GGM gastro SEMB40 User manual

1

Operation

Manual

For

ModelSEMB40

Be#sure#you#read#it,#before#operate

Table of contents

Step 3 LCD Display Panel and Function Button(P6)

Step 4 First cleaning(P7)

Step 5 Pour Ingredients (P8)

Step 6 Ice cream Hardness adjustment (P9)

Step7

Cups clearance and Pre-cooling settings

(P10)

Step 8 Auto Ice cream Production(P11)

Step 9 After Production, Cleaning the machine (P12)

Step 10 Troubleshooting Guide(P13)

Appendix: 1.Machine Testing Notice(P14)

2.Cylinder Frozen Introduction (P15)

Procedure

Step 1Line connection(P4)

Step 2Install The Dispenser Door(P3,P5)

3

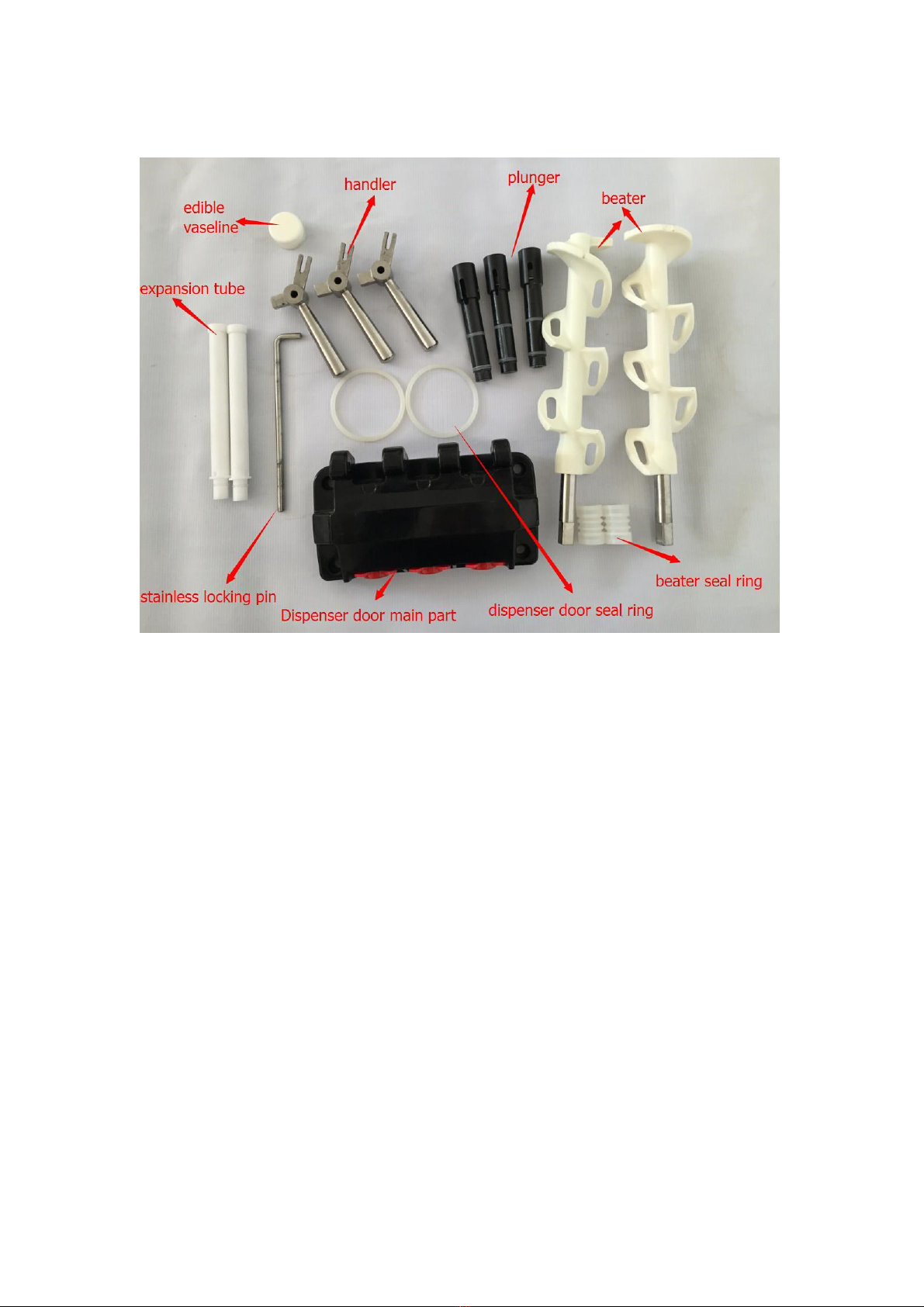

1: Dispenser door

Brief Introduction

1. Edible Vaseline:daub it to plunger seals and dispenser door

seal ring, function for lubrication and seal

2. beater seal ring: put onto end of beater

3. Expansion tube: increase expansion rate

Note: 3 plunger, middle of them have ‘I’ section, different from any

others

4

2: Line Connection

PS:

