GFB WGA User manual

+61 2 9534 0099 www.gfb.com.au[email protected] facebook.com/GFBturbo instagram.com/gofastbits

GFB WGA

Part #7304

For Subaru WRX MY97-07

(TD04 turbo)

GFB WGA Introduction

The GFB WGA is designed to help optimize boost response and control by using a larger diaphragm area for

greater authority and control over the wastegate ap, and by allowing ne adjustment of the base boost

pressure via the 3 supplied springs and turnbuckle adjustment.

PLEASE NOTE:

Adjustment and/or tuning is required when installing this product, as it will result in higher boost

pressure which could damage your engine if the ECU is not tuned to suit.

GFB makes no recommendations regarding “safe” boost levels for your engine. This product is a tuning tool and

maximum boost pressure should be determined by an expert, taking into account the capabilities and

limitation of your specic engine and supporting modications.

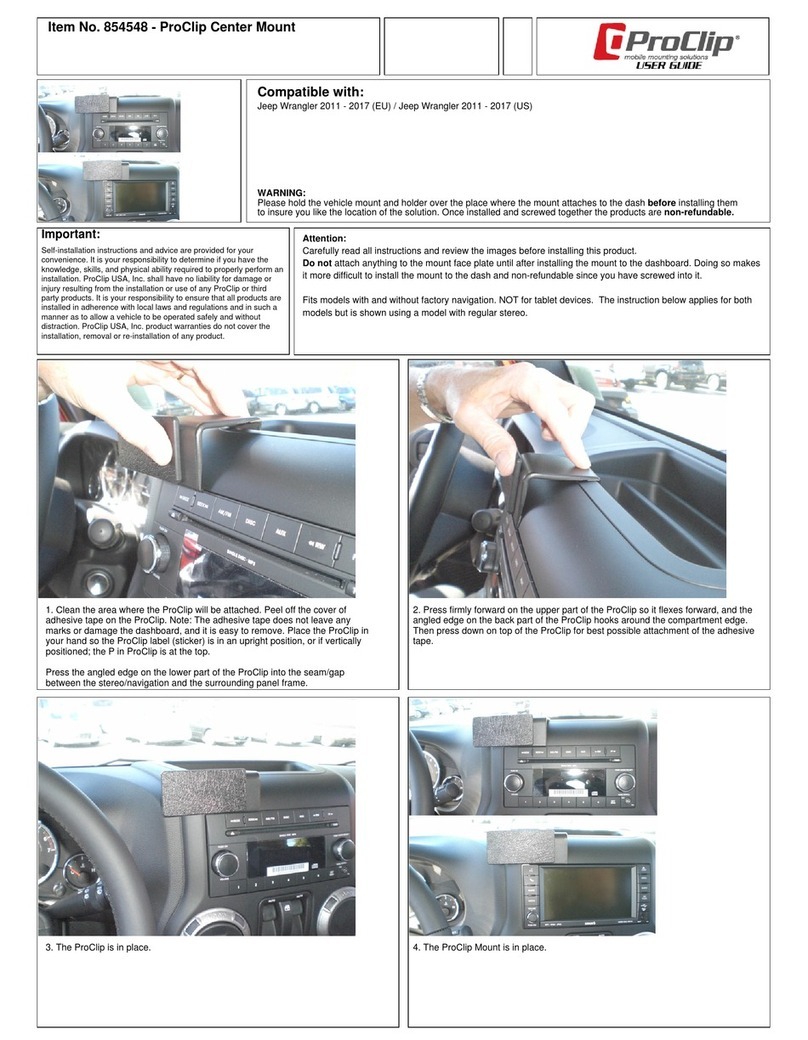

Spring Selection

Gate Pressure (psi) 5psi Inner 7psi Middle 10psi Outer

5

7

10

12 (pre-installed)

15

17

22

If you require a different gate pressure, use the

table opposite to deter mine the most

appropriate spring combination.

Note that this table is only a guide to help your

selection – the actual boost level achieved

ultimately depends on a large number of

variables, and may differ from the gate pressure

shown in the table.

Before installation, you should first determine the minimum and maximum boost pressure that you want to

run, and your control method, and ensure the most appropriate spring combination is selected and installed in

the WGA.

Care should be taken when selecting boost pressures, and it is always best initially to err on the conservative

side, until the engine can be run on a dynamometer to ensure safety. Always consult an expert when making

boost changes, and it is recommended that the car be checked on a dyno, as high boost and/or lean air/fuel

mixtures can cause engine damage or worse, total failure.

If you are planning on having variable boost through the use of a boost controller, the range you can achieve

depends on your turbo setup. The lowest boost your car can run is determined by the spring (this is commonly

known as “gate pressure”), and boost can then be increased through the use of a boost controller.

