RAISE GUARD

GENERAL OPERATING AND MAINTENANCE INSTRUCTIONS

Please follow these instructions carefully for the efficient use and maintenance of this equipment.

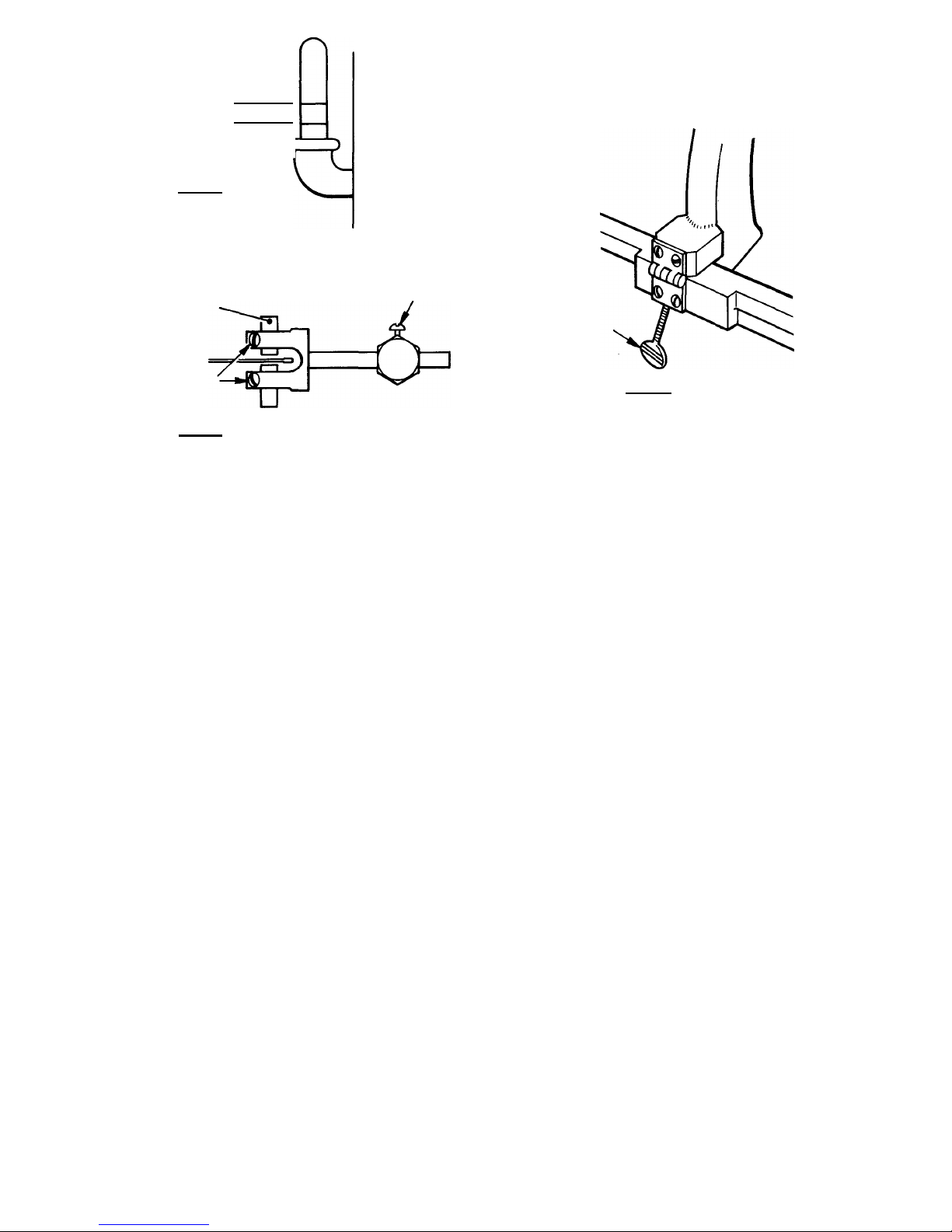

1. COOLANT

a. Always use coolant at the correct level. (See Fig.4)

b. Use of water is not recommended but allowed in special circumstances.

c. Diamond Saw Lube mixed 5 parts to 95 parts water is recommended for most cutting requirements.

d. Kerosene, Diesoline, transformer oil or light mineral oil can be used in a well ventilated area.