For 220V/60Hz equipment, we suggest you use

1.16A plug seat and air switch.

2.Voltage need 200V-240V,

3.Wire rod OD need 2 mm²

PS:Keep more than 20cm for grille exhaust

5

3: Beater assembling, Dispenser Door

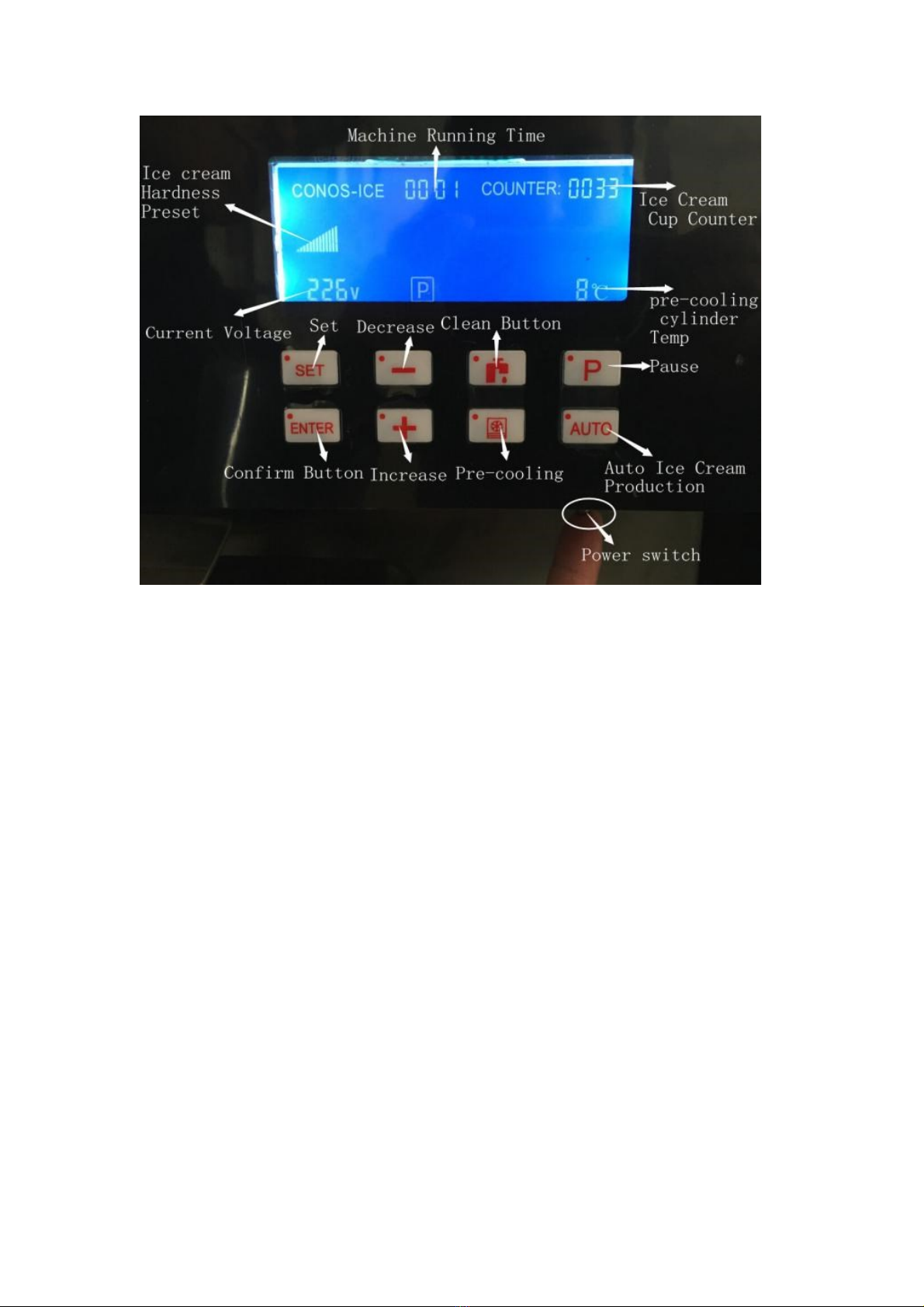

4: LCD panel Description

6

Note: Power Switch below panel

Notice the current voltage, the voltage zone:205-240V.

