3

Section 1: System Description

Function and Theory

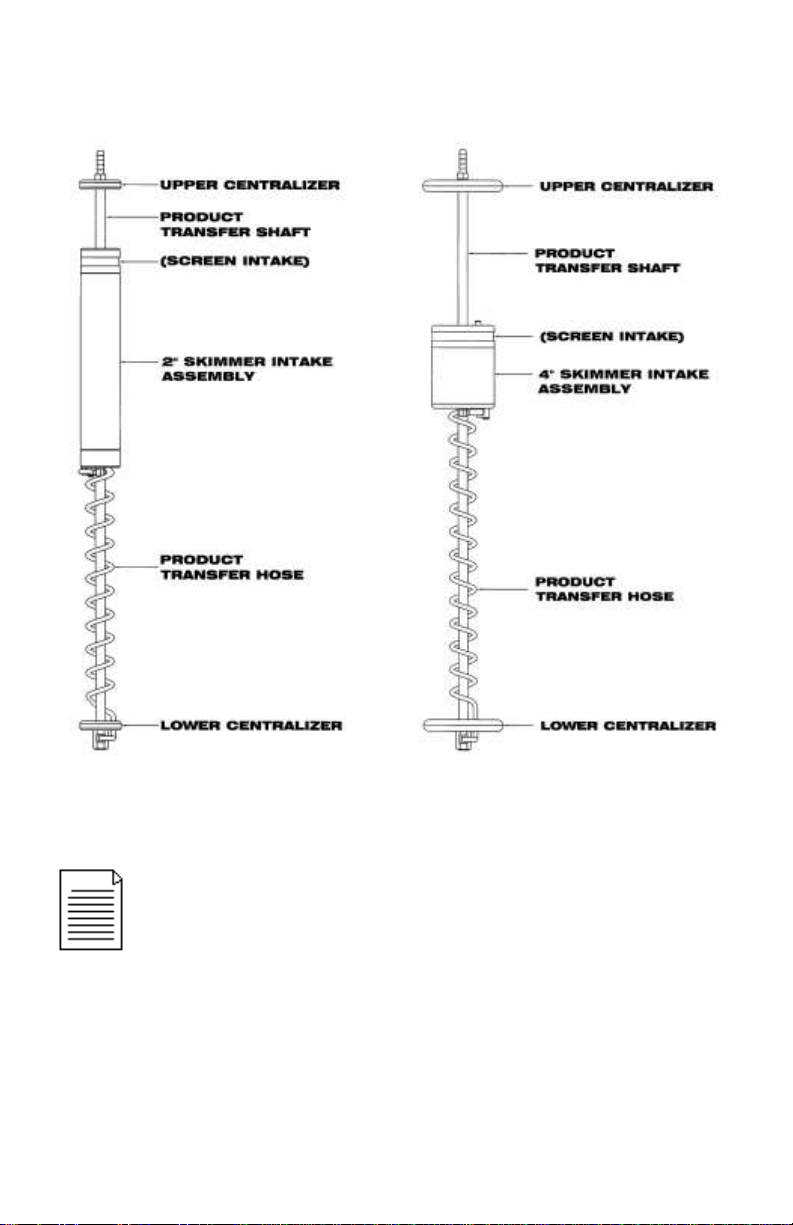

The Geotech Product Recovery System (PRS)

efficiently collects free-floating hydrocarbons in

2” (5 cm) or larger recovery wells. The system

consists of a stainless steel bladder pump, an

attached Skimmer with floating intake cartridge

(or buoy), a control panel that can be mounted

indoors or out, an optional Tankfull Shut-off

Sensor, air and discharge lines, and an

optional air compressor.

The PRS’ unique product intake assembly, or

Skimmer, incorporates both a density float and

an oleophilic/hydrophobic filter that

differentiates between floating hydrocarbons

and water. The intake assembly follows the

water table fluctuations and places the screen

at the water/product interface, skimming light

product (such as gasoline or diesel fuel) down

to a sheen within the range of the float travel.