As a rule of thumb, try to select springs so that your maximum boost is no more than double the “gate pressure”.

Whilst it is possible to increase boost beyond this, you may find that boost becomes less stable and harder to

control. This is because the boost controller must bleed most of the control pressure signal to the actuator, so

the wastegate is less able to self-correct for changes in manifold pressure. Using a stronger spring means the

controller bleeds off less of the pressure signal, giving the wastegate greater ability to regulate boost changes.

The WGA part #7304 comes with 3 springs which can be used individually or installed together to achieve

different boost levels. The 5psi and 7psi springs are pre-installed for a gate pressure of 12psi, which is suitable for

most Subaru applications with the TD04 turbo.

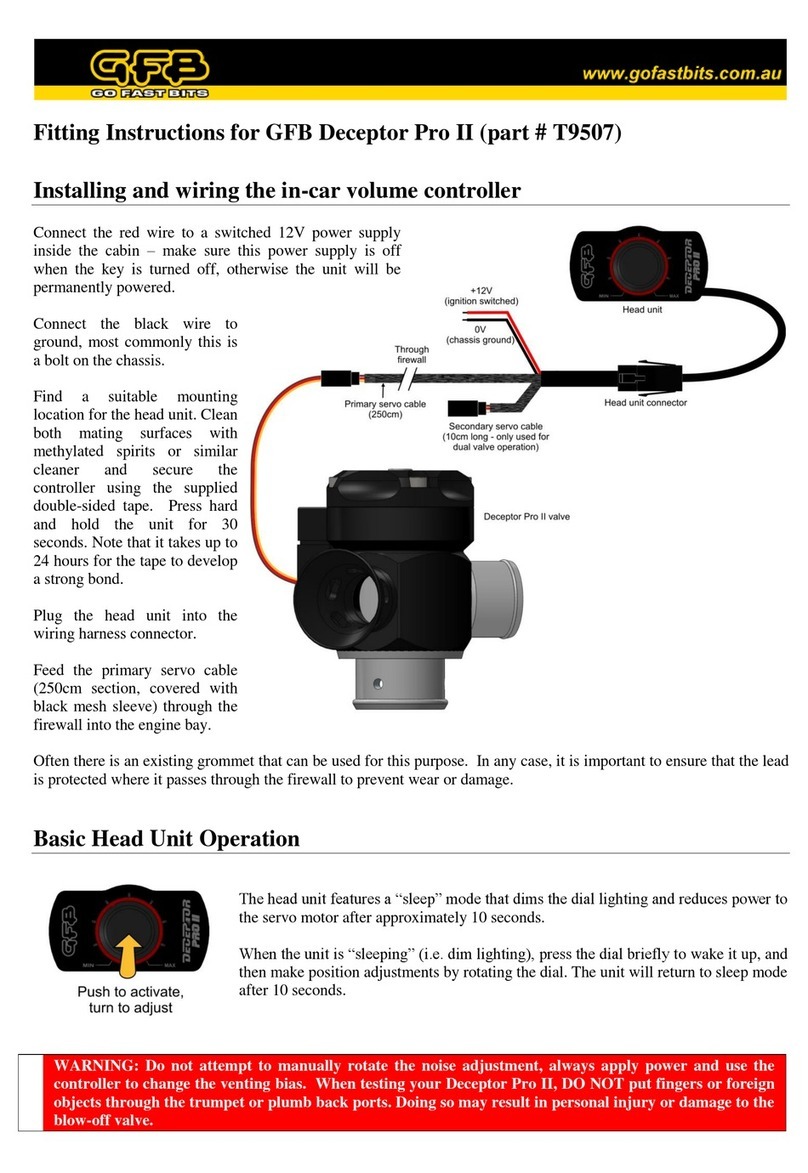

Changing the Springs

1. The spring force must be restrained

before attempting to remove the cap. To do this,

spin the locknut as close as possible to the body -

this will prevent the spring from extending as

you remove the cap

2. Remove all ve cap screws using a metric

3mm hex key

3. Residual friction from the diaphragm

sealing bead will hold the cap on even after the

screws have been removed. If the cap cannot be

removed by hand, it can be carefully pried off

using the at surface under the hose barb

5. Install the new springs, ensuring they are

correctly seated in the grooves at the bottom of

the body, and on the underside of the piston

4. Once the cap and diaphragm are removed,

unscrew the locknut completely to remove the piston,

rod, and springs.

6. CAUTION: during re-assembly take care not

to pinch the diaphragm as it compresses into the

body ( ). It can be helpful to apply a thin smear

of oil or spray lubricant to the outside of the

diaphragm to help it slip into the body easily.

7. E n s ure th e d i a p hr a g m i s c o r re c t l y

convoluted and the piston is centred in the

diaphragm, then press the cap/diaphragm onto the

piston using the same method of compressing the

spring as used during disassembly.

