Setra Systems 256 User manual

Installation Guide

1-800-257-3872 Toll Free

1-978-264-0292 Fax

www.setra.com Web Site

✓

Certified

ISO

9001

Model 256

Gage Pressure Transducer

Industrial

HVAC

Test &Measurement

Barometric

UltraHighPurity/Sanitary

Setra offers a complete line of

products for these industries:

Table of Contents

1.0 GENERAL INFORMATION............................................................................................... 4

2.0 MECHANICALINSTALLATION ...................................................................................... 4

2.1 MediaCompatibility.......................................................................................... 4

2.2 Environment......................................................................................................... 4

2.3 Pressure Fittings .................................................................................................. 4

2.4 Moisture Precautions ........................................................................................ 4

2.5 Venting ................................................................................................................... 4

2.6 Mounting Accessories....................................................................................... 5

3.0 ELECTRICAL INSTALLATION.......................................................................................... 5

3.1 Voltage Output Units......................................................................................... 5

3.2 Current Output Units ........................................................................................ 6

4.0. CALIBRATION .................................................................................................................... 6

4.1 Voltage Output Zero Adjustment ................................................................. 6

4.2 Voltage Output Span Adjustment ................................................................ 7

4.3 Current Output Zero Adjustment................................................................. 7

4.4 Current Output SpanAdjustment................................................................ 7

5.0 MODEL 256 PERFORMANCE SPECIFICATIONS....................................................... 7

6.0 RETURNING PRODUCTSFORREPAIR......................................................................... 8

7.0 WARRANTY AND LIMITATION OF LIABILITY............................................................ 8

4

Setra Model 256

PressureTransducer

1.0 GENERAL INFORMATION

Every Model 256 has been tested and calibrated before shipment. Specific

performance specificationsare listed on Page 7 ofthis Guide.

Setra Systems 256 pressure transducers sense gage pressure and convert this

pressureto aproportional high levelanalog output. Two output versionsare

offered: Avoltageoutputof .1to 5.1VDC,andacurrent outputof 4to 20 mA.

2.0 MECHANICAL INSTALLATION

2.1 Media Compatibility

Model 256 transducers are designed to be used with any gas or liquid compat-

ible with 17-4 PH Stainless Steel. (Hydrogen is not recommended for use with

17-4PH SS.)

2.2 Environment

The operating temperature limits of the 256 are as follows:

OperatingTemperature Range °F (C°) -40to +260 (-40 to +125)

CompensatedTemperature Range°F (C°) -4 to +176 (-20 to +80)

2.3 Pressure Fittings

Typically,standard pipefittings andinstallationproceduresshouldbeused.

However,forvery high pressure ranges in excessof 500 psig,we suggest the

use of a sealant such as Loctite Hydraulic Sealant. Excessive high torquing of

metal fittings may cause a slight shift of the output,but this shift can be

trimmed out by the zero adjustment. Torquingdoesnot significantly affect

linearityor sensitivity.

2.4 Moisture Precautions

The Model 256 is provided with two 1/2”NPT female conduit ports for electrical

termination. These tapered pipe threads are tapped deeper than the NPT

standard,in accordance with industry guidelines. These ports must be sealed

according to standard industry practice,in order to prevent moisture ingress

intothe Model 256.

2.5 Venting

TheModel256 is a true gagepressuretransducer. Thismeans that the

reference side of the pressure sensing diaphragm must be vented to atmo-

sphere. Ifthe reference side of the diaphragm weresealed (asin a sealed gage

transducer),temperaturechanges wouldcausethe referencepressuretovary.

Thismayaffectthe overallaccuracy,especiallyin ranges lowerthan 500 psig.

The Model 256 provides a vent from the reference side of thesensor to the

insideof the housing and the conduit ports. The user-providedelectrical

conduit must be vented to atmosphere in a clean dry location. (It is important

to prevent moisture ingress from the environment into the wiring chamber

or reference side of the transducer.)

