8

Series 958 Embedded Linear Displacement Transducer

1080 North Crooks Road, Clawson, MI 48017 • Phone: 248-435-0700

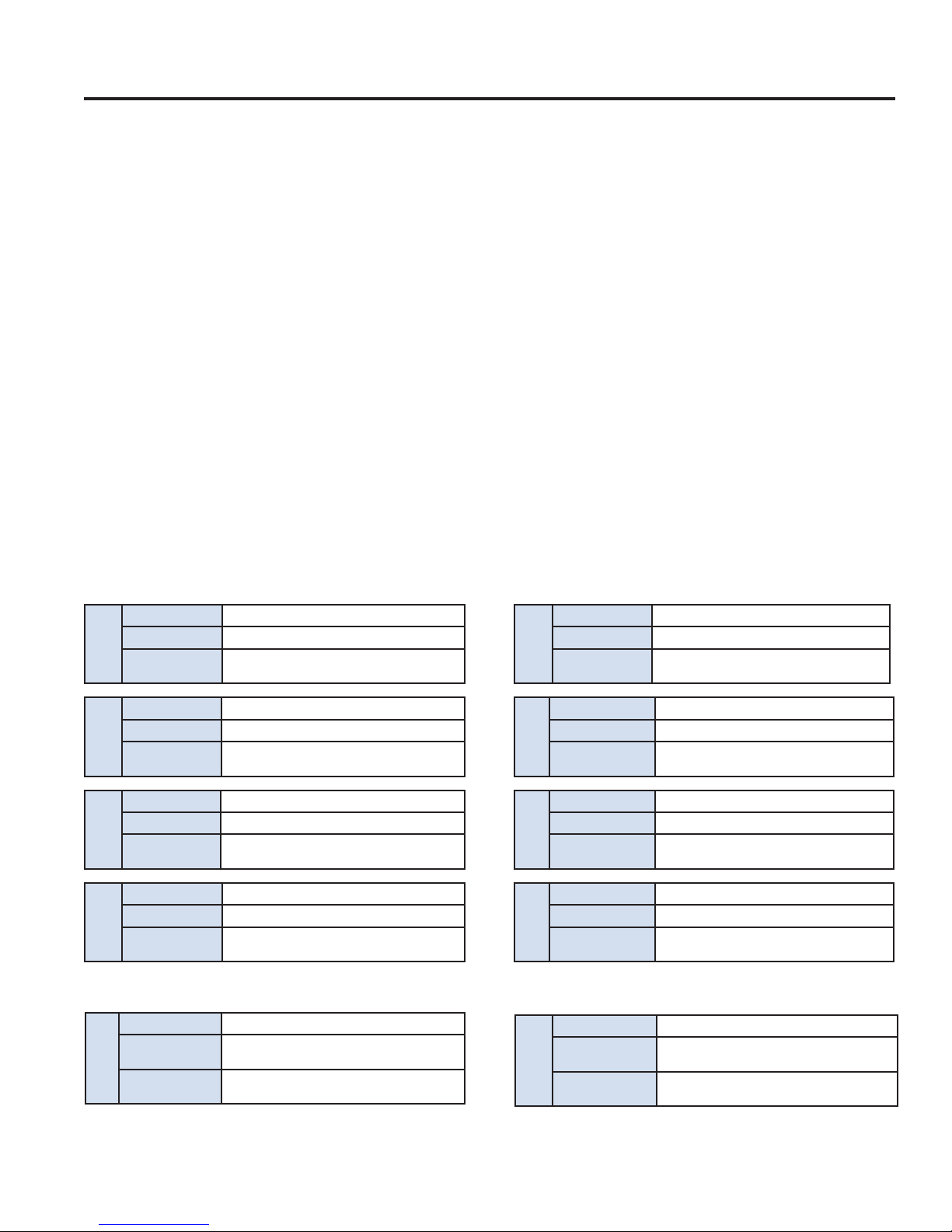

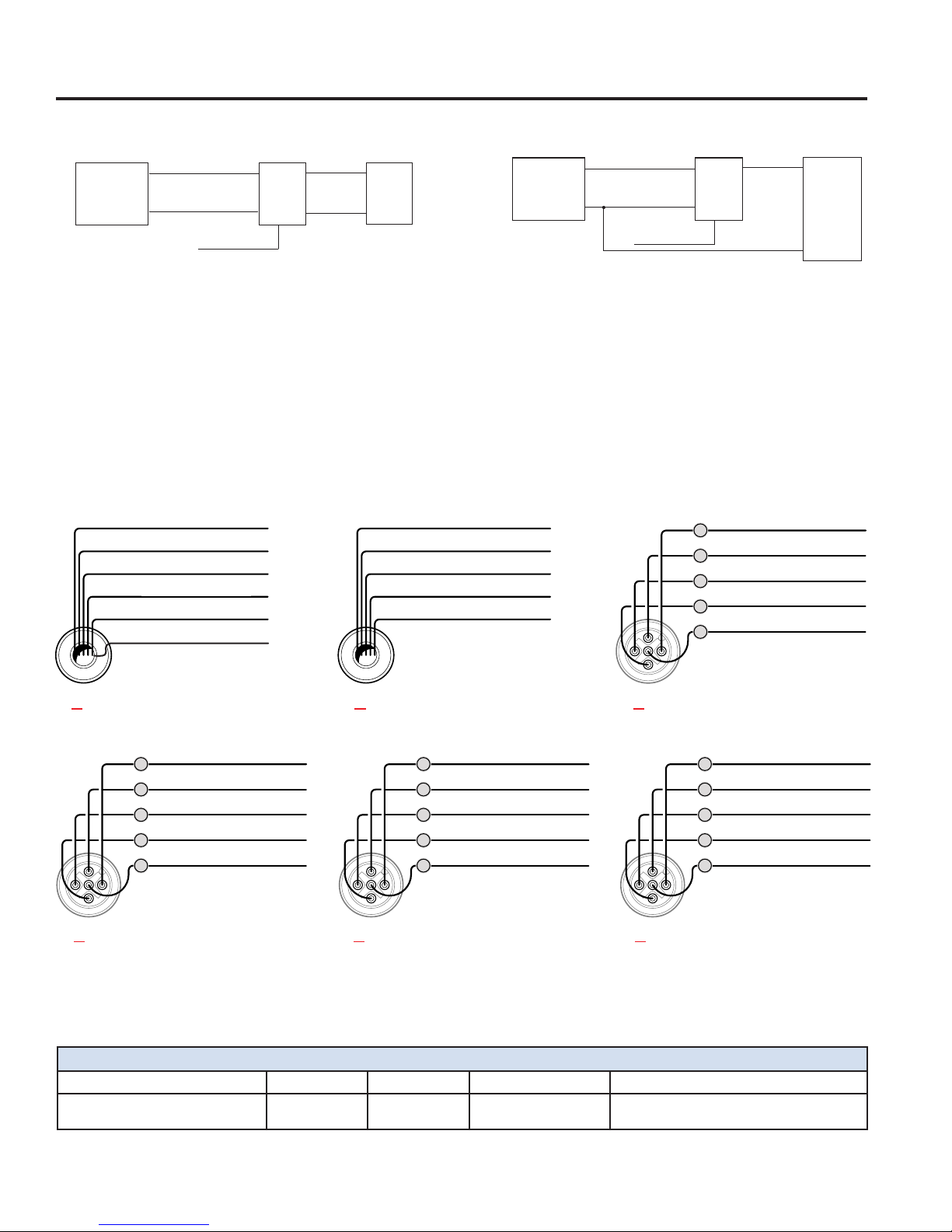

3.2: Pinouts and Wiring

There are six different connection options available. Refer to part numbers on unit in question for proper wiring.

Figure 3-2: Pinouts and Wiring

Page 3 of 4

Z429 958A.DOR LDT Data Sheet

OUTPUT RESOLUTION

0 to 10 VDC: 16 bits (0.0015% of span)

0 to 5 VDC: 15 bits (0.0031% of span)

0.25 to 4.75 VDC: ~15 bits (0.0034% of span) (14.85 bits)

0.5 to 4.5 VDC: ~15 bits (0.0034% of span) (14.68 bits)

4 to 20 mA: 15.7 bits, calibrated for 3.5 to 21 mA (0 to 21 mA, 16 bits )

ISOLATION

Housing to Any Signal: 500 V

OUTPUT LOADING

Voltage: 2k Ω minimum

Current: 500 Ω maximum

CONNECTION OPTIONS

Integral Cable: Multi-conductor, 26 AWG, shielded, TPU jacket

5 Pin – M12: A-Code, Shell installed from "outside" cylinder

(IEC 61076-2-101)

