gefran GF PROMER 35 User manual

GF_PROMER

Graphic setpoint programmer, 4 zones

3.5” and 5.7” screens, TFT, Colour, Touch screen

INSTALLATION AND OPERATION MANUAL

Side 1 Installation and Connection

Electrical connections

Side 2 Technical information

Dimensions

Fixing/Installation

code 80327 - 01/2012 - ENG

ELECTRICAL CONNECTIONS / USER CONNECTIONS

INSTALLATION AND CONNECTION

This section contains the instructions necessary mfor correct installation of the GF_PROMER into the machine

control panel or the host system and for correct connection of the controller power supply, inputs, outputs and

interfaces.

Before proceeding with installation read the following warnings carefully! Remember that lack of observation of

these warnings could lead to problems of electrical safety and electromagnetic compatibility, as well as invalida-

ting the warranty.

ELECTRICAL POWER SUPPLY

•the GF_PROMER is NOT equipped with an On/Off switch: the user must provide a two-phase disconnecting switch that

conforms to the required safety standards (CE marking), to cut off the power supply upstream of the controller.

The switch must be located in the immediate vicinity of the controller and must be within easy reach of the operator.

One switch may control more than one instrument.

• if the controller is connected to NOT isolated electrical equipment (e.g. thermocouples), the earth connection must be

made with a specific conductor to prevent the connection itself from coming directly through the machine structure.

• if the programmer is used in applications with risk of damage to persons, machinery or materials, it is essential to be

connect it up to auxiliary alarm equipment.

It is advisable to make sure that alarm signals are also triggered during normal operation.

The controller must NOT be installed in flammable or explosive environments; it may be connected to equipment

operating in such atmospheres only by means of appropriate and adequate types of interface, conforming to the

applicable safety standards.

NOTES CONCERNING ELECTRICAL SAFETY AND ELECTROMAGNETIC COMPATIBILITY:

CE MARKING: EMC Conformity (electromagnetic compatibility) in accordance with EEC Directive 2004/108/CE.

The programmers series are mainly designed to operate in industrial environments, installed on the switch boards or

control panels of productive process machines or plants.

As regards electromagnetic compatibility, the strictest generic standards have been adopted, as indicated in the table

below.

BT Conformity (low voltage) in accordance with Directive 2006/95/CE.

EMC conformity has been tested with the following connections (table 1 (see “Installation and operation manual”).

FOR A CORRECT “EMC” INSTALLATION

Instrument power supply

Installation category II and pollution degree 2.

• The power supply to the electronic equipment on the switchboards must always come directly from an isolation device

with a fuse for the instrument part.

• The electronic instruments and electromechanical power devices such as relays, contactors, solenoid valves, etc.,

must always be powered by separate lines.

• When the electronic instrument power supply is strongly disturbed by voltage problems from power units or motors, an

isolation transformer should be used for the controllers only, earthing the screen.

• It is essential that the plant has a good earth connection:

- the voltage between neutral and earth must not be >1V

- the resistance must be <6Ω;

• If the mains voltage fluctuates strongly, use a voltage stabilizer.

• In the proximity of high frequency generators or arc welders, use adequate mains filters.

• The power supply lines must be separate from the instrument input and output lines.

Inputs and outputs connection

• To connect the analogue inputs, strain gauge, linear, (TC, RTD) the following is necessary:

- physically separate the input cables from those of the power supply, the outputs and the power connections.

- use woven and screened cables, with the screen earthed in one point only.

• To connect the control outputs, alarm (contactors, solenoid valves, motors, fans, etc.), fit RC groups (resistance and

condensers in series) in parallel to the inductive loads that operate in Alternating Current.

(Note: all the condensers must conform to VDE (class X2) standards and withstand a voltage of at least 220V AC. The

resistances must be at least 2W).

• Fit a 1N4007 diode in parallel with the coil of the inductive loads that operate in Direct Current.

GEFRAN S.p.A. declines all responsibility for any damage to persons or property caused by tampering,

neglect, improper use or any use which does not conform to the characteristics of the controller and to

the indications given in these Instructions for Use.

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with

reference to the generic standards: EN 61131-2 (Product) EN 61010-1 (safety)

GEFRAN spa

via Sebina, 74 - 25050 Provaglio d’Iseo (BS)

Tel. 03098881 - fax 0309839063- Internet: http://www.gefran.com

Prescription UL

- Operating surrounding air temperature rating of 50°C

- For use on a flat surface of a type 1 enclosure

GF_PROMER 35 connector

GF_PROMER 57 connector

Name Description

1 Power supply

2 USB

3 Ethernet 10/100

4 Serial RS485

5 BUS-G

6 Rotary-switch

7 Enabling battery

The user connections specified on Table are made at the bottom

by means of Gefran standard and custom connectors.

123

+24Vcc ±25%

+24V 0V

123

To limit susceptibility to noise of the GF_PROMER 57 programmer you have to install an

electromagnetic emission suppression core as shown in figure.

This component, supplied with the product, is a ferrite core coated in plastic for round section

wires.