+EXC

EXC

GND

OUT

+ OUT

Voltage Connections

Current Connections

Screw Terminal

Designations

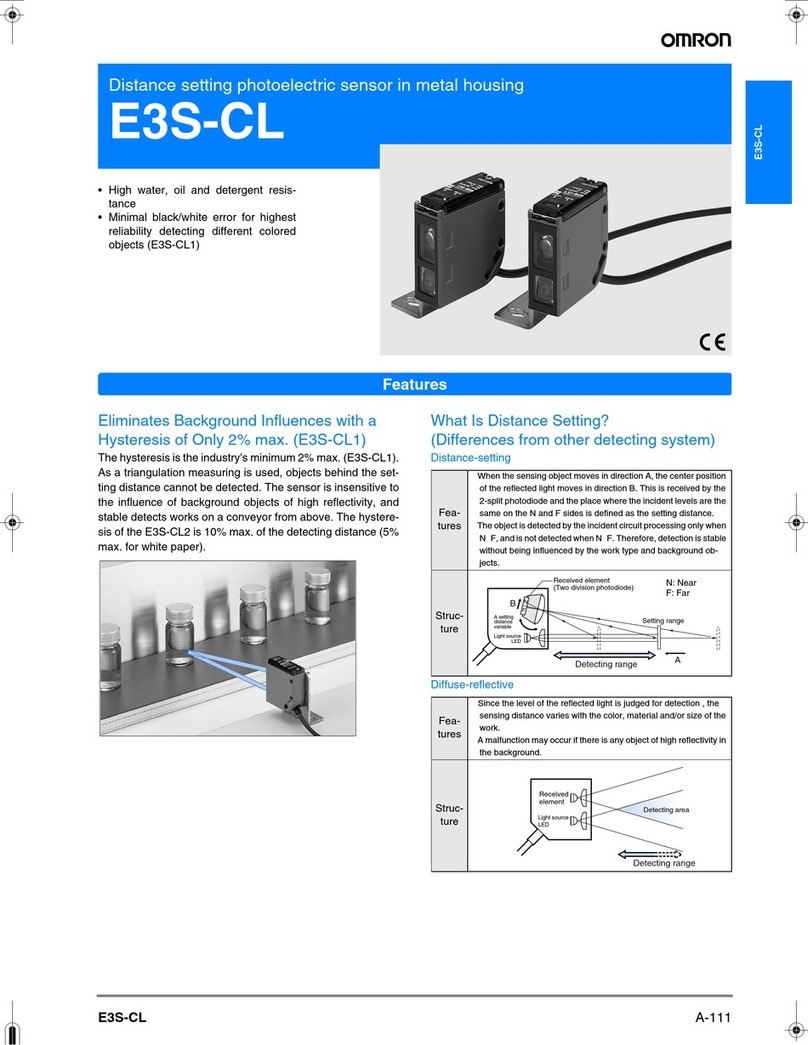

Diagram 1

+EXC

EXC

GND

Diagram 2

Removable

Zero/Span

Access Plugs

Removable

Terminal Block

Connector

5

3.1Voltage Output Units

The Model 256 is a 3-wire circuit. The -EXC and -OUT are commoned on the

circuit. The 256 can operate from a 12 to 28VDC excitation. The 256 has a 0.1-

5.1VDC output.

+ Excitation;connect to 12-28VDC powersupply

+ Output;connect to controller or monitor

–Output;connect to controller or monitor

–Excitation;connect to return of 12-28V power supply

GND Connect to system or earth ground

The Model 256can be wiredas a threewire deviceby connecting –output,

excitationand shield to a common ground.However,accuracywill be reduced

with increase in lead resistance.

2.6 Mounting Accessories

TheModel256 is providedwith a bracket and

twohexboltsformounting and a1/2”NPT plug

for the unused conduit opening.The bracket is

suitable for mounting with a U-bolt or a band

clamp.There are1/4-20 UNC threadedholes on

theback of the 256 transducer fordirect mounting

and/orgrounding.

