troubleshooting..............................................................................................................................................................63

Warranty ...........................................................................................................................................................................83

Water Valve ......................................................................................................................................................................55

Wine Reserve Evaporator Cover.............................................................................................................................37