Operator'sManualSecond Edition · Fourth Printing

PartNo.114474 Z-135/70 7

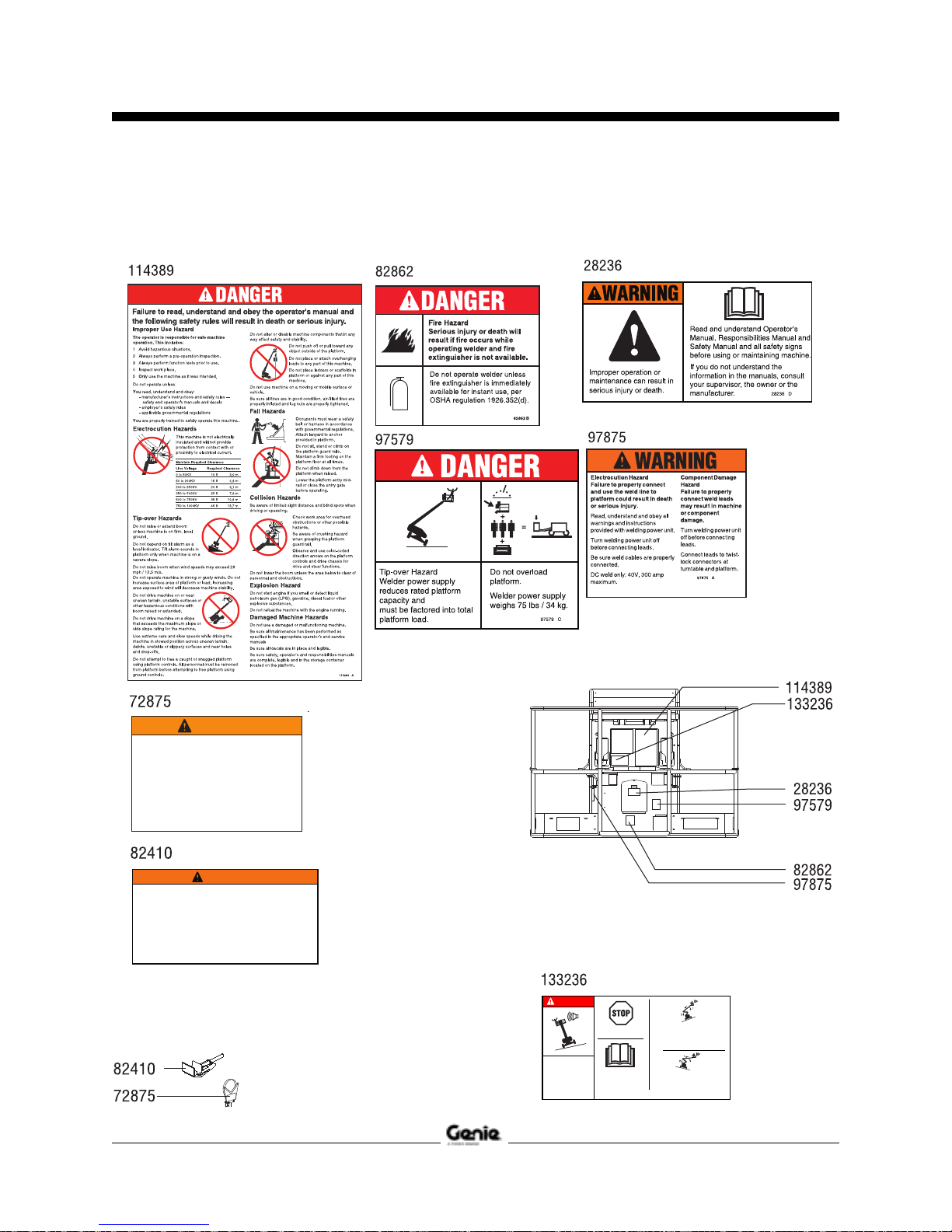

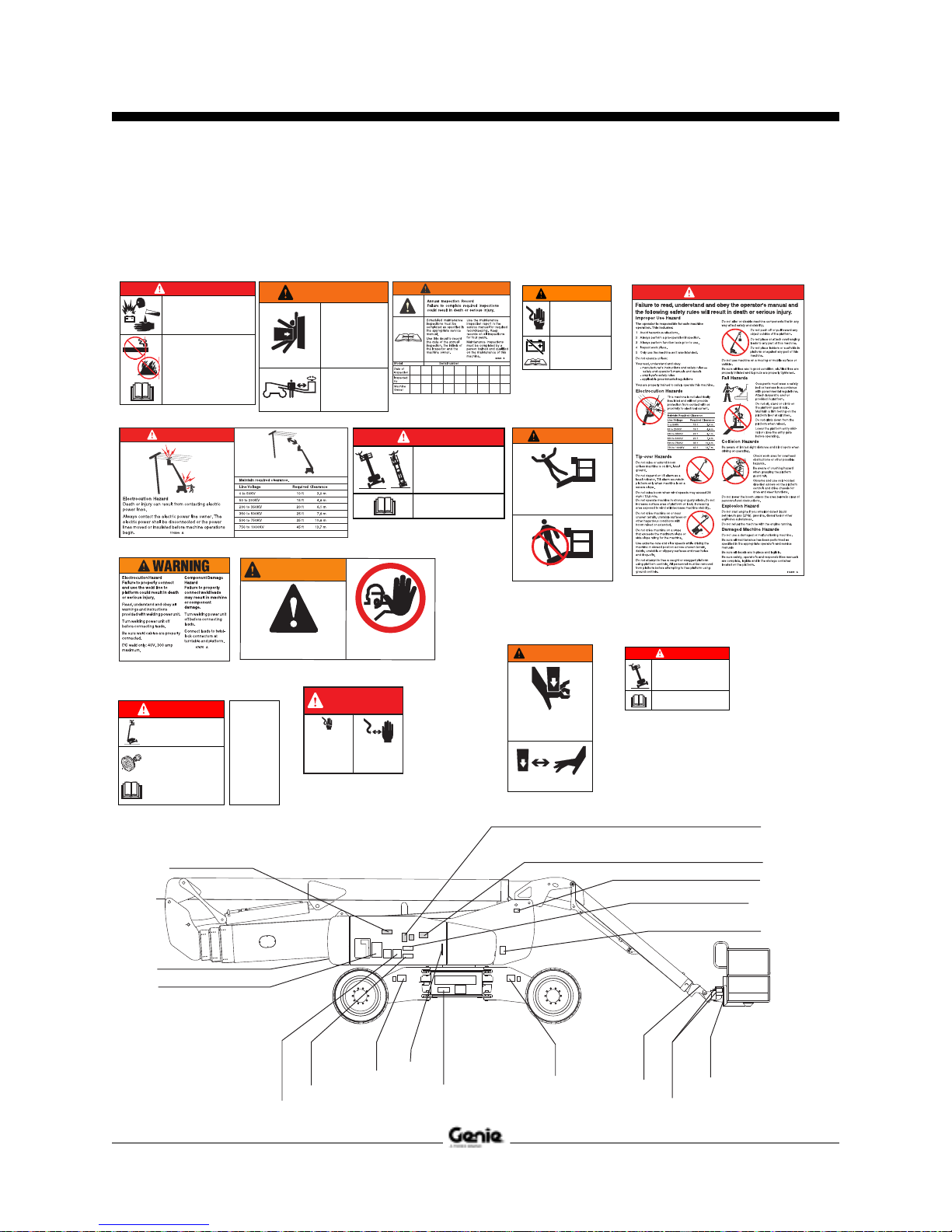

Safety signs and locations

General Safety

31060

31060

52865

97865

82314

28161

114389

28177

28181

1263543

114390

97875

31788 82237

28177

31060

Crush Hazard

Death or serious

injury may result

from platform

crushing

personnel

against boom.

WARNING

28177 C

Keep away from

path of moving

platform.

114390

DANGER

DANGER

114389

WARNING

52865

97875

Tip-over Hazard

Altering or disabling limit

switches can result in machine

tip-over. Machine tip-over will

result in death or serious injury.

DANGER

Do not alter or disable limit

switch(s).

31060 C

28181

Keep off this surface.

WARNING

Fall Hazard

Death or serious injury may result

from climbing or riding on boom.

28181 C

DANGER

Explosion / Burn Hazard

Ignition of explosive gases or contact with corrosive

acid will cause death, burns or blindness

31788 C

Keep all open flames and sparks away. Wear

personal protective equipment, including face

shield, gloves and long sleeve shirt.

READ MANUALS

Read all manuals prior to operation.

DO NOT OPERATE equipment if you do not

understand the information in the manuals.

Consult your supervisor, the owner or the

manufacturer.

31788

Electrocution/BurnHazard

Failure to disconnect all

the batteries before

