3

SAFETY NOTICE....................................................................................................................................... 2

QUICK REFERENCE SHEET .................................................................................................................. 5

Nomenclature location .................................................................................................................. 5

Mini-manual location ..................................................................................................................... 5

Component resistance chart........................................................................................................ 6

Water fill height............................................................................................................................. 6

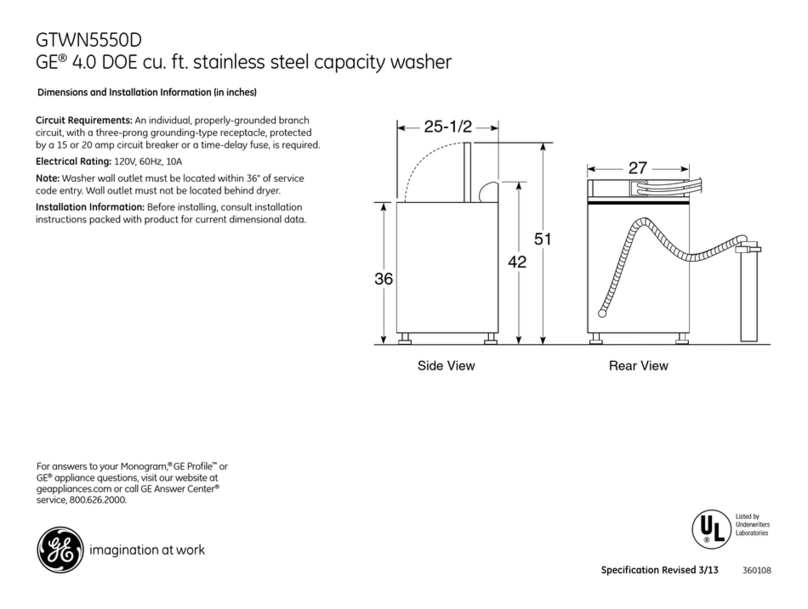

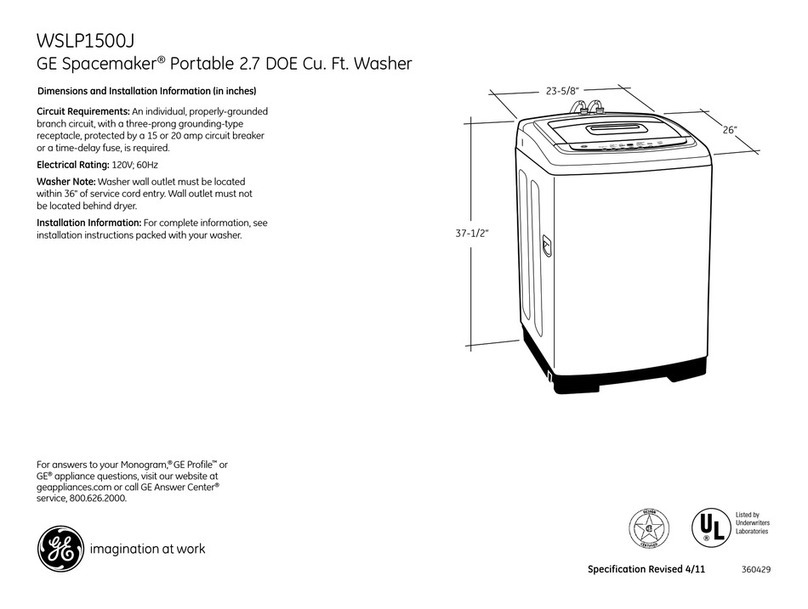

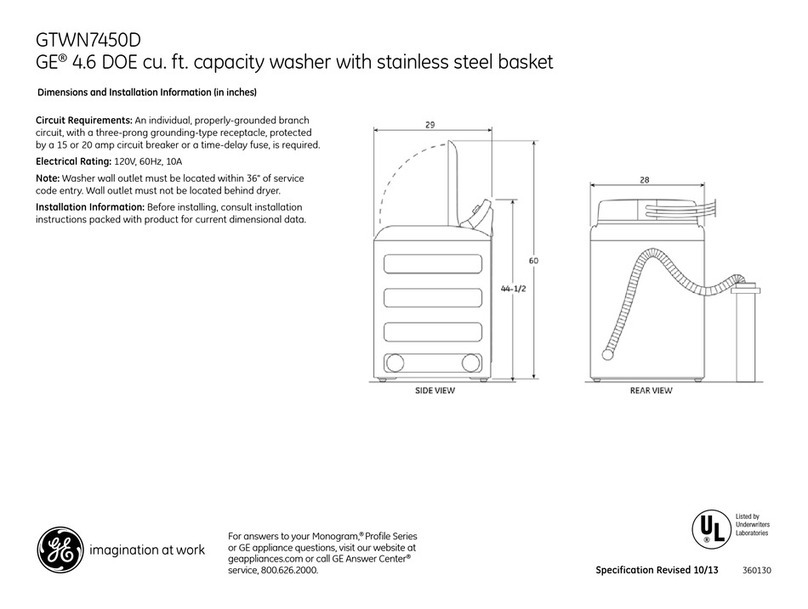

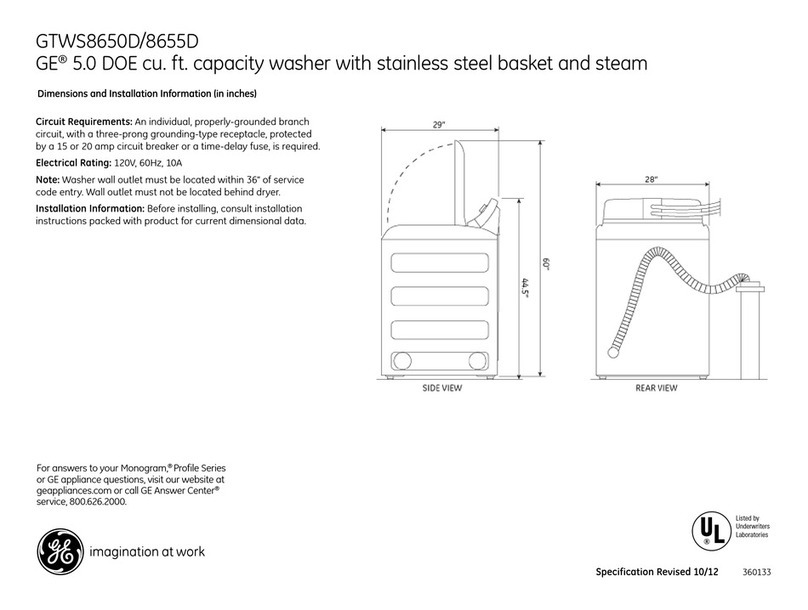

Electrical requirements ................................................................................................................. 6

Incoming water pressure.............................................................................................................. 6

Drain requirements........................................................................................................................ 6

Motor............................................................................................................................................... 6

Diagnostic test............................................................................................................................... 7

Operation speeds .......................................................................................................................... 8

Wiring Diagram.............................................................................................................................. 9

OPERATING INSTRUCTIONS ................................................................................................................. 10

About the washer control panel ................................................................................................. 10

About the washer features .......................................................................................................... 11

OPERATION ............................................................................................................................................... 12

Control ............................................................................................................................................ 12

Dispenser Drawer Reed Switch .................................................................................................. 12

Door Switch Assembly ................................................................................................................. 12

Pressure Switch ............................................................................................................................ 13

Water Inlet Valve Assembly ........................................................................................................ 14

Valve Operation ............................................................................................................................. 14

Water Temperature........................................................................................................................ 15

Automatic Dispenser ..................................................................................................................... 16

Drain Pump.................................................................................................................................... 20

Inverter ........................................................................................................................................... 21

Motor............................................................................................................................................... 21

