Page 10/19 XT-1000

For correct gauging, the float must be slid onto the probe tube with the

“TOP” marking oriented towards the sensor head end, to enable correct

measurements to be made.

(5) Refit collar (1) to hold float (2) on the tube, align the set screws with the groove

and tighten.

(6) Adjust the height of the process connection and secure it in position by tightening

union nut (5).

(7) If applicable, tighten the lock screw (not shown) on union nut (5).

In the case of installation with a cutting ring coupling, it is no longer

possible to alter the position of the level sensor after the union nut has

been tightened. In this event, it would be necessary to return the level

sensor to the factory to have the probe tube replaced.

4.2 Installation with flange

The probe tube is permanently welded to the flange, which means that the installation

length cannot be altered.

Secure the flange using the flange screws.

If the float does not fit through the installation opening, refer to the related installation

instructions in section 4.1.

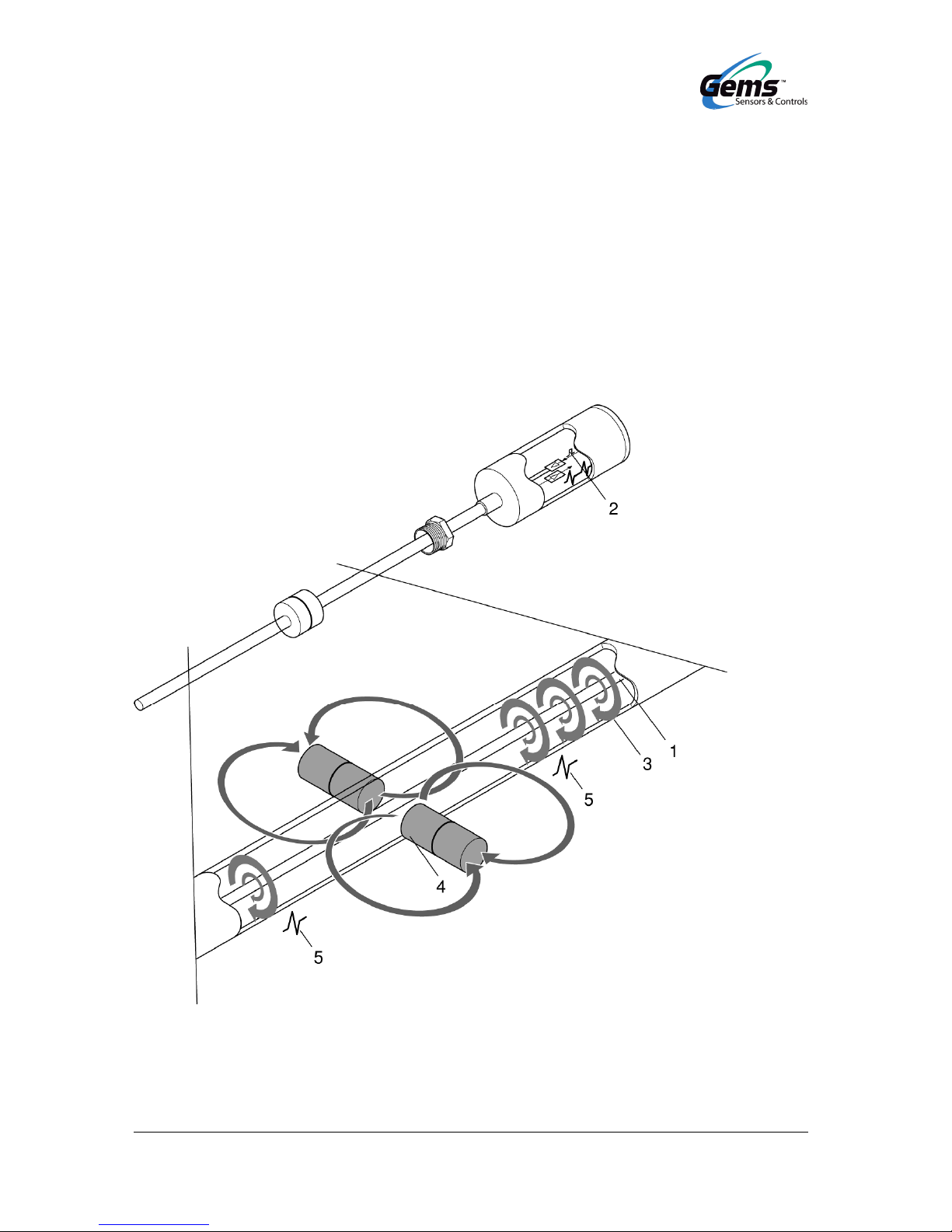

4.3 Installation on the bypass

The level sensor is installed on the bypass tube using suitable fasteners (nonmagnetic).

To ensure reliable gauging, the probe tube must be fitted with no

deformation on the outside.

The distance between the probe and bypass tubes must be as small as

possible.

Only floats approved by GEMS Sensors & Contr0ls can be used.