TABLE of CONTENTS

1. INTRODUCTION ...................................................................................................................................................1

1.1 THEORY OF OPERATION.......................................................................................................................................1

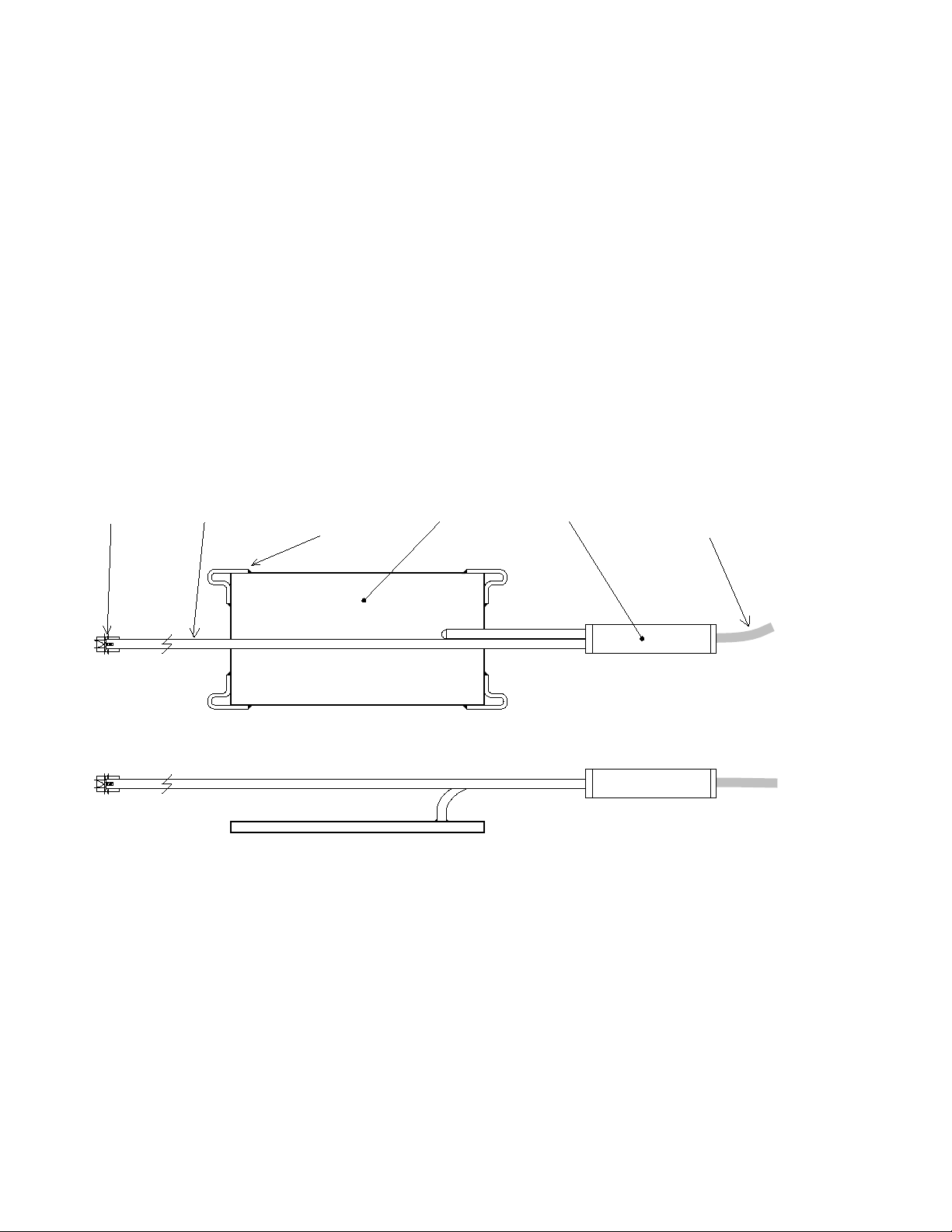

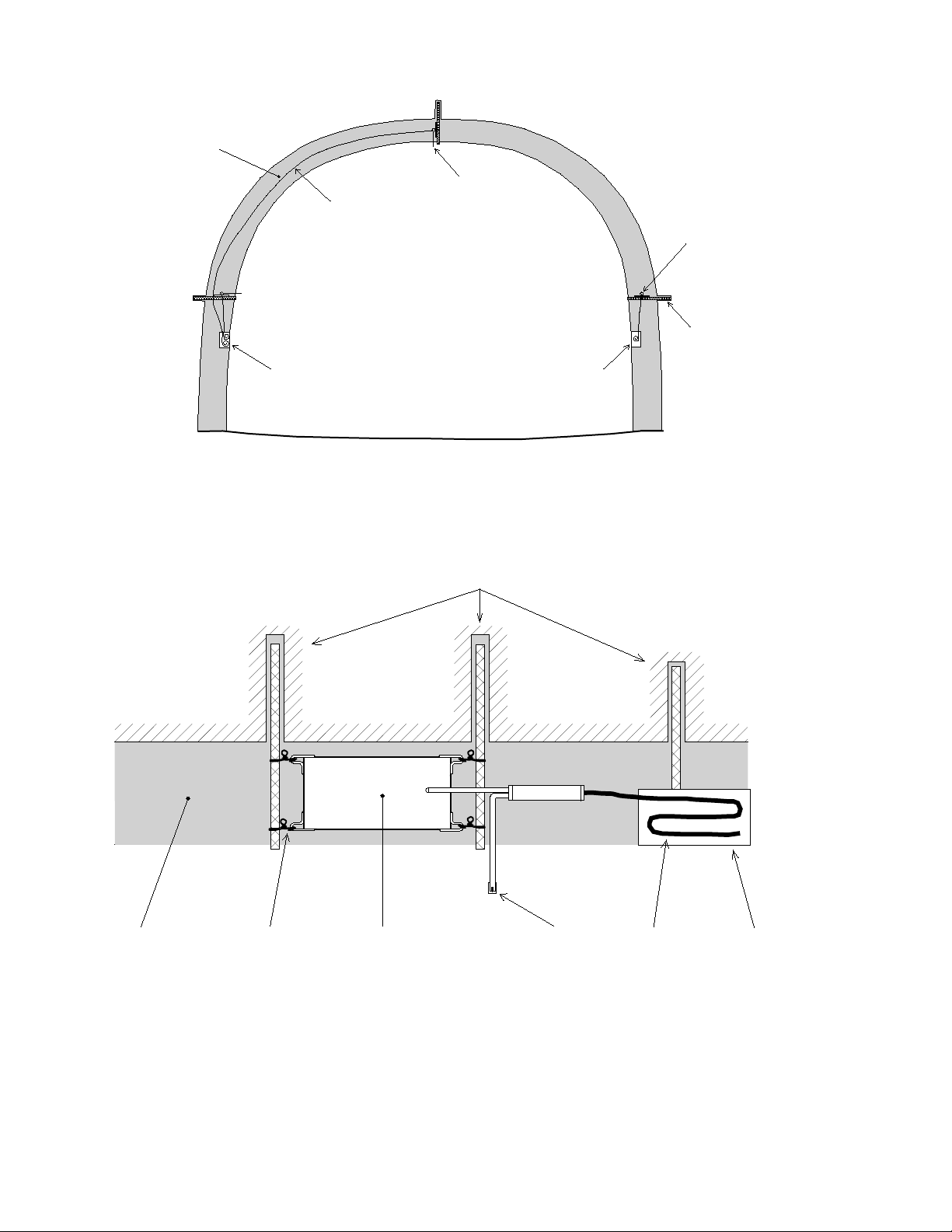

1.2 STRESS CELL DESIGN AND CONSTRUCTION.........................................................................................................2

2. INSTALLATION ....................................................................................................................................................3

2.1 PRELIMINARY TESTS............................................................................................................................................3

2.2 STRESS CELL INSTALLATION ...............................................................................................................................3

2.2.1 Installing the Model 4850-1........................................................................................................................3

2.2.2 Installing the Model 4850-2........................................................................................................................5

2.3 INITIAL READINGS ...............................................................................................................................................5

2.4 RE-PRESSURIZING THE CELL ...............................................................................................................................6

2.4.1 Standard Re-Pressurization Technique.......................................................................................................6

2.4.2 Remote Re-Pressurization Technique .........................................................................................................7

2.5 CABLE INSTALLATION .........................................................................................................................................8

2.6 ELECTRICAL NOISE..............................................................................................................................................8

3. TAKING READINGS.............................................................................................................................................9

3.1 GK-404 READOUT BOX.......................................................................................................................................9

3.1.1 Operating the GK-404 ................................................................................................................................9

3.2 GK-405 READOUT BOX.....................................................................................................................................10

