Operator'sManualSecond Edition · First Printing

PartNo.114475 Z-135/70 1

Introduction

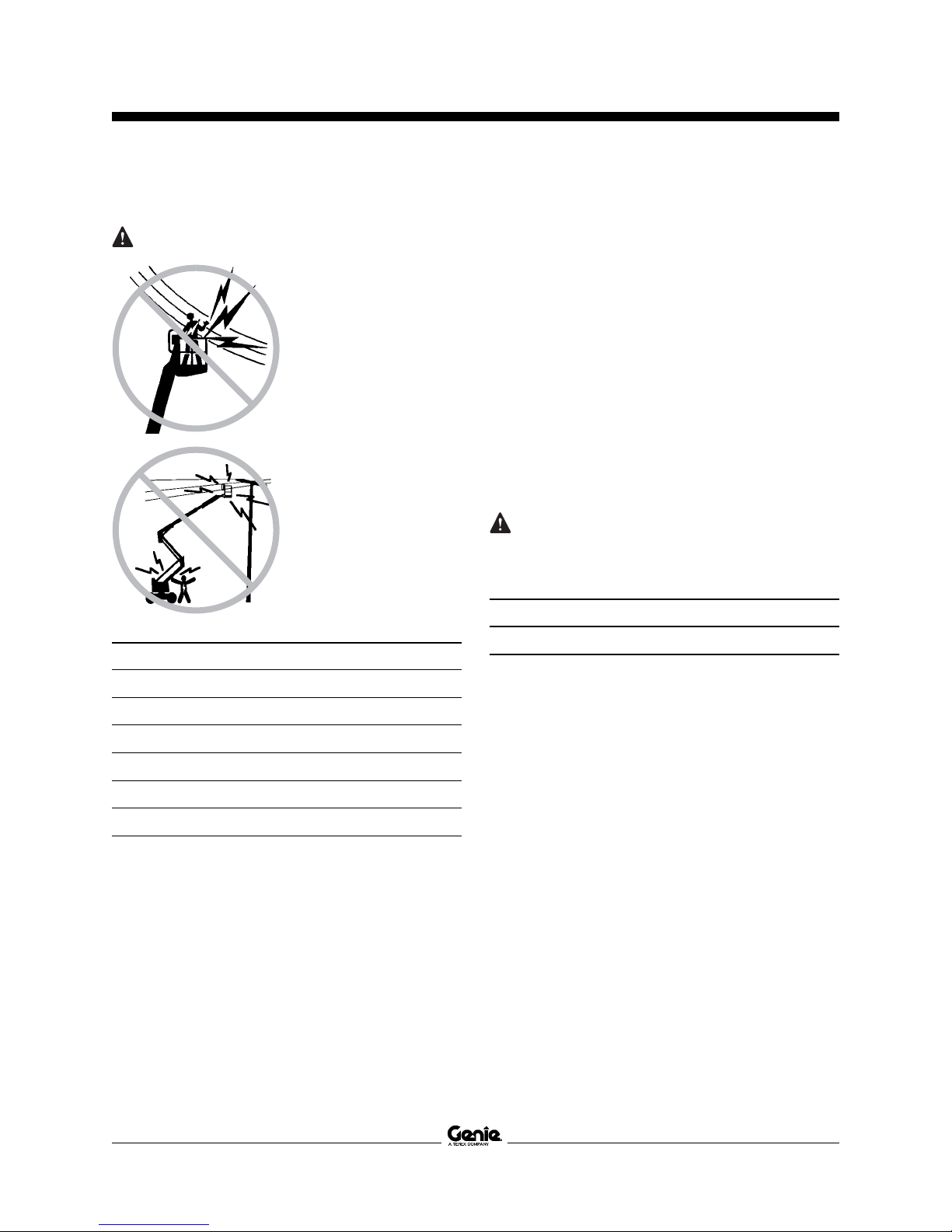

Danger

Failure to obey the instructions and

safety rules in this manual will

result in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machineoperationcontainedinthisoperator's

manual.

1 Avoidhazardoussituations.

Knowandunderstandthesafetyrulesbefore

going on to the next section.

2 Alwaysperformapre-operationinspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Youread,understand andobeythe

manufacturer'sinstructionsand safetyrules—

safetyandoperator'smanualsandmachine

decals.

Youread,understandandobeyemployer's

safety rules and work site regulations.

Youread,understandandobeyallapplicable

governmentalregulations.

Youare properlytrained tosafely operate the

machine.

Owners, Users and Operators:

Genieappreciates your choiceof our machinefor

yourapplication. Ournumber onepriority is user

safety, which is best achieved by our joint efforts.

We feel that you make a major contribution to

safety if you, as the equipment users and

operators:

1 Comply with employer, job site and

governmentalrules.

2 Read, understand and follow the instructions

in this and other manuals supplied with this

machine.

3 Use goodsafe work practices ina

commonsenseway.

4 Onlyhavetrained/certifiedoperators,directed

byinformedandknowledgeablesupervision,

runningthemachine.

If there is anything in this manual that is not clear

orwhich youbelieve should be added, please

contact us.

Internet:www.genielift.com