16

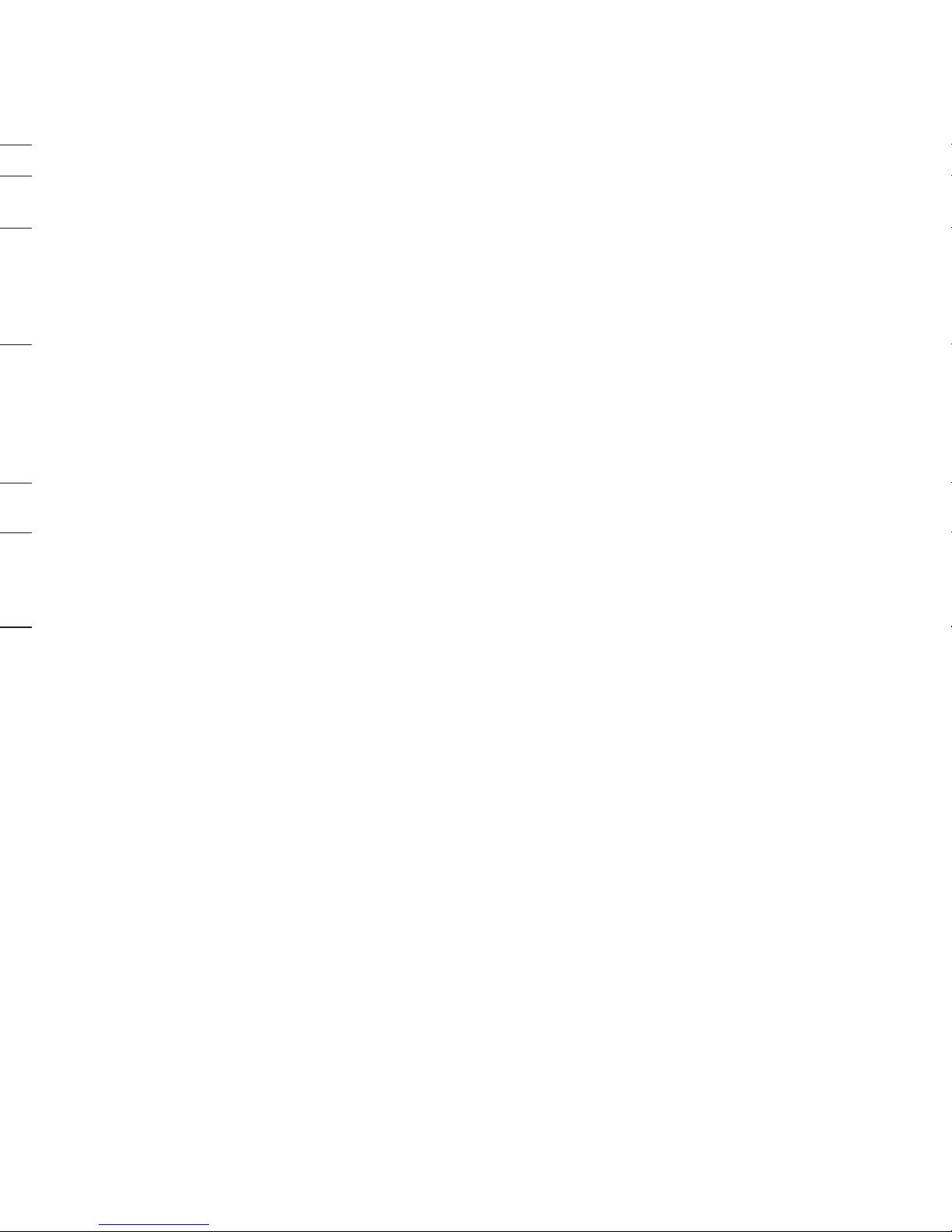

8. Detailed Features and Safety Devices

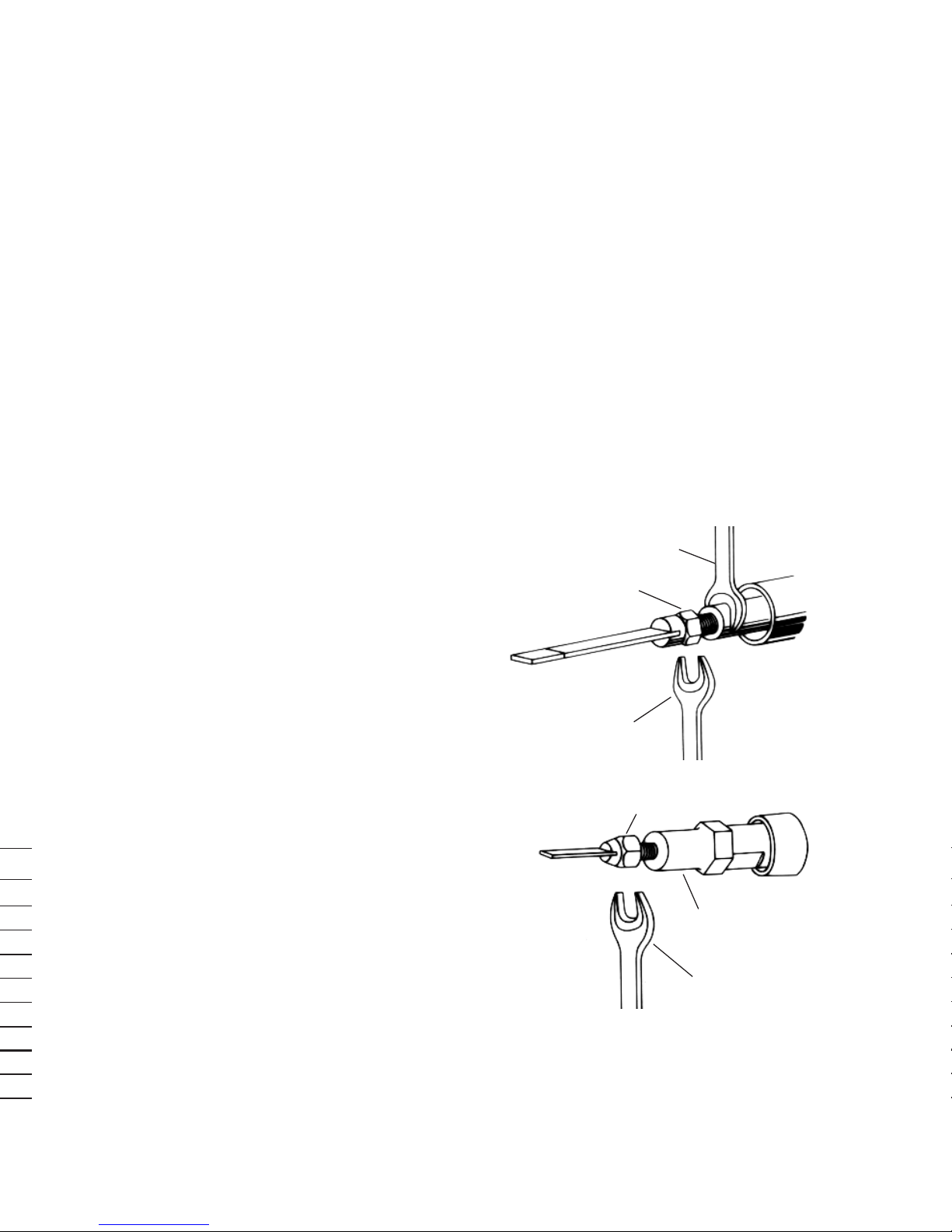

A. On/Off and Reset Switch (DF/SF) – Automatically turns off when ultrasonic

tool is improperly attached, insufficiently tightened or of the wrong size

(DF/SF); automatically turns off when Power Hand 2X rotary handpiece collet

release mechanism is left in the release position (DF only). To reset, attach

ultrasonic tool properly or move Power Hand 2X collet release mechanism to

the secure position, then turn switch on.

