5

Installing and servicing heating and air conditioning equipment can

be hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install, repair

or service heating and air conditioning equipment. Untrained

personnel can perform the basic maintenance functions of cleaning

coils and cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working on

heating and air conditioning equipment, observe precautions in

the literature, tags and labels attached to the unit and other safety

precautions that may apply, such as the following safety measures:

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use a quenching cloth for brazing operations.

• Have a fire extinguisher available for all brazing operations.

Moving and Storage

Move units in the normal “up” orientation. Units may be moved

and stored per the information on the packaging. Do not stack

more than three units in total height. Do not attempt to move units

while stacked. When the equipment is received, all items should

be carefully checked against the bill of lading to be sure all crates

and cartons have been received. Examine units for shipping

damage, removing the units from the packaging if necessary. Units

in question should also be internally inspected. If any damage is

noted, the carrier should make the proper notation on the delivery

receipt, acknowledging the damage.

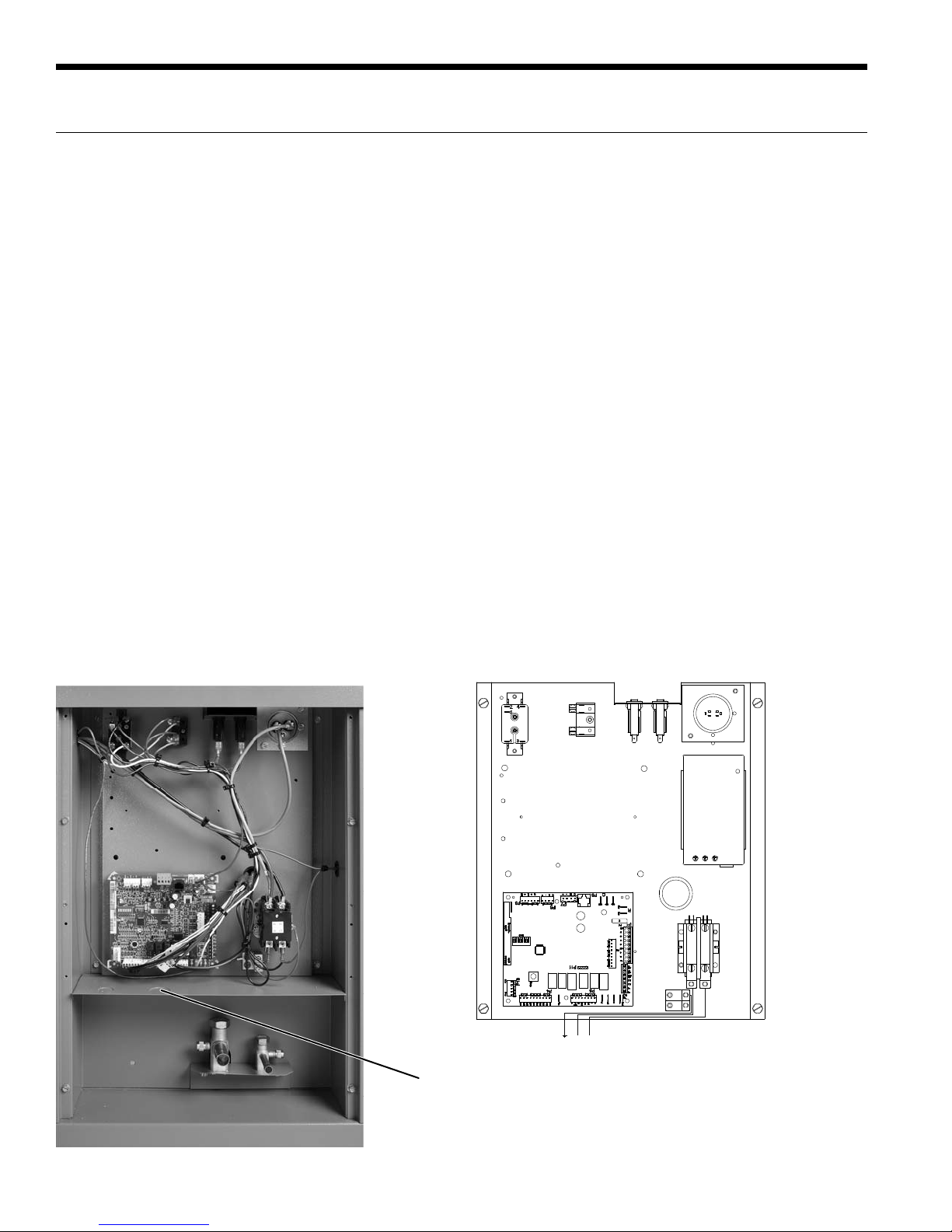

Split Unit Location

Locate the split compressor section away from areas that may

disturb the customer and in a way that allows easy removal of the

access panels and the top of the cabinet. Provide sufficient room

to make water, electrical and refrigerant line connections and allow

space for service personnel to perform maintenance. The outdoor

split is approved for outdoor installation when properly installed.

Air Coil Location

Refer to the air handler manufacturer’s instructions for the blower

coil unit for details on installing the air handling portion of the system.

Condensate Drain

Follow the blower coil manufacturer’s instructions.

WARNING: Before performing service or

maintenance operations on a system, turn off main

power switches to both units. Turn off accessory

heater power switch if applicable. Electrical

shock could cause personal injury. Installing and

