-2- T10812 Carving Vise (Mfd. 09/14)

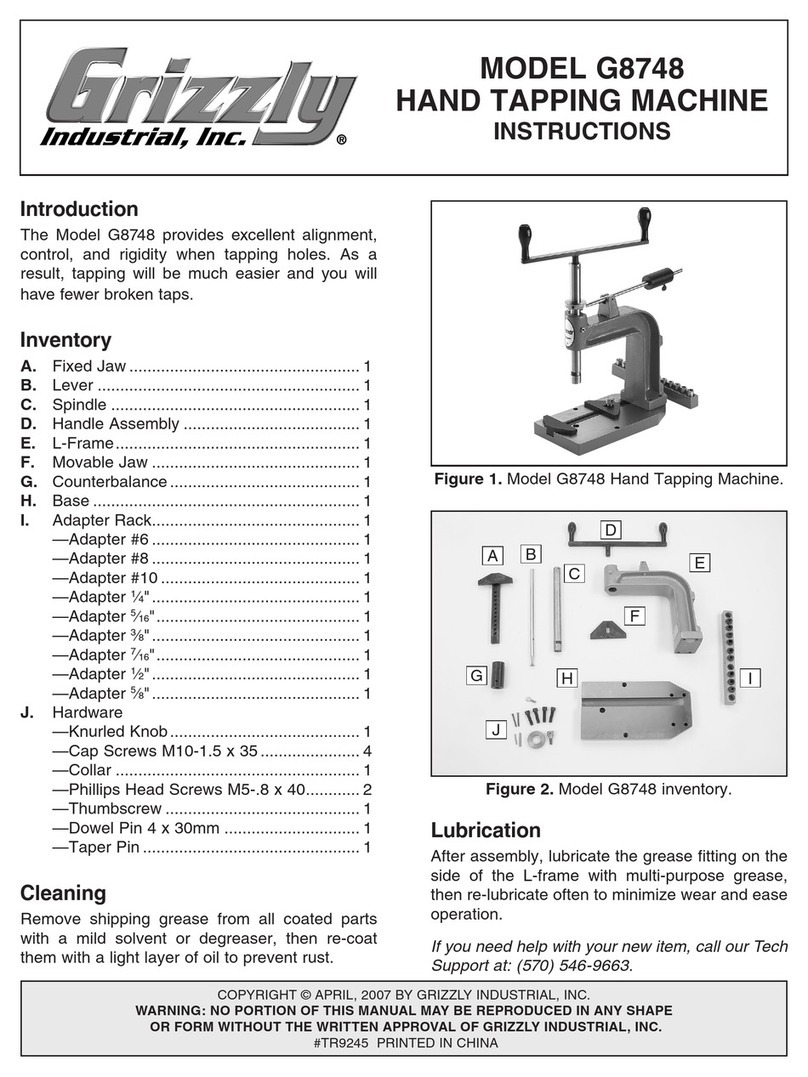

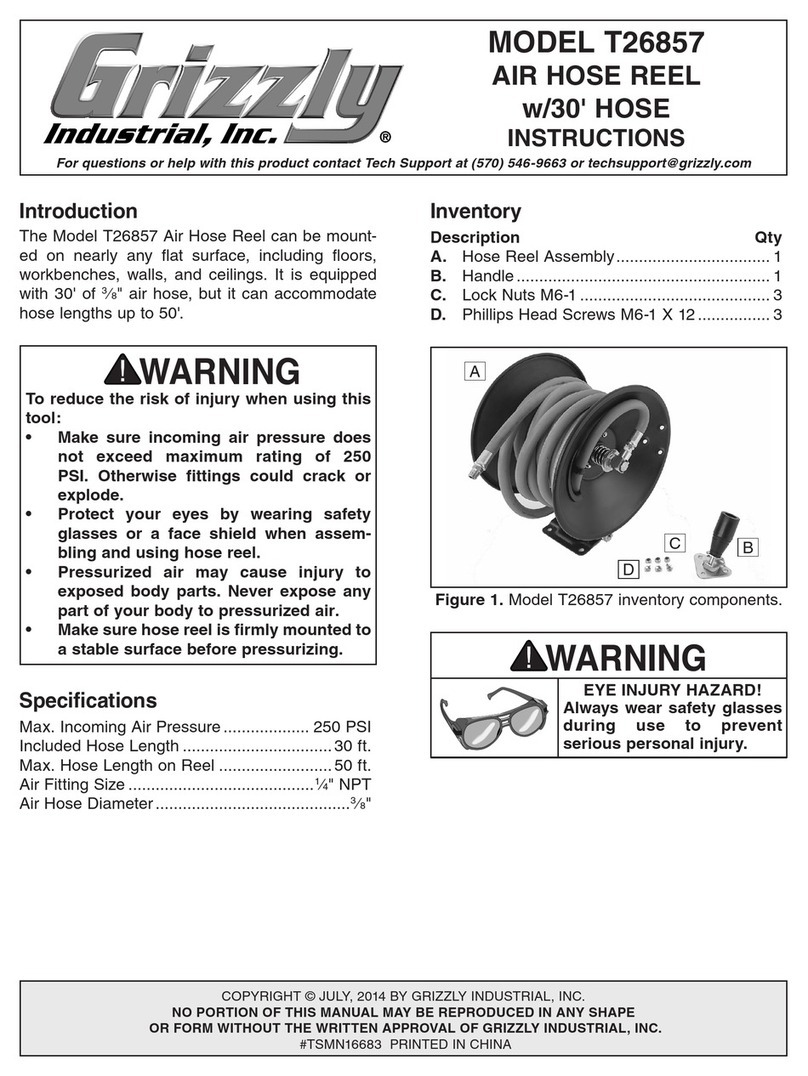

Figure 4. T10812 part identification.