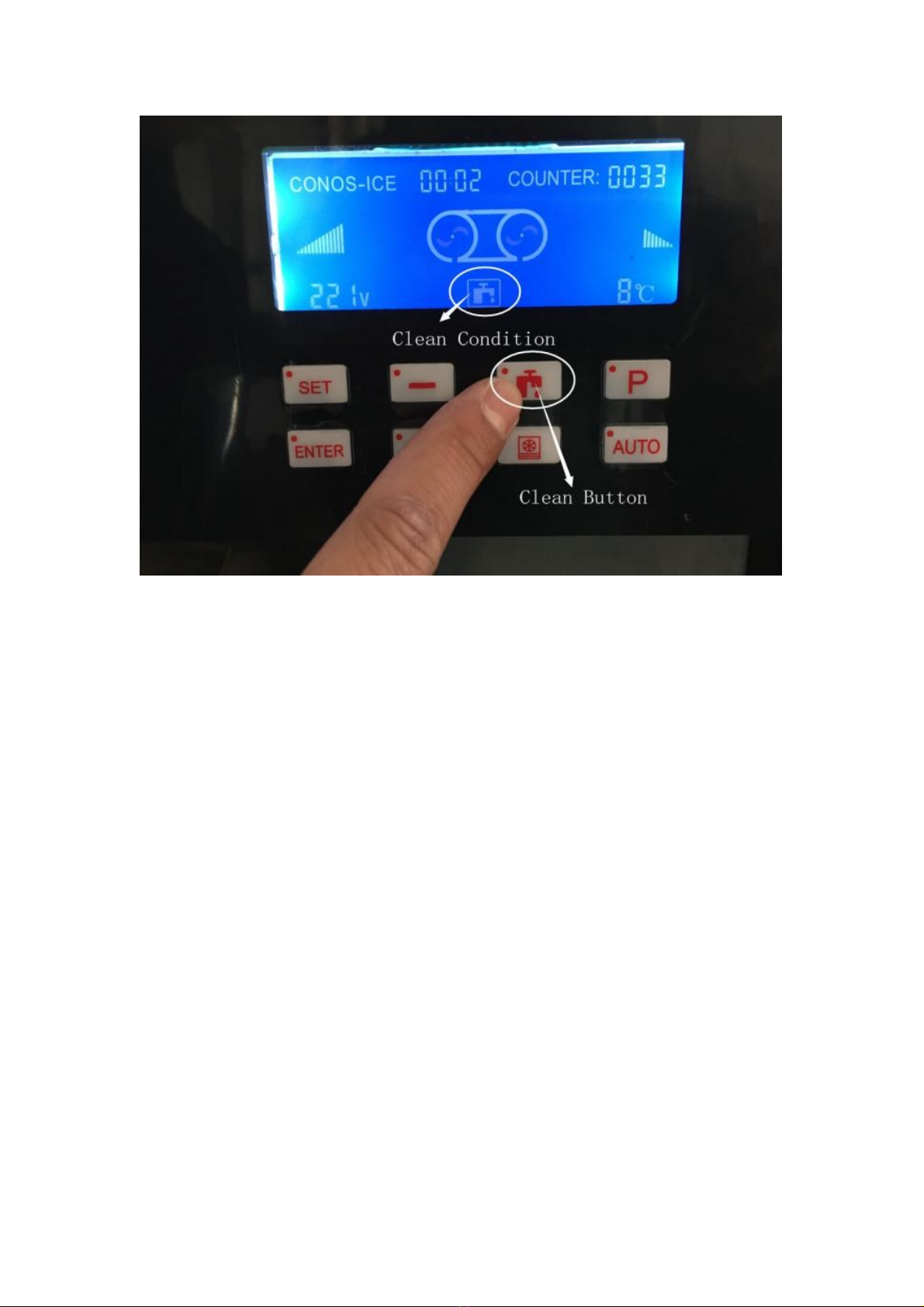

5: First Cleaning

(Note: if the weather is cold, first start machine will have hiss voice or show

blue screen JJ on LCD, is because reducer engine oil is dense, motor current

increase, if show blue screen, Restart, will be OK after running, it is common.)