8. Re-install screws

Warranty

WARNING:

GFB recommends that only qualified motor engineers fit this product. GFB products are engineered for best

performance, however incorrect use or modification may cause damage to or reduce the longevity of the

engine/drive-train components.

GFB LIFETIME WARRANTY:

Our commitment to quality means that when we put our name to something, we are also staking our

reputation on it. That’s why we back our products with the best warranty in the business!

You should expect a lifetime of use from a well-engineered product, so if your GFB product fails as a result of

defective materials or faulty workmanship whilst you remain the original owner, we will repair or replace it

(limited only to the repair or replacement of GFB products provided they are used as intended and in

accordance with all appropriate warnings and limitations. No other warranty is expressed or implied).

If a fault occurs as a result of usage outside of the terms of the warranty, or you are not the original owner, fear

not, we can still help you. You should never need to throw a GFB product away, as spare parts are available

and won't cost the earth.

TECH SUPPORT:

We want you to get the best advice, first time. That’s why our engineers are available to answer any technical

questions you may have. Head to to get in touch.www.gfb.com.au/contact-us

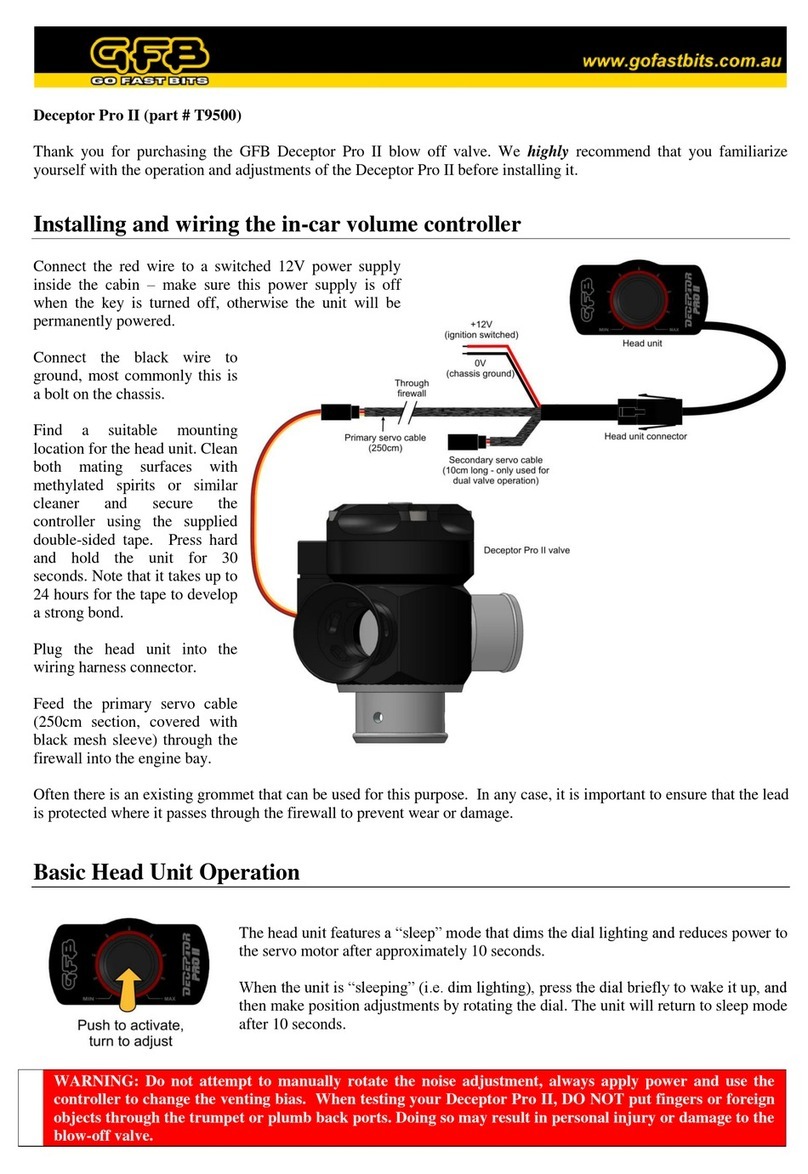

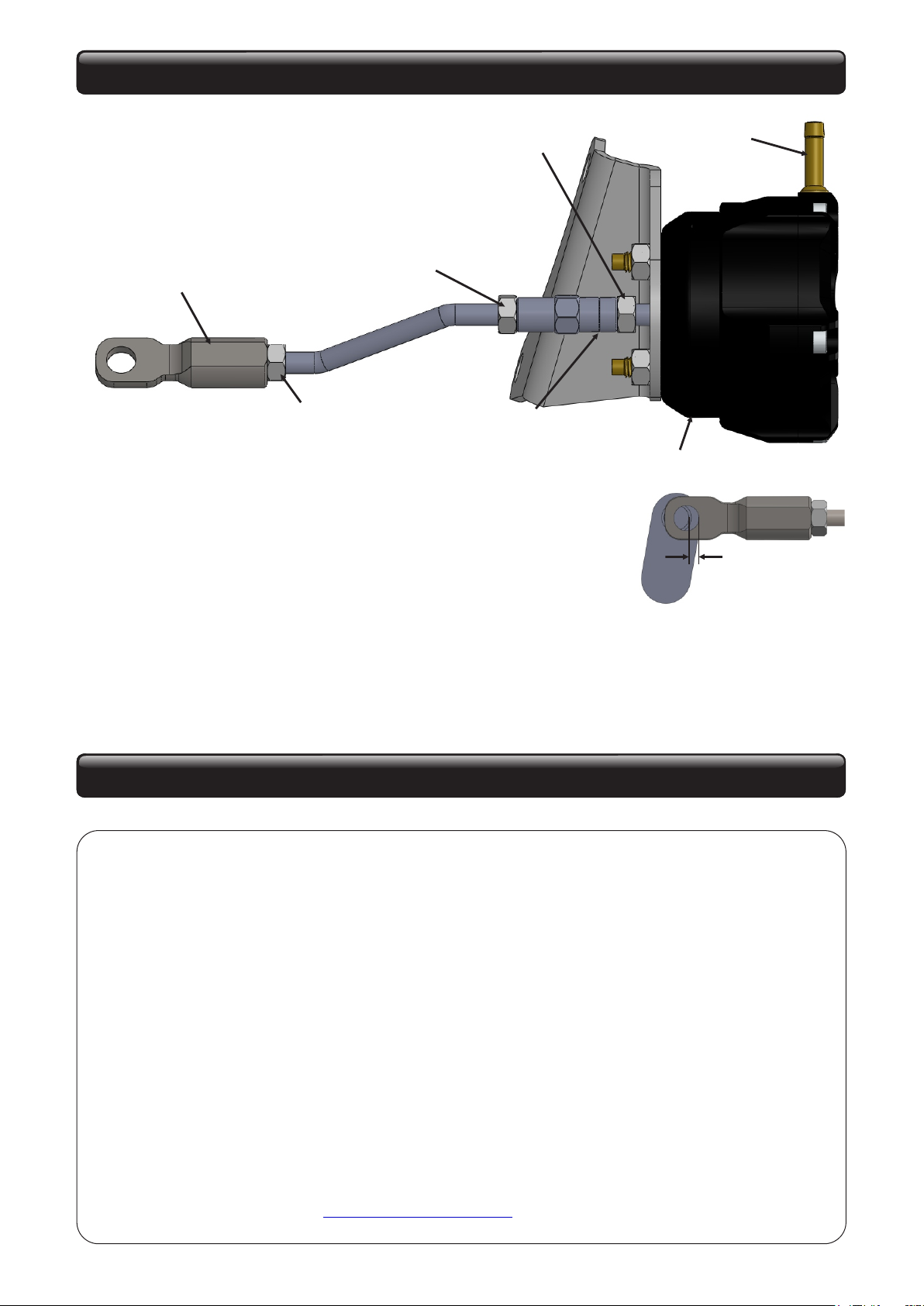

