Kiebitzh rn 18 ● 22885 Barsbüttel ● Germany

Phone +49-40-670 73-0 ● Fax -288

2

able of contents Page

1. Intended use (areas of application) ................................................................. 3

1.1 Safety signs and symbols ........................................................................ 3

1.2 Safety instructions .................................................................................... 4

1.3 Product liability and warranty ................................................................... 4

1.4 Standards and directives .......................................................................... 4

2. Product description .......................................................................................... 5

2.1. Scope of delivery ...................................................................................... 5

2.2. Functional principle .................................................................................. 6

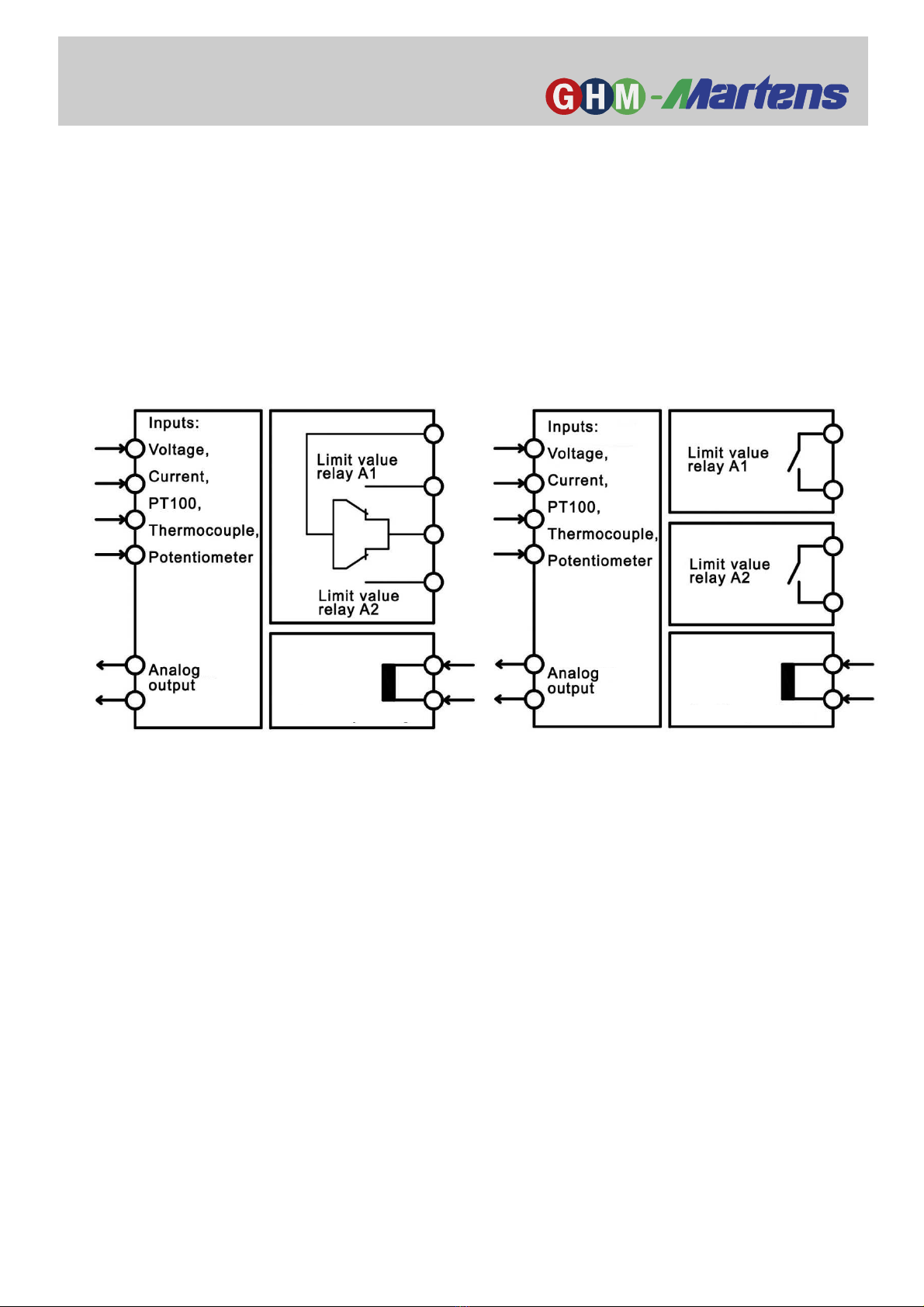

2.3. Connection diagram ................................................................................. 7

2.4. Limit value contacts .................................................................................. 8

2.5. PowerRail ................................................................................................. 9

2.6. Positioning of the adhesive labels with measuring units ........................ 10

2.7. Type plate .............................................................................................. 10

3. Assembly and installation .............................................................................. 11

3.1. Mechanical assembly ............................................................................. 11

3.2. Electrical installation ............................................................................... 11

4. Controls and functional description ............................................................. 12

5. Commissioning, maintenance and service .................................................. 14

5.1 Commissioning ....................................................................................... 14

5.2 Maintenance ........................................................................................... 14

5.3 Service ................................................................................................... 14

6. echnical data ................................................................................................. 15

6.1 Mechanical design / dimensions ............................................................ 17

7. Order code ....................................................................................................... 18

8. Device transport and storage ........................................................................ 18

9. Return to manufacturer .................................................................................. 19

10. Disposal ........................................................................................................... 19

11 Imprint .............................................................................................................. 19

12. Certificate of conformity ................................................................................. 20