Contractor: P.O.:

Engineer:

Project Name: Unit Tag:

Blower Performance Data

ECM Speed Info

1

▶2◀G

3

4

5

6

7

8

9

10

11

12

Option ◀▶ Enter ◙

ECM Speed Info

1

2G

▶3◀Lo

4

5

6

7

8

9

10

11

12

Option ◀▶ Enter ◙

ECM Speed Info

1

2G

3Lo

4

5

▶6◀Hi

7

8

9

10

11

12

Option ◀▶ Enter ◙

ECM Speed Info

1

2G

3Lo

4

5

6Hi

7

8

9

▶10 ◀Aux

11

12

Option ◀▶ Enter ◙

ECM Speed Info

Blower Only Speed 3

Lo Compressor 6

Hi Compressor 9

Aux Heat 10

Want To Change?

Yes

Option ◀▶

No

Enter ◙

Cooling Airflow Setup

--- ECM Only ---

The airflow will be

adjusted by the chosen

amount in cooling mode.

Adjustment:

-15%

Want To Change?

Yes

Option ◀▶

No

Enter ◙

Cooling Airflow Setup

--- ECM Only ---

The airflow will be

adjusted by the chosen

amount in cooling mode.

Adjustment:

-15%

Change ▼▲ Enter ◙

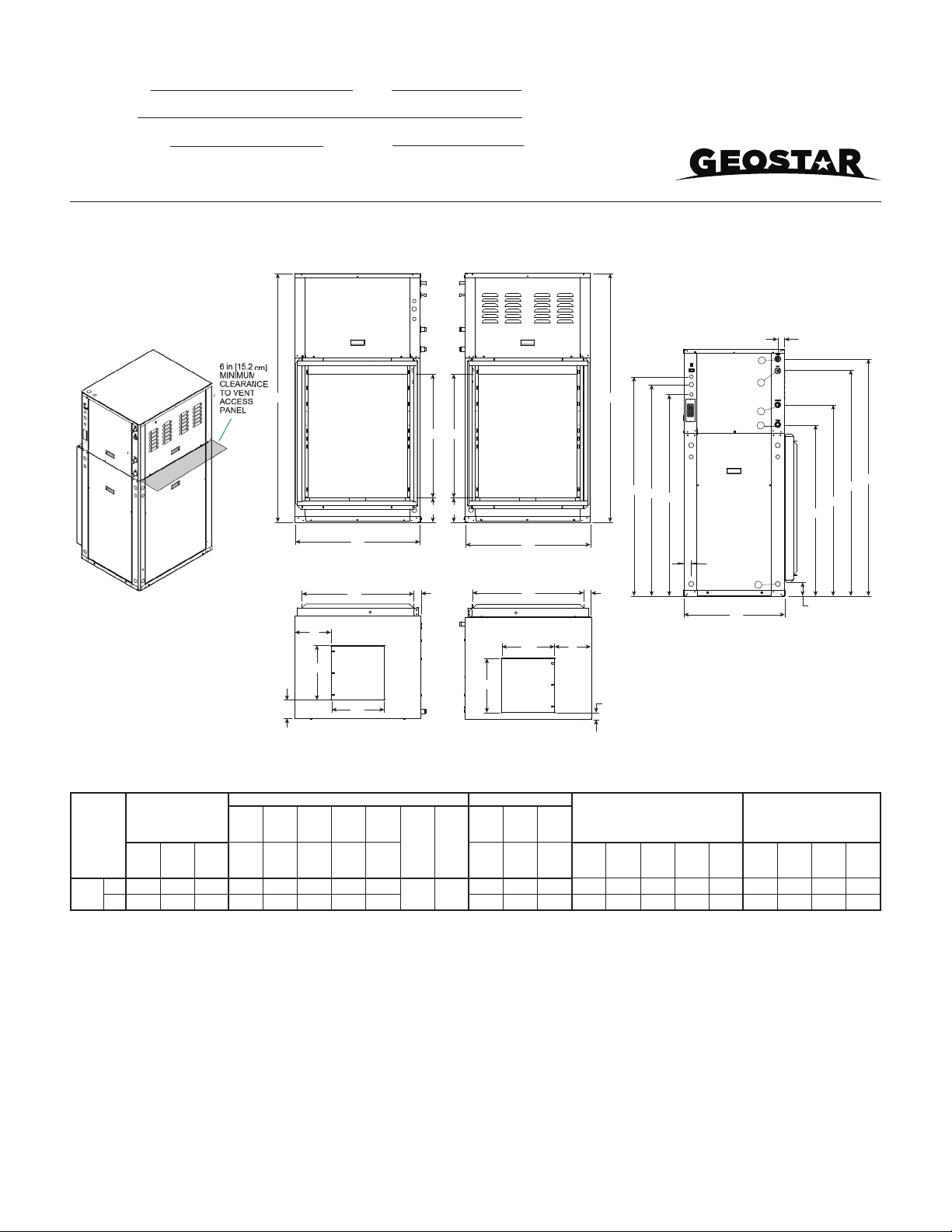

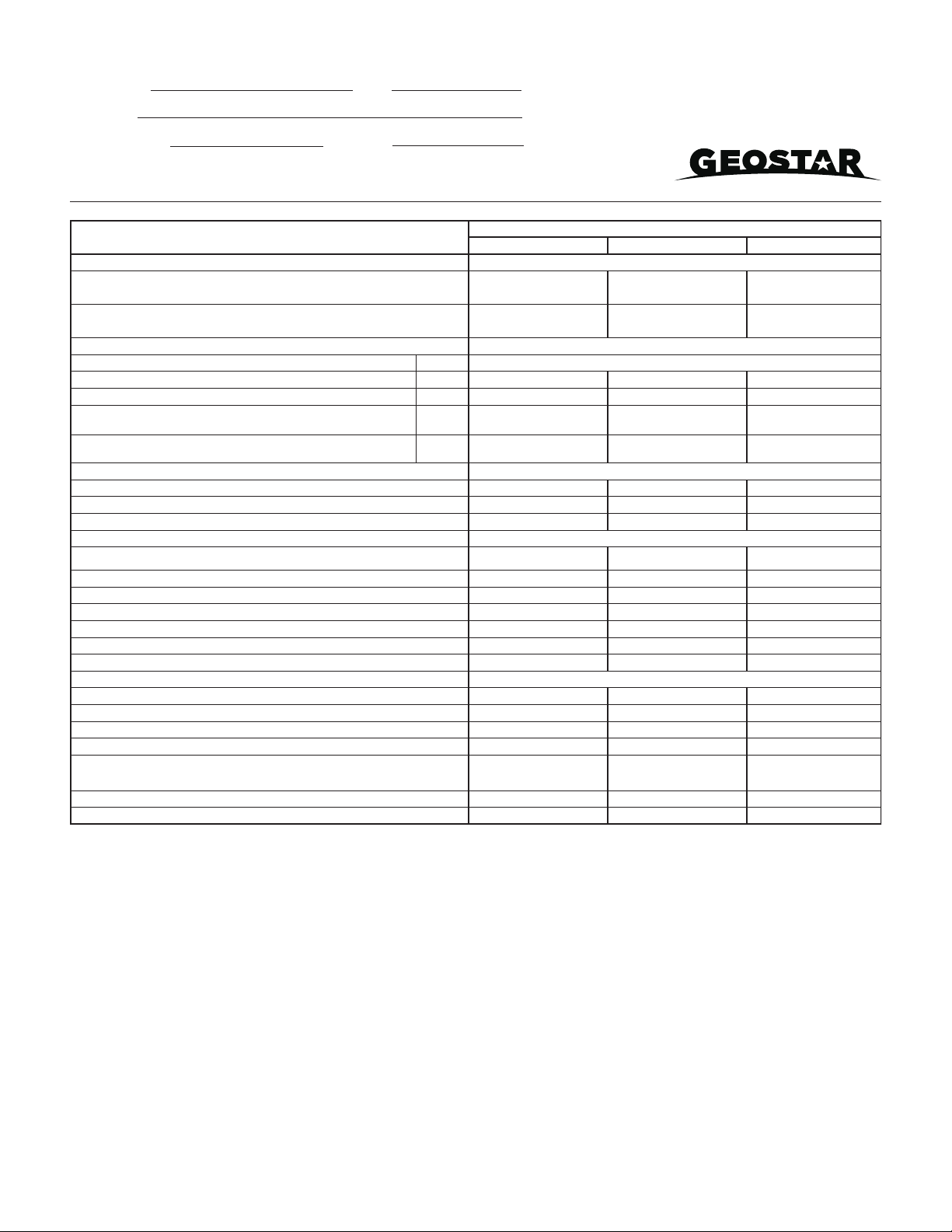