Assembly/Installation

Turnbuckle

(groove indicates

LH thread)

Turnbuckle locknut

(LH thread)

Turnbuckle locknut

(RH thread)

Clevis locknut

(RH thread)

Clevis

(RH thread)

Hose barb

Vent hole

1. Assemble WGA as shown, ensuring hose

barb points in the correct direction and the vent

hole on the WGA body faces away from possible

water ingress

2. Ensure the clevis and turnbuckle have at least 5mm of thread

engaged, but do not tighten any of the locknuts at this stage

3. Mount the WGA onto the turbo, and adjust the clevis until there is

at least 2mm of pre-load before attaching the clevis to the wastegate arm. 2mm MIN

4. Tighten all locknuts, remembering that the locknut closest to the WGA body is a left hand thread.

5. Ensure the hose barb is connected to the boost source/boost controller, then perform a boost run to

check the boost level. If boost pressure is too low, increase the pre-load via the turnbuckle (or clevis)

This manual suits for next models

1

Table of contents

Other GFB Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

curt

curt 17510 installation manual

Menabo

Menabo 000103900000 Fitting instructions

SSV Works

SSV Works TXF-OSP65 installation instructions

Whelen Engineering Company

Whelen Engineering Company Dominator D2 installation guide

Enercell

Enercell 2730696 user guide

Whelen Engineering Company

Whelen Engineering Company TIR3 Super-LED/M4 installation guide