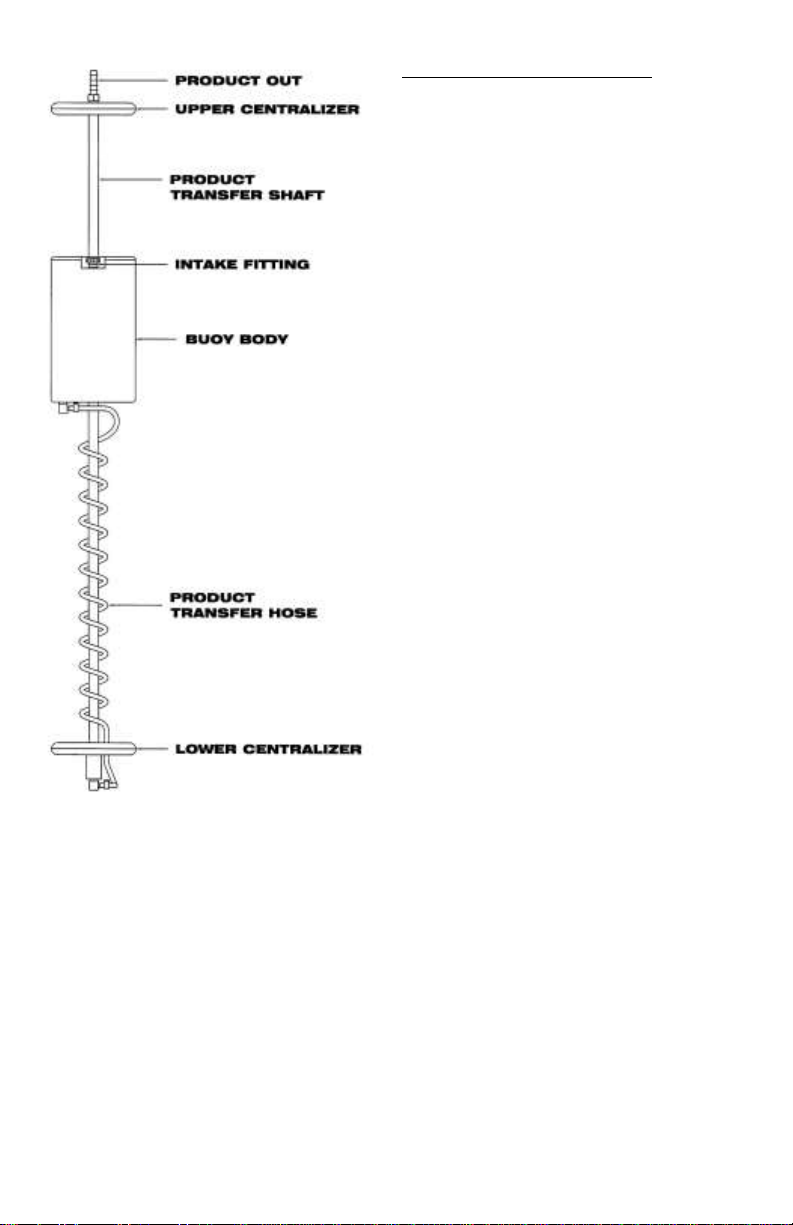

As the system cycles, product is drawn

through the intake screen and is transferred to

the pump through a coiled hose and the

Skimmer’s transfer shaft. Optional Heavy Oil

and High Temperature Skimmers, using intake

buoys, are also available to recover product in

4” (10 cm) diameter and larger wells.

The Product Recover System Control Panel

regulates the system and features two timers,

which vary the cycle time and flow rate of the

Skimmer pump. The control panel also

contains a level control valve (to which the

Tankfull Shut-off Sensor connects) that will

shut off the pump when the recovery tank is

filled.

The automatic stainless steel bladder pump has a two-phase pumping cycle. During the

first phase, or “pump intake”phase, pressurized air is vented from the pump, thus creating

a vacuum. This vacuum closes the top discharge check valve and opens the bottom

intake check valve, causing product to be drawn through the Skimmer’s product intake

assembly and into the pump.

During the second phase, or pump “discharge phase”, pressurized air is directed into the

pump bladder, causing it to expand within the pump body. This action closes the bottom