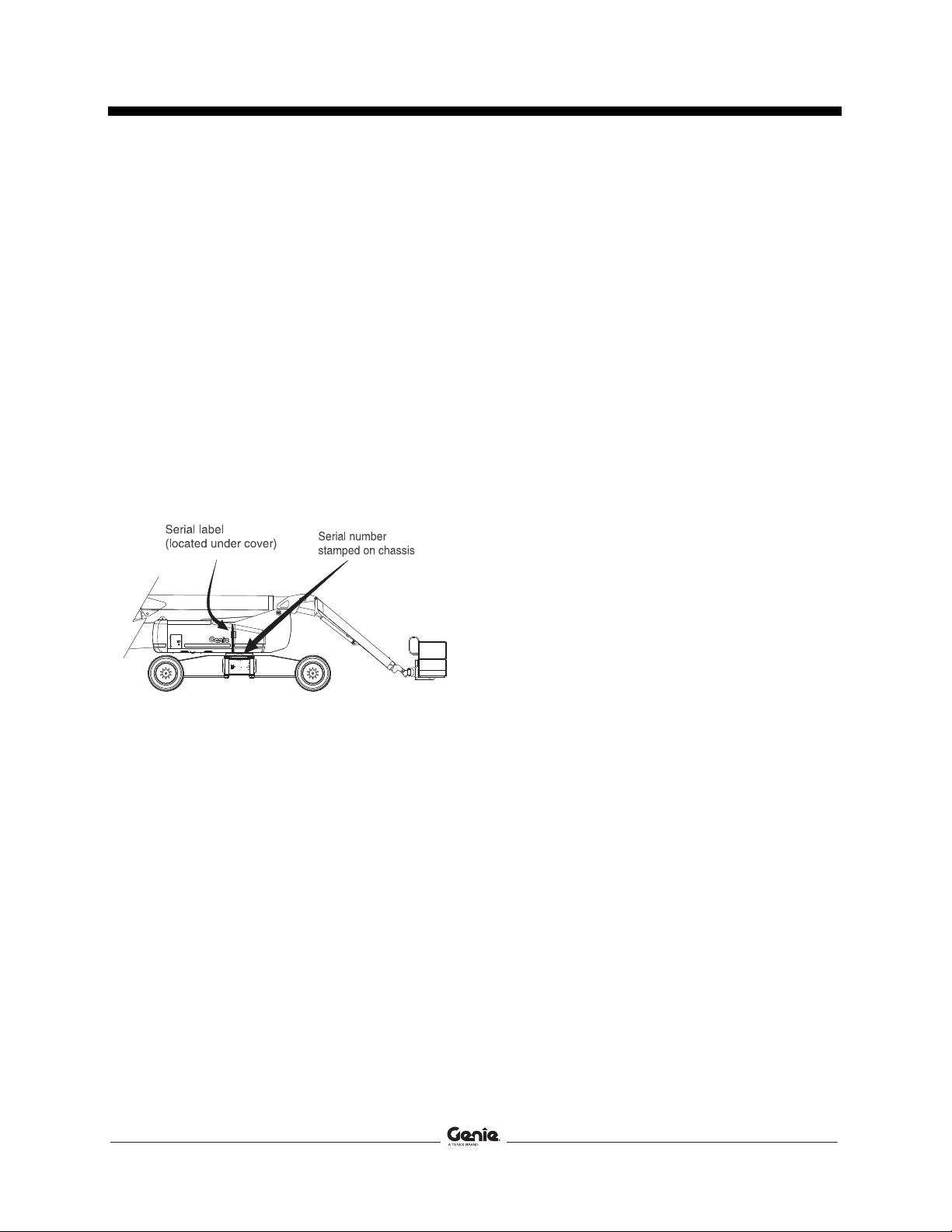

Second Edition • Third Printing Operator's Manual

Introduction

Part No. 1272822GT ZX®-135/70 5

Danger

Failure to obey the instructions and

safety rules in this manual will result

in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer’s instructions and safety

rules—safety and operator’s manuals and

machine decals.

