MECHANICAL INSTALLATION

(Note:Allinstructionshere afterareforreferenceonly. A licensed/qualifiedperson or

installer must be responsible for the design, installation, mechanical load calculation and

security of the photovoltaic system.)

3.1

Select suitable locations for installation

Select a suitable location for installing the modules.

PHONO SOLAR recommends that to achieve the best performance the modules

should face south in northern latitudes and north in southern latitudes. The

exact tilt angle and orientation of mounted modules should be recommended by a

licensed/ qualified installer.

The modules should be completely free of shade at all times.

Do not place the modules near a location where flammable gases are either

generated or collected.

Note1: Saline environments can accelerate the processes of electrical insulation

losses and galvanic corrosion, especially when different metals with high

electrochemical potential come into contact each other.

In saline environments, based on the distance to seashore, Phono

Solar generally

classifies coastal PV installation into three different levels:

From 0 up to 50 meters, Phono Solar does not recommend any installation due

to concerns for salt-mist corrosion.

From 50 to 500 meters, Phono Solar regards this as “Near -Coast”

installation requiring adherence to salt-mist corrosion prevention.

From 500 meters and onwards, Phono Solar estimates the risk of salt mist

corrosion is minor and only requires annual preventive maintenance.

In “Near- Coast” installation, Phono Solar PV modules must be installed

under the following conditions:

During the installation, do not scratch or break the corrosion-resistant

coating (e.g.

electroplated layer, oxidized coating, etc.) on the modules and mounting

systems.

Phono solar recommends that the modules shall be mounted with a minimum tilt

angle of 10° in respect to the horizen , or follow the recommendations of

experienced PV module installers.

Use corrosion-resistant materials (e.g. stainless steel SUS 316) for

components (nut,

bolt, gasket, etc.) to fixing the modules and mounting systems.

To avoid possible galvanic corrosion between the aluminum frame and the

support structure, mica lamination, or other silicone, or fluoride made

gasket shall be interposed between the two metals

When grounding the module frames, stainless steel hardware must also

be used. To prevent salt corrosion to grounding block, fluorocarbon varnish

could be sprayed on the grounding block thoroughly to form an anti-corrosion

coating (at least 40um thick) or a pad of butyl plaster covering could be

placed on the grounding block completely.

To ensure optimum module performance for near-coast installation, a

system maintenance service of every three months is generally recommended and

additionally the following maintenance measures shall be taken:

Check the frame, mounting system, grounding block and other junction areas

for potential signs of corrosion.

Clean the frame, mounting system, grounding block and other junction

areas from salt and dust accumulation.

To repair the rusty areas, apply butyl plaster or fluorocarbon varnish

spray to cover the area thoroughly after clean the salt and other dust

accumulations around the rusty areas.

Note2 :In environments where ammonia is present, Phono Solar PV modules must be

installed under the following conditions:

When fixing the modules using the 8 mounting slots, all the hardware (washers,

screws and nuts) shall be made of stainless steel;

To avoid possible galvanic corrosion between the aluminum frame and the support

structure, PVC washers or neoprene tape shall be interposed between the two metals;

When grounding the module frames, stainless steel hardware must also be used.

Note3 :If you are planning to use the PV modules where the water damage

(Humidity: > 85RH%) may be possible, please consult with Phono Solar technical

support first to determine an appropriate installation method and module type ,

or to determine whether the installation is possible.