servicing heating and air conditioning equipment

can be hazardous due to system pressure and

electrical components. Only trained and qualified

service personnel should install, repair or service

heating and air conditioning equipment.

Duct System

All blower coil units/air coils must be installed as specified by the

manufacturer’s installation instructions; however, the following

recommendations should considered to minimize noise and

service problems.

An air filter must always be installed upstream of the air coil on

the return air side of the air handler or furnace. If there is limited

access to the filter rack for normal maintenance, it is suggested

that a return air filter grill be installed. Be sure that the return duct

is properly installed and free of leaks to prevent dirt and debris

from bypassing the filter and plugging the air coil.

In applications using galvanized metal ductwork, a flexible duct

connector is recommended on both the supply and return air

plenums to minimize vibration from the blower. To maximize sound

attenuation of the unit blower, the supply and return plenums

should include an internal duct liner of 1-inch thick glass fiber or

be constructed of ductboard. Insulation is usually not installed in

the supply branch ducts. Ducts in unconditioned areas should be

wrapped with a minimum of 1-inch duct insulation. Application of

the unit to uninsulated ductwork in an unconditioned space is not

recommended as the unit’s performance will be adversely affected.

If the air handler is connected to existing ductwork, a previous

check should have been made to assure that the duct system has

the capacity to handle the air required for the unit application. If

ducting is too small, as in replacement of heating only systems,

larger ductwork should be installed. All existing ductwork should be

checked for leaks and repairs made accordingly. The duct systems

and diffusers should be sized to handle the design airflow quietly.

If air noise or excessive airflow is a problem, the blower speed can

be changed to a lower speed to reduce airflow. This will reduce the

performance of the unit slightly in heating; however, it will increase

the temperature rise across the air coil. Airflow must still meet

minimum requirements.