Retaining

Collar

Clamping

Handle

Clamping

Assembly

Faceplate/Column

Assembly

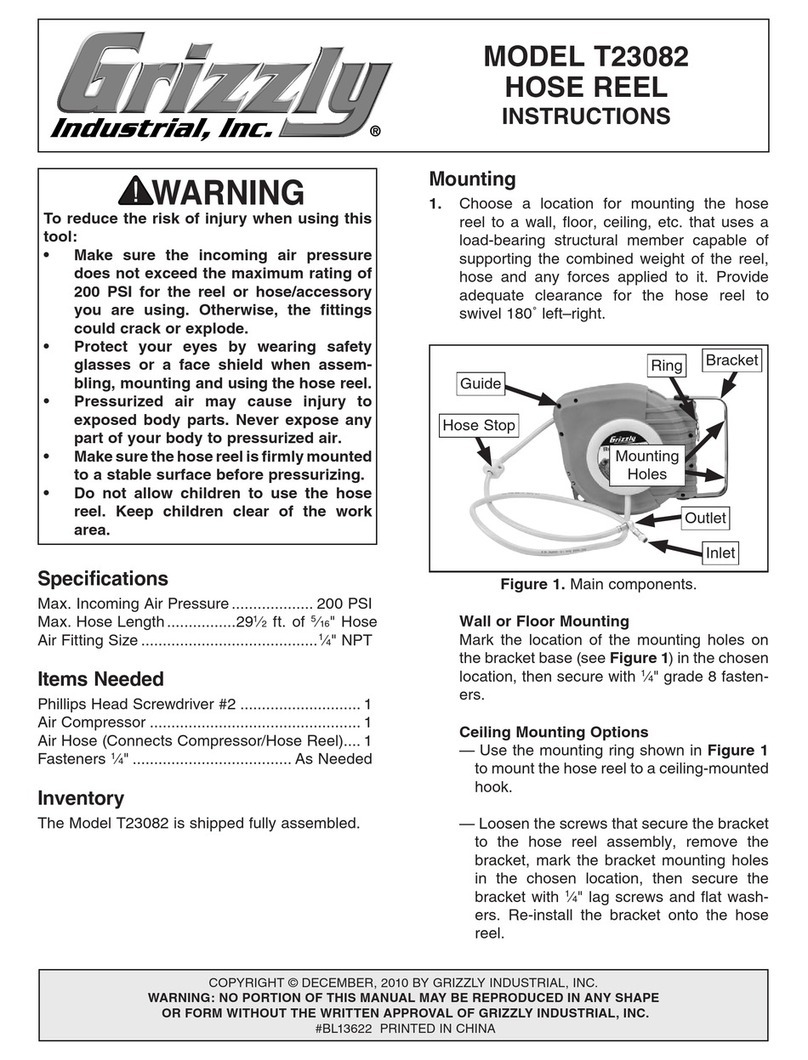

Attaching Workpiece

The Carving Vise faceplate has 16 mounting holes

to accommodate a variety of workpieces. When

attaching a workpiece, use a minimum of four but-

ton head screws. Make sure the screws are long

enough to provide a safe, stable work surface, but

will not interfere with carving activities.

