VANNER

Incorporated Owner’s Manual

Vanner High Voltage Distribution Module OWNER’S MANUAL

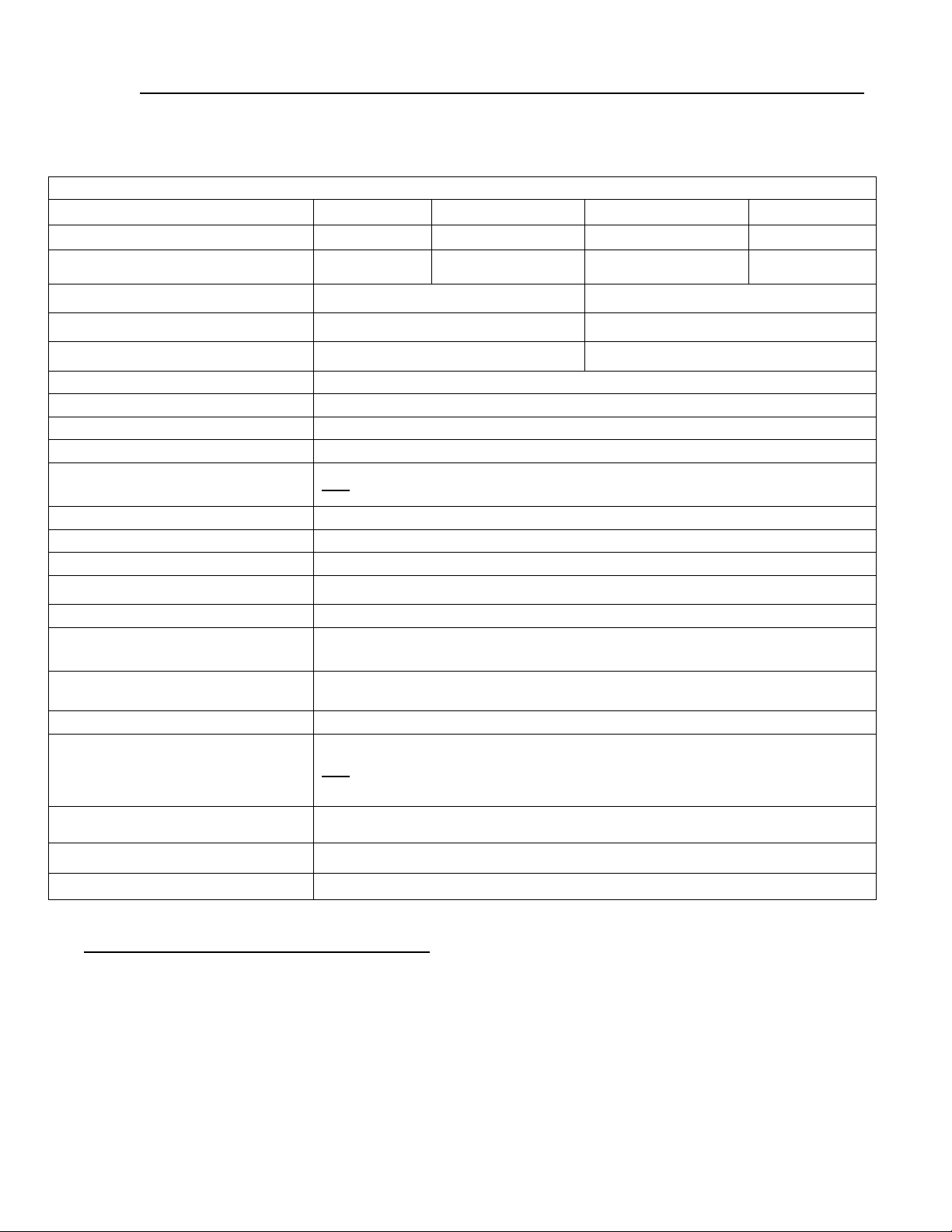

Operational Specifications

High Voltage Distribution Module

IAPIModel Numbers (250kbps)

IAPIModel Numbers (500kbps)

IAPIFuse Ratings (See notes below table.)

IAPII Model Numbers (250kbps)

IAPII Model Numbers (500kbps)

IAPII Fuse Ratings (See notes below table.)

High Input Voltage Range (VDC)

High Input Voltage Nominal (VDC)

High Input Voltage Max Survivable (VDC)

Low Input Voltage Range (VDC)

Max Continuous Current (AMPS)

60A/Channel

Note: The HVDM hardware is capable of supporting 60A/Channel, however, it is limited by the

exportable power rating of the hybrid traction drive system.

