EPIC®200 SERIES TWO-MAN HOLE DIGGER

FORM GOM07042001EU, VERSION 1.0

English-EN 6

1. Use extreme caution handling gasoline. Always use UN marked,

European ADR regulation approved container for storage and

transportation of fuel. Shut engine off and allow to cool before fueling.

Never remove fuel tank filler cap or fill fuel tank while engine is running.

Never operate engine without fuel tank filler cap. Select bare ground for

fueling and move at least 3.05 M (10 feet) from fueling spot before

starting engine.

2. Carefully clean filler cap and surrounding area to prevent dirt/debris

falling into fuel tank.

3. Fill fuel tank with fresh, clean, unleaded automotive gasoline. Leaded

“regular” grade gasoline is acceptable substitute. DO NOT USE

GASOLINE CONTAINING METHANOL (WOOD ALCOLHOL). Gasoline

containing maximum 10 percent ethanol/grain alcohol (sometimes

referred to as Gasohol) may be used but requires special care when

storing engine for extended periods.

NOTE: DO NOT use gasoline left over from previous season for easier engine

start-up and prevent poor engine performance.

4. DO NOT completely fill tank. Fill tank to within 6.4 mm (1/4 inch) to 13

mm (1/2 inch) of tank top to allow for fuel expansion. Replace filler cap.

Wipe any fuel spillage and oil if leak is detected from engine and Hole

Digger BEFORE operating engine. DO NOT operate engine until oil leak

is fixed and fuel is wiped away. Properly dispose of any fuel or oil wiped

from machine/rags per international and local regulations. DO NOT allow

fuel or oil to get on clothing. Change clothes immediately if this happens.

7 APPLICATION THEORY & TECHNIQUES

The Hole Digger operates on principle of accessory augers attached to the

transmission drive shaft to rotate and dig holes in a variety of soil types. The

combination of auger diameter, blade, screw bit, soil type and down pressure

supplied by operators will affect the hole digging rate.

Hole digging process is directly controlled by:

1. Soil type.

2. Auger boring head design and diameter selected.

3. When required, sufficient application and/or reduction of machine weight

and/or down force provided by operators to assist auger soil penetration.

4. No two soil types are exactly alike, no two holes can be dug by exact

same method, overall operator feed rates vary. The hole digging process,

along with operator experience, skill and common sense, suggests hole

digging is a matter of trial and error and directly determines overall

success of the job application.

HOLE DIGGING TECHNIQUES

1. Normal Hole Digger operation runs engine at full, governed speed

allowing centrifugal clutch to become firmly engaged. Technique

transmits more usable power to auger, increasing productivity and

reducing component wear. For any soil condition, allow auger to dig at

rate most comfortable to operators, but not cause centrifugal clutch to

overload and slip.

NOTE: Hole Digger is equipped with a centrifugal clutch assembly within the

transmission. The clutch assembly is designed to ALWAYS slip (NOT

DISENGAGE) when overloaded or if auger contacts buried obstruction. When

slipping, clutch still transmits a specific amount of torque to auger. Response

time for clutch to react to overload condition is directly proportional to rotational

speed. With higher rotational speeds (RPM) of clutch at time of overload, it

takes more time for clutch to react and actually slip.

2. In general, pressing down on operator handles is not required to initiate

and/or sustain the digging process. In most moderate density soils, auger

dig rates will not cause centrifugal clutch to overload and slip. In most

soft, low density soils (sandy, etc.), it may be necessary to hold up on

operator handles to reduce auger dig rate due to tendency of any auger

design to cause centrifugal clutch to overload and slip. In most hard, high

density soils (hard clay, etc.), it may be necessary to press down on

operator handles to establish and maintain acceptable dig rates.

3. Some soil conditions may require more power to dig than machine is

capable of delivering for a given auger diameter. To minimize problem,

apply suitable down force by operators and use augers with new screw

bits and blades. DO NOT use more than two operators to apply down

force.

4. When digging in areas filled with known, buried obstructions such as tree

roots, rocks and other debris, operate Hole Digger at less than full (an

intermediate) speed for more rapid release of centrifugal clutch when

obstruction is encountered. This is an industry wide operating procedure.

5. When digging in areas filled with small tree roots, small rocks or other

buried obstructions, allow auger blade to "chip away" at obstruction until

auger can pass by (by working object loose) or go through it (as in

penetrating tree roots). Technique usually involves holding up on

operator handles using minimal auger feed rate. Many times size and

nature of buried object will prevent auger from passing by or going

through it. Instead, remove buried object with shovel or other suitable tool

and proceed to dig to desired depth using Hole Digger.

6. Some job applications may encounter buried obstructions too massive in

size or soil classifications too compacted for Hole Digger use. Another

type equipment of proper size may be required.

7. In most soil conditions, the auger will retract with less effort if allowed to

rotate at slow speed. This procedure, however, will leave more loose soil

at bottom of hole. To minimize amount of loose soil remaining at bottom

of hole, stop rotation before retracting auger.

8. When restarting a Hole Digger with auger in a partially or completely dug

hole extra caution is required. The throttle control can be advanced

beyond idle speed before operators can exercise proper control of Hole

Digger. The accepted procedure (when not using non-flighted auger

extension) is to first remove unit from hole and restart engine per

STARTING ENGINE WITH AUGER ATTACHED in OPERATING

INSTRUCTIONS section of this manual. Return unit to hole with engine

at idle speed and complete hole to desired depth.

