GEKCO DIGITAL CLOCK P/N CLK036 ASSEMBLY & OPERATION MANUAL

GEKCO INC. Rev 1.0 1

TABLE OF CONTENTS

1. INTRODUCTION................................................................................................................................................ 3

2. OPERATIONAL SUMMARY.......................................................................................................................... 3

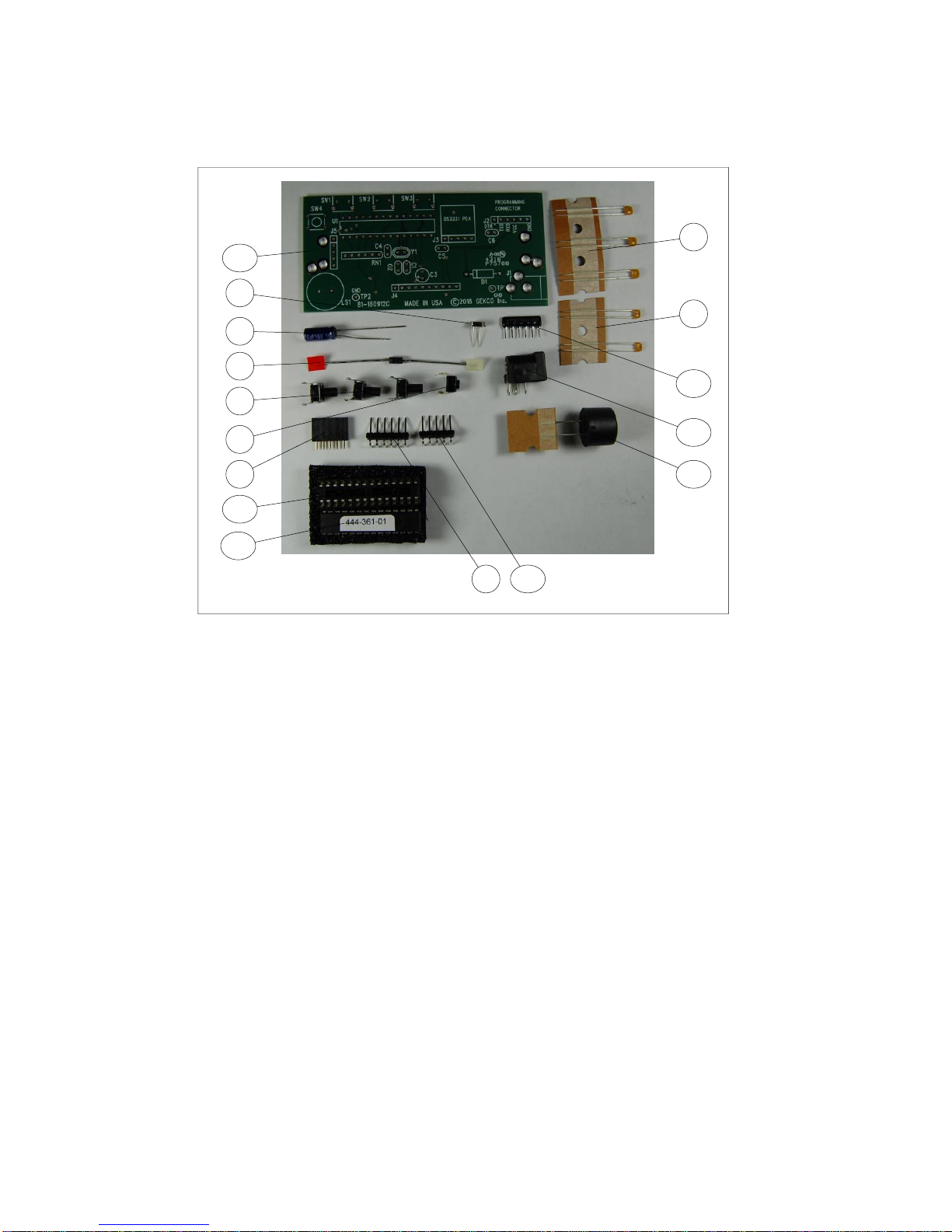

3. PARTS AND UNPACKING.............................................................................................................................. 4

3.1. TOP LEVELPARTS LIST ...................................................................................................................................... 4

3.2. DISPLAY BOARD PARTS LIST.............................................................................................................................. 5

3.3. MAIN BOARD PARTS LIST................................................................................................................................... 5

3.4. FINALASSEMBLY HARDWARE PARTS LIST....................................................................................................... 7

3.5. ENCLOSURE PARTS LIST..................................................................................................................................... 8

4. ASSEMBLY NOTES........................................................................................................................................... 9

4.1. TOOLS............................................................................................................................................................... 9

4.2. ASSEMBLY ...................................................................................................................................................... 9

4.3. SOLDERING..................................................................................................................................................... 9

5. STEP-BY-STEP ASSEMBLY .........................................................................................................................10

5.1. MAIN CIRCUITBOARD...................................................................................................................................... 10

6. INITIAL TESTS.................................................................................................................................................12

7. FINAL TESTS....................................................................................................................................................13

8. IN CASE OF DIFFICULTY ............................................................................................................................13

9. FINAL PCA ASSEMBLY................................................................................................................................13

10. FINAL ASSEMBLY......................................................................................................................................13

11. THEORY OF OPERATION.......................................................................................................................16

11.1. BLOCKDIAGRAM.............................................................................................................................................. 16

11.1. MAIN BOARD CIRCUIT DESCRIPTION............................................................................................................... 16

11.2. DISPLAY BOARD CIRCUITDESCRIPTION..........................................................................................................17

12. FIRMWARE ..................................................................................................................................................18

12.1. FLOWCHART ....................................................................................................................................................18

12.2. FIRMWARE DESIGN DESCRIPTION....................................................................................................................19

13. PCA PICTORIAL DIAGRAMS.................................................................................................................19

13.1. MAIN BOARD....................................................................................................................................................19

13.2. DISPLAY BOARD ...............................................................................................................................................20

14. SCHEMATIC MAIN BOARD....................................................................................................................22

15. SCHEMATIC DISPLAY BOARD............................................................................................................. 23

16. DOCUMENT REVISION HISTORY........................................................................................................ 24