Photovoltaic Module User Manual

1.General information................................................................................................................... 3

1.1. Overview..........................................................................................................................3

1.2. Warning............................................................................................................................3

1.3. Safety Precautions:........................................................................................................3

1.4. Module Application Class-Class A:...........................................................................4

2.General Installation:................................................................................................................4

3.Mechanical Installation..............................................................................................................5

3.1. Mechanical Installation introduction............................................................................5

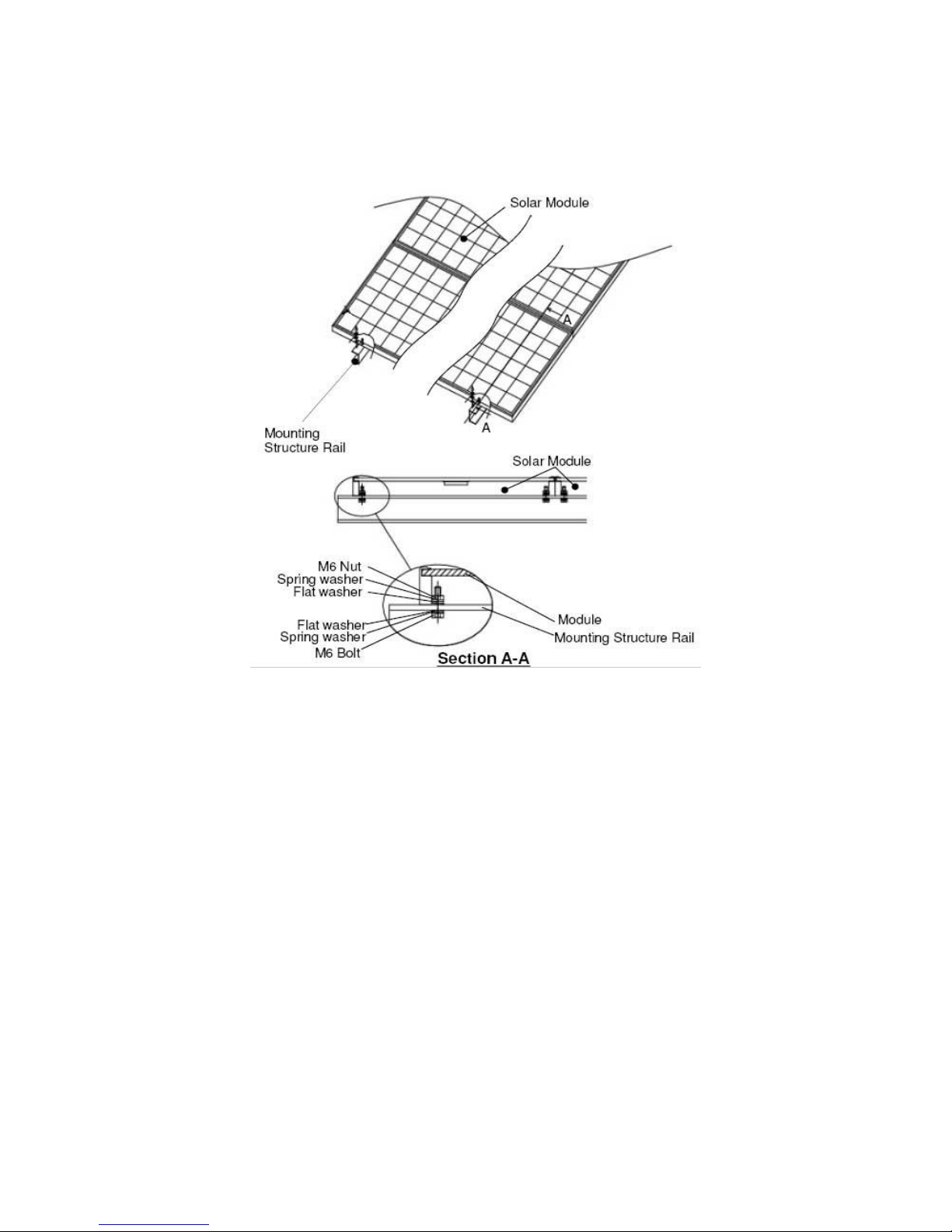

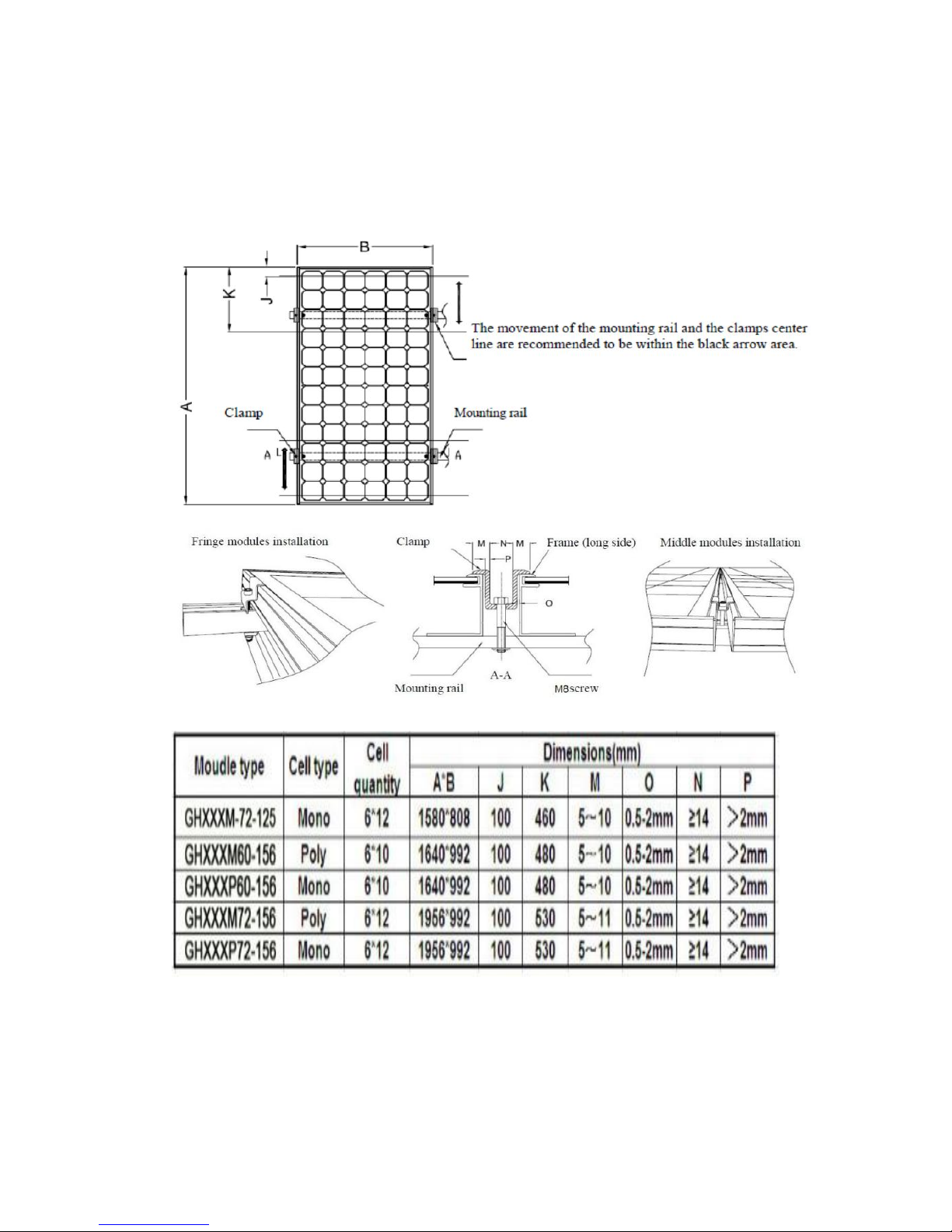

3.1.1. Screw fitting........................................................................................................ 6

3.1.2. Independent installation of Z-type clamp single module.............................7

3.2. Site selection................................................................................................................ 10

3.2.1. Ground mounting:............................................................................................10

3.2.2. Roof mounting:.................................................................................................10

3.2.3. Pole mounting:................................................................................................. 10

3.3. Attention:....................................................................................................................... 10

4.Electrical Installation................................................................................................................11

4.1. Grid-connected electrical system:.............................................................................11

4.2. Installation conditions:.................................................................................................11

5.Grounding..................................................................................................................................12

6.Modules’ Electrical parameter as below:............................................................................. 13

6.1. GHxxxP-36 (140-160W)............................................................................................. 13

6.2. GHxxxP-48 (190-220W)............................................................................................. 14

6.3. GHxxxP-54 (210-250W)............................................................................................. 15

6.4. GHxxxP-60 (230-275W)............................................................................................. 16

6.5. GHxxxP-72 (275-315W)............................................................................................. 17

6.6. GHxxxM-36 (140-165W).............................................................................................19

6.7. GHxxxM-48 (195-220W).............................................................................................20

6.8. GHxxxM-54 (215-250W).............................................................................................21

6.9. GHxxxM-60 (235-275W).............................................................................................22

6.10. GHxxxM-72 (280-330W)...........................................................................................24

7.Maintenance:............................................................................................................................ 26

8.Disclaimer of liability................................................................................................................26

9.Contact us:................................................................................................................................ 27