Environmental Products

Model LS-800 HLI

High Level Indicator

Instruction Bulletin No. 155896

These Sensors may not be compatible with indicating

and alarm equipment supplied by other manufacturers

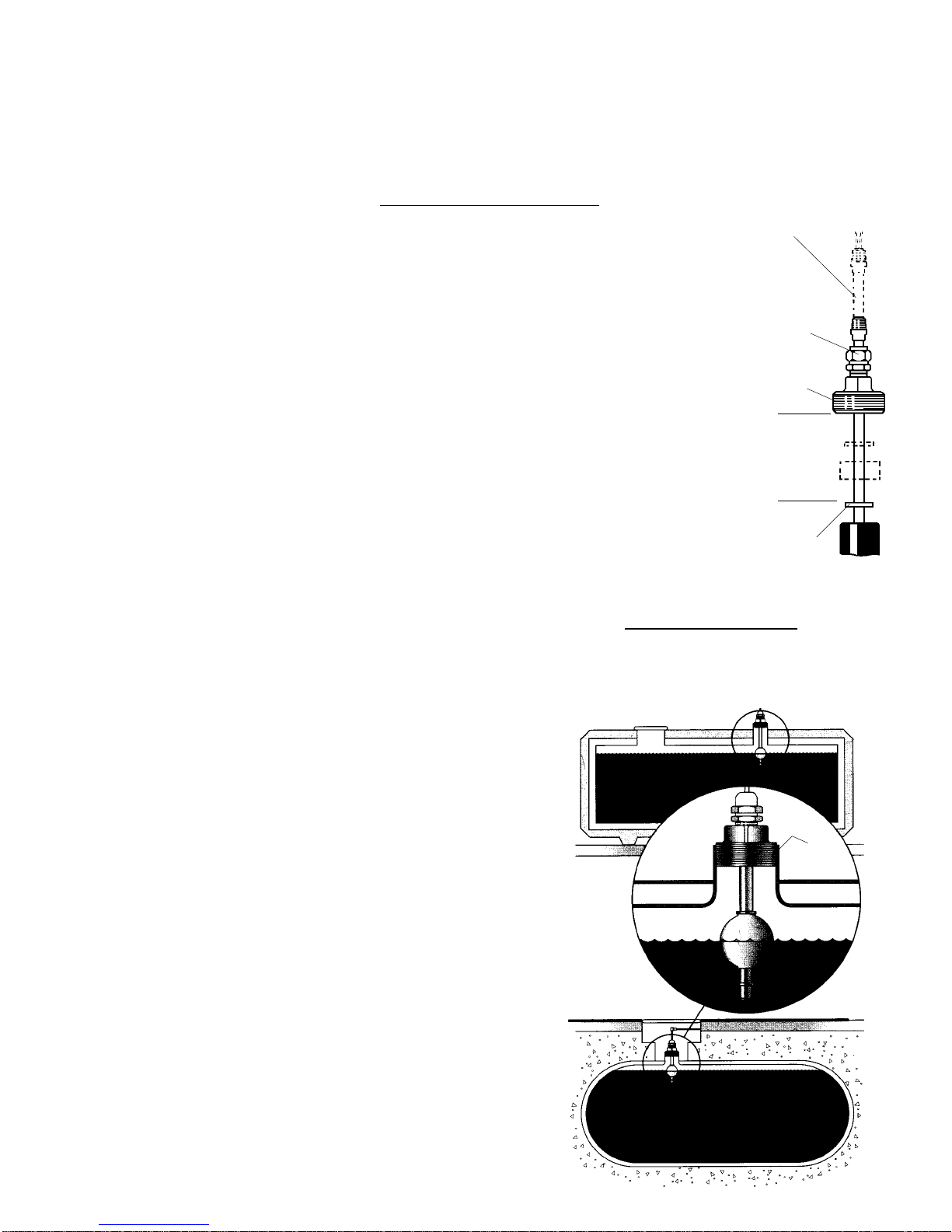

Note: LS-800 HLI sensors are non-voltage producing devices and do not contain energy storing com-

ponents. However, since primary use is in hazardous locations, an appropriate intrinsically safe inter-

face device is required.