7

1:First clean ,pour some water into hopper and beat 10 minutes.

2:First Clean: after assembly,pour some water into hopper, if the

water pour from the dispenser door, it means dispenser door is not

correct assemble.

3:Press clean button and clean about 10 minutes, press handler

release water and wipe hopper water

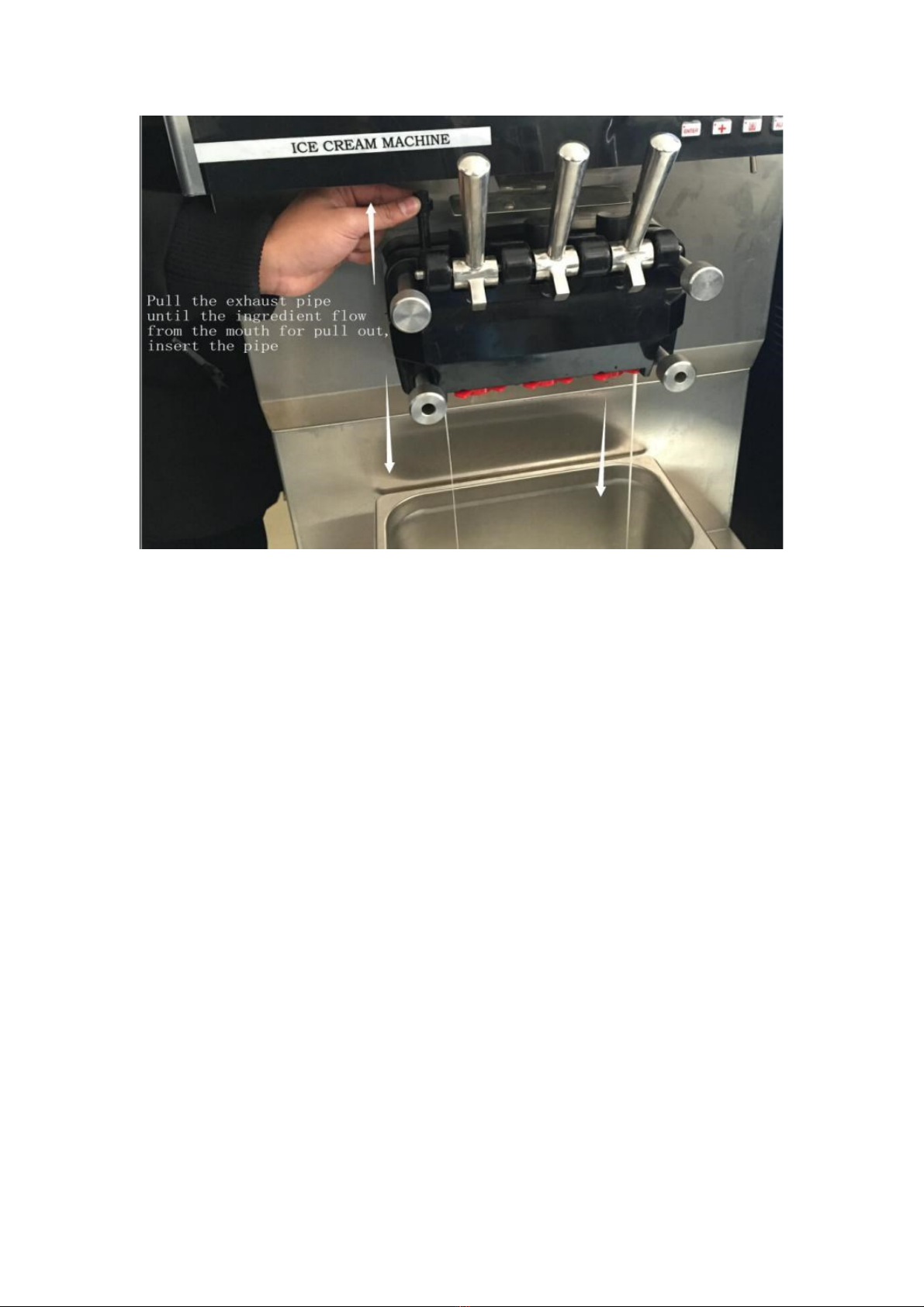

6: Pour ingredient

After pour ingredients, please do like this.

