T45.0.0X.6C-09 Mounting and operating manual GMUD MP Page 2 of 16

_____________________________________________________ _____________________________________________________________________________

1GENERAL NOTE......................................................................................................................................................3

2SAFETY......................................................................................................................................................................3

2.1 INTENDED USE.......................................................................................................................................................3

2.2 QUALIFIED STAFF ..................................................................................................................................................3

2.3 SAFETY SIGNS AND SYMBOLS................................................................................................................................3

2.4 SUITABILITY ..........................................................................................................................................................3

2.5 REASONABLY FORESEEABLE MISUSE ....................................................................................................................3

2.6 SAFETY INSTRUCTIONS..........................................................................................................................................4

2.6.1 During configuration .....................................................................................................................................4

2.6.2 During normal operation...............................................................................................................................4

3PRODUCT DESCRIPTION......................................................................................................................................5

3.1 SCOPE OF SUPPLY ..................................................................................................................................................5

3.2 OPERATING AND MAINTENANCE ...........................................................................................................................5

3.3 TYPE PLATE ...........................................................................................................................................................5

3.4 AVAILABLE OPTIONS.............................................................................................................................................5

3.5 GENERAL INSTALLATION INSTRUCTIONS ..............................................................................................................6

3.5.1 Wall mounting................................................................................................................................................6

3.5.2 Connector mounting.......................................................................................................................................6

3.5.3 Pressure connection.......................................................................................................................................6

3.5.4 Commissioning...............................................................................................................................................7

3.5.5 Decommissioning...........................................................................................................................................7

3.5.6 Ready for operation .......................................................................................................................................7

3.6 CONNECTION .........................................................................................................................................................8

3.7 DISPLAY ................................................................................................................................................................9

3.8 KEYPAD.................................................................................................................................................................9

4CONFIGURATION.................................................................................................................................................10

4.1 PASSWORD LOCK.................................................................................................................................................10

4.2 OUTPUT CONFIGURATION....................................................................................................................................10

4.3 CORRECTION .......................................................................................................................................................11

4.4 SEA LEVEL CORRECTION (ONLY FOR ABSOLUTE DEVICES) .................................................................................11

4.5 TRANSISTOR OUTPUT (ONLY AVAILABLE WITH OPTION –OUT) .........................................................................11

4.6 FILTER SETTINGS .................................................................................................................................................12

4.7 LOCK SETTINGS ...................................................................................................................................................12

5DETAILS FOR PRESSURE MEASUREMENT ..................................................................................................12

5.1 ABSOLUTE PRESSURE ..........................................................................................................................................12

5.2 DIFFERENTIAL PRESSURE ....................................................................................................................................12

5.3 RELATIVE PRESSURE ...........................................................................................................................................12

6ERROR AND SYSTEM MESSAGES....................................................................................................................13

7INSPECTION OF ACCURACY / ADJUSTMENT SERVICE ...........................................................................13

8RESHIPMENT AND DISPOSAL...........................................................................................................................13

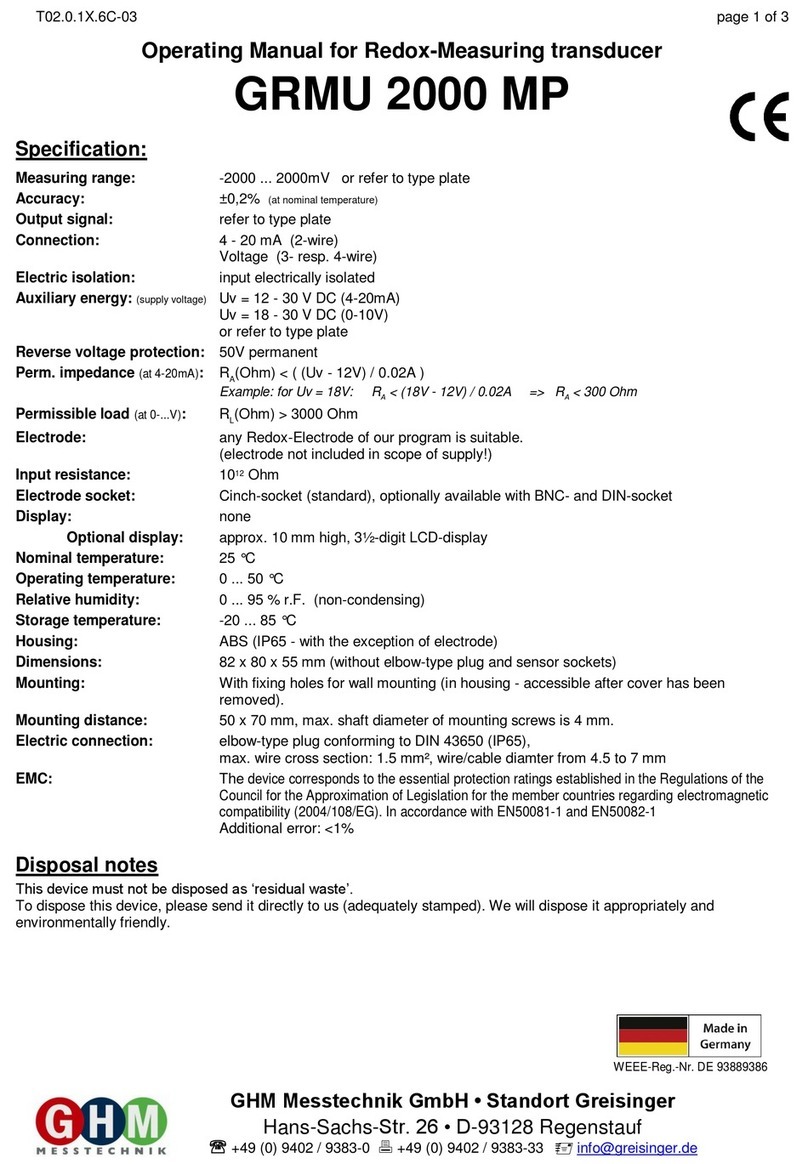

9SPECIFICATION ....................................................................................................................................................14

10 SENSOR ACCURACIES.....................................................................................................................................15

10.1 ACCURACIES WITH STANDARD MEASURING RANGES......................................................................................15

10.1.1 GMUD-MP special model for low pressure (differential pressure) ............................................................15

10.1.2 GMUD-MP standard (differential pressure)...............................................................................................15

10.1.3 GMUD-MP standard (absolute pressure) ...................................................................................................15

10.1.4 GMUD-MP special model for barometric pressure ....................................................................................15

10.2 ACCURACIES WITH SPECIFIC MEASURING RANGES..........................................................................................15