Wire – Bare Leads: Multi-conductor, 26 AWG

WIRING DIAGRAMS

APPROVALS

lCE (Electromagnetic Compatibility)—2014/30/EU

lRoHS 2—2011/65/EU

lElectromagnetic compatibility - Part 6-4: Generic

standards – Emission standards for industrial environ-

ments—EN61000-6-4

lElectromagnetic compatibility (EMC) - Part 6-2: Generic

standards – Immunity for industrial environments—

EN61000-6-2

lAgricultural and forestry machinery—ISO 14982:1998

lRoad vehicles - electrical disturbances from nar-

rowband radiated electromagnetic energy — Part 5:

Stripline—ISO 11452-5

lRoad vehicles - Electrical disturbances from conduction

and coupling—ISO 7637-1/2/3

lEarthmoving Machinery—ISO 13766

lIndustrial Trucks—EN 12895

lRailway Applications—EN 50121-3-2

Pinouts and Wiring

(C

_

) Integral Cable

(M

_

S1) M12 – 5 Pin (A Code) (M

_

S2) M12 – 5 Pin (A Code) (M

_

S3) M12 – 5 Pin (A Code)

(W

_

) Wire – Bare Leads

* **

* * *

(G

_

S1) M12 – 5 Pin (A Code)

Analog Common (Green)

Analog Out (White)

Program (Orange)

Power Supply Common (Black)

VDC Power (Red)

Analog Common (Green)

Analog Out (White)

Program (Orange)

Power Supply Common (Black)

VDC Power (Red) VDC Power (Brown)

1

2

Power Supply Common (Blue)

Program (White)

3

Analog Out (Black)

4

Analog Common (Gray)

5

VDC Power (Brown)

1

2

Power Supply Common (Blue)

Analog Out (White)

3

Analog Common (Black)

4

Program (Gray)

5

Analog Common (Brown)

1

2

Power Supply Common (Blue)

VDC Power (White)

3

Analog Out (Black)

4

Program (Gray)

5

VDC Power (Brown)

1

2

Power Supply Common (Blue)

Analog Common (White)

3

Analog Out (Black)

4

Program (Gray)

5

* Insert length of wire.

958A LDT Linear Displacement Transducer

Page 3 of 4

Z429 958A.DOR LDT Data Sheet

OUTPUT RESOLUTION

0 to 10 VDC: 16 bits (0.0015% of span)

0 to 5 VDC: 15 bits (0.0031% of span)

0.25 to 4.75 VDC: ~15 bits (0.0034% of span) (14.85 bits)

0.5 to 4.5 VDC: ~15 bits (0.0034% of span) (14.68 bits)

4 to 20 mA: 15.7 bits, calibrated for 3.5 to 21 mA (0 to 21 mA, 16 bits )

ISOLATION

Housing to Any Signal: 500 V

OUTPUT LOADING

Voltage: 2k Ω minimum

Current: 500 Ω maximum

CONNECTION OPTIONS

Integral Cable: Multi-conductor, 26 AWG, shielded, TPU jacket

5 Pin – M12: A-Code, Shell installed from "outside" cylinder

(IEC 61076-2-101)

Wire – Bare Leads: Multi-conductor, 26 AWG

WIRING DIAGRAMS

APPROVALS

lCE (Electromagnetic Compatibility)—2014/30/EU

lRoHS 2—2011/65/EU

lElectromagnetic compatibility - Part 6-4: Generic

standards – Emission standards for industrial environ-

ments—EN61000-6-4

lElectromagnetic compatibility (EMC) - Part 6-2: Generic

standards – Immunity for industrial environments—

EN61000-6-2

lAgricultural and forestry machinery—ISO 14982:1998

lRoad vehicles - electrical disturbances from nar-

rowband radiated electromagnetic energy — Part 5:

Stripline—ISO 11452-5

lRoad vehicles - Electrical disturbances from conduction

and coupling—ISO 7637-1/2/3

lEarthmoving Machinery—ISO 13766

lIndustrial Trucks—EN 12895

lRailway Applications—EN 50121-3-2

Pinouts and Wiring

(C

_

) Integral Cable

(M

_

S1) M12 – 5 Pin (A Code) (M

_

S2) M12 – 5 Pin (A Code) (M

_

S3) M12 – 5 Pin (A Code)

(W

_

) Wire – Bare Leads

* **

* * *

(G

_

S1) M12 – 5 Pin (A Code)

