INTRODUCTION

This Operating Manual (hereinafter referred to as Manual or RE), that also includes certifi-

cate data, applies to series of Capri refrigerated wall-sited undermount cabinets (hereinafter re-

ferred to as cabinet or device). Data listed below provides information as well as guidelines for

consumers and maintenance specialists regarding:

−technical characteristics;

−manufacturer’s guarantees and certification;

−transportation and storage;

−installation, startup and operating the device (including maintenance and repairs),

disposal of the above-mentioned cabinet.

WARNING: THE MANUFACTURER BEARS NO RESPONSIBILITY FOR ANY KIND

OF DAMAGE, CAUSED BY IMPROPER OR ERRONEOUS USE OF THE CABINET, OR

ANY OTHER ACTIONS THAT ARE NOT DIRECTLY SPECIFIED IN THIS MANUAL.

1. GENERAL DATA

1. 1. Refrigeration cabinet is used for demonstration, short-time storage and selling feed

products, pre-cooled (frozen) to a temperature of effective volume is designed to operate in trade

and public catering enterprises.

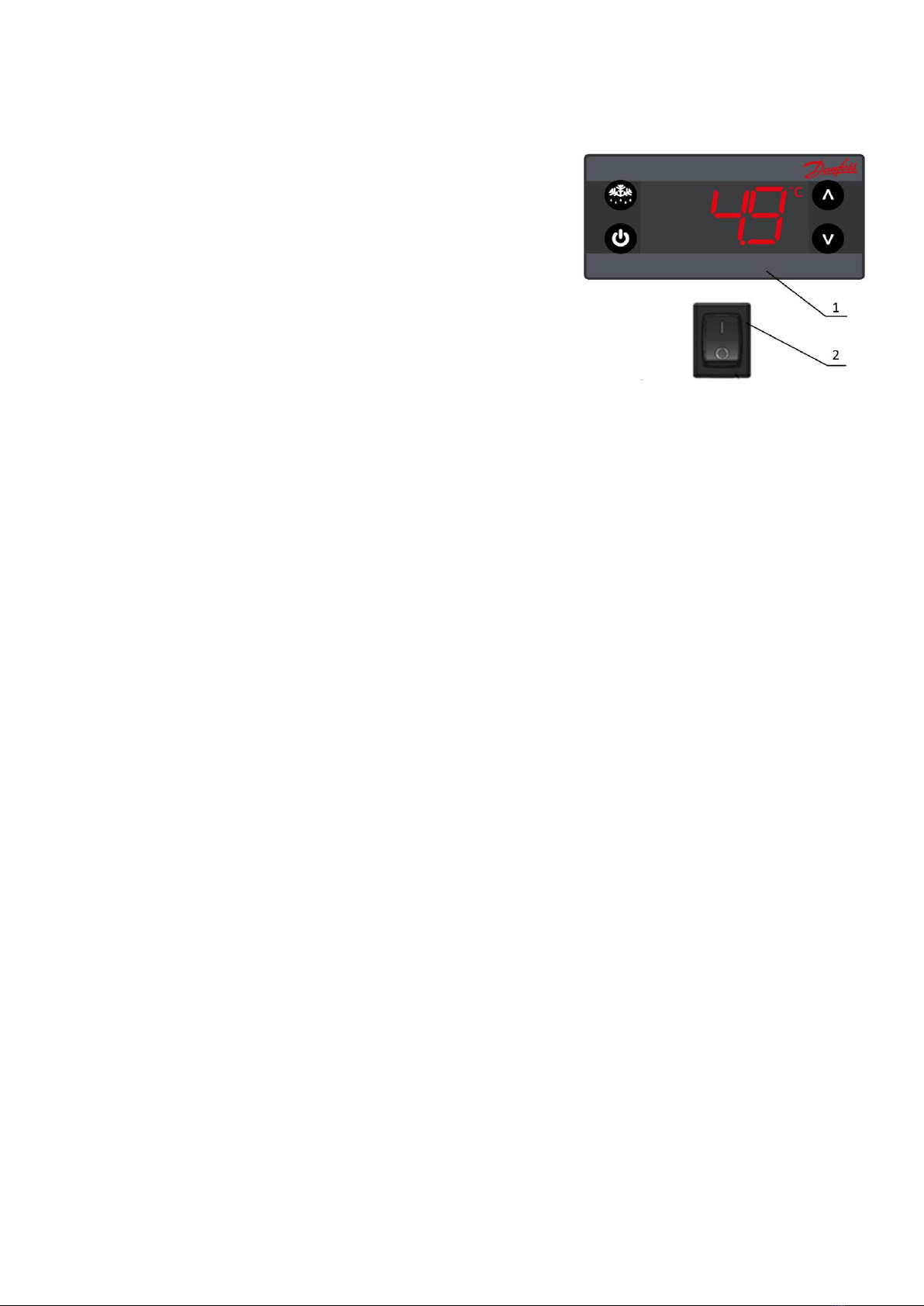

1. 2. Refrigeration cabinet consists of the case and refrigerating unit, located in the lower

part of the cabinet.