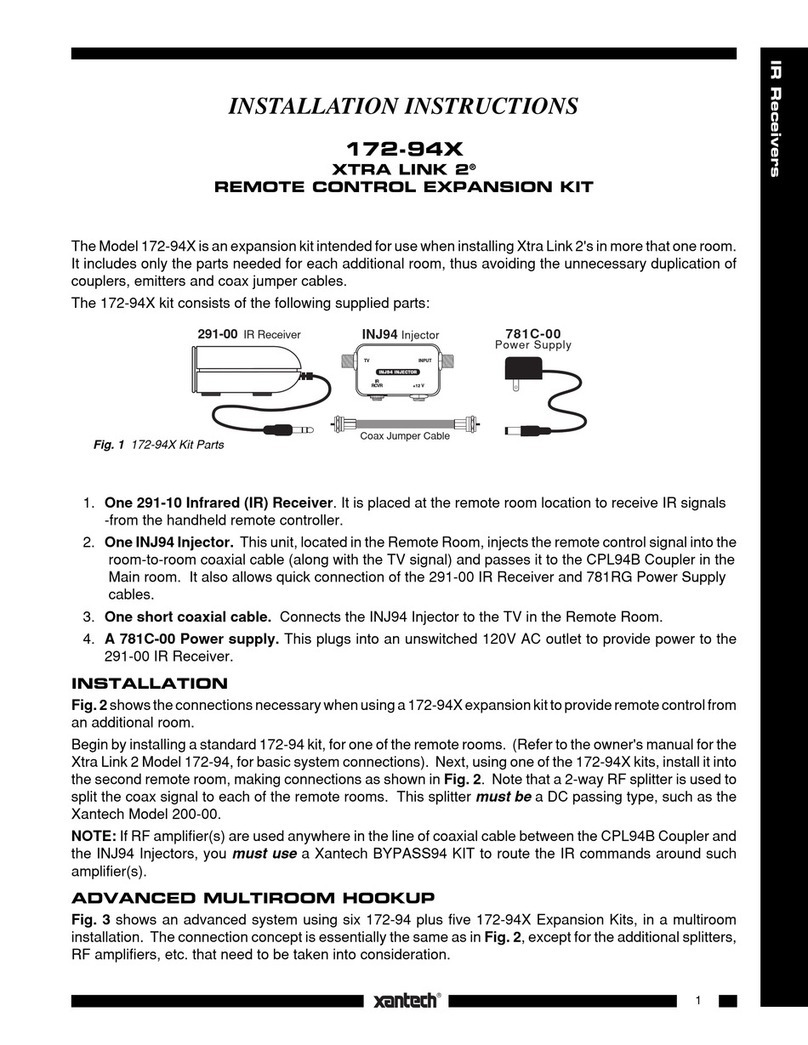

3.0 ELECTRICAL INSTALLATION

Wiring is through a 1/2”conduit opening. Remove the

screw cover to access the removable wiring terminal

block connector. The terminal block connector version

has five terminals for wiring +EXC,-EXC,GND,-OUT,and

+OUT(see Diagram1).

Removetheterminal blockconnector to facilitatewiringto screwterminals.

Refer to the terminal block connector label for terminal designations. (See

Diagram 2 for screw terminal designations.) After wiring,plug connector back

into pin socket and neatly tuck all wiring into wire recess cavity.

3.2 Current Output Units

The 4-20 mA current output units are designed to have current flow in one

direction only -PLEASEOBSERVEPOLARITY.

We suggest that the electrical conduit shield be connected to the system’s loop

circuit ground to improve electrical noise rejection.

The Model 256 is a two-wire loop-powered 4 to 20mA current output unit and

delivers rated current into any external load of 0-800 ohms.(See Diagram 2 for

location of +EXC and -EXC current output screw terminals.) The current flows

into the + terminal and returns back to the power supply through the

-terminal.(ThecenterGND terminal maybe used for shielding.) The power

supplymust be a DC voltage sourcewith a voltagerange between9 and 30

measured between the + and - terminals. The unit is calibrated at the factory

witha 24VDC loop supply voltageand a 250 ohm load.

Minimum SupplyVoltage(VDC)= 9+ 0.02x (resistanceofreceiverplus line).

Maximum SupplyVoltage (VDC) =30 +0.004 x(resistanceof receiverplus line).

4.0 CALIBRATION

The 256 transducer is factory calibrated and should require no field

adjustment. Whenever possible,any zero and/or span offsets should be

corrected by software adjustment in the user’s control system. However,both

zero and span adjustments are accessible by removing the screw top cover and

theadjustment accesscoverand turningthe potentiometer screw inside.(See

Diagram 1 for the location of the Zero and Span potentiometers.)

4.1 Voltage Output ZeroAdjustment

While monitoring the voltage between the positive output (+OUT) and

negativeoutput (–OUT),and with the pressureportopen toatmosphere,or

with zero pressure applied,the zero may be adjusted by turning the zero

potentiometerscrew. The factorysetting is0.1VDC (±25mV).

Note:–OUT and –EXC are commoned on the circuit.

4.2 Voltage Output Span Adjustment (Complete the zero adjust-

mentbeforesetting span.)

Span or full scale output adjustments should only be performed by using an

accuratepressure standard(electronicmanometer,digitalpressuregage,etc.),

with at least comparable accuracy to the 256 transducer. With full

range pressure applied to the pressure port,the span may be adjusted by

turning the span potentiometer screw. The factory setting is 5.1VDC (±50mV).

6

4.3 Current Output Zero Adjustment

While monitoring the current output,and with the pressure port open to

atmosphere or with zero pressure applied,the zero may be adjusted by turning

the zero potentiometer screw. The factory setting is 4mA (±.08mA).

4.4 Current Output Span Adjustment

Span or full scale output adjustments should only be performed by using an

accurate pressure standard (electronic manometer,digital pressure gage,etc.)

with at least comparable accuracy to the 256 transducer. With full range

pressure applied to the pressure port,the span may be adjusted by turning the

spanpotentiometerscrew. The factorysetting is 20mA (±.16mA).