Analog Common (Green)

Analog Out (White)

Program (Orange)

Power Supply Common (Black)

VDC Power (Red)

Analog Common (Green)

Analog Out (White)

Program (Orange)

Power Supply Common (Black)

VDC Power (Red) VDC Power (Brown)

1

2

Power Supply Common (Blue)

Program (White)

3

Analog Out (Black)

4

Analog Common (Gray)

5

VDC Power (Brown)

1

2

Power Supply Common (Blue)

Analog Out (White)

3

Analog Common (Black)

4

Program (Gray)

5

Analog Common (Brown)

1

2

Power Supply Common (Blue)

VDC Power (White)

3

Analog Out (Black)

4

Program (Gray)

5

VDC Power (Brown)

1

2

Power Supply Common (Blue)

Analog Common (White)

3

Analog Out (Black)

4

Program (Gray)

5

* Insert length of wire.

958A LDT Linear Displacement Transducer

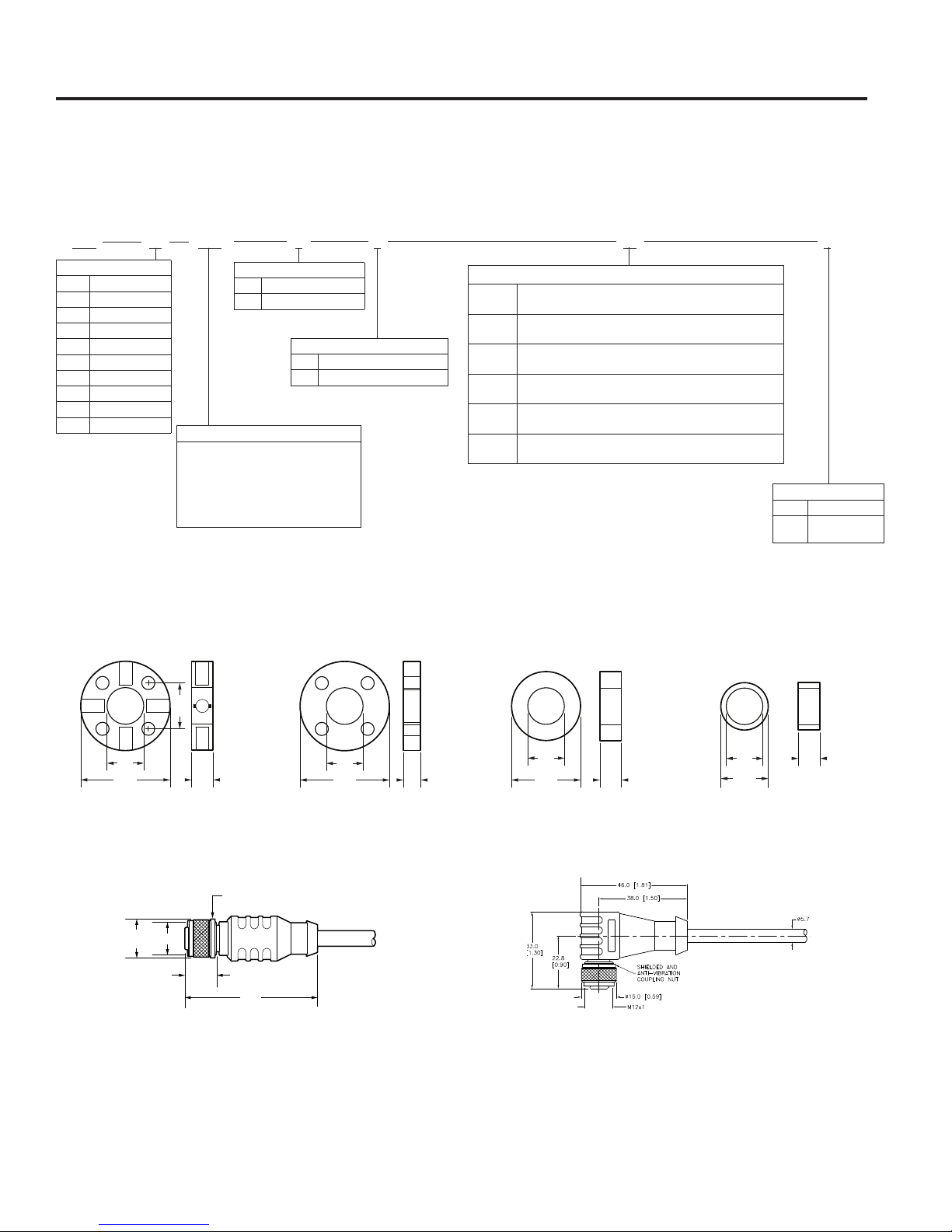

Power

Supply

8-30 VDC

958A

LDT

+ Input

- Input

Customer

Supplied Power

Power

Supply Common

Position

Output

Position

Common

Program Input

+

_

Power

Supply

8-30 VDC

958A

LDT

+ Input

Common

Customer

Supplied Power

Power

Supply Common

Position

Output

Program Input

+

_

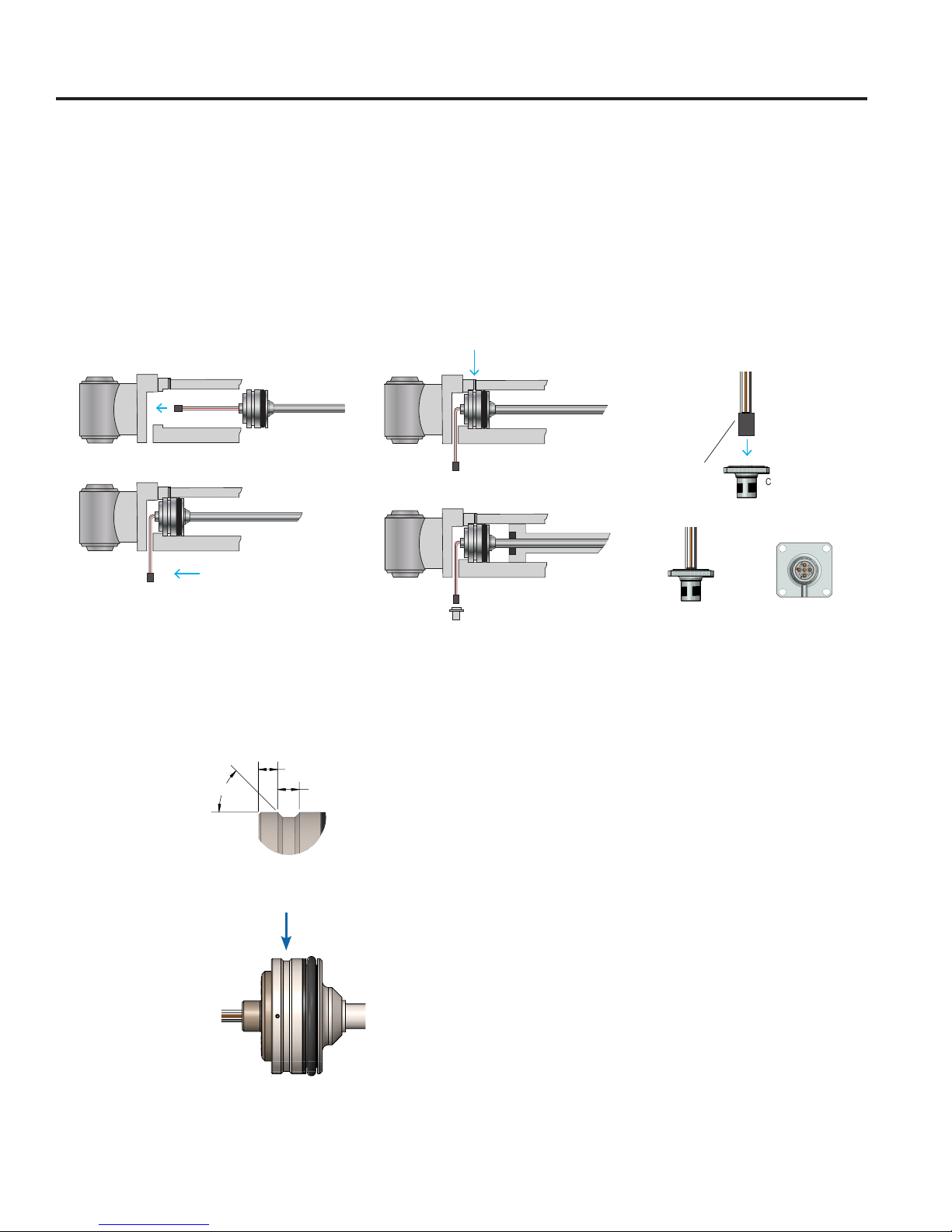

Single Ended Input

Figure 3-1: Wiring – Single Ended vs. Differential

The 958A-C is current sourcing, which allows the current to flow from the LDT into the user’s equipment.