3.2.1 Connecting Sensors...................................................................................................................................10

3.2.2 Operating the GK-405 ..............................................................................................................................10

3.3 GK-403 READOUT BOX (OBSOLETE MODEL)....................................................................................................11

3.3.1 Connecting Sensors...................................................................................................................................11

3.3.2 Operating the GK-403 ..............................................................................................................................11

3.4 MEASURING TEMPERATURES.............................................................................................................................11

4. DATA REDUCTION ............................................................................................................................................12

4.1 PRESSURE CALCULATION ..................................................................................................................................12

4.2 TEMPERATURE CORRECTION .............................................................................................................................12

4.3 BAROMETRIC CORRECTION ...............................................................................................................................12

5. TROUBLESHOOTING........................................................................................................................................13

6. APPENDIX A. SPECIFICATIONS.....................................................................................................................14

A.1 STRESS CELLS...................................................................................................................................................14

A.2 THERMISTOR (SEE APPENDIX BALSO) ..............................................................................................................14

APPENDIX B. THERMISTOR TEMPERATURE DERIVATION.....................................................................15

APPENDIX C. TEMPERATURE EFFECT ON EARTH PRESSURE AND CONCRETE STRESS CELLS 16

C.1 FORMULAS ........................................................................................................................................................16

C.2 EXAMPLES ........................................................................................................................................................19

APPENDIX D. TYPICAL CALIBRATION REPORT..........................................................................................21