B. Regulated Power Feedback System (DF/SF) – Drops output power to minimum

when ultrasonic handpiece is lifted from the workpiece; returns output power to

last setting when ultrasonic handpiece reestablishes contact with the workpiece.

Increases handpiece transducer life and keeps handpiece and tools cool during

extended operation.

C. Memory function (DF/SF) – Saves the last output power setting as long as the

Main Power Switch is on.

D. Angled Front Panel (DF/SF) – Ensures clear view of all controls.

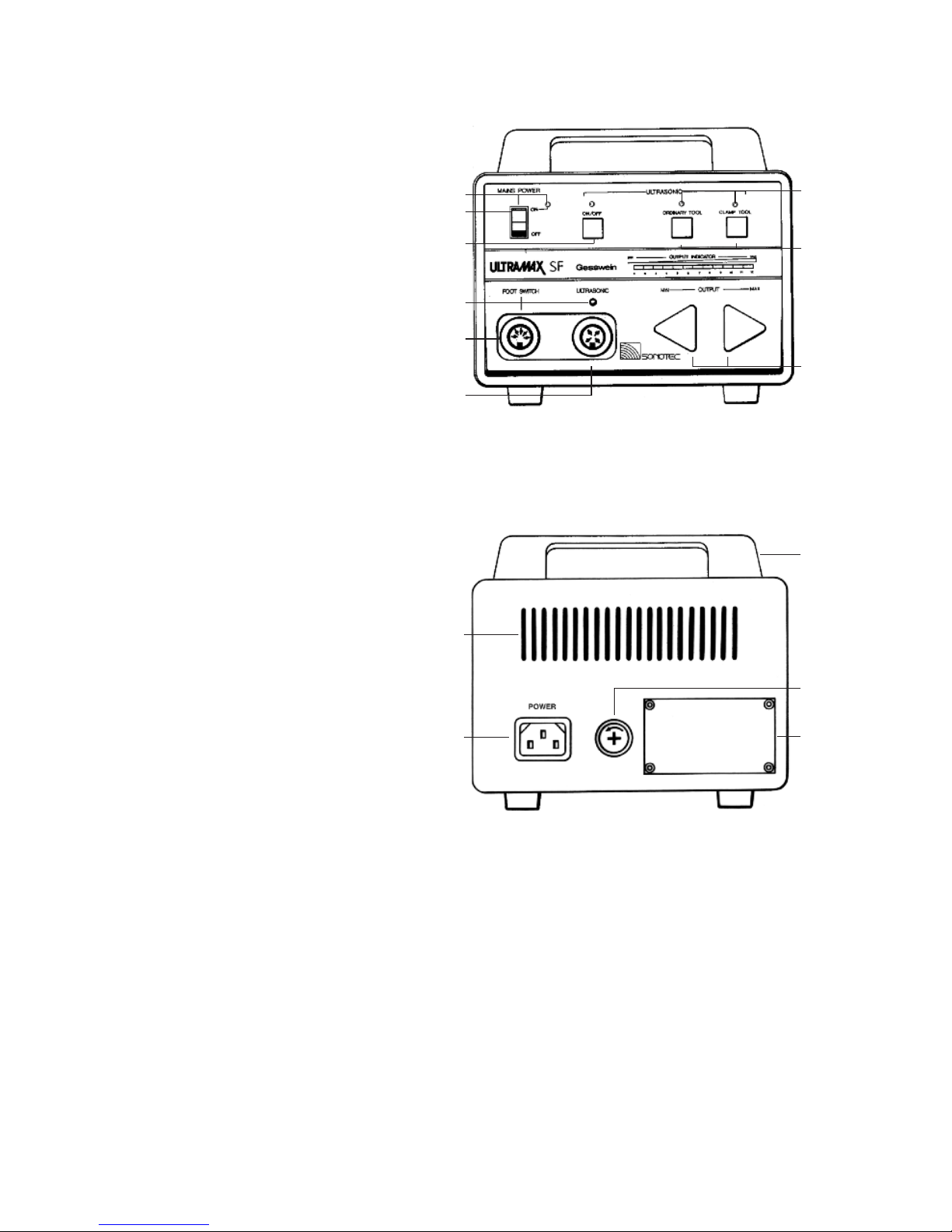

E. Carrying Handle (DF/SF) – Provides portability.

F. Standard Fuse (DF/SF) – Allows easy replacement with a Phillips screwdriver.

ULTRAMAX DF: 2A in 115V model, 1.5A in 230V model. ULTRAMAX SF: 1.5A in

115V model, 1A in 230V model.

G. Small and Beveled Protector Sleeves (DF/SF) – Small protects ordinary tools;

beveled protects clamped tools.

H. Forward/Reverse Rotation Function (DF only) – Allows Power Hand 2X hand-

piece to run in forward and reverse. Brings handpiece to a complete stop

before changing direction, protecting motor armature from damage.

I. Motor Overload Protection Circuitry (DF only) – Slows then stops Power hand 2X

Handpiece in the event of overload. Brings handpiece back up to original speed

once it is lifted from the workpiece, triggers a buzzer and turns off the On/Off and

Reset Switch in the event of abnormal overload. To reset, fix problem

(i.e., replace bent or broken tool), then turn on the On/Off and Reset Switch.

J. Electronic Feedback Circuitry (DF only) – Maintains Power Hand 2X handpiece

speed as work force increases.

K. Electronic Transformer (DF only) – Allows reliable Power Hand 2X handpiece

operation.