Gems LS-800 HLI liquid level sensor operates on a direct,

simple principle. A float is equipped with powerful, permanent

magnets.Asthefloatrisesorlowerswithliquidlevel,itactuates

amagnetic reed switch mounted within the stem. This condition

either opens or closes the electrical circuit to operate an exter-

nal alarm or control circuit. When mounted vertically, this basic

design provides a consistent accuracy of ±1/8th inch.

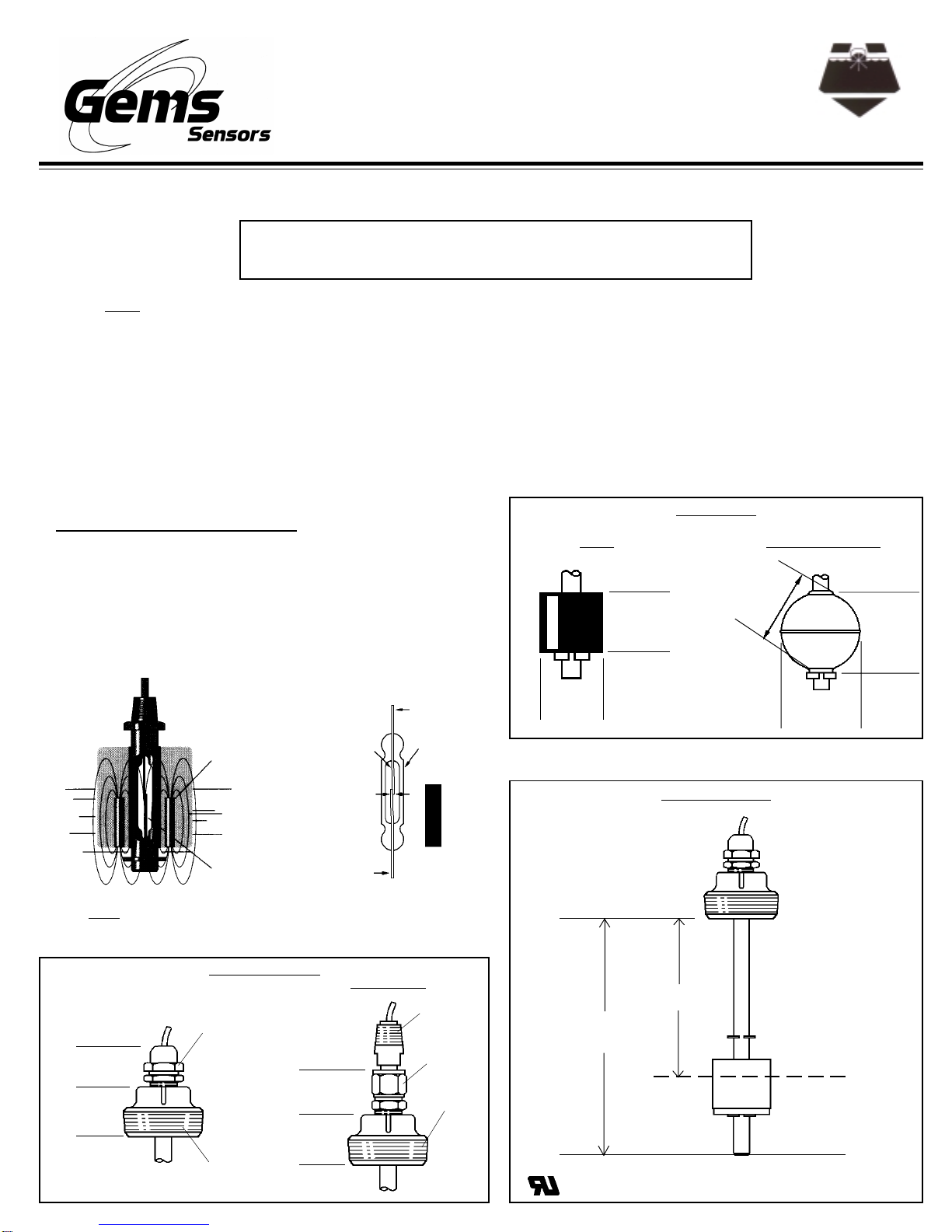

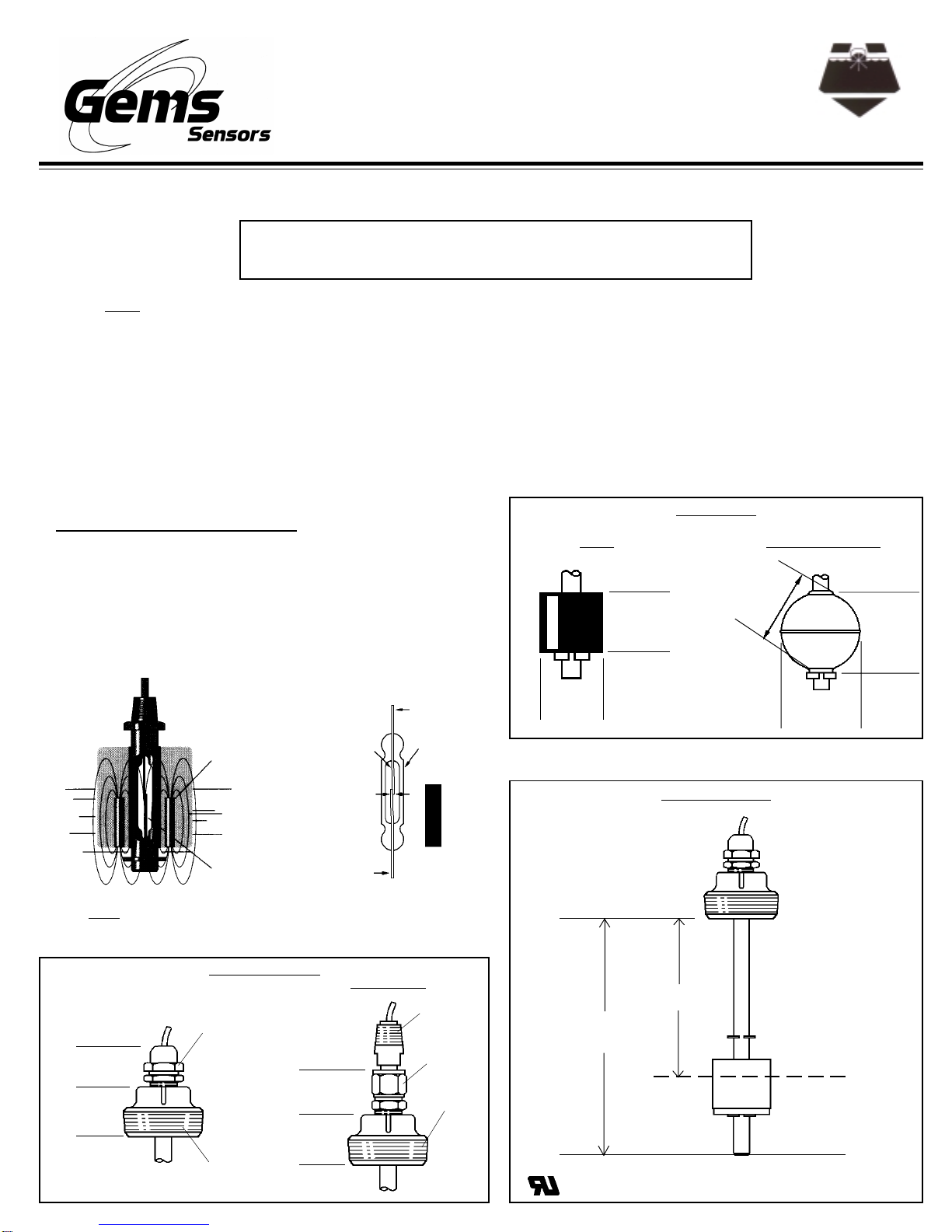

Sensor Operating Principle

