Second Edition • First Printing Operator's Manual

General Safety

Part No. 1261735 S-60X 7

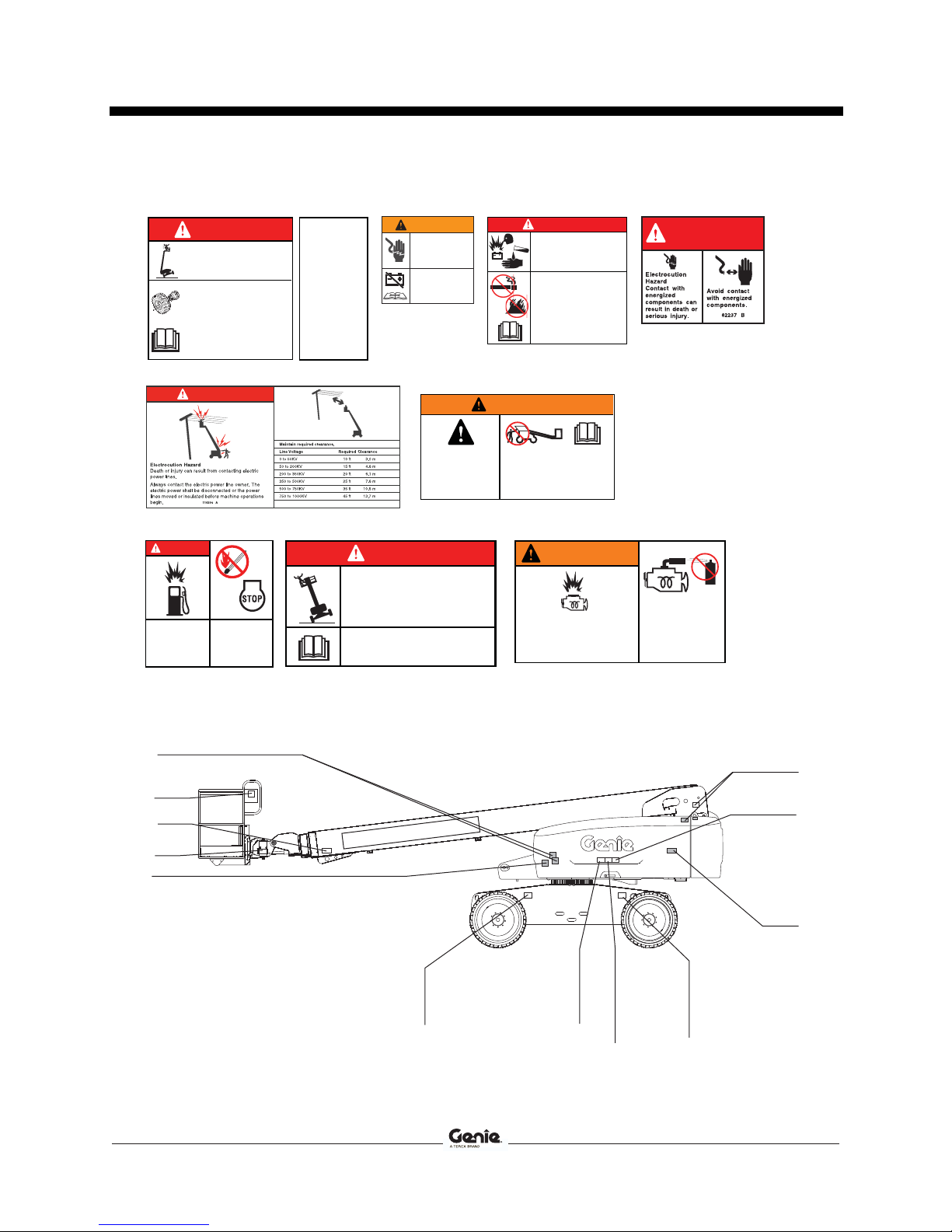

WARNING

Runaway Hazard

Machine movement can occur

when a machine is operated

on a slope that exceeds rated

uphill, downhill or side slope

rating.

A runaway machine could result

in death or serious injury.

2WD: 30% (17°)

4WD: 45% (24°)

TRAX: 45% (24°)

2WD: 10% (6°)

4WD: 30% (17°)

TRAX: 30% (17°)

1262342 A

Do not drive machine on a slope that exceeds

maximum uphill, downhill or side slope rating.

Determine slope and side slope ratings for

machine and determine slope grade.

Maximum slope rating,

platform downhill

(gradeability):

Maximum slope rating,

platform uphill

Note: Slope rating is subject to ground conditions

and adequate traction. Gradeability applies to

platform downhill configuration only.

Be sure boom is below horizontal

and platform is between non-steer

wheels or tracks.

Move drive speed select switch to

machine on incline symbol.