Avoid placing hands close to pinch points

located at clamping assembly and retaining

collar. Serious injury may occur.

Carving Vise

Workbench

Hex

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

Carving Vise

Workbench

Lag Screw

Flat Washer

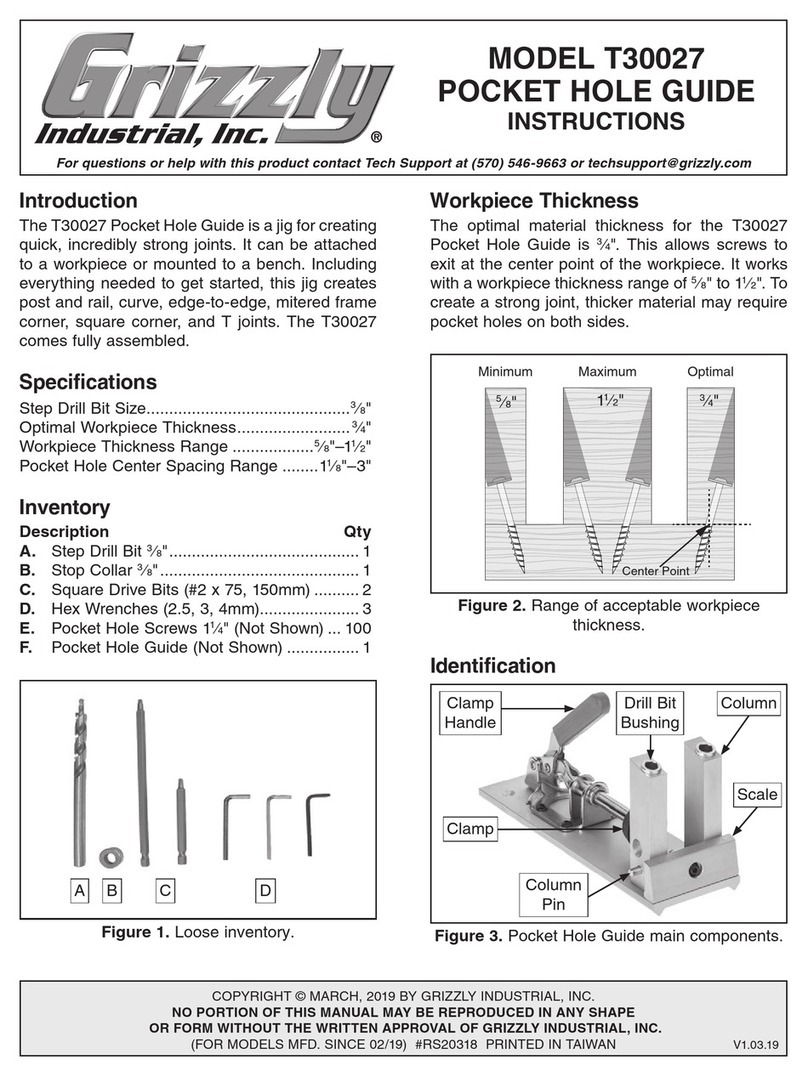

Another option is a "Direct Mount" (see example

below) where the vise is secured directly to the

workbench with lag screws and washers.