Inserting cores in the power supply lines of GF_PROMER 57

24Vdc supply.

The internal power supply 24Vdc is galvanically isolated and protected against

polarity reversal and short circuits. The panel has a power terminal.

The connector diagram is shown in Figure.

Note: check that the power supply is able to deliver the power needed for correct

operation of the device.

The device must always be grounded.

Grounding helps limit the effects of electromagnetic noise on the control system.

All electronic devices of the control system must be grounded.

Ground the devices in a manner conforming to applicable standards and regulations.

Max consumption.GF_PROMER 35: Max consumption.GF_PROMER 57:

• (without I/O) 240mA, 5W • (without I/O) 480mA, 8,5W

• (with I/O) 360mA, 7W • (with I/O) 490mA, 9W

Power supply connector

Pin Name Description

1 +24 VDC Positive feed

2 0 V GND

3 GND Ground

Length and type of connection cable between GF_PROMER and GFX / GFX4 / GFX4-IR / GFXTERMO4 units:

- standard telephone up to 10m

- shielded cable up to 150m (shield to GND)

- woven and shielded cable (Belden, shield to GND) for distances > 150m up to a maximum of 1200m

14

Connector of the RS-485 port

Signal assignment of the RS-485 port

Pin Name Description

1 GND -

2 Tx/Rx + Data reception/transmission (A+)

3 Tx/Rx - Data reception/transmission (B-)

4 +V (reserved) -

Ethernet port connections

18

Yellow

Green

Led Color Description

Sx Green Link

Dx Yellow Data

Pin Name Description

1 TX_D+ Tranceive data +

2 TX_D- Tranceive data -

3 RX_D+ Receive data +

4 N.C. Not connected

5 N.C. Not connected

6 RX_D- Receive data -

7 N.C. Not connected

8 N.C. Not connected

Signal assignment of the Ethernet port

The terminals let you set the Ethernet node ID via a user-accessible 16-position rotary

switch.