You read, understand and obey employer’s

safety rules and worksite regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

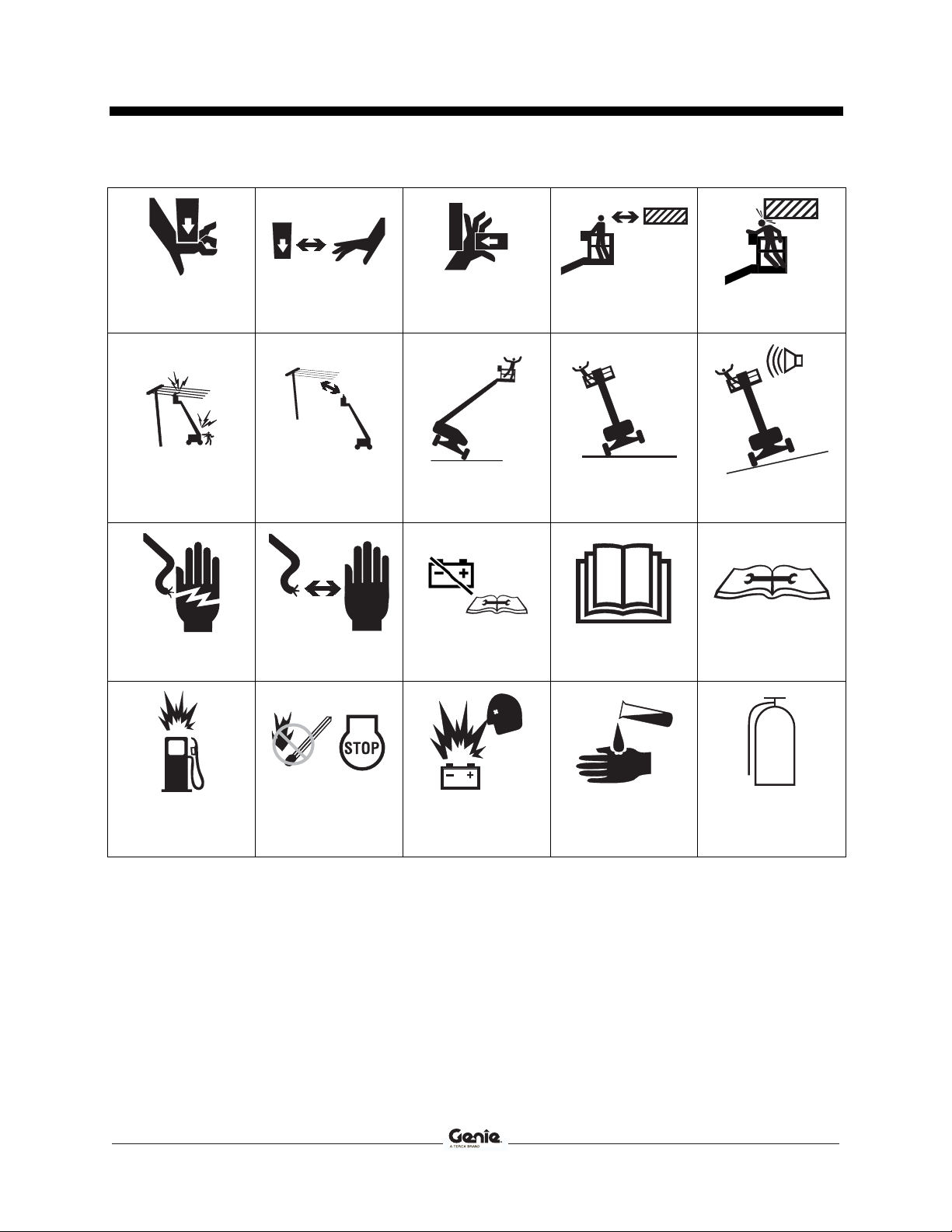

Safety Sign Maintenance

Replace any missing or damaged safety signs.

