Installation Manual Series CF (excluding encapsulated screw compressors) 23042013 Rev. A / May 2007 3 of 60

Table of contents

1

General ........................................4

1.1

Intended purpose ..........................................4

1.2

Type designation...........................................4

1.3

Marking .........................................................4

1.4

Information required for inquiries and orders 4

1.5

Sale and service point...................................4

2

Safety...........................................5

2.1

General .........................................................5

2.2

Marking of instructions in the installation

manual ..........................................................5

2.3

Qualification and training of personnel .........5

2.4

Safety conscious operation...........................5

2.5

Safety instructions for the operating

company/operator .........................................6

2.6

Safety instructions for maintenance,

inspection and mounting work ......................6

2.7

Unauthorized conversion and manufacturing

of spare parts ................................................6

2.8

Unauthorized operation modes.....................6

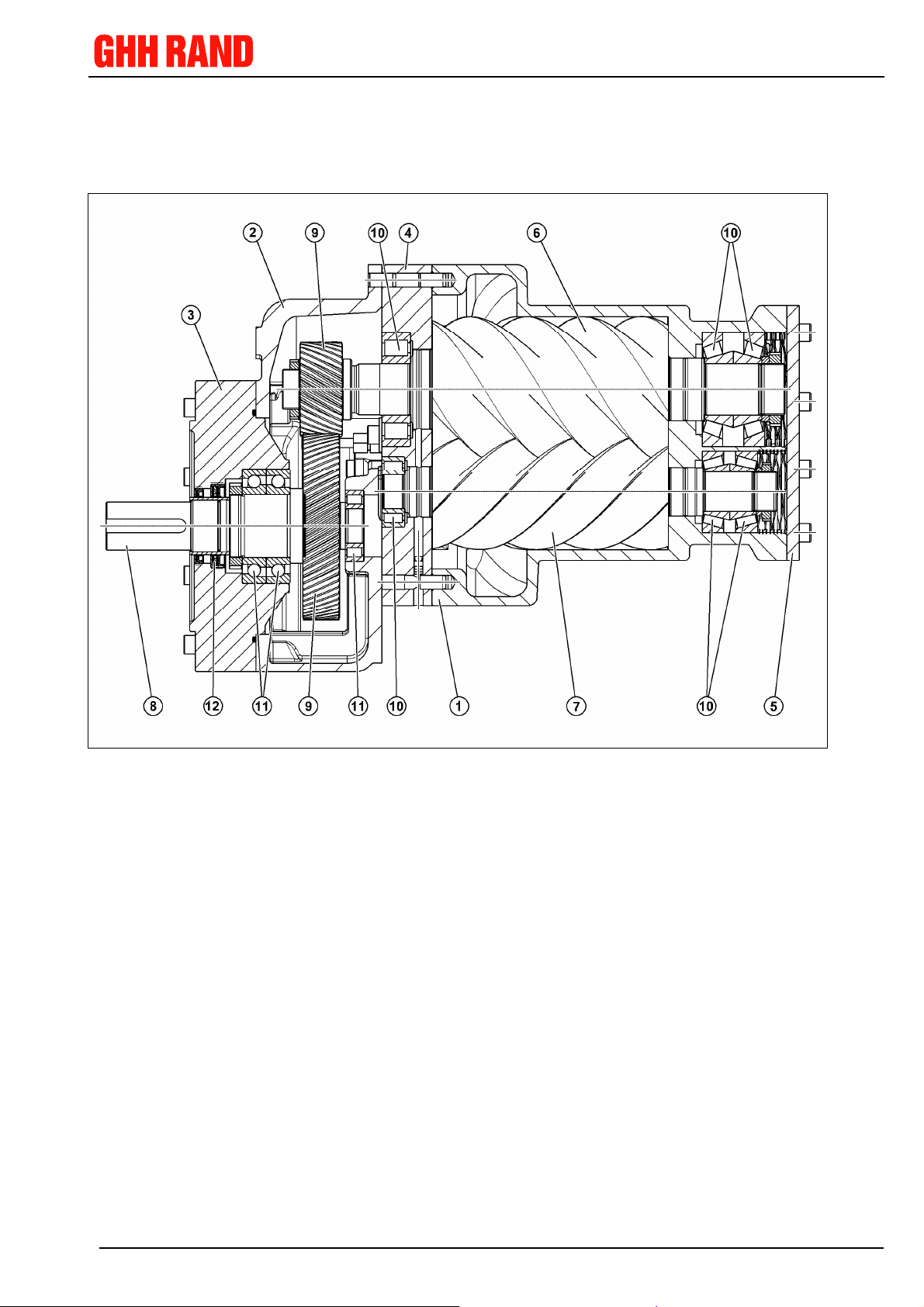

3

Description of product and

accessories .................................7

3.1

Main assemblies of the compressor .............7

3.2

Direct drive....................................................8

3.3

Belt drive .......................................................8

3.4

Gear execution..............................................8

4

Recommendation for plant

construction ................................9

4.1

Electromotor drive piping diagram ................9

4.2

Explanations to the electromotor drive tubing

plan .............................................................11

4.2.1

Start-up .................................................... 11

4.2.2

Operation under load............................... 11

4.2.3

No-load operation.................................... 11

4.2.4

Switch-off ................................................. 12

4.2.5

Oil system................................................. 12

4.3

Explanations to the diesel engine drive

tubing plan ..................................................13

4.3.1

Start-up .................................................... 13

4.3.2

Operation under load............................... 13

4.3.3

No-load operation.................................... 13

4.3.4

Switch-off ................................................. 14

4.3.5

Oil system................................................. 14

4.4

Recommendations for plant protection .......15

4.5

Dew point diagram ......................................17

4.6

Recommendations for Lubricants ..............18

4.6.1

Type of lubricants .................................... 18

4.6.2

Lubricant selection .................................. 18

4.6.3

Admixtures, impurities ............................. 19

4.7

Permissible flow rates .................................19

4.8

Filter fineness..............................................20

4.8.1

Oil filter fineness...................................... 20

4.8.2

Suction air filter fineness .........................20

4.8.3

Explanations to the filter fineness

according to ISO 4572:............................20

4.9

Fitting instructions ...................................... 21

4.9.1

Coupling...................................................21

4.9.2

Belt drive..................................................22

5

Preparation prior to start

operation....................................23

5.1

Filling up oil ................................................ 23

5.2

Checking the direction of rotation.............. 23

6

Maintenance ..............................23

7

Spare parts ................................24

8

Annex I Technical data .............26