GE Profile ENERGY STAR WPDH8800J Installation instructions

Other GE Washer manuals

GE

GE WPSQ4160 User manual

GE

GE GTWS8650DWS User manual

GE

GE Profile WPRB8050 User manual

GE

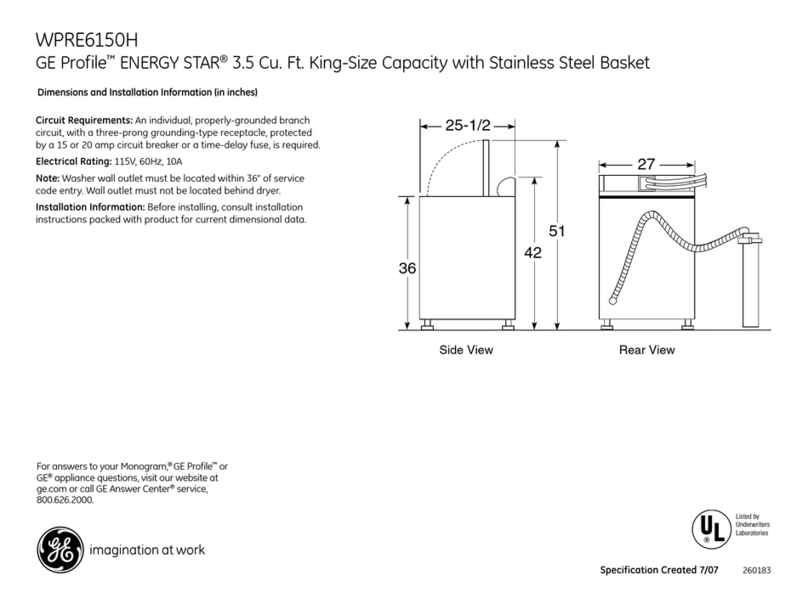

GE Profile ENERGY STAR WPRE6150H Manual

GE

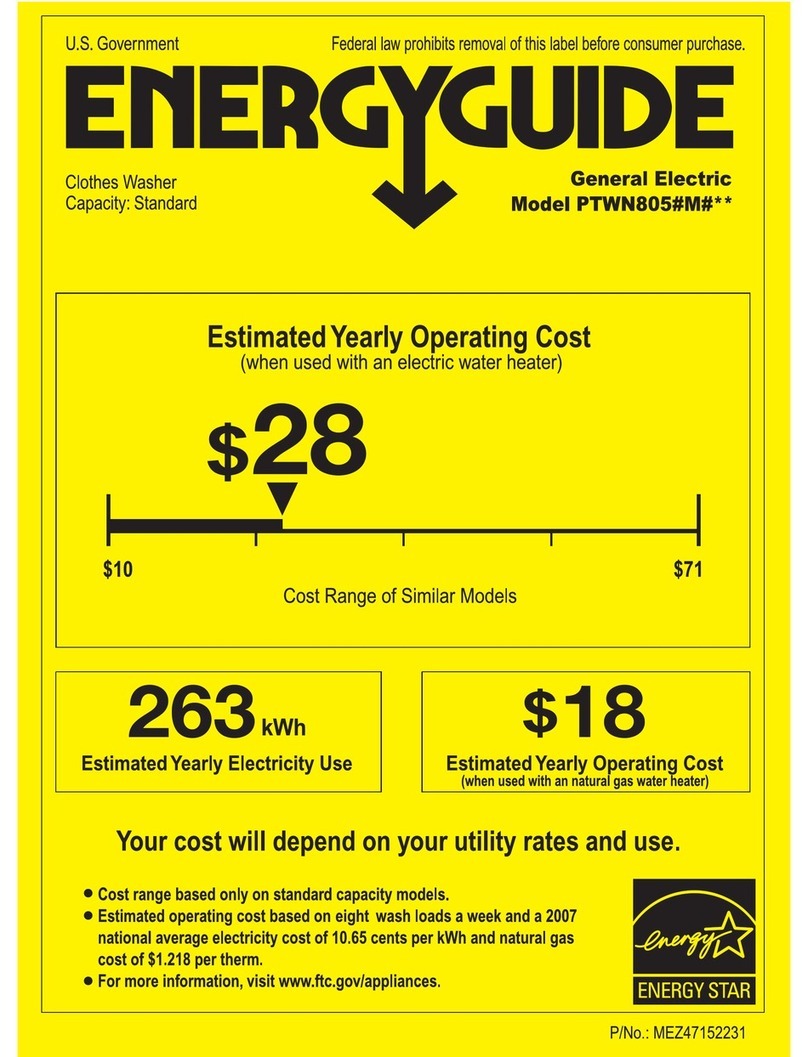

GE Profile PTWN8055MMS Assembly instructions

GE

GE WPSE7003 User manual

GE

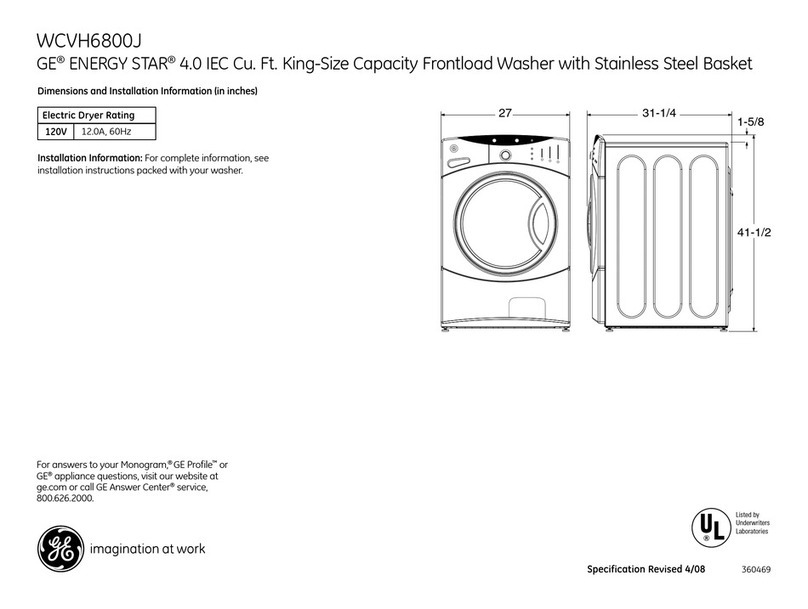

GE WCVH6800J User manual

GE

GE WSLP1500H0WW How to use