Setting Blower Speed - Variable Speed ECM

The ABC board’s Yellow Config LED will flash the current ECM

blower speed selections for G, low, and high continuously with a

short pause in between. The speeds can also be confirmed with the

ID Tool under the Setup/ECM Setup screen. The Aux will not be

flashed but can be viewed in the AID Tool. The ECM blower motor

speeds can be field adjusted with or without using an AID Tool.

ariable Speed ECM Setup without an AID Tool

The blower speeds for G only, Low (Y1), and High (Y2/Aux) can be

adjusted directly at the Aurora ABC board which utilizes the push

button (SW1) on the ABC board. This procedure is outlined in the

ECM Configuration Mode portion of the Aurora ‘Base’ Control System

section. The Aux cannot be set manually without an AID Tool.

ariable Speed ECM Setup with an AID Tool

much easier method utilizes the AID Tool to change the airflow

using the procedure below. First navigate to the Setup screen and

then select ECM Setup. This screen displays the current ECM

settings. It allows the technician to enter the setup screens to

change the ECM settings. Change the highlighted item using the

◀and ▶buttons and then press the ◙button to select the item.

Selecting YES will enter ECM speed

setup, while selecting NO will return to

the previous screen.

ECM Speed Setup - These screens allow the technician to select

the G, low, high, and auxiliary heat blower speed for the ECM

blower motor. Change the highlighted item using the ▲and ▼

buttons. Press the ◙button to select the speed.

After the auxiliary heat speed setting is selected the AID Tool will

automatically transfer back to the ECM Setup screen.

Cooling Airflow Setup - These screens allow the technician to select

-15%, -10%, -5%, None or +5% change from the heating airflow.

Change the adjustment percentage using the ▲and ▼buttons.

Press the ◙button to save the change.

