I

TABLE OF CONTENTS

1. INTRODUCTION............................................................................................................................................1

1.1 THEORY OF OPERATION...............................................................................................................1

1.2 EARTH PRESSURE CELL DESIGN.........................................................................................2

1.3 EARTH PRESSURE CELL CONSTRUCTION ..................................................................3

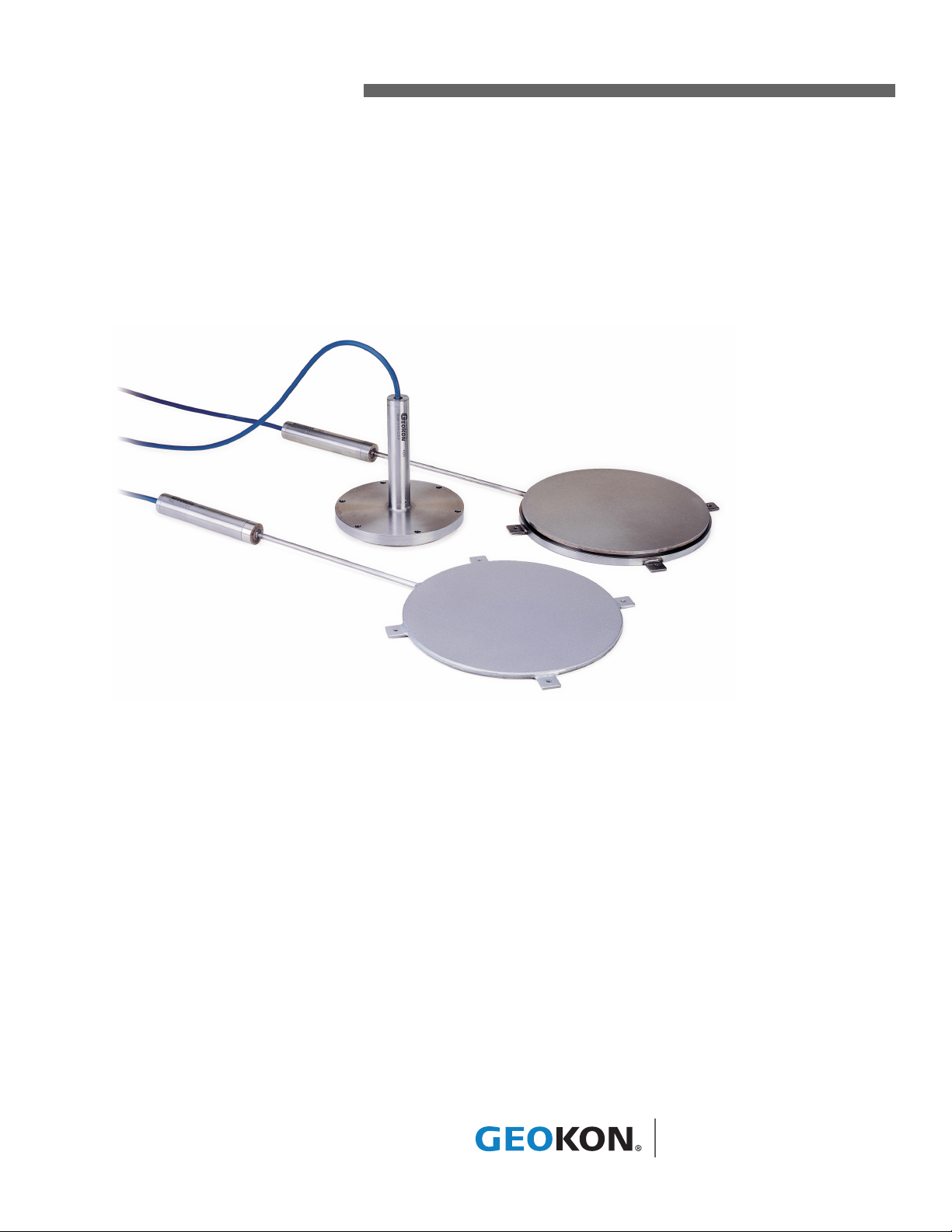

1.3.1 MODEL 4800 EARTH PRESSURE CELLS.................................................................................3

1.3.2 MODEL 4810 CONTACT ("FAT BACK") PRESSURE CELL.................................................4

1.3.3 MODEL 4815 HYDRAULIC LOAD CELL ...................................................................................4

1.3.4 MODEL 4820 EARTH PRESSURE "JACKOUT" CELL ..........................................................5

1.3.5 MODEL 4830 PUSH-IN PRESSURE CELL ................................................................................5

2. INSTALLATION..............................................................................................................................................6

2.1 PRELIMINARY TESTS......................................................................................................................6

2.2 PRESSURE CELL INSTALLATION .........................................................................................6

2.2.1 INSIDE FILLS AND EMBANKMENTS ........................................................................................6

2.2.2 INSTALLATION OF MODEL 4810 CONTACT ("FAT BACK") PRESSURE CELL.........8

2.2.3 INSTALLATION OF MODEL 4815 HYDRAULIC LOAD CELL ....................................... 10

2.2.4 INSTALLATION OF MODEL 4820 JACKOUT PRESSURE CELL IN SLURRY

TRENCHES........................................................................................................................................ 10

2.2.5 INSTALLATION OF CELLS TO MEASURE EARTH PRESSURE AT THE BASE

OF FOOTINGS, FLOOR SLABS, PAVEMENTS, ETC......................................................... 11

2.2.6 INSTALLATION OF PUSH-IN PRESSURE CELLS TO MEASURE LATERAL

EARTH PRESSURES ..................................................................................................................... 12

2.3 CABLE INSTALLATION AND SPLICING ...................................................................... 13

2.4 ELECTRICAL NOISE ....................................................................................................................... 14

2.5 INITIAL READINGS ........................................................................................................................ 14

3. TAKING READINGS ............................................................................................................................. 15

3.1 OPERATING THE GK-404 ......................................................................................................... 15

3.2 GK-405 VIBRATING WIRE READOUT............................................................................ 15

3.2.1 CONNECTING SENSORS WITH 10-PIN BULKHEAD CONNECTORS

ATTACHED ....................................................................................................................................... 16

3.2.2 CONNECTING SENSORS WITH BARE LEADS................................................................... 16

3.2.3 OPERATING THE GK-405 ........................................................................................................... 16

3.3 MEASURING TEMPERATURES ........................................................................................... 16

4. DATA REDUCTION ................................................................................................................................17

4.1 PRESSURE CALCULATION...................................................................................................... 17

4.2 TEMPERATURE CORRECTION ............................................................................................. 18

4.3 BAROMETRIC CORRECTION ................................................................................................. 18

5. TROUBLESHOOTING .......................................................................................................................... 20

APPENDIX A. SPECIFICATIONS .................................................................................................. 21