5

ASTON LOW SILL SERIES INSTALLATION MANUAL

Safety Considerations

WARNING: Before performing service or maintenance

operations on a system, turn off main power switches

to the indoor unit. If applicable, turn off the accessory

heater power switch. Electrical shock could cause

personal injury.

Installing and servicing heating and air conditioning equipment can

be hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install, repair

or service heating and air conditioning equipment. Untrained

personnel can perform the basic maintenance functions of cleaning

coils and cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working on

heating and air conditioning equipment, observe precautions in

the literature, tags and labels attached to the unit and other safety

precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves.

Use a quenching cloth for brazing operations and have a fire

extinguisher available.

Moving and Storage

Move units in the normal “up” orientation. Do not stack units. When

the equipment is received, all items should be carefully checked

against the bill of lading to be sure all crates and cartons have

been received. Examine units for shipping damage, removing the

units from the packaging if necessary. Units in question should also

be internally inspected. If any damage is noted, the carrier should

make the proper notation on the delivery receipt, acknowledging

the damage.

Water Piping

The proper water flow must be provided to each unit whenever the

unit operates. To assure proper flow, use pressure/temperature

ports to determine the flow rate. These ports should be located at

the supply and return water connections on the unit. The proper

flow rate cannot be accurately set without measuring the water

pressure drop through the refrigerant-to-water heat exchanger.

All source water connections on commercial units are fittings that

accept a male pipe thread (MPT). Insert the connectors by hand,

then tighten the fitting with a wrench to provide a leakproof joint.

When connecting to an open loop (groundwater) system, thread

any copper MPT fitting into the connector and tighten in the same

manner as described above.

Refrigerant Systems

To maintain sealed circuit integrity, do not install service gauges

unless unit operation appears abnormal. Compare the change in

temperature on the air side as well as the water side to the Unit

Operating Parameters tables. If the unit’s performance is not

within the ranges listed, and the airflow and water flow are known

to be correct, gauges should then be installed and superheat and

subcooling numbers calculated. If superheat and subcooling are

outside recommended ranges, an adjustment to the refrigerant

charge may be necessary.