Max Pre-Charge Current (AMPS)

+24V Battery Input Current (AMPS)

Ignition Input Current (AMPS)

High Voltage Passive Discharge

Upon opening of contactors, removal of high voltage or terminal access cover, a capacitive load of

3,400µF will discharge to 50 VDC or less within 5 minutes.

A capacitive load of 6,800µF will discharge to 50 VDC or less within 10 minutes.

Ambient Operating Temperatures

Min: -40°C (-40°F)

Max: 70°C (158°F)

-40°C to +105°C (-40°F to 221°F)

Internal components to be serviced by Vanner personnel only.

No routine maintenance of module is required.

Note: In the event an internal fuse is blown, it may be replaced by a qualified technician. Care

must be taken in following high voltage safety procedures prior to servicing and tightening

hardware to specified torque values.

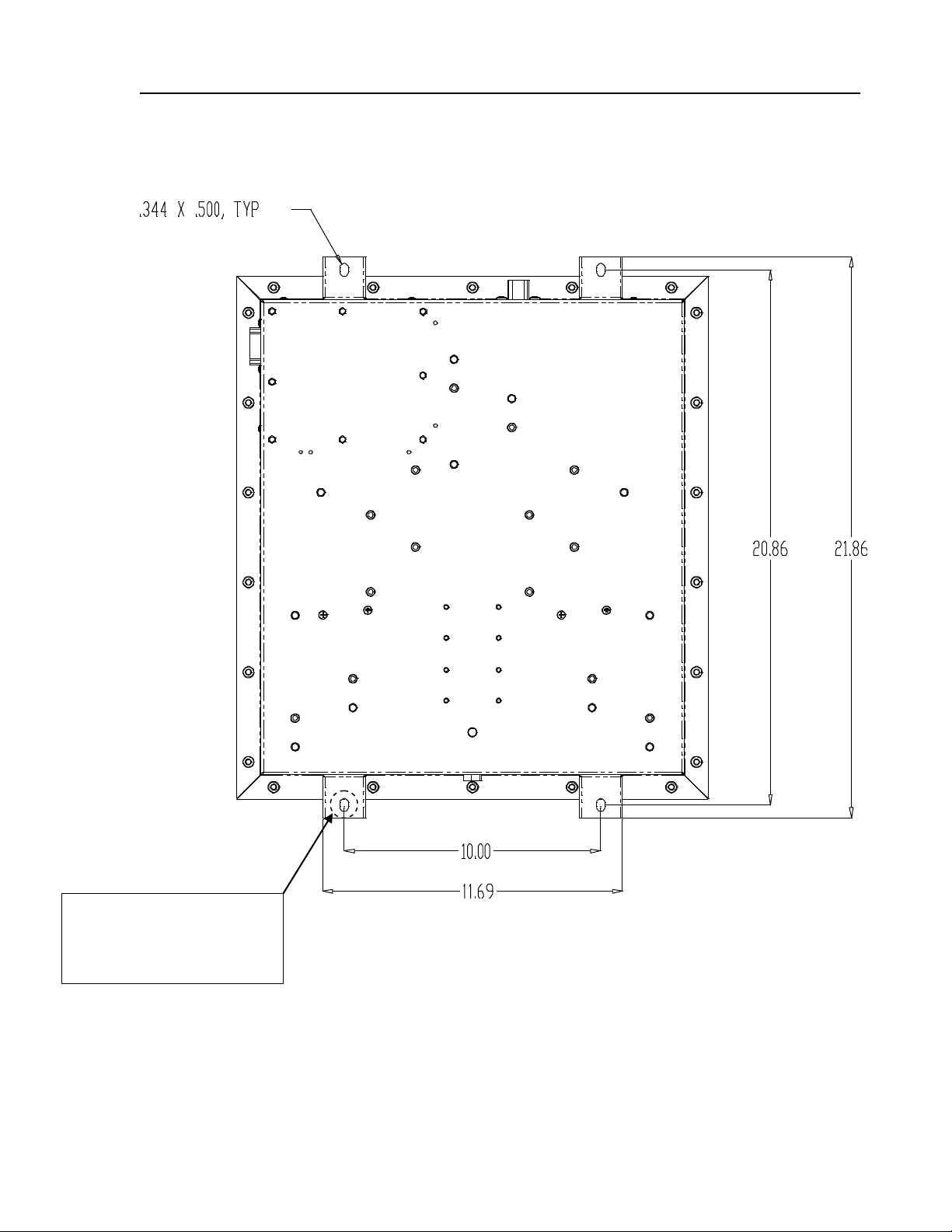

Environmental Considerations

IP55 Rated

Powder coated galvannealed steel enclosure provides protection against salt, fungus, dust, water,

fuel vapors and all fluids associated with commercial and off-highway vehicle operations.

