3

1. Be sure to read, understand and follow all safety warnings and

instructions in the supplied Operator’s Manual.

2. Do not operate the saw when tired, distracted, or under the

eects of drugs, alcohol or any medication that impairs reexes

or alertness. Stay alert! Give your work your undivided attention.

3. Keep the work area well lit, clean and free of debris. Cluttered

areas and benches invite injuries.

4. Keep children and shop visitors at a safe distance while

operating the saw; do not permit them to operate the scroll saw.

5. Childproof and tamper proof your shop and all machinery

with locks, master electrical switches and switch keys, to prevent

unauthorised or unsupervised use. Fine particulate dust is a

carcinogen that can be hazardous to health. Work in a well

ventilated area and use a dust collector whenever possible.

7. Wear approved safety glasses, dust mask and nonskid

footwear. Do not wear loose clothing, gloves, bracelets, necklaces

or jewellery while operating the saw. Keep long hair contained by

wearing protective hair covering.

8. Be sure all adjustment tools, wrenches or other

clutter are removed from the machine and/or the table surface

before operation. When not in use, tools should be locked-up

in a dry place, out of children’s reach and away from ammable

substances.

9. Keep hands well away from saw blade and all moving parts.

Use a brush, not hands, to clear away chips and sawdust.

10. Be sure that the saw blade is properly installed, and in the

correct cutting direction, before operation. Always use a clean,

properly sharpened blade. Dirty or dull blades are unsafe and can

lead to accidents. Also, be sure the blade has gained full operating

speed before beginning to cut.

11. Do not push or force wood into the blade. The saw will perform

better and more safely when working at the rate for which it was

designed. Do not use for purposes not intended.

12. Avoid working from awkward or o balance positions. Do not

overreach while cutting; keep both feet on oor. Never lean over

or reach behind the blade and never pull the work piece through

the cut from behind.

13. Never stand or lean on the saw. Serious injury could occur if the

unit is tipped over or if the blade is unintentionally contacted.

14. Use of parts and accessories NOT recommended by Maxis

Distribution may result in equipment malfunction or risk of injury.

15. Never leave the machine unattended while running or with

the power “ON”.

16. Always turn o and disconnect from power source before

servicing or changing accessories, blades, bits, and cutters, or

before performing any maintenance or adjustments.

17. Make sure that switch is in the “OFF” position before plugging

in the power cord. Do not use the saw if the power switch is

defected, have defective switches replaced by an authorized

service centre.

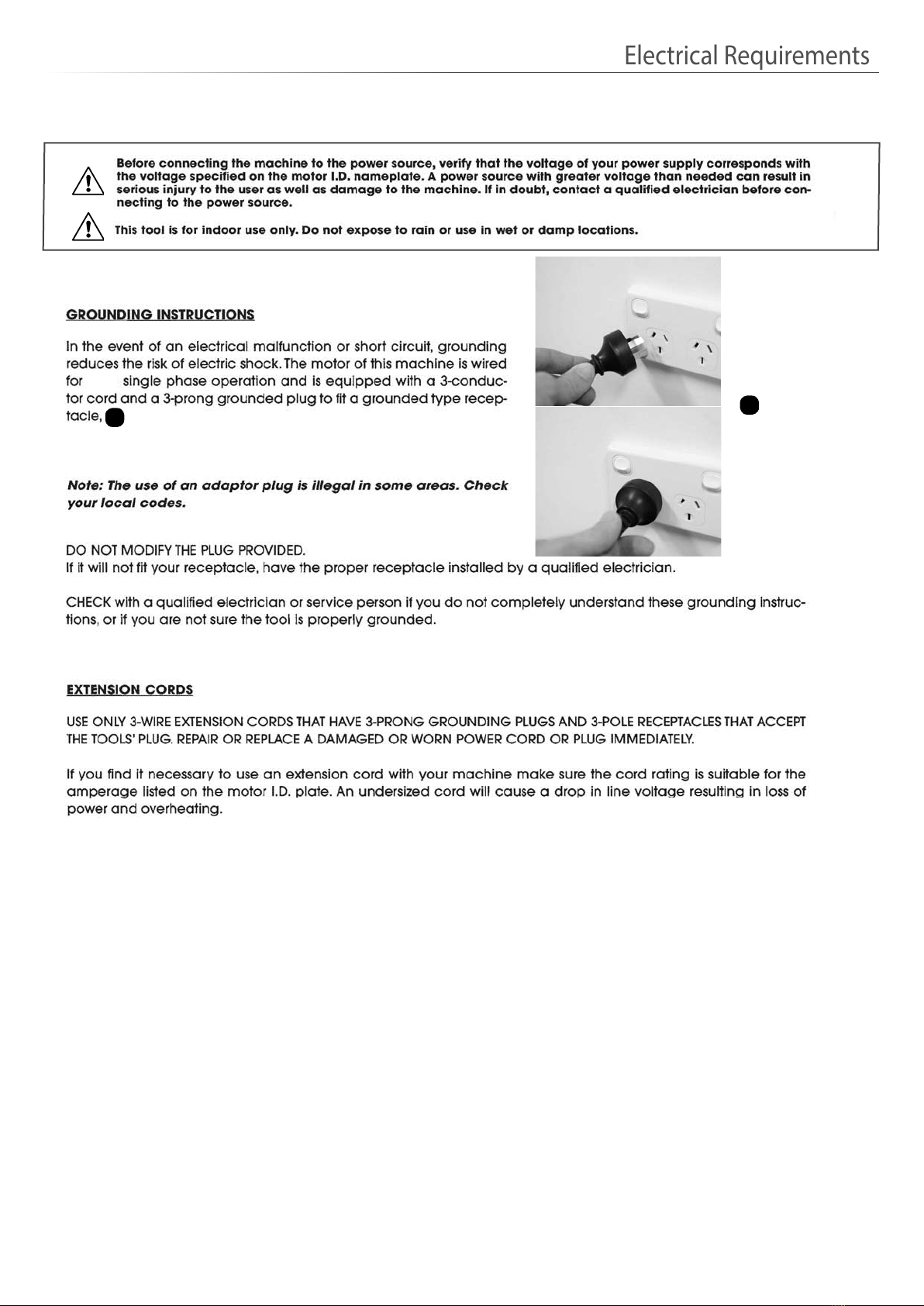

18. Make sure saw is properly grounded. If equipped with a three

prong plug it should be used with a three-pole receptacle. Never

remove the third prong. Avoid body contact with grounded

surfaces (e.g. pipes, radiators, stoves, refrigerators).

19. Repairs to the saw should only be carried out by qualied

people using original spare parts. A guard or other damaged part

should be properly repaired or replaced by an authorized service

centre.

20. Inspect power cords and extension wires periodically. If

damaged, have them repaired by an authorized service facility.

Never yank cords and wires and keep away from heat, oil, and

sharp edges.

21. This tool is for indoor use only. Do not expose to rain or use

in wet or damp locations.

To help ensure safe operation, please take a moment to learn the machine’s

applications and limitations, as well as potential hazards. Maxis Distribution Pty

Ltd, or its authorised resellers, disclaim any real or implied warranty and is not liable for

any injury that may result from the improper use of its equipment.