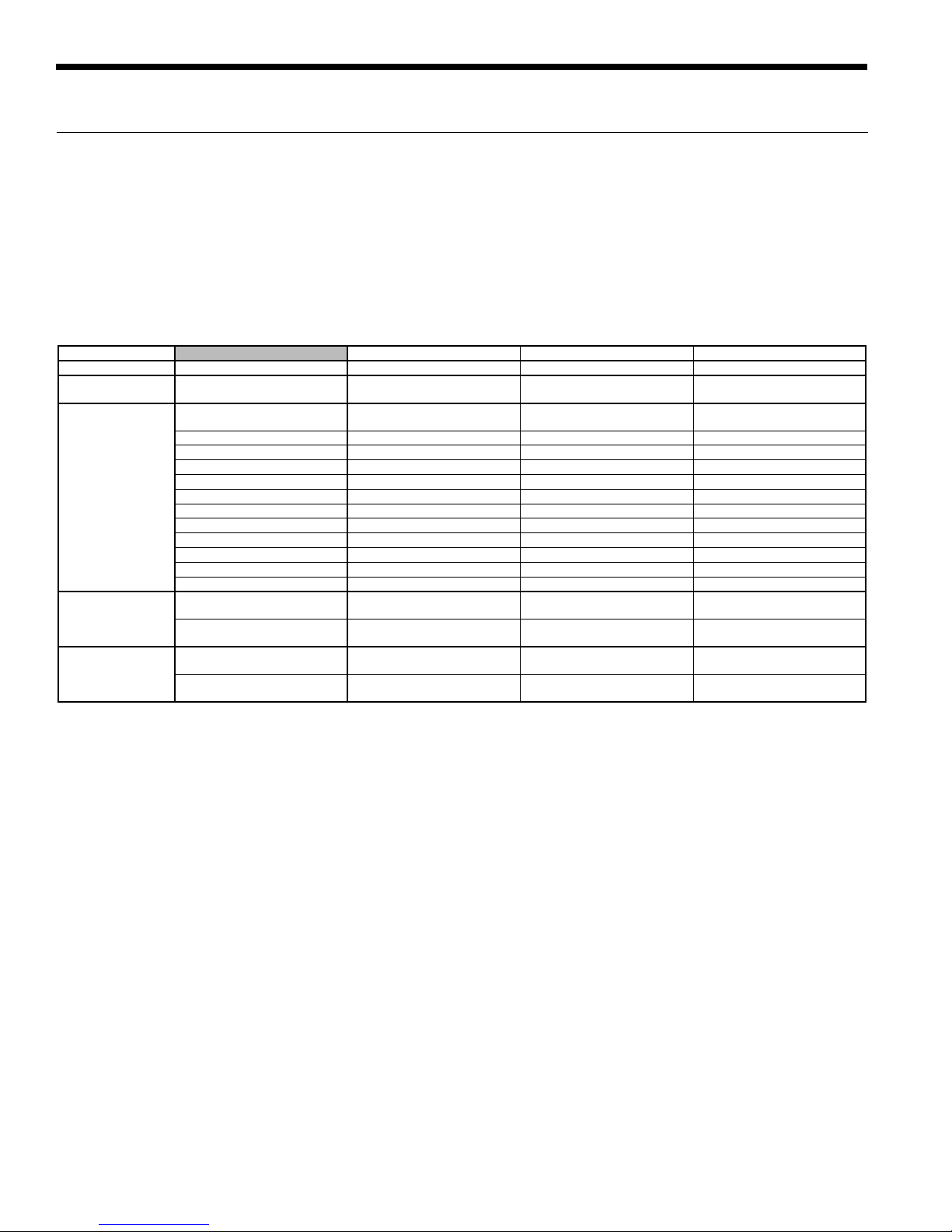

Equipment Selection

The following guidelines should be used when mating a

Outdoor Split to an air handler/coil.

• Select R-410A components only.

• Match the air handler to the air handler coil data table.

• Indoor matching adjustable TXV is factory installed on every

air handler/coil. Fixed orifice or cap tube systems should not

be used.

• Minimum of two (2) blower speeds

Utilizing Existing Coil or Air Handler

It is recommended that a new R-410A air handler be installed with a

Outdoor Split considering the long term benefits of reliability, warranty,

etc. versus the short term installation cost savings. However, the

existing air handler may be retained provided the following:

• Coil currently is R-410Arated

• Coil uses a TXV. No capillary or fixed orifice systems should

be used

• Alife expectancy of more than 7 years remaining for the air

handler and components

• Flush air coil and line set

Safety Considerations

General Installation Information

ASTON DUAL-CAPACITY OUTDOOR SPLIT SERIES INSTALLATION MANUAL