5.0 MODEL 256 PERFORMANCE SPECIFICATIONS

For Ranges For Ranges

25 PSI and Higher Less Than 25 PSI

AccuracyRSS*(atconstanttemperature.) ±.13%FS ±0.25%FS

Non-Linearity,BFSL ±0.1%FS ±0.22%FS

Hysteresis 0.08%FS 0.10%FS

Non-Repeatability 0.02%FS 0.05%FS

*RSSofNon-Linearity,Non-RepeatabilityandHysteresis.

ThermalEffects

CompensatedRange°F(°C) -4to+176(-20to+80) -4to+176(-20to+80)

ZeroShift%FS/100°F(50°C) ±1.0(±0.9) ±2.0(±1.8)

SpanShift%FS/100°F(50°C) ±1.5(±1.4) ±1.5(±1.3)

Warm-upShift ±0.1%FStotal ±0.1%FStotal

7

8

6.0 RETURNING PRODUCTS FOR REPAIR

Pleasecontact a Setra Systemsapplication engineer (1-800-257-3872,1-978-263-1400)

beforereturningunit forrepairtoreview informationrelativetoyour application.

Many times only minor field adjustments maybe necessary.When returning a product

toSetra Systems,thematerialshould be carefully packaged and shipped prepaidto:

Setra Systems,Inc.

159Swanson Road

Boxborough,MA 01719-1304

Attn:Repair Department

To assure prompt handling,please supply the following information and include it

insidethe packageor returnedmaterial:

1. Name and phone number of person to contact.

2. Shippingand billing instructions.

3. Full description of the malfunction.

4. Identify any hazardous material used with product.

Notes: Please remove any pressure fittings and plumbing that you have installed and

enclose any required mating electrical connectors and wiring diagrams.

Allowapproximately 3 weeks after receiptat SetraSystemsforthe repair and return of

theunit.Non-warrantyrepairs will not be made without customerapprovaland a

purchase order to cover repair charges.

CalibrationServices

Setra maintains a completecalibration facility that is traceable to the National Institute

of Standards &Technology (NIST). If you would like to recalibrate or recertify your

Setra pressure transducers or transmitters,please call our Repair Department at 800-

257-3872(978-263-1400) for scheduling.

7.0 WARRANTY AND LIMITATION OF LIABILITY

SETRAwarrantsitsproductstobefreefromdefectsinmaterialsandworkmanship,subjecttothefollowingtermsandconditions: Withoutcharge,SETRAwillrepairorreplace

productsfoundtobedefectiveinmaterialsorworkmanshipwithinthewarrantyperiod;providedthat:

a) theproducthasnotbeensubjectedtoabuse,neglect,accident,incorrectwiringnotourown,improperinstallationorservicing,oruseinviolationofinstructions

furnishedbySETRA;

b) theproducthasnotbeenrepairedoralteredbyanyoneexceptSETRAoritsauthorizedserviceagencies;

c) theserialnumberordatecodehasnotbeenremoved,defaced,orotherwisechanged;and

d) examinationdiscloses,inthejudgmentofSETRA,thedefectinmaterialsorworkmanshipdevelopedundernormalinstallation,useandservice;

e) SETRAisnotifiedinadvanceofandtheproductisreturnedtoSETRAtransportationprepaid.

Unlessotherwisespecifiedinamanualorwarrantycard,oragreedtoinwritingandsignedbyaSETRAofficer,SETRApressureandaccelerationproductsshallbewarrantedfor

oneyearfromdateofsale.

Theforegoingwarrantyisinlieuofallwarranties,express,impliedorstatutory,includingbutnotlimitedto,anyimpliedwarrantyofmerchantabilityforaparticularpurpose.

SETRA’sliabilityforbreachofwarrantyislimitedtorepairorreplacement,orifthegoodscannotberepairedorreplaced,toarefundofthepurchaseprice. SETRA’sliabilityforall

otherbreachesislimitedtoarefundofthepurchaseprice. InnoinstanceshallSETRAbeliableforincidentalorconsequentialdamagesarisingfromabreachofwarranty,or

fromtheuseorinstallationofitsproducts.

NorepresentativeorpersonisauthorizedtogiveanywarrantyotherthanassetoutaboveortoassumeforSETRAanyotherliabilityinconnectionwiththesaleofits

products.

SS2033 Rev.F 02/04/02

159SwansonRoad,Boxborough,MA01719

TollFree:(800)257-3872,Fax:(978)264-0292

Table of contents

Other Setra Systems Accessories manuals

Popular Accessories manuals by other brands

WBOX Technologies

WBOX Technologies 0E-PIRCM Installation

Waeco

Waeco ColdMachine 54 operating manual

Invisible systems

Invisible systems QC0161 installation manual

aci

aci Room Series Installation & operation instructions

Tait

Tait TB7100 Installation and operation manual

Xantech

Xantech 172-94X installation instructions