9. DO NOT dig an initial “pilot” hole with a smaller auger then use larger

diameter auger to “ream” hole to desired size. This method will prevent

auger screw bit of larger auger from providing sufficient directional

stability during “reaming” process.

10. DO NOT use shovel and/or foreign object to remove loose soil from

around hole area while operating Hole Digger. This can result in shovel

and/or foreign object to become entrapped by rotating auger.

11. Grass and other overgrowth conditions will hamper digging capability of

any auger by becoming "clogged" around auger teeth and screw bit.

Removal of such obstructions from hole location BEFORE digging will

increase digging efficiency and overall productivity.

8 OPERATING INSTRUCTIONS

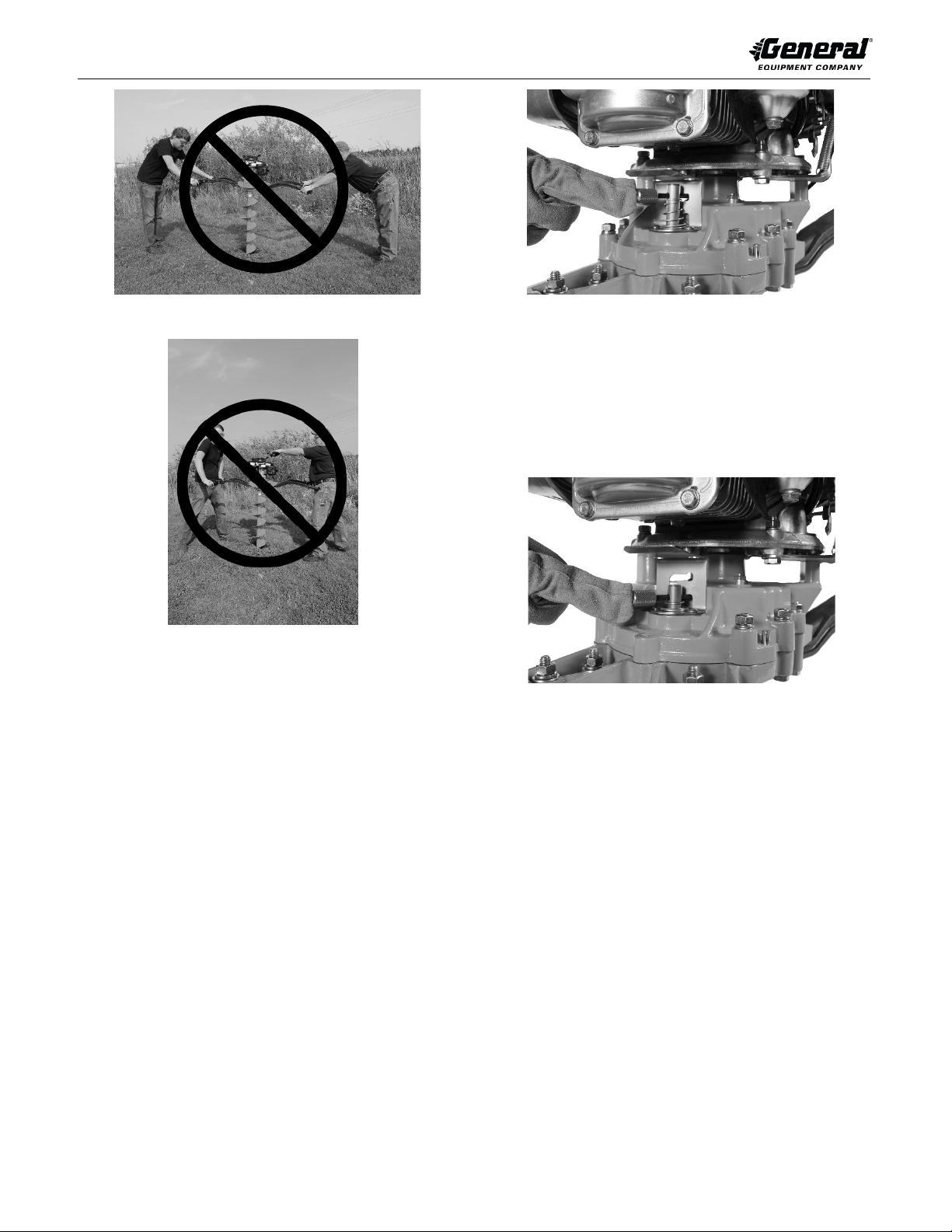

INSTALLING AUGER

1. DO NOT connect auger to Hole Digger while engine is running. Refer to

STOPPING HOLE DIGGER in OPERATING INSTRUCTIONS section of

this manual. To install auger, place Hole Digger with spark plug facing up

to minimize potential oil and/or gasoline entering combustion chamber

and creating a hydraulic lock up.

2. Connect auger to Hole Digger with correct factory supplied auger pin. DO

NOT use any other connecting device, including cap screws, bolts, pins,

etc., that can damage Hole Digger driveshaft and/or auger hub.

STARTING ENGINE WITH AUGER ATTACHED

DO NOT attempt to dig with Hole Digger until Crew Chief and Crew Member

have acknowledged to each other they are ready and are in full control of

machine/accessories. Crew Chief operates engine throttle control with right

hand and is responsible for verbal commands. Crew member operates choke

control and starts engine.