8

Note1: This machine is single cooling system, Both of hopper need

pour ingredient and more than 3L for each hopper.

Note2: pull the exhaust pipe,

9

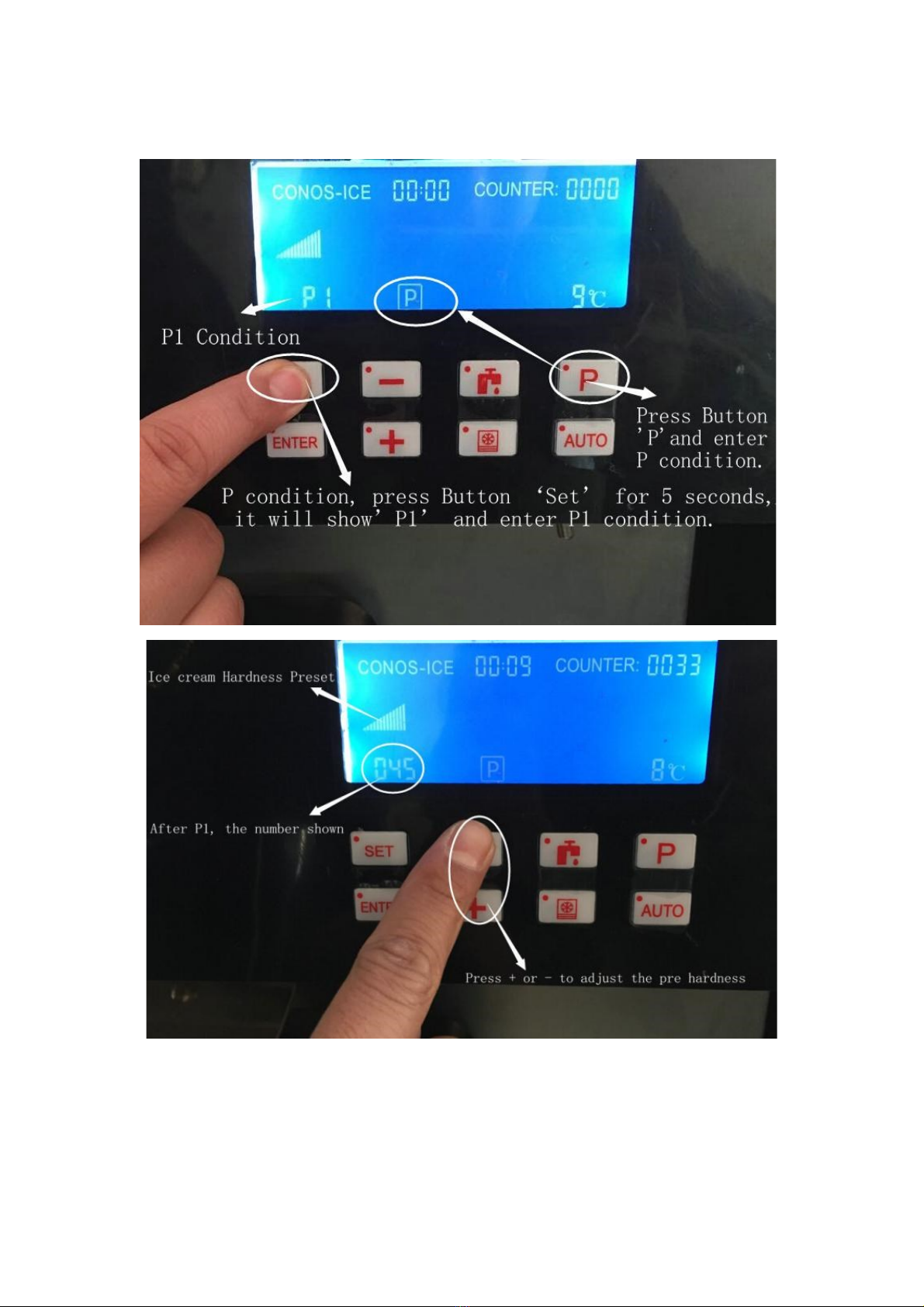

7: Ice cream Hardness adjustment

8: Cups clearance and Pre-cooling settings

P1 condition, press Button SET for a continuous short time, you can ignore other data,

until it shows ‘CUP’ like below. Press 10 seconds, then the cups counter will be

clearance.

