GHIELMETTI AG –7UW50 - Technische Dokumentation ROR/09.02.2021 Page 2 of 19

Contents

1Conformity.................................................................................................................................................................................3

2Introduction3

3Warranty.....................................................................................................................................................................................3

4Safety Considerations ...........................................................................................................................................................3

4.1 General...............................................................................................................................................................................3

4.2 Safety Earth Ground......................................................................................................................................................4

5Installation .................................................................................................................................................................................4

5.1 Initial Inspection .............................................................................................................................................................4

5.2 Before Applying Power................................................................................................................................................4

5.3 Servicing ............................................................................................................................................................................4

6Disclaimer ..................................................................................................................................................................................4

7Functional description ..........................................................................................................................................................4

8Mode of Operation ................................................................................................................................................................5

9Block Diagram..........................................................................................................................................................................6

10 Control elements of the Tripping Matrix.......................................................................................................................7

10.1Connecting and Diode plugs.....................................................................................................................................7

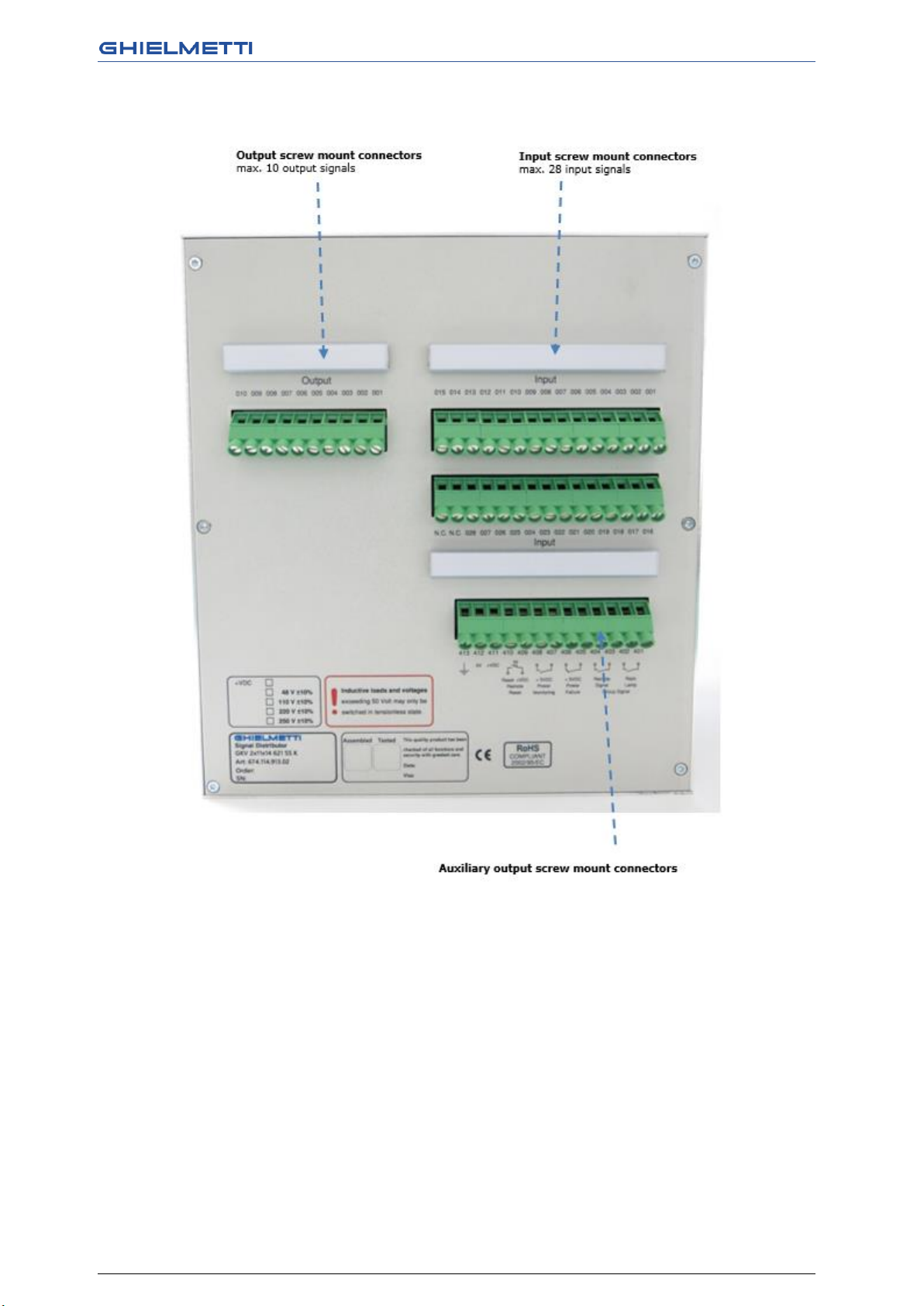

11 Interconnecting the Tripping Matrix...............................................................................................................................8

