Contents

Chapter 1 Product Introduction1.......................................................................................................3

1.1 Product Name.....................................................................................................................3

1.2 Model ................................................................................................................................3

1.3 Intended use.......................................................................................................................3

Chapter 2 Function Introducion ........................................................................................................4

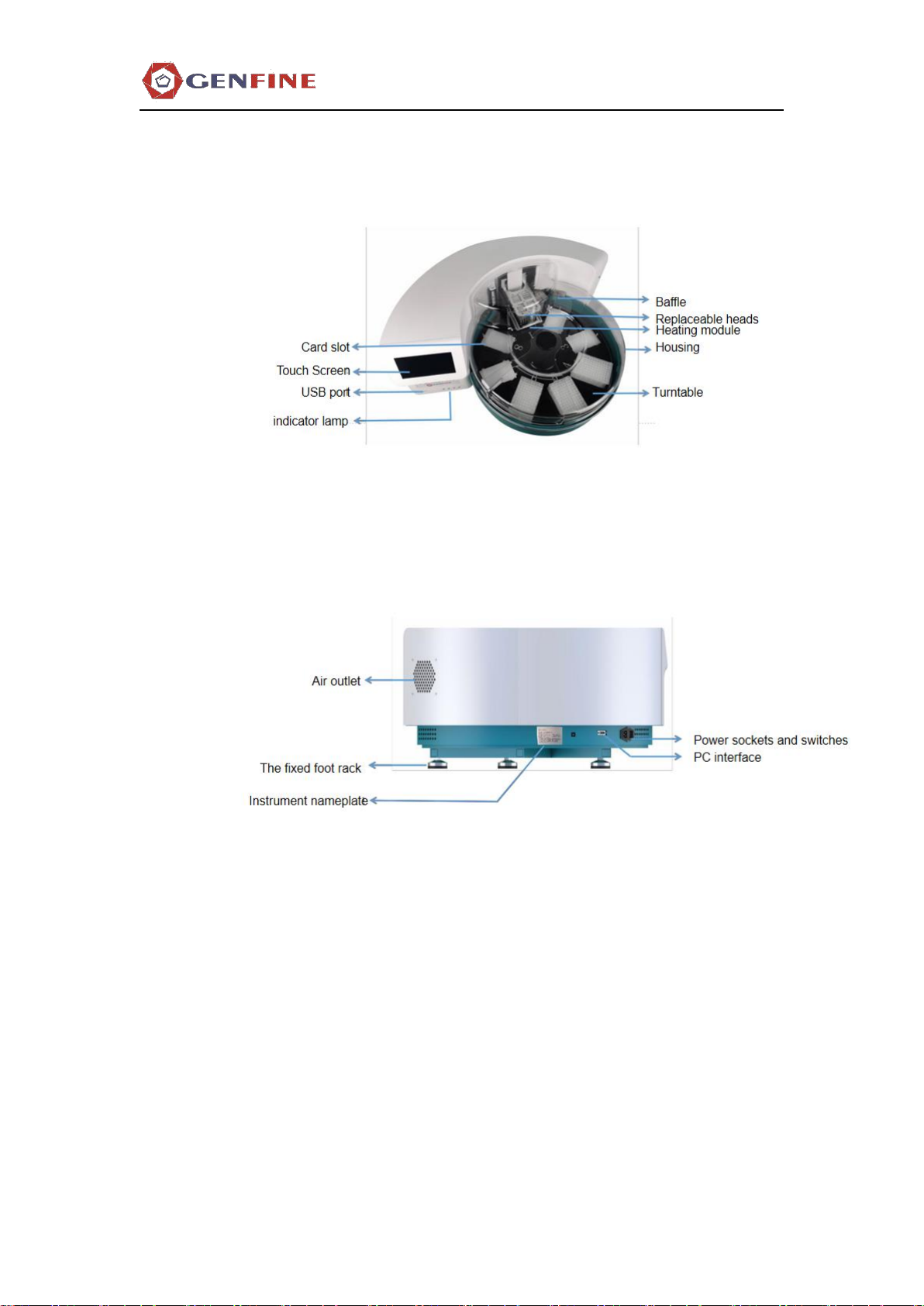

2.1 Main Components...............................................................................................................4

2.1.1 Front View.............................................................................................................4

2.1.2 RearView ...............................................................................................................4

2.2 Working Principle...............................................................................................................5

2.3 USB Port.............................................................................................................................5

2.4 Consumables .....................................................................................................................5

Chapter 3 Installation ......................................................................................................................6

3.1 Delivery Check ..................................................................................................................6

3.1.1 Unboxing.................................................................................................................6

3.1.2 Integrity Check.........................................................................................................6

3.2 Environment Requirements................................................................................................6

3.3 Precautions........................................................................................................................6

3.4 Installtion Settings...............................................................................................................7

3.4.1 Power Connection....................................................................................................7

3.4.2 Operation Check ......................................................................................................7

Chapter 4 Instructions for Use...........................................................................................................8

4.1 Starting................................................................................................................................8

4.2 Programs .............................................................................................................................8

4.2.1 Home Screen...........................................................................................................8

4.2.2 Program Running....................................................................................................8

4.2.3 New Pogram Creation.............................................................................................9

4.2.4 User Settings ......................................................................................................12

4.2.5 UV Light Settings.................................................................................................12

4.3 Shutting Down .................................................................................................................12

4.4 Emergencies.....................................................................................................................13

Chapter 5 Care and Maintenance ....................................................................................................14

5.1 Instrument Maintenance....................................................................................................14

5.2 Cleaning...........................................................................................................................14

5.3 Magnetic Rods Cleaning..................................................................................................14

5.4 Waste Disposal.................................................................................................................14

5.5 Decontamination Procedure ............................................................................................14

5.5.1 Decontamination reagents Types...................................................................14

5.5.2 Decontamination Procedure ................................................................................15

5.6 Packaging for repair..........................................................................................................15

5.7 Service Contract...............................................................................................................15

5.8 System Log ......................................................................................................................15

5.9 Instrument Disposal.........................................................................................................15

Chapter 6 Technical Parameters......................................................................................................17