10

Pre-cooling setting, The function for keeping hopper ingredients fresh , it depends on the

temperature in your location, if the temperature is high, we suggest you open this

function.

11

9: Ice cream production

You need about 9-12 minutes to finish produce ice cream at your First time.

First ice cream production time also depends on your exhaust space and your

local temperature.

NOTE: when finish production, you need left side 2 cups, then right side 2

cups, because after 2 cups, the compressor will restart and refreezing,

if you only output from one side, the compressor restart, but the other

cylinder is freezing, but no output, it will frozen, the beater can not

work well. But the motor is running, it will make the beater broken or

make the triangle belt smog , smell not well, even broken, burn the

motor. So it is very important to output ice cream use handler left side -

right side-left side-right side. If the ingredient are same for two hopper,

you can output the ice cream use the middle handler all the time.

10: Finish Production Cleaning Machine

Press Button ‘P’, then Press Button ‘Clean’.

12

After 15-20 minutes cleaning, you can press handler output the left

available ingredients, then you pour clean water to hopper, press

Button ‘Clean’ , after cleaning, press handler output water, and

wipe hopper, then unpack dispenser door, clean the beater ,

dispenser door and cylinder for your next using.

Above is a brief introduction how to use our machine. Below is

very important Notice, please read it carefully.

11: Trouble shoot and solution

Fault Display

Fault content

Trouble shoot

Solution

JJ

Cylinder Frozen

Check

ingredients in

Turn of the

13

hopper

machine more

than 45 minutes

then restart and

press clean

button

Check whether

only use one side

handler

Check pre

hardness settings

whether is too

hard

Check whether

you do not use

the machine for a

long time

CB

Reset Switch

abnormal

Check reset

switch whether

reset or not

Make the reset

switch on reset

Check plunger

whether reset or

not

Make the plunger

reset

UL

Voltage

The voltage is too

low

Turn off the

machine and

check the circuit

UH

The voltage is too

high

PS: How to get Max production

Left side 2 cups, then right side 2 cups, in this interval way When

no output, the compressor will auto restart every 15-20

minutes.

Thanks for your attention and your carefully reading.

If you have any other questions, you can contact our sales directly.

Appendix1 Machine Testing Notice

1: No one cylinder operate

Output need left side-right side-left side-right side. The ingredient need filled

2/3 of each hopper. If ingredient shortage, can not provide enough output

pressure, the ingredient will stay in cylinder and frozen cylinder.

14

2: Expansion tube Using

(Expansion tube function: increase fit expansion rate, No need use during ice

cream production.)

Expansion tube need professional ice cream machine operators operate.

a. Pour ingredients into hopper, then pull the end of dispenser door air gate

tube, until the ingredient flow out.

b. Insert expansion tube to the charging hole(Ingredients need higher than the

expansion tube charging hole)

c .Press ‘AUTO’ Start auto ice cream production, first 5-8 cups ice cream is

cylinder ingredient, so the expansion rate feeling is not higher than with

expansion tube.

d. If the ingredients is little or more foam, pull out the expansion tube, if you

need very large output in a short time, you need pull out the expansion tube,

because the input is not direct proportion with output, or the ingredient can

not flow easy to the cylinder, it will be cause ingredient shortage in the

cylinder.

e. If the density of ingredient is very thick, we do not suggest you use

expansion tube.

Appendix2 Cylinder Frozen Introduction

15

Cylinder frozen , in a word, beater is frozen in cylinder and can not turn or turn

not well, but the motor is running, it maybe smoking and have rubber smell, it

means the triangle belt is moving, but the belt pulley can not move, then they

friction and release smoking and smell not well. The screen shows ‘JJ’ and

nothing else shows.

Cylinder Frozen solution:

Turn of the machine, wait for natural melt, about 45 -60 minutes, during this

time no matter whether you have customers, please do not turn on the

machine. If you turn on the machine, it will cause beater broken. When finish

melt, turn on the machine and press button clean, if the machine work well,

when you clean the beater, check whether it has crack, if so, change a new

beater.

Cause of Cylinder frozen and Prevention

1. Ingredients shortage

a. it most happen in machine testing, because not willing to pour enough

ingredients

b. The operators do not realize ingredients shortage.

2.Only output ice cream from one side. Not left side-right side-left side-right

side.

3. Ice cream hardness setting too hard.

4. Ingredients density are too thick, can not use yogurt.

Table of contents

Other GGM gastro Ice Cream Maker manuals