T02.0.1X.6C-01 page 2of 3

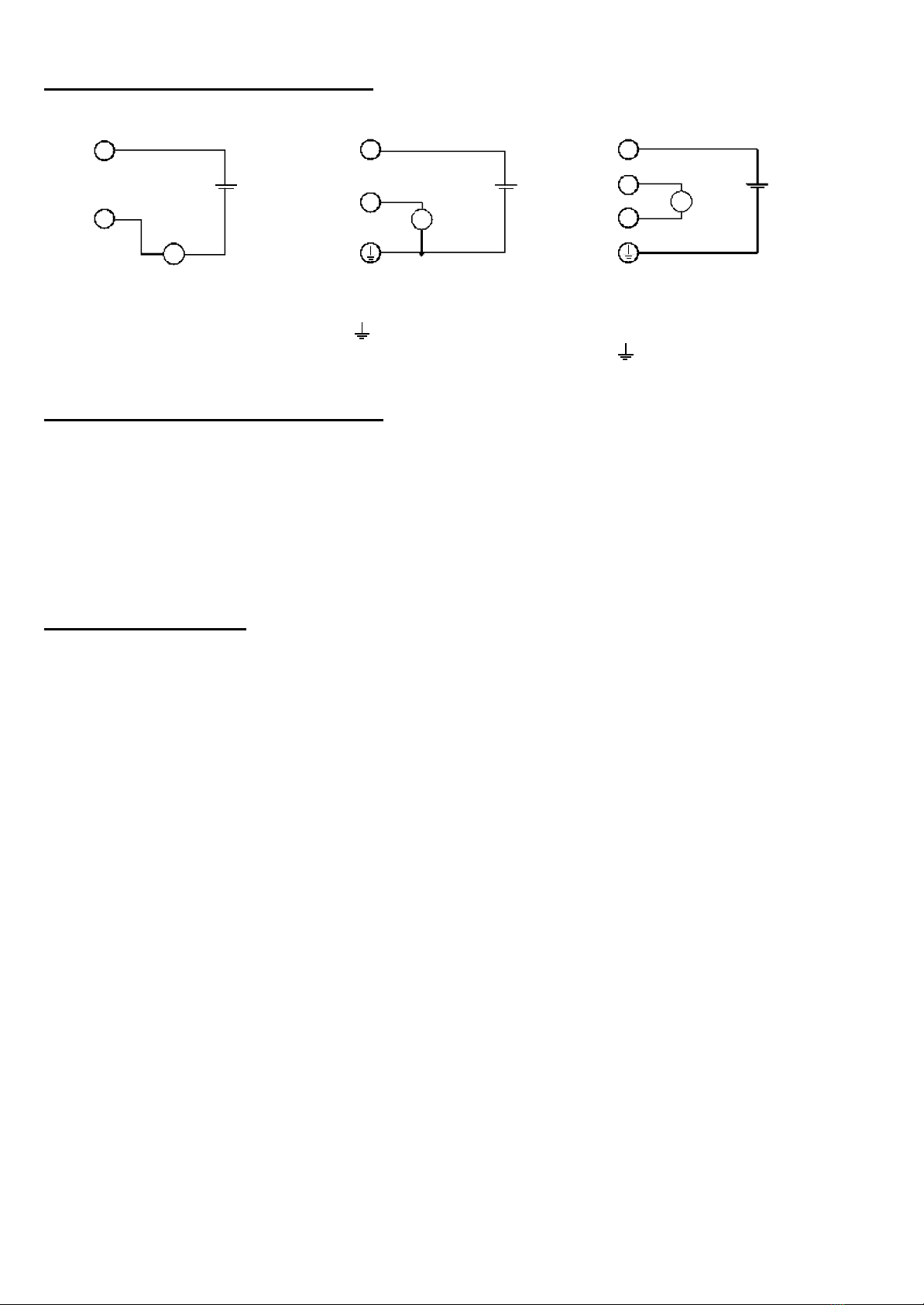

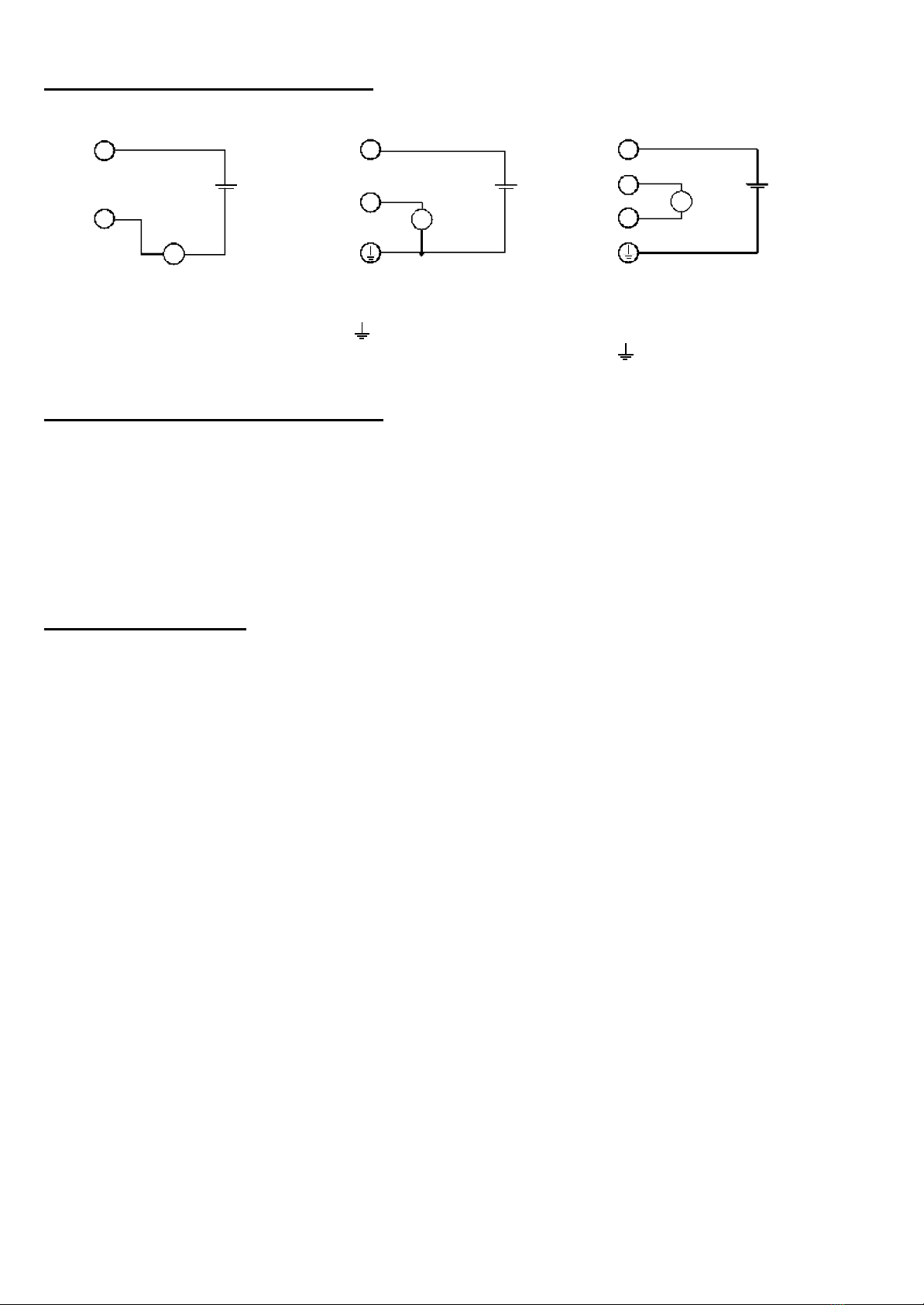

Assignment of elbow-type plug:

2-wire connection (4-20mA) 3-wire connection (voltage) 4- wire connection (voltage)

1= supply voltage +Uv 1= signal + 1= signal +

2= GND / signal 3= supply voltage +Uv 2= signal -

=supply voltage -Uv 3= supply voltage +Uv

signal - = supply voltage -Uv

General installation instructions:

To mount the connection cable (2-, 3-, or 4-wire depending on type of device) the angle plug screw has to be loosened

and the coupling insert has to be removed by means of a screw driver at the position indicated (arrow).

Pull out connection cable through PG glanding and connect to the loose coupling insert as described in the wiring

diagram. Replace loose coupling insert onto the pins at the transmitter housing and turn cover cap with PG glanding in

the direction desired till it snaps on (4 different starting positions at 90° intervals). Re-tighten the screw at the angle plug.

Before connecting to supply voltage, ensure that a working electrode is connected.

Safety instructions:

This device has been designed and tested in accordance with the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special

safety advises given in this manual will be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if the device is not subjected to any other

climatic conditions than those stated under "Specification". If the device is transported from a cold to a warm

environment condensation may cause in a failure of the function. In such a case make sure the device temperature

has adjusted to the ambient temperature before trying a new start-up.

2. General instructions and safety regulations for electric, light and heavy current plants, including domestic safety

regulations (e.g. VDE), have to be observed.

3. If device is to be connected to other devices (e.g. via PC) the circuitry has to be designed most carefully. Internal

connection in third party devices (e.g. connection GND and earth) may result in not-permissible voltages impairing or

destroying the device or another device connected.

4. If there is a risk whatsoever involved in running it, the device has to be switched off immediately and to be marked

accordingly to avoid re-starting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer time.

In case of doubt, please return device to manufacturer for repair or maintenance.

1

2

A

Uv V

3

Uv1VUv

3

1

2