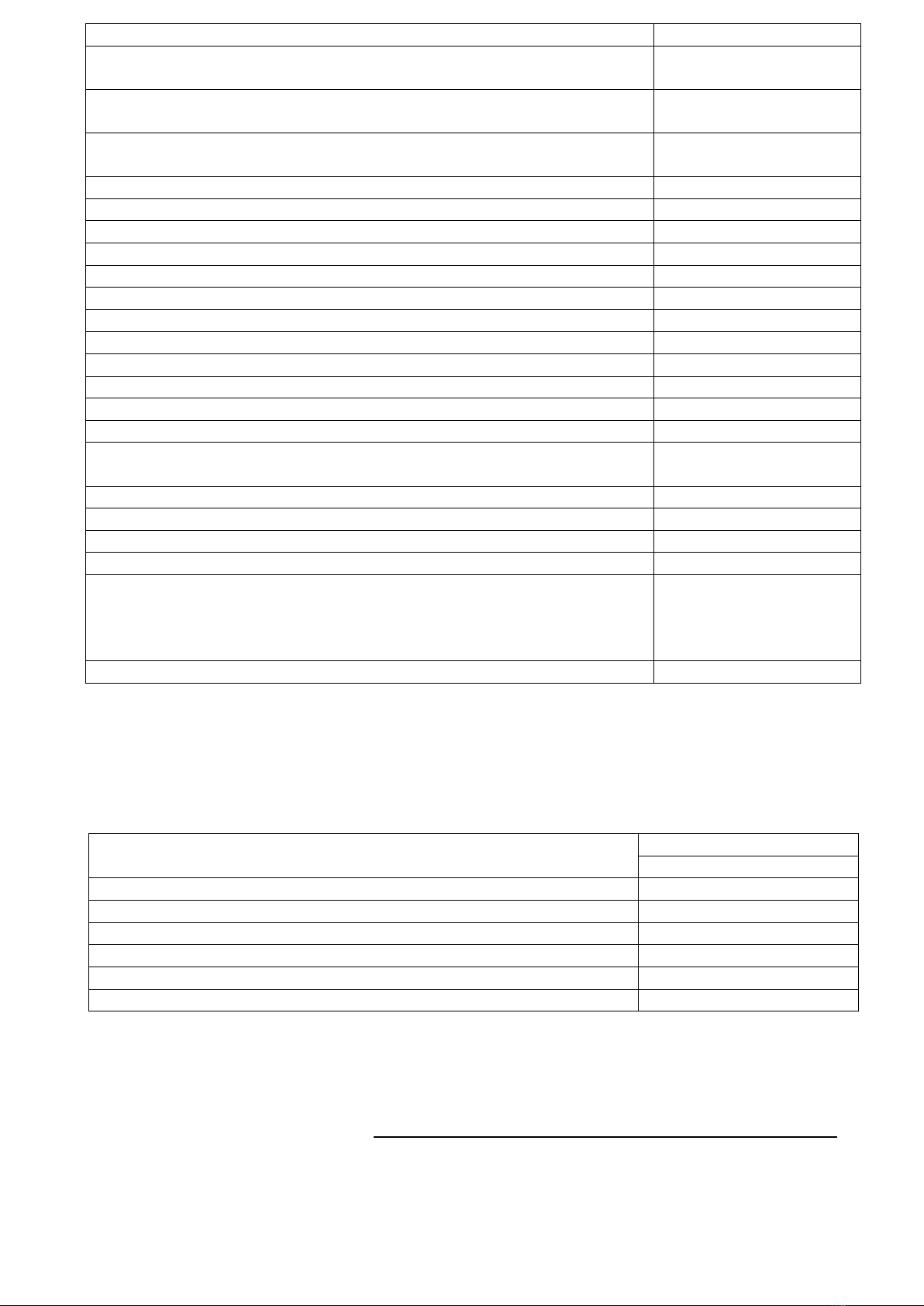

The device is designed for storing the products in a temperature range, that are specified in

table 1, section 2 of this manual.

Basic technical specifications for the cabinets are provided in table 1, section 2 of this manu-

al.

1. 3. Climatic categories for the device according to GOST IEC 60335-2-89-2013:

1 (tов=16С/80%), 2 (tов=22С/65%), 3 (tов=25С/ 60%), 4 (tов=30С/ 55%).

The environment air humidity exceeding the sets parameters, might cause condensed water

on the external device surface which does not constitute malfunction.

1. 4. The device meets the requirements for safety and environment protection, listed in the

following technical regulations, adopted by Customs Union:

1. 5. Average total service life of the device before reaching the limit state is at least 12

years.

Limit state of a device is a state where frame deficiencies no longer allow to sustain set tem-

perature range on an acceptable level and economical losses caused by the cost of the repairs and

idle time become comparable to the cost of a new device.

1. 6. The device can be transported by any types of transport, excluding air transport, in a

properly packed condition and meeting the transportation requirements, standing for the chosen

type of transport. When transporting by means of an automobile transport, the maximum allowed

speed should not exceed 60 km/h (37m/h). Loading, boarding, transportation, unloading should

be executed carefully so as not to hit or push the device. Packed device should be placed accord-

ing to the markings on the label. Do not tilt the package.

1. 7. Store the device in a storage facility or under a shed and in a shipping container provid-

ed by the manufacturing company, with storage temperature above minus 35°Сand humidity lev-

el under 80%. Storage conditions group 4 according to GOST 15150. Avoid exposure to direct

sunlight. Storage cannot exceed 6 months.