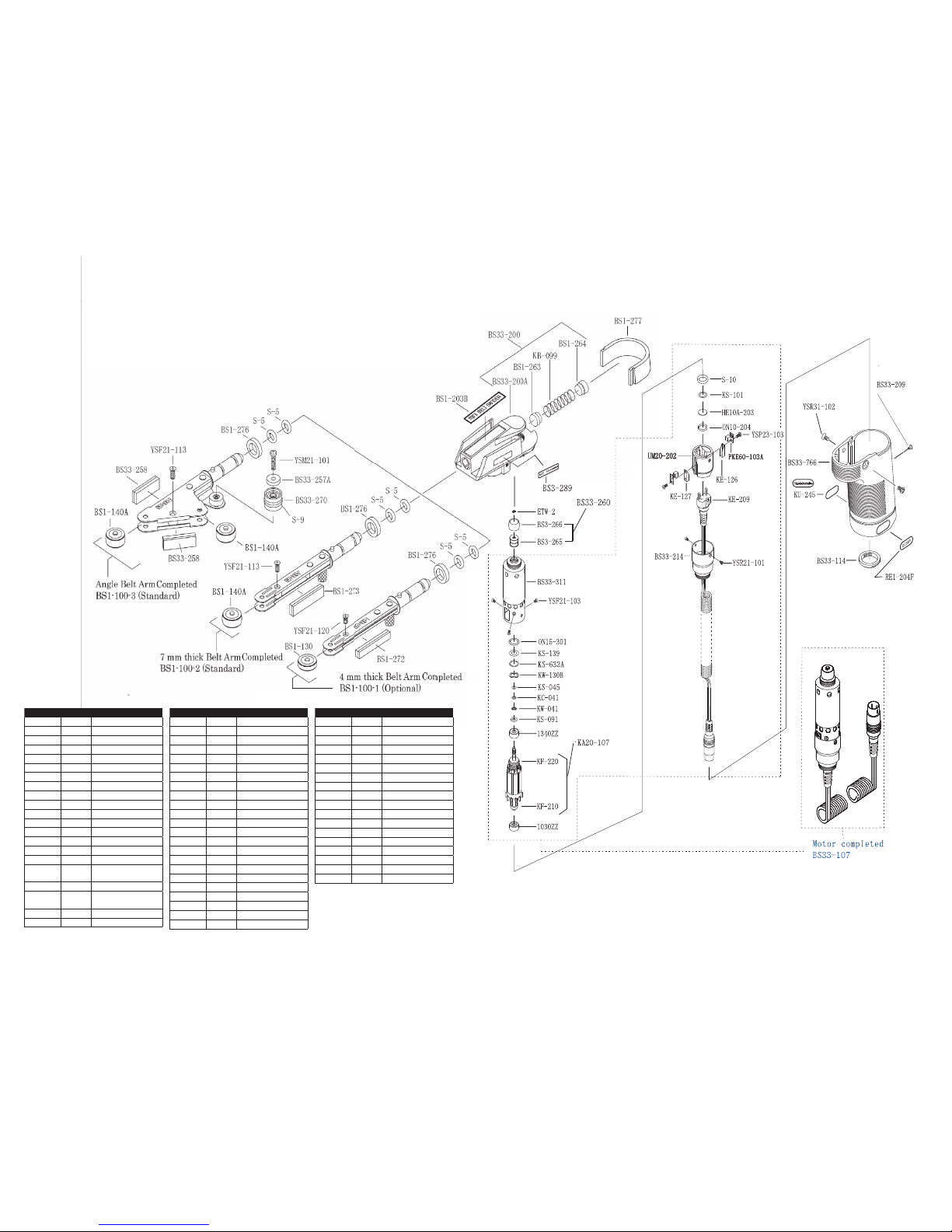

6 7

Part# Item# Description

BS1-100-1 510-0494 Belt Arm Completed (4mm)

BS1-100-2 510-0496 Belt Arm Completed (7mm)

BS1-100-3 510-0495 Belt Arm Completed (45°)

BS1-130 896-0183 Belt Arm Pulley (4 mm)

BS1-140A 896-0350 Belt Arm Pulley (7 mm)

BS1-272 896-0185 Support Arm Pad (4 mm)

BS1-273 896-0186 Support Arm Pad (7 mm)

BS33-258 896-0187 Support Arm Pad (45°)

BS1-276 896-0188 Dust Proof Cushion

S-5 896-0189 O-Type Rubber Ring

YSF21-120 896-0190 Pan Headed Screw

YSF21-113 896-0191 Pan Headed Screw

BS33-270 896-0192 Guide Pulley Completed

S-9 896-0193 O-Type Rubber Ring

BS33-257A 896-0194 Pulley Cover

YSM21-101 896-0195 Countersunk Head Screw

BS33-200 896-0196 Belt Holder Body

Completed

BS33-200A 896-0197 Belt Holder Body

BS1-203B 896-0198 Minibelt Sander Name

Plate

BS3-289 896-0351 BZX Name Plate

BS1-263 896-0200 Spring Base

Part# Item# Description

BS1-264 896-0201 Screw Lid

KB-099 896-0202 Coil Spring

BS1-277 896-0203 Protection Cover

BS33-107 896-0352 Motor Completed

BS33-260 896-0353 Driving Pulley Completed

BS3-265 896-0206 Driving Pulley Only

BS3-266 896-0207 Driving Rubber Ring

ETW-2 896-0156 E-Type Clip Ring

BS33-311 896-0354 Motor Housing

ON15-301 896-0160 O-Type Rubber Ring

KS-139 896-0161 Metal spacer

KS-632A 896-0163 Metal spacer

KW-130B 896-0355 Wave Washer

KS-045 896-0165 Fiber Spacer

KC-041 896-0209 C-Type Clip Ring

KW-041 896-0167 Wave Washer

KS-091 896-0210 Spacer

YSF21-103 896-0002 Countersunk Head Screw

KA20-107 896-0356 Armature

KF-220 896-0357 Dust Proof Collar

KF-210 896-0011 Dust Proof Collar

1340ZZ 510-3094 Ball Bearing

1030ZZ 510-3073 Ball Bearing

Part# Item# Description

S-10 896-0012 O-Type Rubber Ring

KS-101 896-0013 Teflon Spacer

HE10A-203 896-0014 Rear Lid

PKE60-103A 510-0161 Carbon Brush ( 2 pcs)

UM20-202 896-0321 Brush Side Lid

YSP23-103 896-0017 Pan Headed Screw

ON10-204 896-0015 O-type Rubber Ring

BS33-214 896-0358 Motor Cap

KE-126 896-0018 (+) Terminal Plate

KE-127 896-0019 (-) Terminal Plate

KE-209 510-0171 Motor Cord with Plug

YSR21-101 896-0359 Countersunk Head Screw

BS33-766 896-0360 Handgrip

BS33-114 896-0361 Handgrip Retaining Nut

BS33-209 — Grounding Pin

YSR31-102 896-0119 Handgrip Locking Screw

KU-245 896-0122 Gesswein Name Plate

RE1-204F 896-0121 DC30V Name Plate

BZX Belt Sander Parts List

When ordering parts, specify part# (or item# if applicable) and description.