L. Cooling fan (DF only) – Operates continuously when Main Power Switch is on.

5

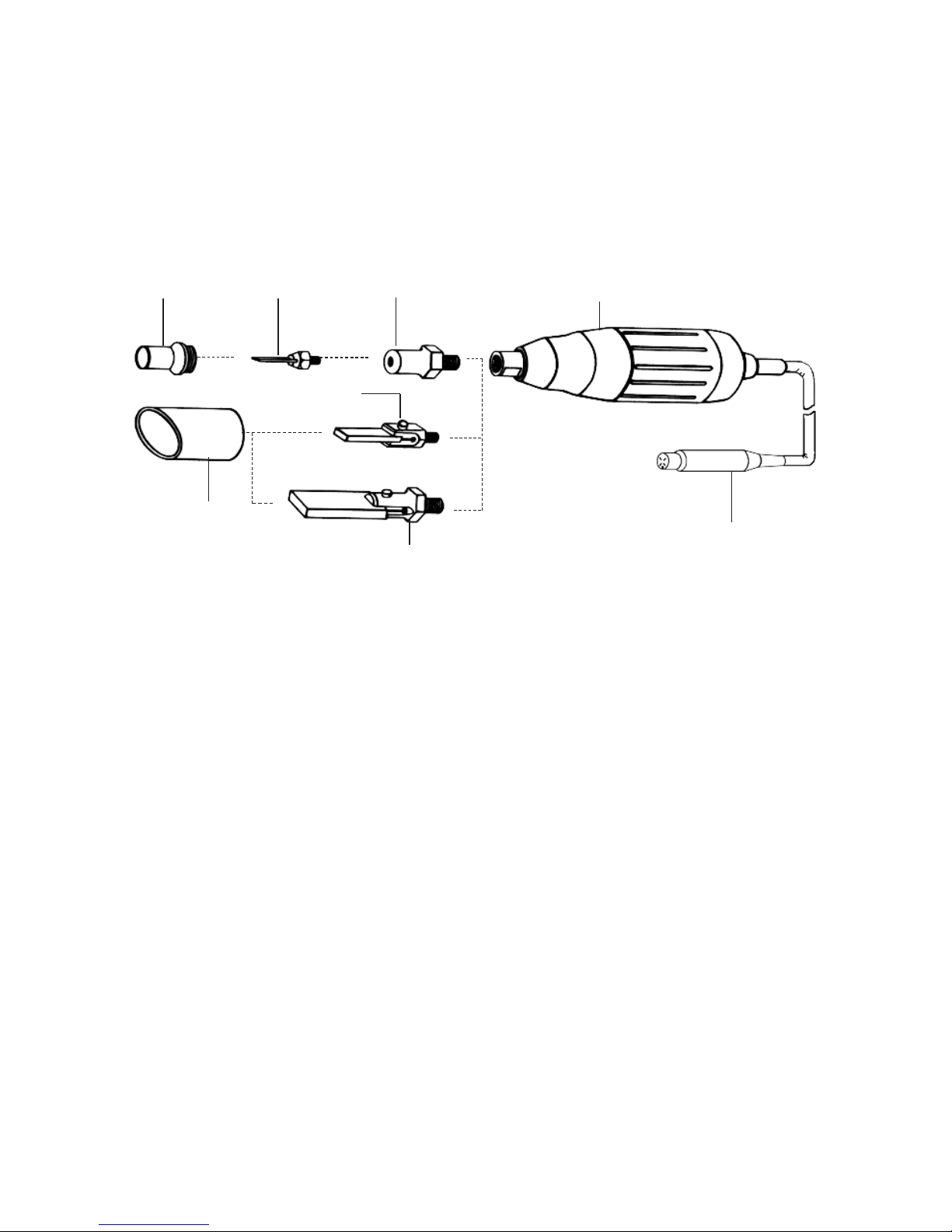

4. Accessories*

•UF-9700 Ultrasonic Handpiece

•Wooden Handpiece Case

•Handpiece Rest

•Power Cord

•Replacement Fuse

•Plastic Tool Box

•Cloth Tool Holder

•Flat Diamond File,

1T x 5W x 133L, #200

•Flat Diamond File,

1T x 5W x 133L, #320

•Chisel Diamond File,

0.5T/1W x 4W x 44L, #200

•Chisel Diamond File,

0.5T/1W x 4W x 44L, #320

•Flat Diamond Stone,

1T x 3W x 41L, #200

•Flat Diamond Stone,

1T x 5W x 41L, #200