GE

GE WISQ416C User manual

GE

GE WCCD2050 User manual

GE

GE WWT2450G Installation instructions

GE

GE Appliances WASR3110 User manual

GE

GE GNW128P Original instructions

GE

GE LAVEUSES WBVH5200 Original instructions

GE

GE WWA3650R User manual

GE

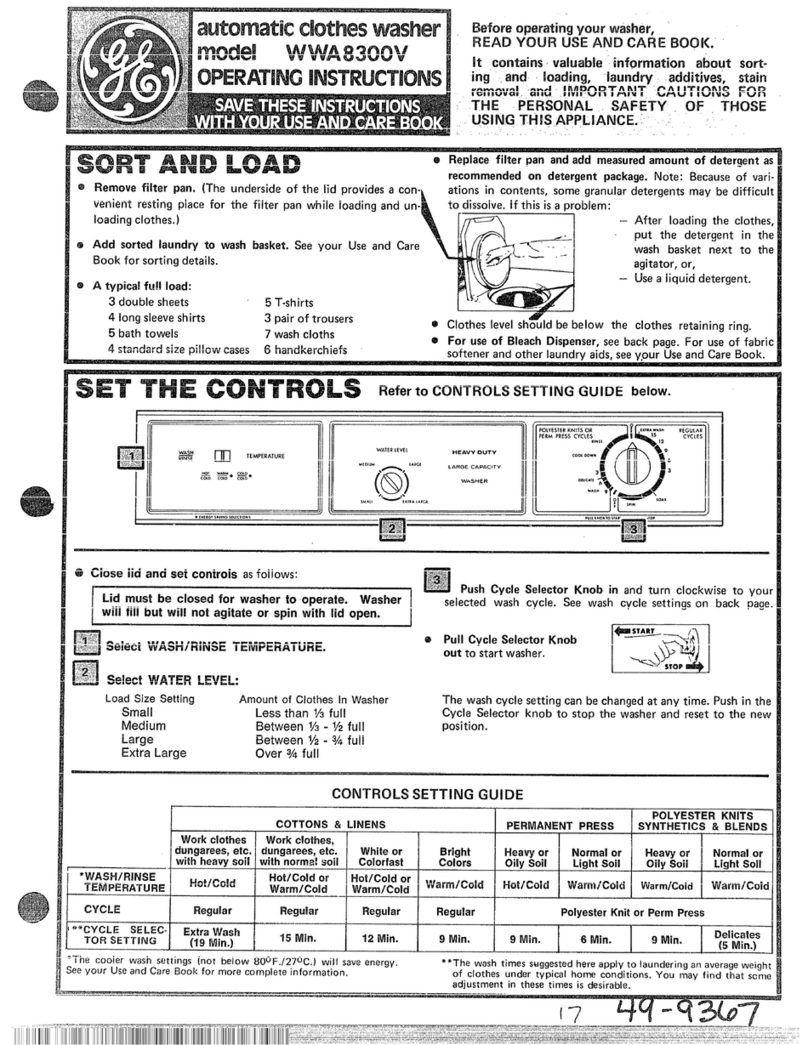

GE WWA8300V User manual

GE

GE WSXH208HWW - 27" Front-Load Washer Original instructions

GE

GE PROFILE WPDH8900J Manual

GE

GE GTW485 Original instructions

GE

GE WNRD2050 User manual