CONSTRUCTION.......................................................................................................................................... 22

Cabinet ........................................................................................................................................... 22

Front Panel and Door Assembly...................................................................................................22

Bellows ........................................................................................................................................... 22

Outer Tub Assembly....................................................................................................................... 22

Spin Basket Assembly ................................................................................................................... 22

TROUBLESHOOTING .................................................................................................................................. 23

Consumer error code chart........................................................................................................... 57

Failure code chart ......................................................................................................................... 24

Tests ................................................................................................................................................ 25

Jacks and plugs ............................................................................................................................. 27

TEARDOWN ................................................................................................................................................. 28

Removing the detergent drawer .................................................................................................. 28

Detergent drawer disassembly ..................................................................................................... 28

Removing door strike .................................................................................................................... 29

Removing the loading door handle ............................................................................................. 29

Removing loading door ................................................................................................................ 29

Disassembling the door................................................................................................................. 30

Removing door hinges .................................................................................................................. 30

Releasing the bellows from the front panel ................................................................................ 31

Removing the door safety switch .................................................................................................31

Removing the lower front access panel ...................................................................................... 32

Removing the drain pump ............................................................................................................ 32

Disassembling the drain pump ..................................................................................................... 33

Removing the top panel................................................................................................................ 33

Removing the pressure switch ..................................................................................................... 34

Releasing the console................................................................................................................... 34

Removing the water temperature selector knob ........................................................................ 35

Removing the console................................................................................................................... 35