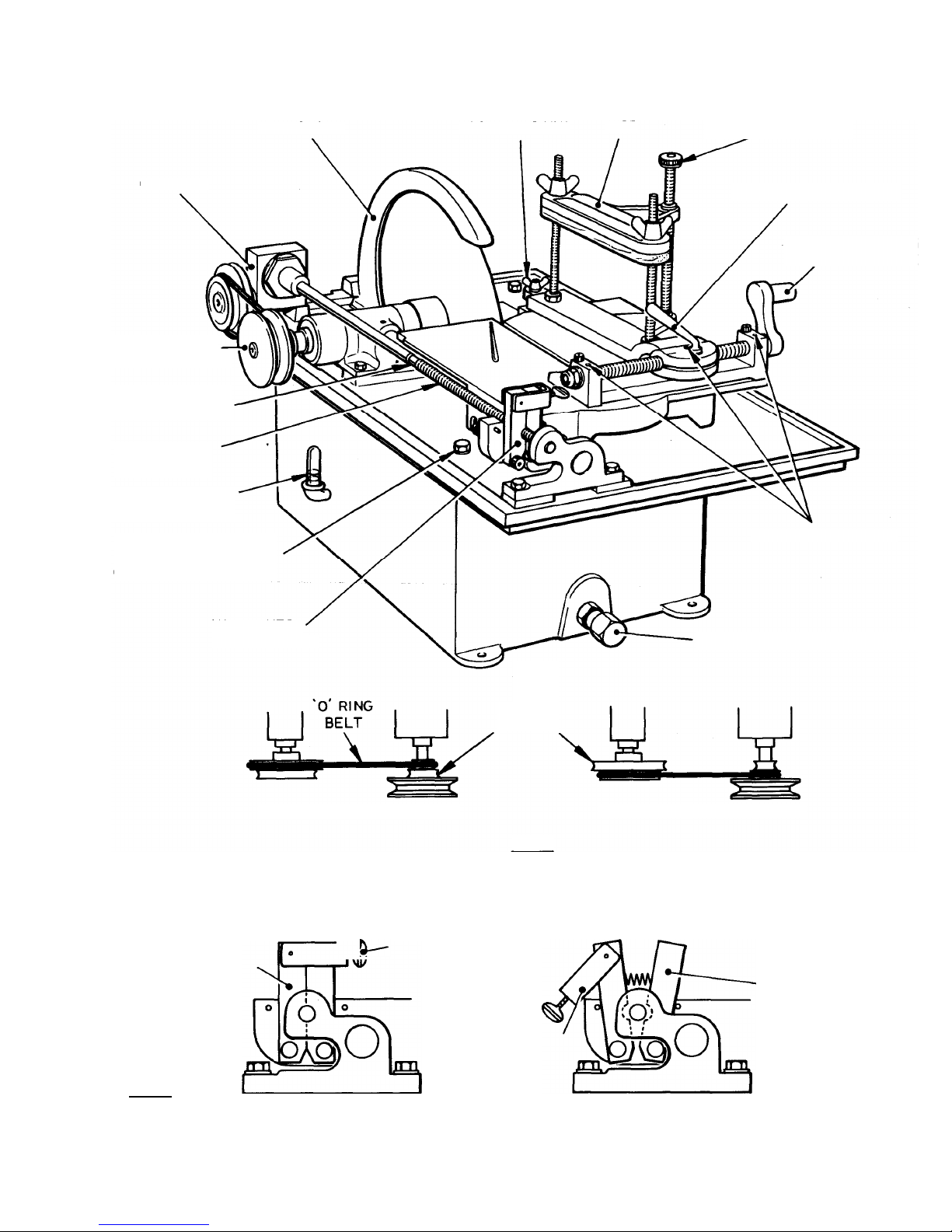

2. USE OF VICE

a. Hold rock in vice, level top jaw with levelling screw then tighten wing nuts.

b. Test rock for movement. If it moves loosen the screws and start again.

c. One complete turn of the slab thickness screw handle gives 1/16" sideways movement.

d. Lock vice to slab thickness screw by tightening front screw lever and back wing nut.

3. SAWING

a. Push slide table forward until the rock is nearly but not quite touching the saw blade.

b. Position the saw guard so that it is slightly above the rock and not in line with the vice.

c. Engage the half-nuts on the lead screw. (See Fig. 3)

d. Close the perspex hood. (If fitted)

e. Switch on the power.

f. Leave until slab is cut and the vice held rock has passed the cutting edge of the saw.

g. Switch off power.

4. TO CUT THE NEXT SLAB

a. Release half-nuts.

b. Slide the saw table towards the operator.

c. Firstly loosen the back wing-nut screw.

d. Secondly loosen the front lever.

e. Repeat operation as instructed in part 2b.

5. Keep the saw blade sharp by regularly running a small cut into a silicon carbide dressing stick or a worn grinding wheel.

6. Do not position the vice so that it will be cut by the saw blade.

7. Make sure that the saw guard is free from all forward movement of both the vice and rock by using the raising screw at the rear of the

machine. (See Fig. 6)

8. Keep the saw running centrally by adjusting the Teflon guides to be found beneath the sliding table. (See Fig. 5)

9. Always disconnect feed drive belt when sawing is finished.

10. Remember NEVER USE WATER

11. For TRIMMING SLABS the vice may be removed by taking out the two counter sunk screws that hold it to the sliding table. After having

removed the screws and completely loosened the back screw wing nut,the vice may be slid off to the right.

When trimming, use a gentle forward pressure so as to avoid pushing the blade sideways.

12. To clean out the coolant tank, which becomes necessary when the saw throws up too much sludge, firstly remove the

saw

for safety

against damage, secondly remove the four hexagonal headed bolts; the top section may then be lifted off the tank.

13. Always leave the saw clean by wiping off loose rock particles with a dry rag, and by cleaning the drive screws with a brush before finishing.

14. When replacing the top section remember to re-pack the rear section of the coolant tank in order to avoid "throw-out" of coolant liquid.

15.When placing the machine for use, have it slightly tilted toward the rear so that the coolant thrown up by the saw, will run back through

the drain holes, which should be kept free of dirt.