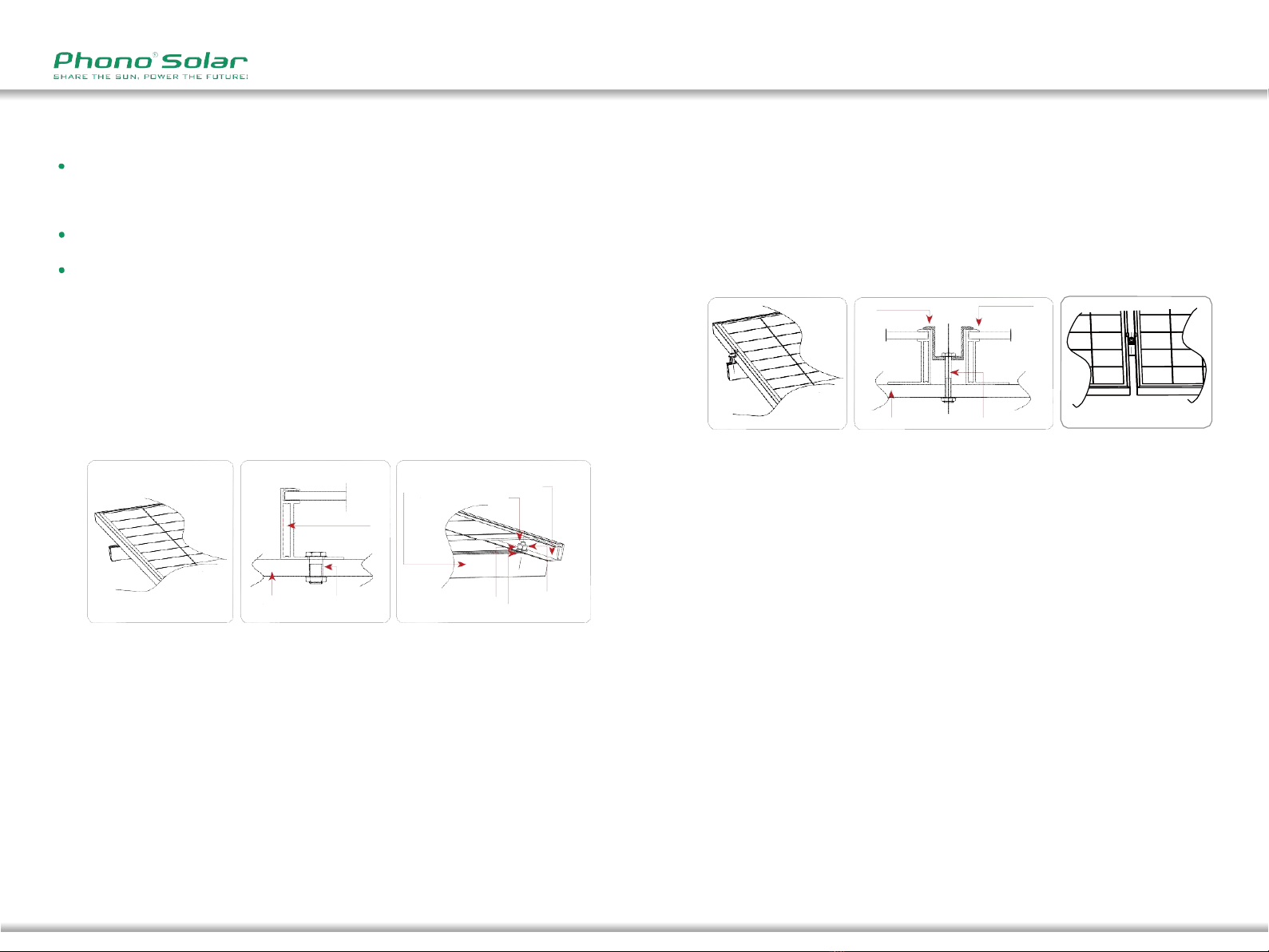

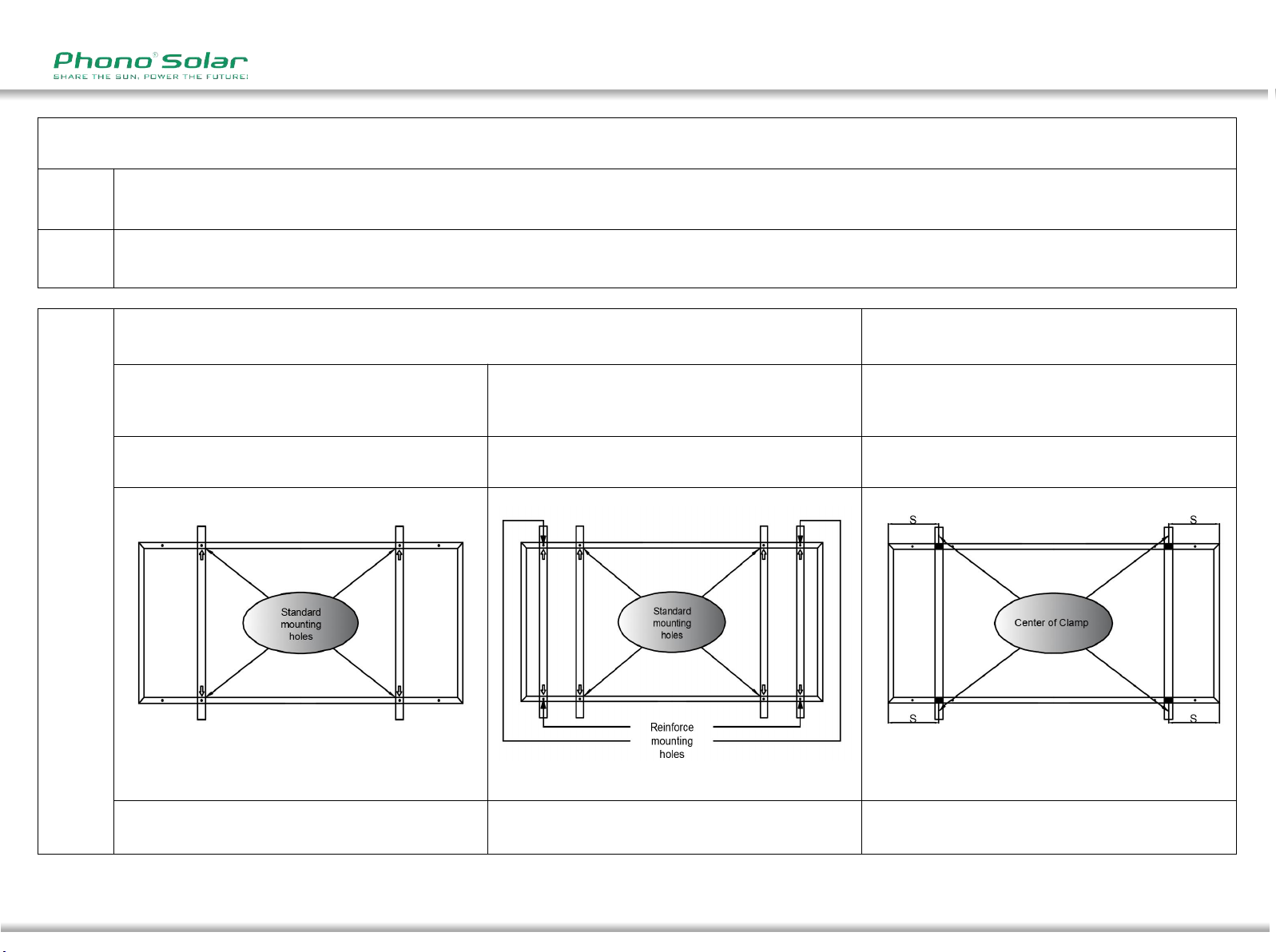

3.2

Select suitable mountingrails

Please observe the safety regulations and installation instructions included

with the