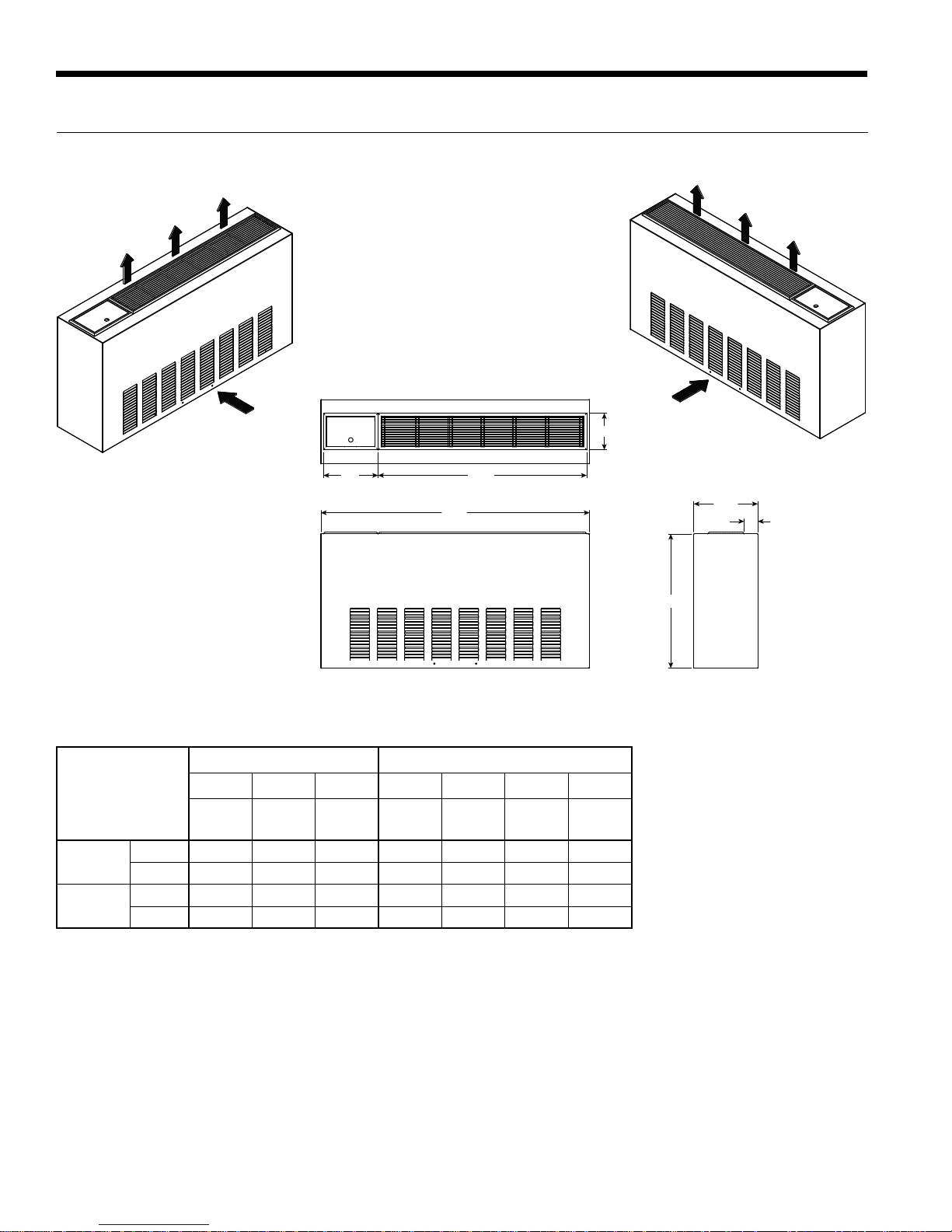

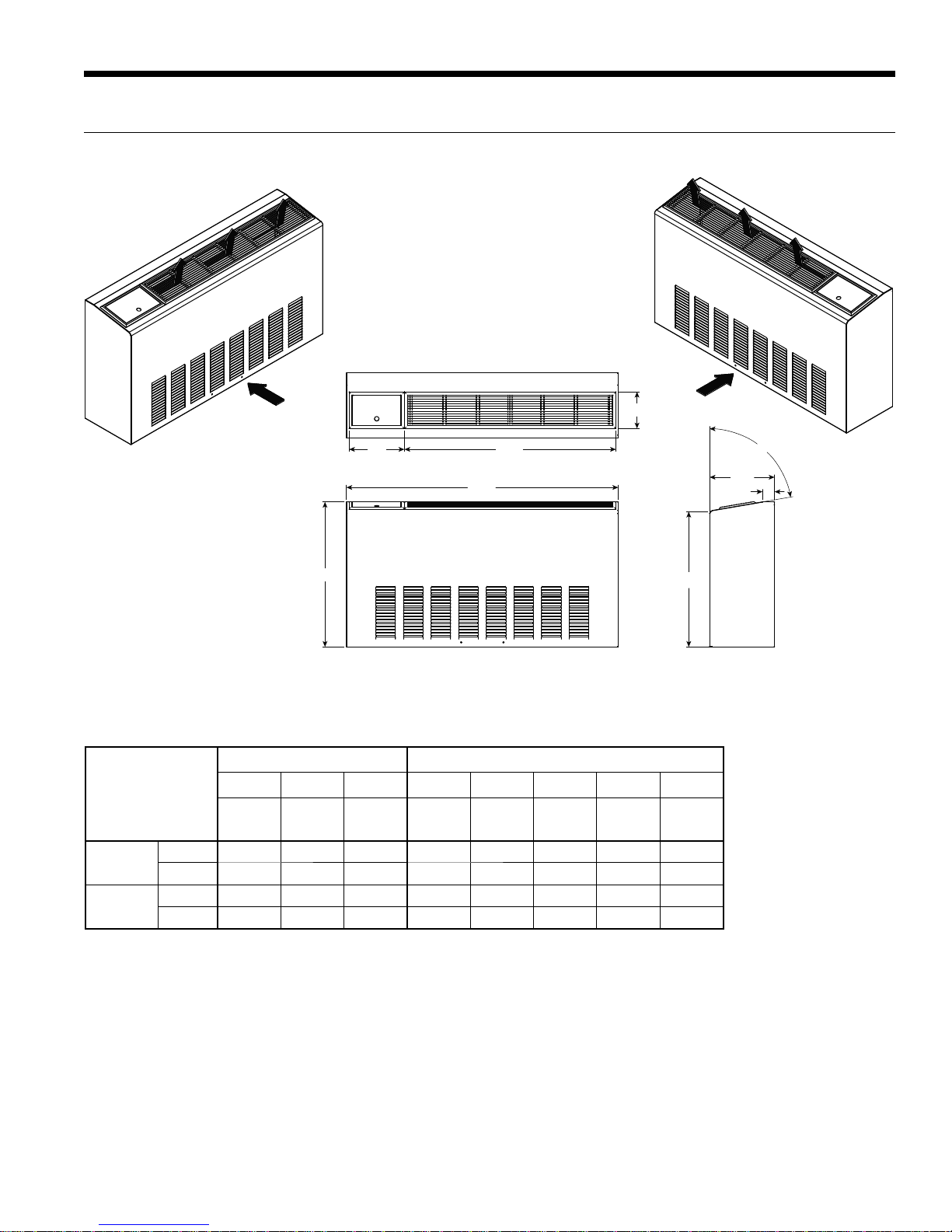

General Installation Information