Driving On a Slope

Maximum

side slope rating

25% (14°)

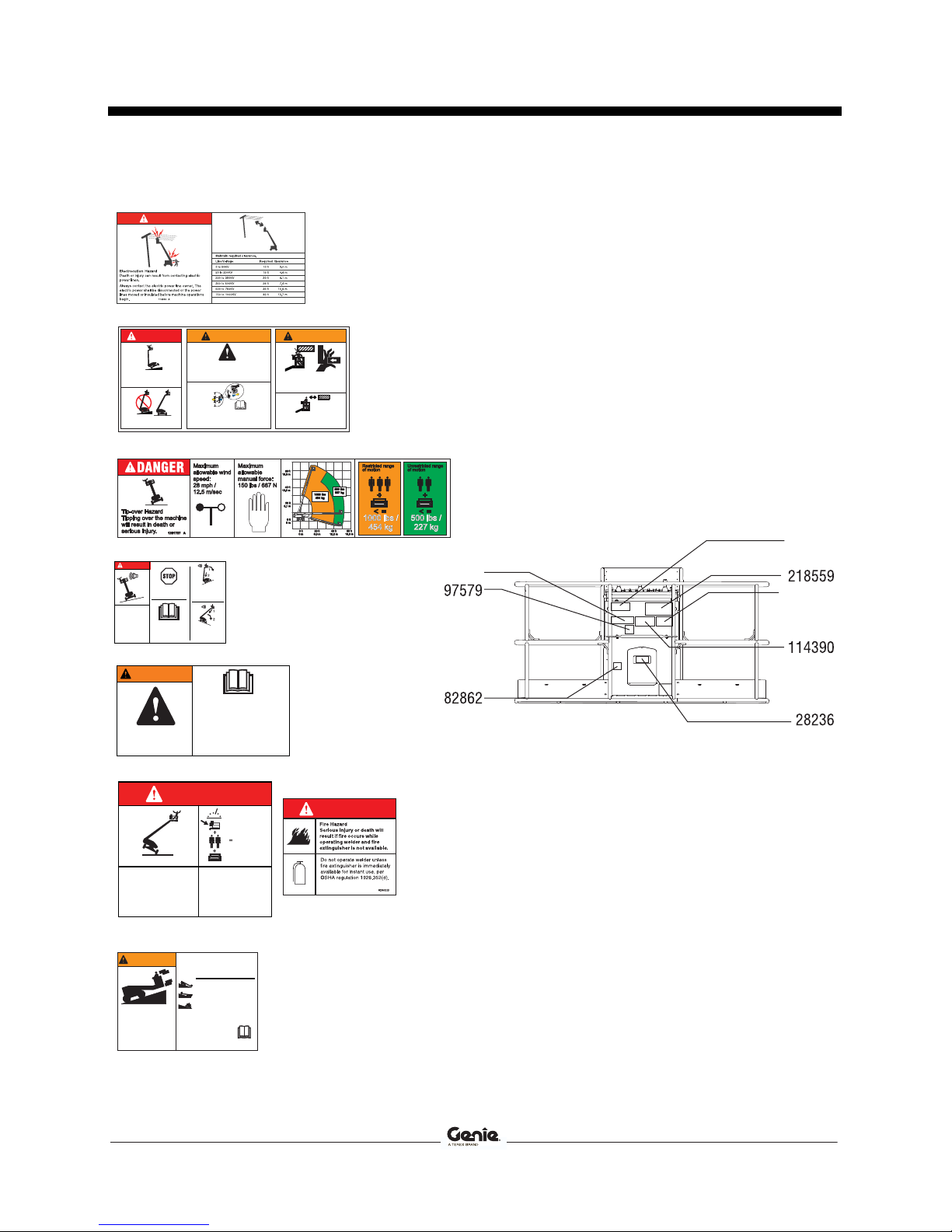

28236

Read and understand Operator's

Manual, Responsibilities Manual and

Safety Manual and all safety signs

before using or maintaining machine.

If you do not understand the

information in the manuals, consult

your supervisor, the owner or the

manufacturer.

28236 D

WARNING

Improper operation or

maintenance can result in

serious injury or death.

DANGER

82862

Tip-over Hazard

Welder power supply

reduces rated platform

capacity and

must be factored into total

platform load.

DANGER

Do not overload

platform.

Welder power supply

weighs 75 lbs / 34 kg.

97579

114390

DANGER

218559

218559 A

Keep away from overhead obstructions

or other possible hazards.

Crush Hazard

Contact with overhead obstructions

could result in death or serious injury.

WARNING

Drive Direction Hazard

Machine can move in opposite direction of

joystick movement. Movement in an unplanned

direction can result in death or serious injury.

Always match the color-coded direction arrows

on platform controls and drive chassis to

determine direction of machine travel. Read

and understand operator's manual.

WARNING

Only raise the platform when the

machine is on a frm, level

surface.

Tip-over Hazard

Tipping over this machine will

result in death or serious injury.

DANGER

1261737

1261737

1262342

114416

114416

Tip-over Hazard

If tilt-alarm

sounds, unit is

on a severe

slope. Death or

serious injury

will result.

114416 A

DANGER

Platform uphill:

1 Lower boom.

2 Retract boom.

Platform downhill:

1 Retract boom.

2 Lower boom.

• Read operator’s

manual before

attempting to move

machine.

• Stop all movement.

1262342