The base of this vise has mounting holes that allow

it to be fastened to a workbench or other mounting

surface to prevent it from moving during operation

and causing accidental injury or damage.

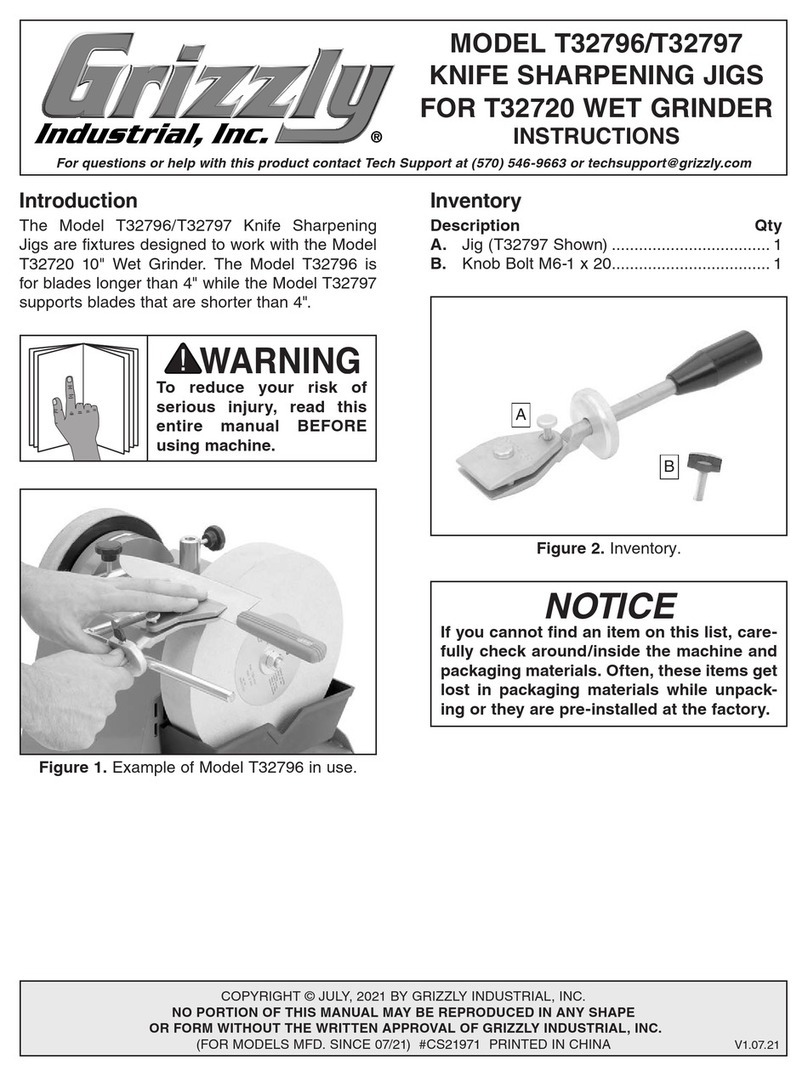

The strongest mounting option is a "Through

Mount" where holes are drilled all the way through

the workbench—and hex bolts, washers, and hex

nuts are used to secure the vise in place.

Bench Mounting

Mount the carving vise on a workbench that is

sturdy enough to hold the weight of the equipment

and any downward pressure that may be applied

during operation.

When mounting your carving vise, remember to

allow enough room so workpiece position can be

fully adjusted, and to place carving vise in a well

lit area.

Installation

Damage to your eyes, lungs, and ears could

result from using this item without proper

protective gear, such as safety glasses, a

respirator, and hearing protection.

Refer to Figure 4 to become familiar with the

names and locations of the controls and features.

Figure 2. Typical "Through Mount" setup.

Figure 3. Typical "Direct Mount" setup.