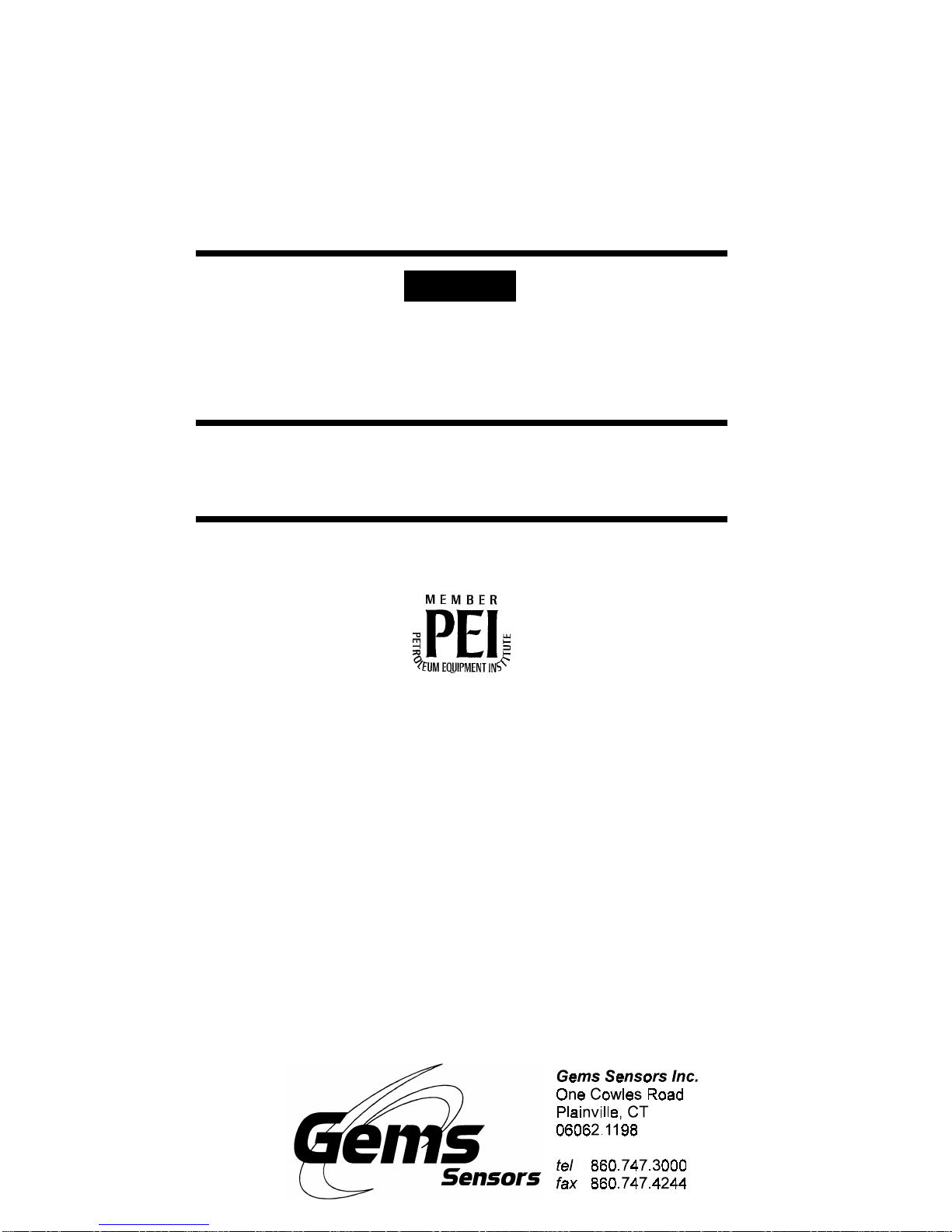

Gems LS-800 HLI High Level Indicator has a 2" NPT mounting, making it ideal for use in underground and aboveground

storage tanks. When mounted vertically at the tank top, it reliably indicates high liquid level. This indicator is exceptionally

versatile. The unit adapts to just about any environment due to rugged construction and the multiple design options avail-

able. The LS-800 HLI is available in brass or stainless steel, making it suitable for use with a wide range of liquids.

Adjustable versions of the LS-800 HLI are available for varying tank sizes. A special cinch nut on the mounting allows the

stem to travel up or down, to fine-tune actuation points. The extent of the adjustment depends on the unit length and dis-

tance from the mounting to the highest float stop.

Note: Please refer to specific Gems outline drawings for

operational specifications.

Permanent

Magnet

Float

Hermetically

Sealed Magnetic

Reed Switch

N

S

Reed

Switch Glass

Envelope

NS

N

S

MAGNET

Adjustable

1-1/4"

Ref.

1-1/2"

Ref.

Liquid Tight

Fitting

2" NPT

1-5/16"

Ref.

1-1/2"

Ref.