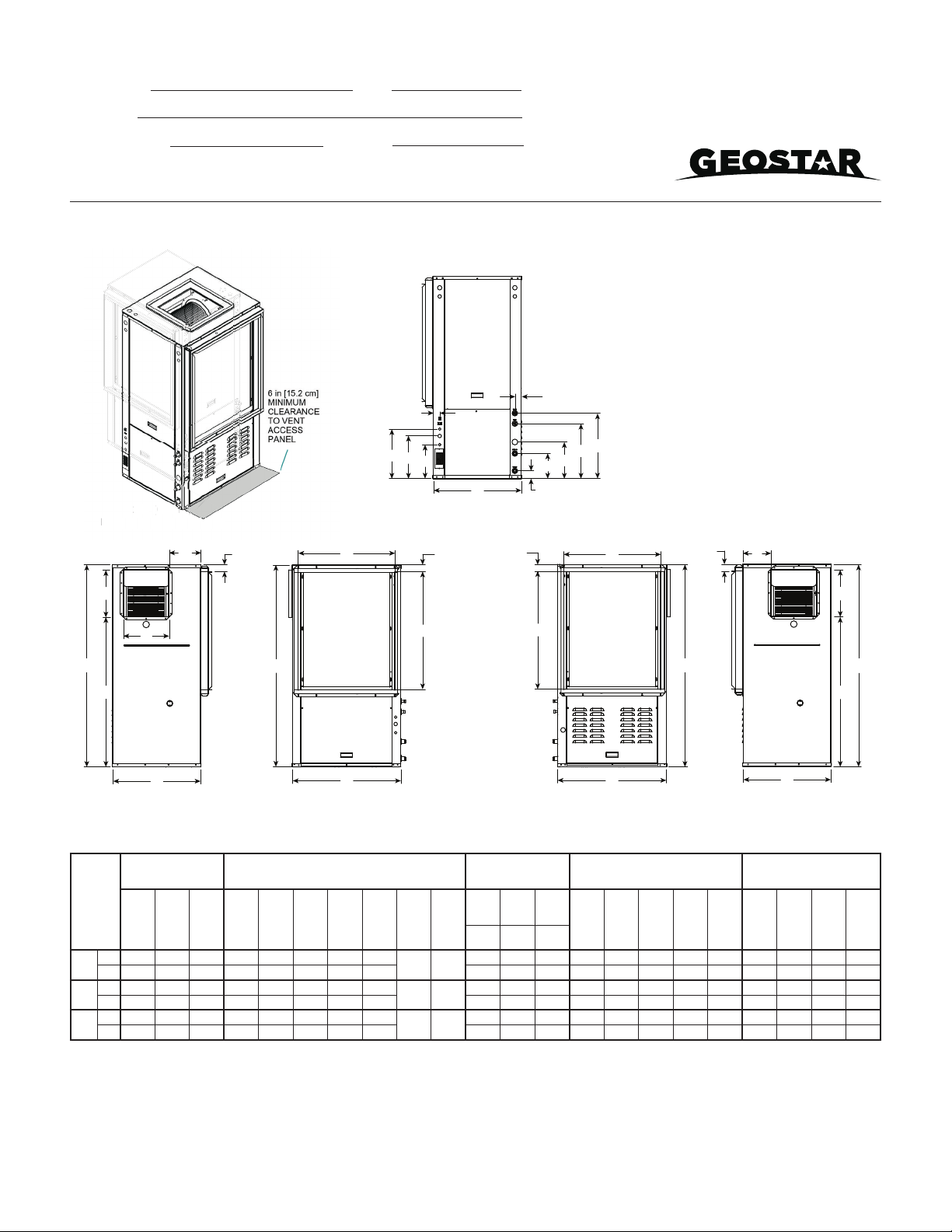

Variable Speed ECM Blower Motor

Model

Air Flow

Max

ESP

Speed

1

Speed

2

Speed

3

Speed

4

Speed

5

Speed

6

Speed

7

Speed

8

Speed

9

Speed

10

Speed

11

Speed

12

036 0.50 285 380

G

525

L

675 815 980 1100 1220 1330 1440

H

1540

Aux

1575

036 w/1hp* 0.75 480 565

G

665

L

761 870 1000 1100 1200 1300 1410

H

1520

Aux

1630

048 0.75 475 620

G

730

L

850 1020 1140 1270 1400 1520 1650

H

1790

Aux

1925

060 0.75 400 600

G

830

L

1050 1230 1400 1560 1700 1870 2010

H

2140

Aux

2265

**VS Compressor Speed 1-2 3-4 5-6 7-8 9-10 11-12

** VS Compressor speed is given for the factory default cfm settings. When the cfm default settings are changed it will change the relationship to the

compressor speed that is shown in the table. In cooling mode compressor speeds 10-12 are only available when SuperBoost mode is selected at the

thermostat.

* Optional 1 hp Variable Speed ECM

Factory settings are at recommended L , H and Aux positions

“G” may be located anywhere within the airflow table

“L” setting should be located within the boldface cfm range

“H” setting MUST be located within the shaded cfm range

“Aux” setting MUST be equal to or greater than “H” setting

“Aux” setting MUST be equal to or greater than the minimum allowable cfm for the auxiliary heater kit (see auxiliary heat ratings table)

Cfm is controlled within 5% up to the maximum ESP

Max ESP includes allowance for wet coil and standard filter

6/7/12

SD2700AGA 02/21 10 Page _____ of _____

Sycamore Series

3 - 5 Tons 60Hz

The manufacturer works continually to improve its products. As a result, the design and specifications of each product at the time of order may be changed without notice. Purchaser’s approval of this data set signifies that the equipment is acceptable under the provisions

of the job specification. Statements and other information contained herein are not express warranties and do not form the basis of any bargain between the parties, but are merely the manufacturer’s opinion or commendation of its products.