performing service on this

machine may result in

death or serious injury.

Disconnect all the batteries

before performing service on

this machine.

WARNING

97865 B

97865

Electrocution

Hazard

Contact with

energized

components can

result in death or

serious injury.

82237 B

DANGER

Avoid contact

with energized

components.

82237

28161

28161 C

Crush Hazard

Contact with moving parts can

result in death or serious

injury.

WARNING

Keep away from moving parts.

Tip-over Hazard

Altering or disabling angle sensor

can result in machine tip-over.

Machine tip-over will result in

death or serious injury.

DANGER

Do not move, alter or disable

angle sensor.

82314 B

82314

97715

or 229356

or 230977

LugNutTorque

Dry bolts:

420 ft-lbs /

569.5Nm

Lubricatedbolts:

320 ft-lbs /

433.9Nm

Tip-overHazard

Failure to replace tires with tires

ofsamespecification willresult

in death or serious injury.

Do not use air-filled tires.

Foam-filled tires are critical to

machinestability.

Donotreplace factory-installed

tires with tires of different

specification or ply rating.

Tire Size

445/65D22.5, 18ply Foam-filled

DANGER

97715 B

97715 or 229356 or 230977

97715

or 229356

or 230977

Improper operation or maintenance of

this equipment can result in death or

serious injury.

WARNING

Access by trained and

authorized personnel only.

1263543

1263543

1263543