1/2" NPT

Adjustment

Nut

2" NPT

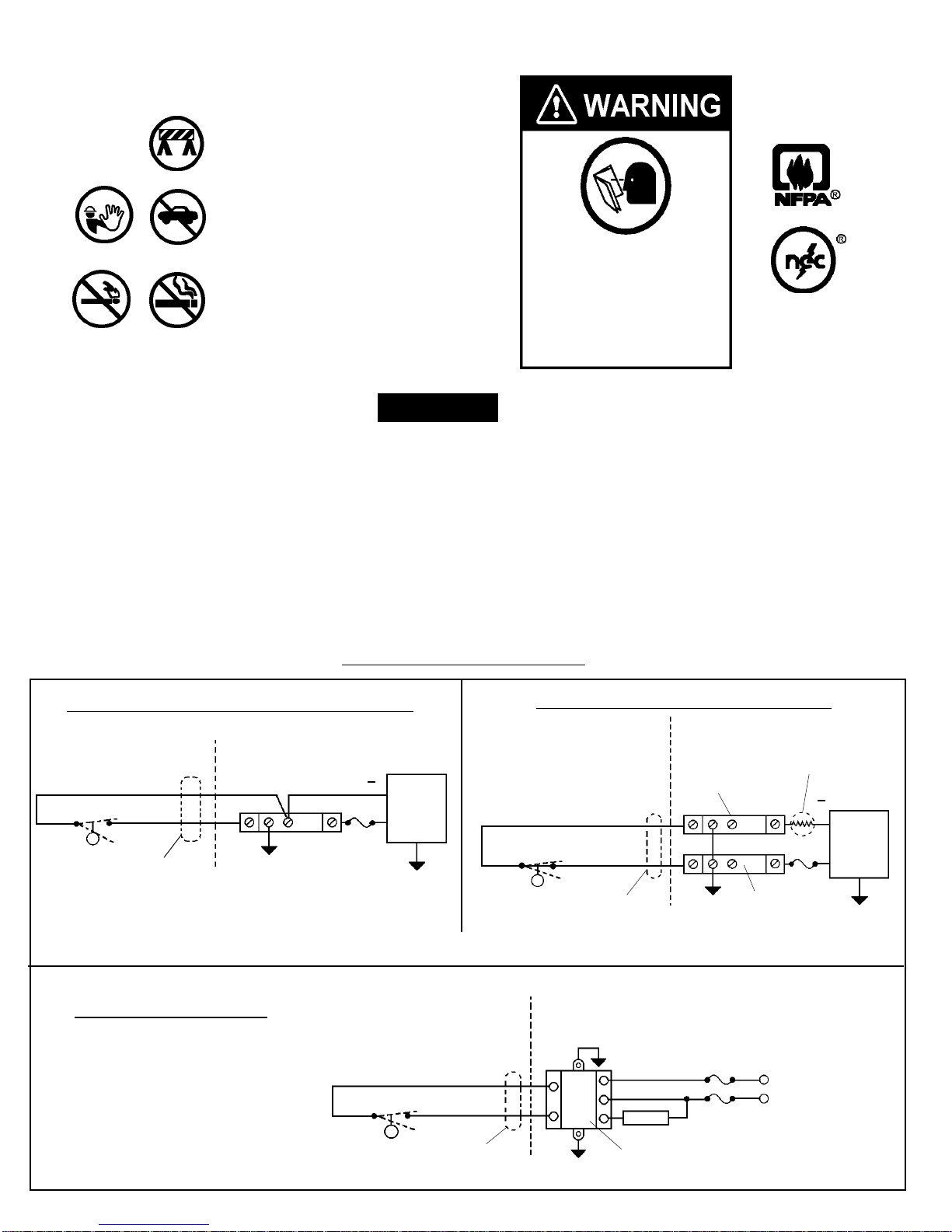

Mounting Types

Float Types

Nitrile 316 Stainless Steel

1-13/16"

(46.0 mm)

1-7/8" Dia.

(47.6 mm)

!

!

!

!

2"

(50.8 mm)

2-3/32"

(53.3 mm)

2-9/64"

(54.2 mm)

!

!

!

!

Actuation Level

LO ± 1/16"

(Length

Overall)

L1 ± 1/8"

Actuation

Level

2" Min.

(63.5 mm)

!

!

®