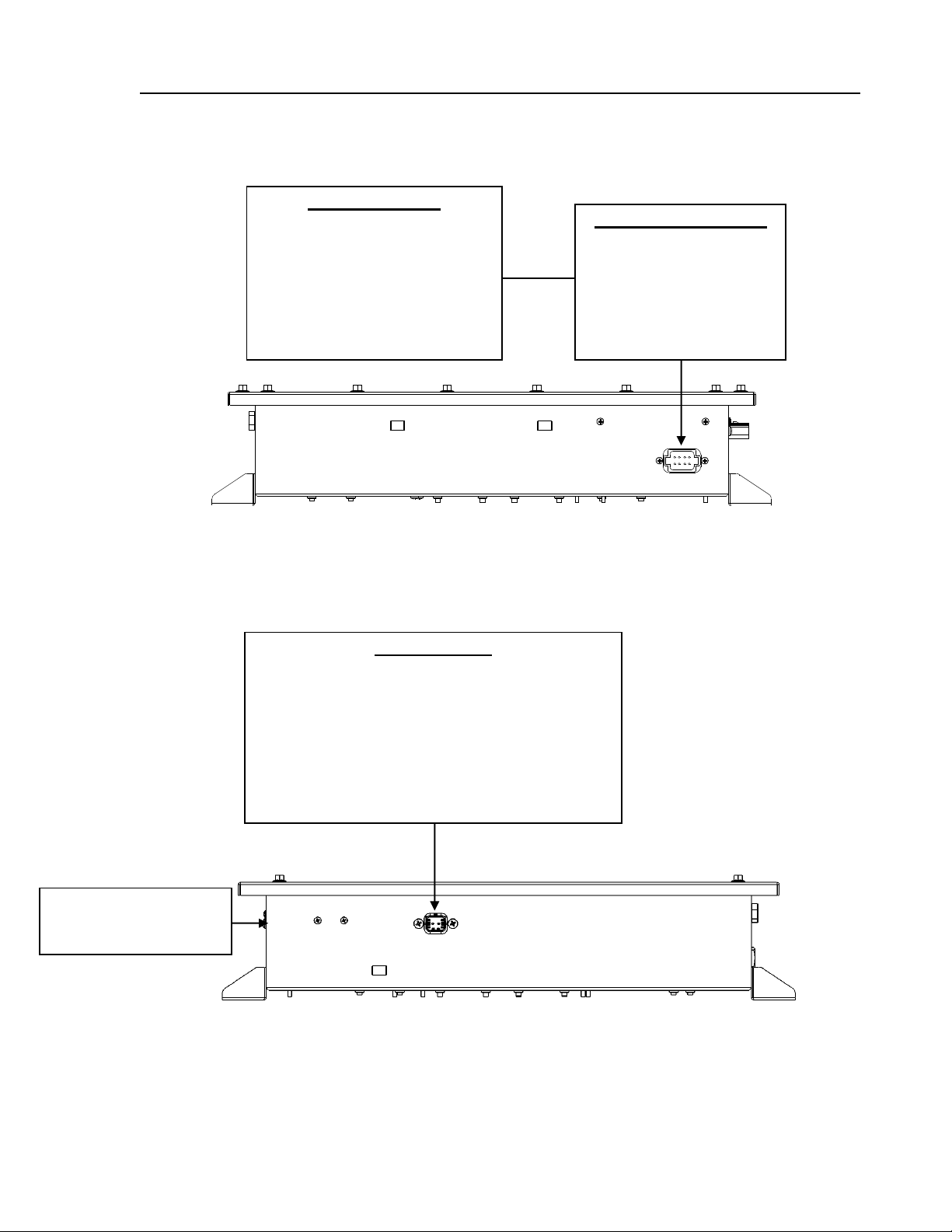

Mount on a flat surface (horizontal or vertical orientation) close to the high voltage batteries to

permit short cable runs.

Notes:

1. Channel 1 output is reserved for Vanner HBA's. Performance of the HVDM will be compromised if the load

connected to Channel 1 is not single or dual HBA's.

2. Channel 1 output is fused at 50A for Dual HBA's used in IAPIand IAPII applications.

3. Channel 2 output is fused at 80A for the VEPI (Vanner Exportable Power Inverter) used in IAPII applications.