Power

Supply

8-30 VDC

958A

LDT

+ Input

- Input

Customer

Supplied Power

Power

Supply Common

Position

Output

Position

Common

Program Input

+

_

Power

Supply

8-30 VDC

958A

LDT

+ Input

Common

Customer

Supplied Power

Power

Supply Common

Position

Output

Program Input

+

_

Differential Input

(Preferred Method)

(C) Integral Cable (W) Wire – Bare Leads (GS1) M12 – 5 Pin (A Code)

(MS1) M12 – 5 Pin (A Code) (MS2) M12 – 5 Pin (A Code) (MS3) M12 – 5 Pin (A Code)

indicates wire length. Refer to part numbers Appendix A for available options

Page 3 of 4

Z429 958A.DOR LDT Data Sheet

OUTPUT RESOLUTION

0 to 10 VDC: 16 bits (0.0015% of span)

0 to 5 VDC: 15 bits (0.0031% of span)

0.25 to 4.75 VDC: ~15 bits (0.0034% of span) (14.85 bits)

0.5 to 4.5 VDC: ~15 bits (0.0034% of span) (14.68 bits)

4 to 20 mA: 15.7 bits, calibrated for 3.5 to 21 mA (0 to 21 mA, 16 bits )

ISOLATION

Housing to Any Signal: 500 V

OUTPUT LOADING

Voltage: 2k Ω minimum

Current: 500 Ω maximum

CONNECTION OPTIONS

Integral Cable: Multi-conductor, 26 AWG, shielded, TPU jacket

5 Pin – M12: A-Code, Shell installed from "outside" cylinder

(IEC 61076-2-101)

Wire – Bare Leads: Multi-conductor, 26 AWG

WIRING DIAGRAMS

APPROVALS

lCE (Electromagnetic Compatibility)—2014/30/EU

lRoHS 2—2011/65/EU

lElectromagnetic compatibility - Part 6-4: Generic

standards – Emission standards for industrial environ-

ments—EN61000-6-4

lElectromagnetic compatibility (EMC) - Part 6-2: Generic

standards – Immunity for industrial environments—

EN61000-6-2

lAgricultural and forestry machinery—ISO 14982:1998

lRoad vehicles - electrical disturbances from nar-

rowband radiated electromagnetic energy — Part 5:

Stripline—ISO 11452-5

lRoad vehicles - Electrical disturbances from conduction

and coupling—ISO 7637-1/2/3

lEarthmoving Machinery—ISO 13766

lIndustrial Trucks—EN 12895

lRailway Applications—EN 50121-3-2

Pinouts and Wiring

(C

_

) Integral Cable

(M

_

S1) M12 – 5 Pin (A Code) (M

_

S2) M12 – 5 Pin (A Code) (M

_

S3) M12 – 5 Pin (A Code)

(W

_

) Wire – Bare Leads

* **

* * *

(G

_

S1) M12 – 5 Pin (A Code)

Analog Common (Green)

Analog Out (White)

Program (Orange)

Power Supply Common (Black)

VDC Power (Red)

Analog Common (Green)

Analog Out (White)

Program (Orange)

Power Supply Common (Black)

VDC Power (Red) VDC Power (Brown)

1

2

Power Supply Common (Blue)

Program (White)

3

Analog Out (Black)

4

Analog Common (Gray)

5

VDC Power (Brown)

1

2

Power Supply Common (Blue)

Analog Out (White)

3

Analog Common (Black)

4

Program (Gray)

5

Analog Common (Brown)

1

2

Power Supply Common (Blue)

VDC Power (White)

3

Analog Out (Black)

4

Program (Gray)

5

VDC Power (Brown)

1

2

Power Supply Common (Blue)

Analog Common (White)

3

Analog Out (Black)

4

Program (Gray)

5

* Insert length of wire.

958A LDT Linear Displacement Transducer

VDC Power (Brown)

Power Supply Common (Blue)

Program (White)

Analog Out (Black)

Analog Common (Gray)

No Connect (Pink)

Cable Specifications

Cable Type Gauge Jacket Temp Bend Radius

Multi-conductor Shielded 26 PUR -40° to 90°C Fixed Applications 1.05"

Moving Applications 3.15"