Contents

Foreword ............................................................................................................................................3

Availability.............................................................................................................................................3

Formatting features in the document ......................................................................................................3

Safety..................................................................................................................................................4

Use for the intended purpose .................................................................................................................4

Basic safety notes .................................................................................................................................4

Information on property damage or malfunctions .....................................................................................5

Qualification of personnel.......................................................................................................................5

Protective gear......................................................................................................................................5

Typographic features of warning notes....................................................................................................5

Formatting features for warnings of property damage ..............................................................................5

Description .........................................................................................................................................5

Scope of supply.....................................................................................................................................5

Equipment specification .........................................................................................................................6

Name plate ...........................................................................................................................................8

Task and function..................................................................................................................................8

Application of European Directives..........................................................................................................9

Storing and transporting the equipment...........................................................................................9

Storing the equipment ...........................................................................................................................9

Transporting the equipment ...................................................................................................................9

Using the equipment ........................................................................................................................10

Preparing for installation ......................................................................................................................10

Adjusting the length of the rail hook......................................................................................................11

Tensioning the nose ............................................................................................................................11

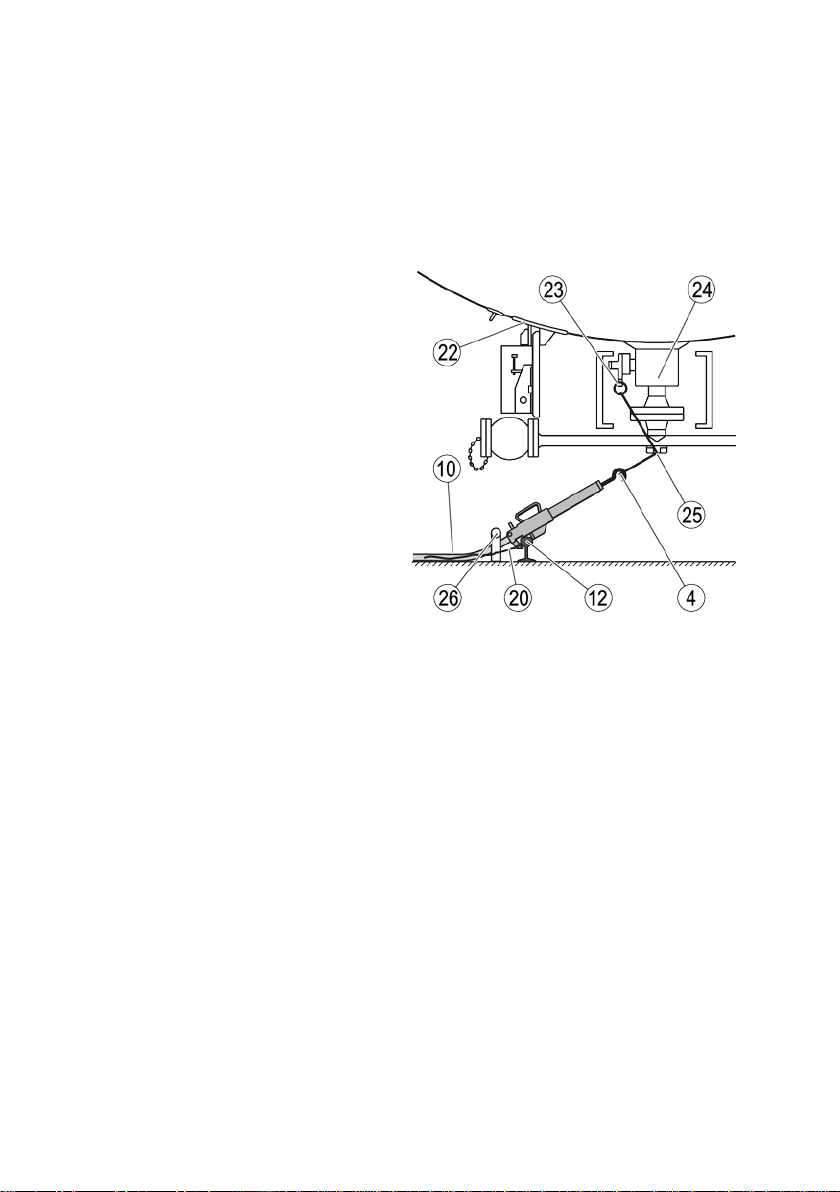

Installing the rail hook..........................................................................................................................12

Removing the rail hook ........................................................................................................................12

Troubleshooting ...............................................................................................................................12

After operation .................................................................................................................................12

Removing external dirt deposits............................................................................................................12

Maintaining the equipment...................................................................................................................12

Servicing the equipment and installing spare parts ................................................................................12

Putting the equipment out of operation ..........................................................................................13

Returning the valve..............................................................................................................................13

Disposing of the equipment..................................................................................................................13

Technical data..................................................................................................................................14

Dimensions and weights ......................................................................................................................14

Operating data ....................................................................................................................................15

Pressure & temperature ratings............................................................................................................15

Manufacturer's declaration .............................................................................................................15