Keep operator safety in mind at all times. Use mild

soap and water to clean safety signs. Do not use

solvent-based cleaners because they may damage

the safety sign material.

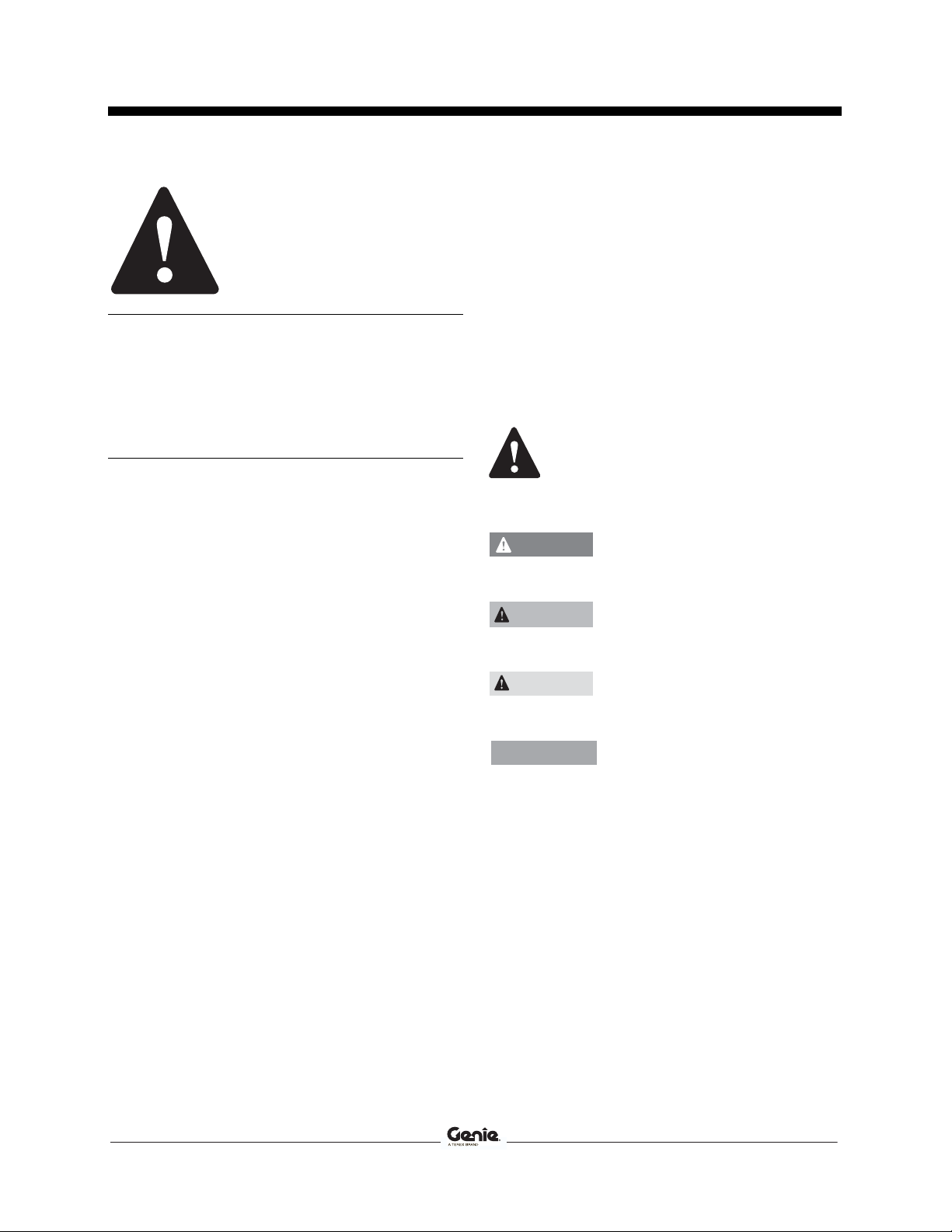

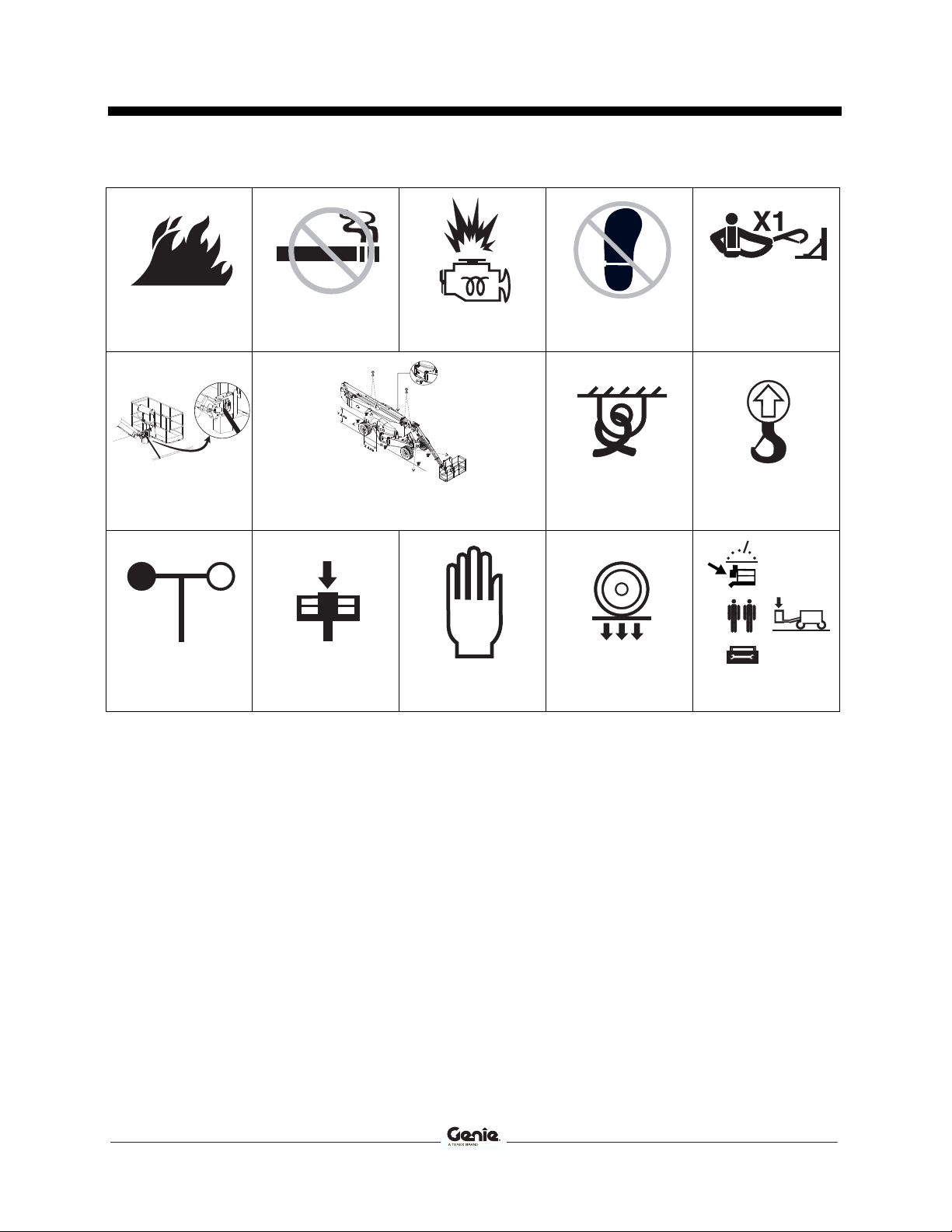

Hazard Classification

Decals on this machine use symbols, color coding,

and signal words to identify the following:

Safety alert symbol—used to alert

you to potential personal injury

hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a hazardous situation

which, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation

which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could result

in minor or moderate injury.

Indicates a property damage

message.

DANGER

WARNING

CAUTION