TEMPHION INSTRUCTIONS

Seametrics • 253.872.0284 Page 3 seametrics.com

General Information

General Information ...................................................................................................................................................Page 4

Dimensions ....................................................................................................................................................................Page 4

Specications ................................................................................................................................................................Page 5

Initial Inspection and Handling..............................................................................................................................Page 6

Do’s and Don’ts............................................................................................................................................................Page 6

TempHion Reference Electrode..............................................................................................................................Page 7

General Precautions....................................................................................................................................................Page 7

Installation

Connecting External Power......................................................................................................................................Page 8

Connecting a TempHion to a Computer ............................................................................................................Page 8

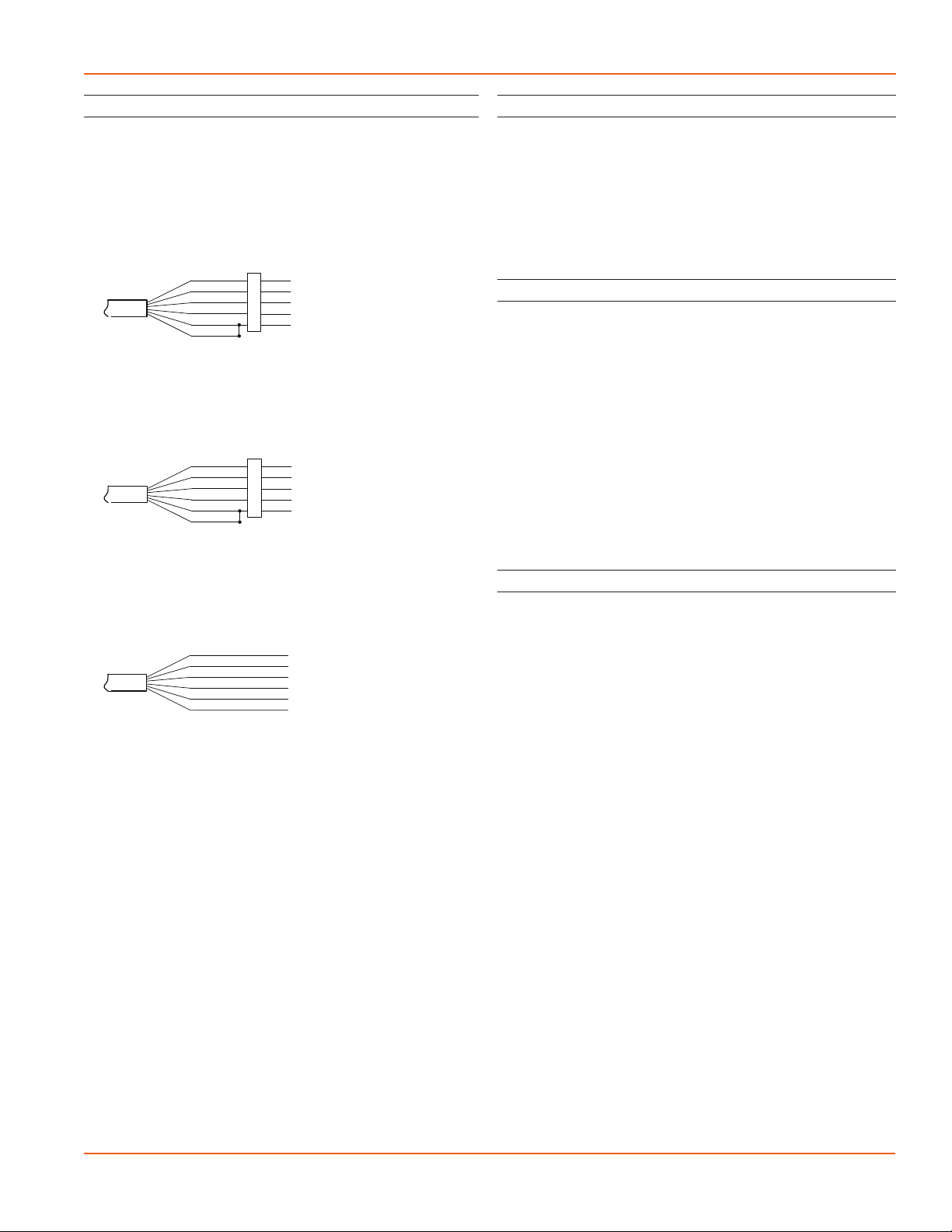

Cable Wiring..................................................................................................................................................................Page 9

Installing Aqua4Plus or Aqua4Plus Lite Software ...........................................................................................Page 9

Using Without Aqua4Plus or Aqua4Plus Lite Software ................................................................................Page 9

Grounding Issues.........................................................................................................................................................Page 9