Rotary switch for setting Ethernet node ID

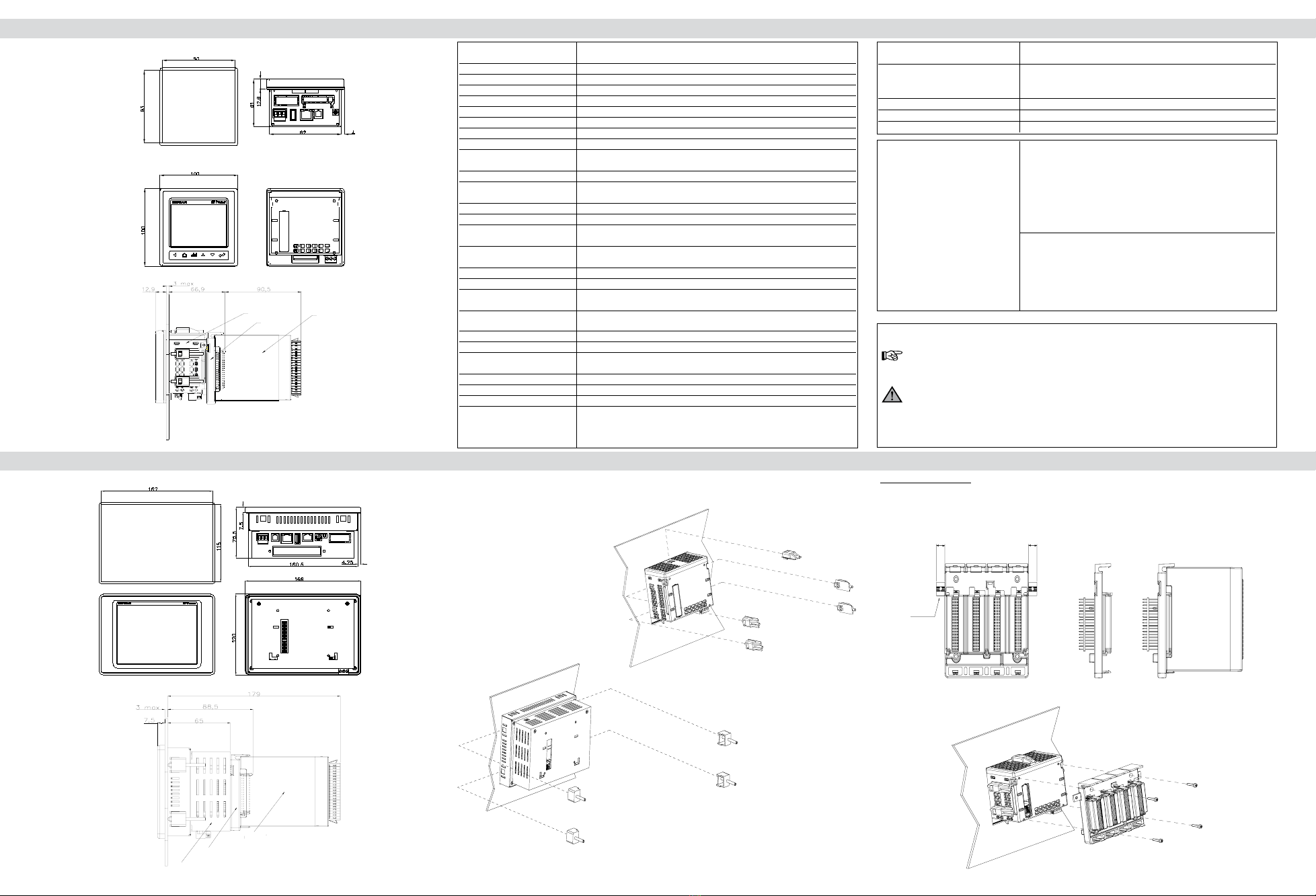

GF_PROMER 57 DIMENSIONS FIXING / INSTALLATION OPTIONAL MODULE

GF_PROMER 35 DIMENSIONS TECHNICAL SPECIFICATION

Graphic symbols

Indicates the contents of the various sections of the manual, general warnings, notes, and other

important points.

Indicates a particularly delicate situation that could affect the safety or good operation of the product, or

an instruction that must absolutely be followed in order to prevent hazardous situations

Dimensions and cut-out

GF_VEDO35...PRM

L-BUS4

GILOGIK II

All measurements are expressed in mm, with tolerance of ± 0.5.

Dimensions

Dimensions and cut-out

Dimensions

All measurements are expressed in mm, with tolerance of ± 0.5.

GF_VEDO57...PRM

L-BUS4

GILOGIK II

The GF_PROMER 35 and GF_PROMER 57 are designed for front panel installation.

After making the opening shown on the template drawing, fasten the instrument with the blocks required and supplied

with the product.

Panel mounting

GF_PROMER 35...PRM

Panel mounting

GF_PROMER 57...PRM

L-BUS4 module (optional)

It is a 4-slot back-plane that supports a maximum of 4 GILOGIK II I/O modules.

Run the following procedure after this module is installed:

• Shut down the system by detaching it from the outside power source

• Insert the module in its connector as shown in the drawing

• Switch on the system

L-BUS4 mounting on GF_PROMER 35

Module L-BUS4

1010

N° 2 holes M4

Display

Type TFT color

Number colors 262K

Diagonal 3,5” (35CT) 5,7” (57CT)

View area display 70,08 x 52,56 mm (35CT) 117,2 x 88,4 mm (57CT)

Resolution 320 x 240

Luminosity 400 cd/mq (35CT) 500 cd/mq (57CT)

Contrast 400:1 (35CT) 400:1 (57CT)

Backlighting 8 white LEDs (35CT) 18 white LEDs (57CT)

Angle of view O/V 75°/55°-75° (35CT) 75°/60°-75° (57CT)

- Keyboard

Number keys 6 (35CT) absent (57CT)

Operations > 3 milion

- Touch Screen

Type resistive 4 wires

Life > 1 million operations

Controller integrated

Processor

Type EP9307 Cirrus Logic

Memory

System 128MB (DRAM)

User 512KB (SRAM)

Mass 64MB (FLASH)

Peripherals

Ethernet Ethernet 10/100 Mbps Base-T / RJ45 connector with led

Serial RS485 RS485 optically isolated , baud rate 9,6 … 115 kBaud

Connector RJ10 4p4c

USB port USB 2.0 HOST (500mA) type A a 4 pin connector

BUS for I/O Expansion for L-BUS4, 50 pin connector

Other informations

Power supply 24Vdc +/- 25% (3 pin female screw-type connector)

Max consumption 240mA 5W (35CT) 480mA 8,5W (57CT)

Max consumption with I/O 360mA 7W (35CT) 490mA 9W (57CT)

Protection from polarity inversion (both) overcurrents on input circuit (57CT)

Battery Lithium Manganese Dioxide 3V 65mA/h rechargeable (ML2032T6)

life without power supply > 7500 h

Expected life 7 years

Low-voltage signal

Weight (Kg) 0,4 (35CT) 0,8 (57CT)

With 2 modules GilogikII (Kg) 0,7 (35CT) 1,1 (57CT)

Front dimensions (mm) 100x100x64 (35CT) 169x120x76 (57CT) Protection IP65

with modules GilogikII (mm) 100x100x171 (35CT)

169x120x187 (57CT)

Template (mm) 93x93 (35CT) 162x115 (57CT)

Max panel thickness (mm) 4 (35CT) 3 (57CT)

Certifications CE UL

Optional Units / Modules

Unit for distributed control - GFX Controller for single zone

- GFX4 / GFX4-IR 4 zone modular power controller

- GFXTERMO4 Modular controller with 4 control zones

see the individual data sheets for characteristics of modular

controllers

The following modules are inserted in Backplane L-BUS4 (slot 2-3)

R-EU16 : mixed module with 8 digital inputs and 8 digital outputs.

The 24V PNP inputs have a programmable software filter.

The module is organized in 8 inputs + common GND and 2

groups of 4 outputs.

The PNP outputs are provided for inductive loads and protected

against short circuit, overload and overheat.

This manual suits for next models

1

Other gefran Motherboard manuals