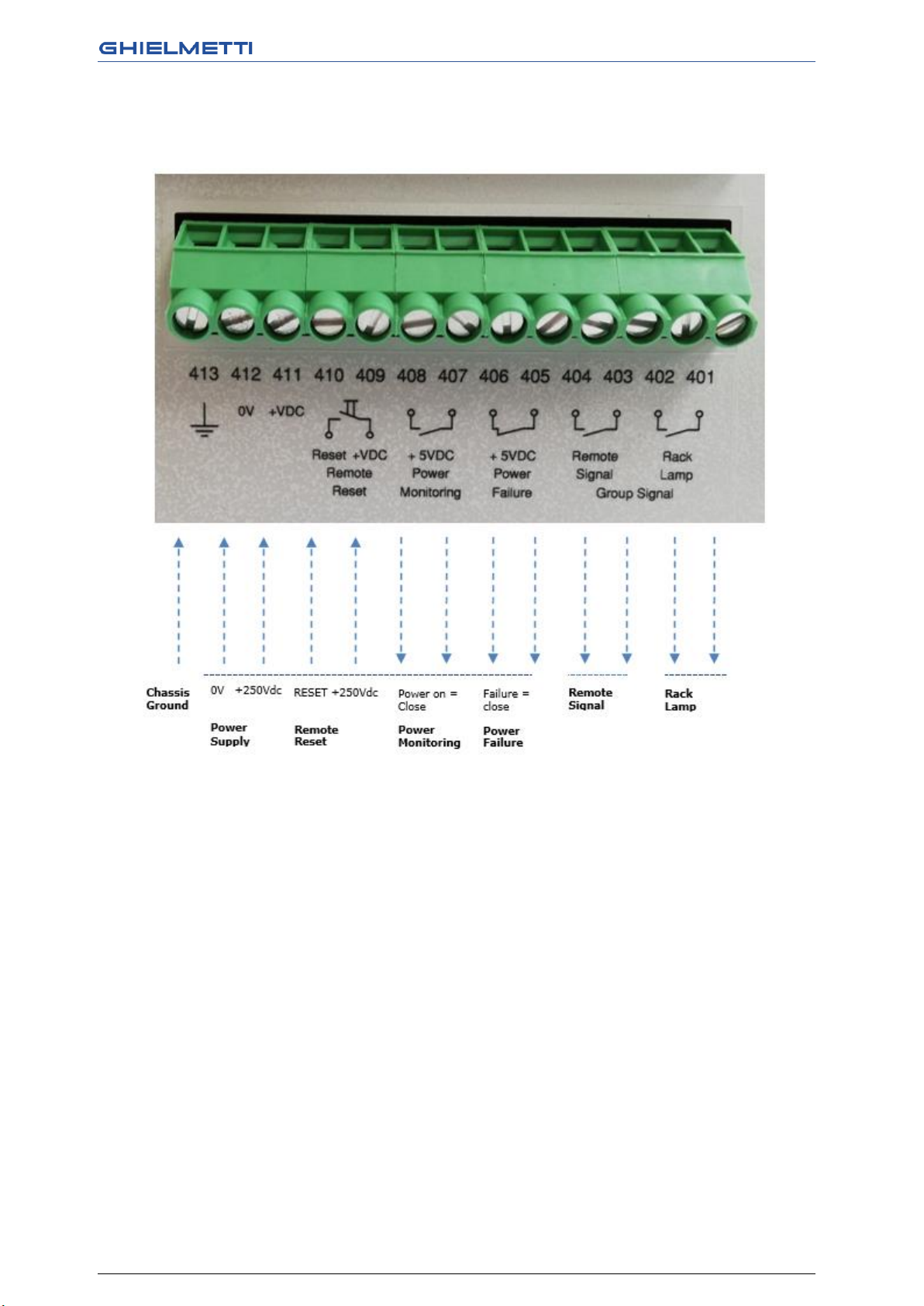

11.1Auxiliary output screw mount connectors...........................................................................................................9

12 Installation instruction ....................................................................................................................................................... 10

12.1Unpacking and repacking........................................................................................................................................ 10

12.2Preparations .................................................................................................................................................................. 10

12.2.1Mounting and connections............................................................................................................................................ 10

12.2.2Checking the rated data.................................................................................................................................................. 10

12.2.3Connections ......................................................................................................................................................................... 10

13 Operating Instructions....................................................................................................................................................... 11

13.1Safety precautions ...................................................................................................................................................... 11

13.2Operation of the device............................................................................................................................................ 11

13.2.1Marshalling of the trip commands .............................................................................................................................. 11

13.3Test and commissioning .......................................................................................................................................... 12

13.3.1General................................................................................................................................................................................... 12

13.3.2Tripping test......................................................................................................................................................................... 12

13.4Making ready for service.......................................................................................................................................... 12

14 Dimensions............................................................................................................................................................................. 14

14.1Front view....................................................................................................................................................................... 14

14.2Back view........................................................................................................................................................................ 15

14.3Side view......................................................................................................................................................................... 16

15 Specifications......................................................................................................................................................................... 17

16 Ordering Data ....................................................................................................................................................................... 18

17 Service condition and repairs.......................................................................................................................................... 18

17.1Replace the mini-fuse................................................................................................................................................ 18