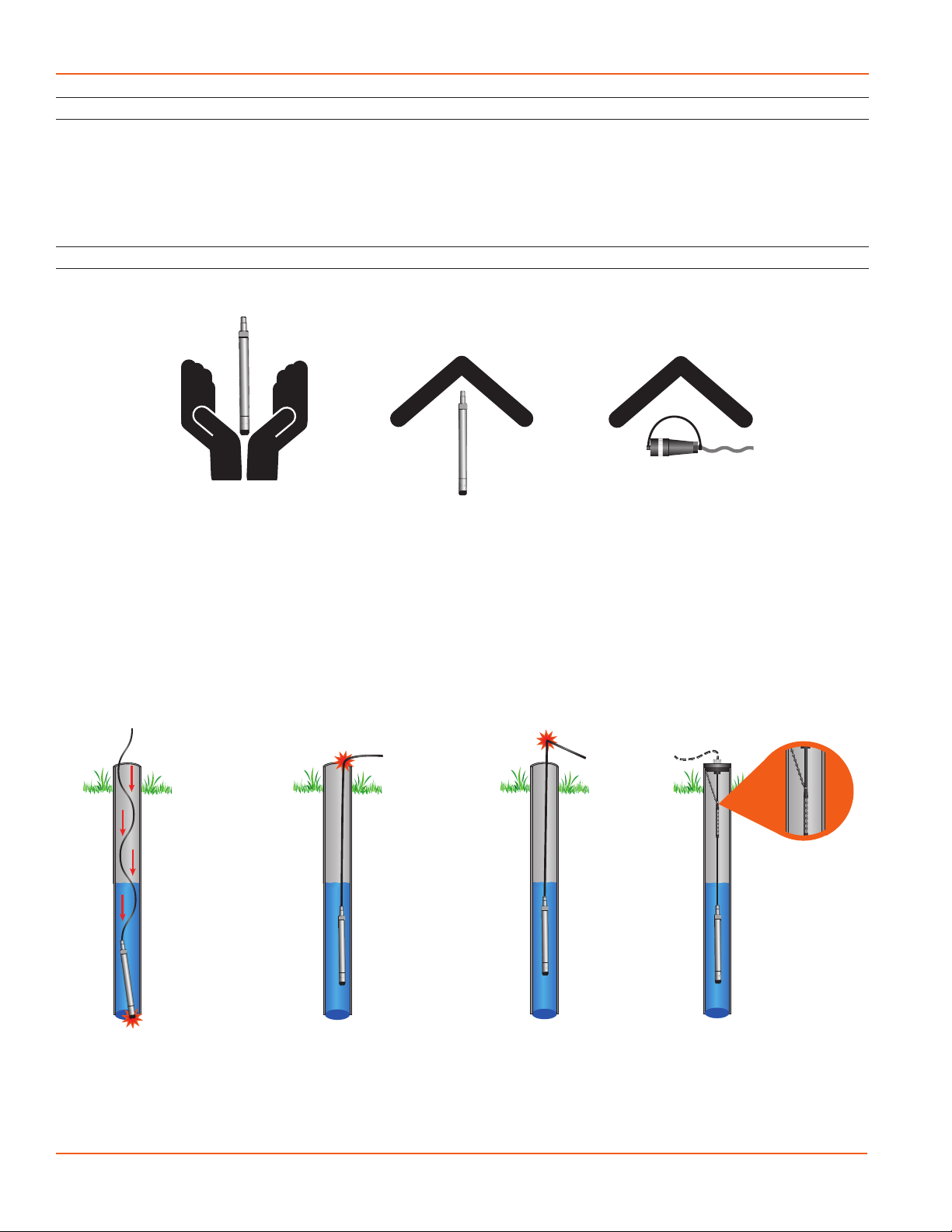

Installing the Sensor...................................................................................................................................................Page 10

Settings and Calibration

General Calibration Information............................................................................................................................Page 11

Important Calibration Notes ...................................................................................................................................Page 11

pH Channel ....................................................................................................................................................................Page 12

Pressure Channel .........................................................................................................................................................Page 12

ISE Channel ....................................................................................................................................................................Page 13

ORP (Redox) .................................................................................................................................................................Page 15

Operation

Collecting Data with Aqua4Plus and Aqua4Plus Lite ....................................................................................Page 16

Real Time Monitor.......................................................................................................................................................Page 16

Setting up Data Recording ......................................................................................................................................Page 16

Retrieving Data.............................................................................................................................................................Page 16

Viewing Data .................................................................................................................................................................Page 16

Exporting Data..............................................................................................................................................................Page 17

A Word about Units....................................................................................................................................................Page 17

Direct Read Modbus/SDI-12

Setting Units for Direct Read ..................................................................................................................................Page 17

Power Consideration ..................................................................................................................................................Page 18

Reading via Modbus RTU .........................................................................................................................................Page 18

Reading via SDI-12......................................................................................................................................................Page 19

Maintenance and Reference

Sensor/Cable/End Connections .............................................................................................................................Page 21

Care and Filling of Reference Solution................................................................................................................Page 21

pH Field Calibration Temperature Chart.............................................................................................................Page 22

M & I Range for pH Calibration.............................................................................................................................Page 22

How to Store and Recondition...............................................................................................................................Page 22

Changing Batteries......................................................................................................................................................Page 23

Troubleshooting

Problems/Probable Causes/Things to Try..........................................................................................................Page 26

TABLE OF CONTENTS

IF USING ALKALINE BATTERIES—PREVENT BATTERY LEAKAGE!

TempHion sensors are typically shipped with lithium batteries. If, however,

you are using alkaline batteries, be aware that under some circumstances

alkaline batteries can leak, causing damage to the sensor. To prevent leakage,

the following is recommended. (Does not apply to lithium batteries.)

• Change the batteries at least every 18 months.

• If the sensor will not be deployed for 3 months or more, remove the

batteries.