•Flat Diamond Stone,

1.5T x 6W x 80L, #200

•Flat Resin-Bonded Diamond Stone,

3T x 6W x 22L, #200

•Flat Resin-Bonded Diamond Stone,

3T x 6W x 22L, #320

•Flat Ceramic Stone Tool,

0.8T x 4W x 40L, #600

•Flat Ceramic Stone Tool,

0.8T x 4W x 40L, #800

•Flat Ceramic Stone Tool,

1T x 6W x 40L, #600

•Flat Ceramic Stone Tool,

1T x 6W x 40L, #800

•Round Ceramic Stone Tool,

3D x 30L, #600

•Round Ceramic Stone Tool,

3D x 30L, #800

•Flat Wood Lapping Tool,

3.2T x 6W x 30L

•Round Wood Lapping Tool,

3D x 30L

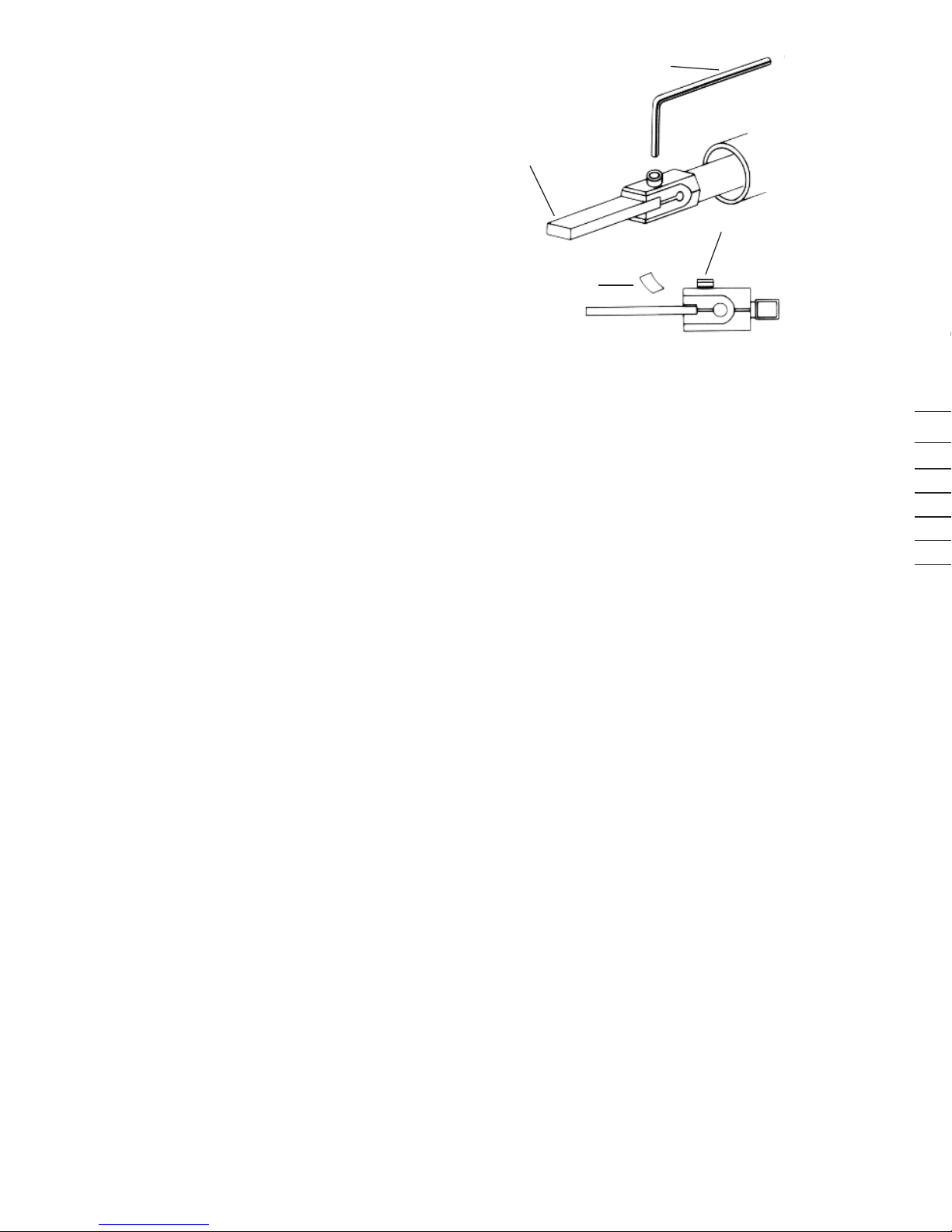

•Clamp Tool Holder (M6) for 0.8T Flat

•Clamp Tool Holder (M6) for 1.1T Flat

•Clamp Tool Holder (M6) for 3.1T Flat

•Clamp Tool Holder (M6) for 3.3T Flat

•Clamp Tool Holder (M6) for 3.2D Round

•Tool Adapter (M6 to M4)

•Wrench (M8)

•Wrench (M10)

•Wrench (M13)

•Allen ey (M2.5)

•Small Protector Sleeve for UF-9700

•Beveled Protector Sleeve for UF-9700

•Earplugs

*Measurements in mm.

ptional Accessories

Contact Gesswein for information on the complete line of tool accessories and

Power Hand 2X mechanical handpiece options.