IM-T-257b2014.4

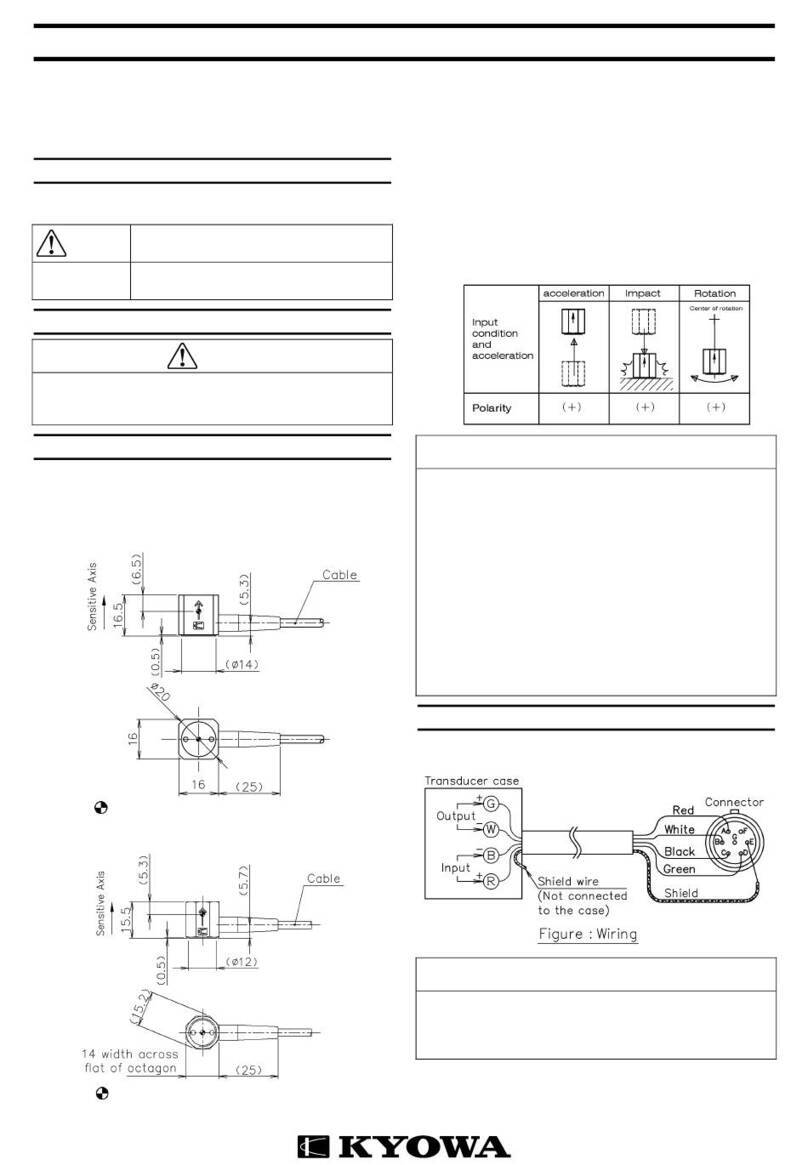

BER-A-15S Wall-surface Soil Pressure Transducer

INSTRUCTION MANUAL

Thank you for purchasing BER-A-15S Wall-surface Soil Pressure

Transducer.

Before using it, please read this instruction manual carefully. Also, keep

the manual within easy reach so that you can refer to it whenever

necessary.

1. Calling the operator’s attention

The following cautionary symbols and headlines are used to invite the

operator's attention. Be sure to observe the accompanying precautions in

order to safeguard the operator and preserve the performance of the

instrument.

Caution

Cautions are given to invite the operator’s attention,

in order to avoid instrument failure or mal-function.

Be sure to observe the accompanying instructions.

2. Safety precautions

mounted state. Do not bury the

BER-A-15S for measuring underground pressure. Since the

BER-A-15S does not satisfying the shape factor (thickness to diameter

ratio: 1/5) for measuring underground pressure, precise measurements

cannot be performed.

Barometric pressure and temperature affect the Zero point of the

BER-A-15S. The amount of change in barometric pressure equals that

of the Zero point. You can compensate the Zero point by measuring

barometric pressure. For long-term continuous measurements, we

recommend you to compensate the barometric pressure. (1hPa =

0.00102 kgf/cm2)

Avoid pressure and impact beyond the max. load (As for the numerical

value, 7 refers to the list of specifications) rating on the pressure

sensing diaphragm. If not, residual stress will occur to alter

measurements largely, and measuring will thus fail.

Always pack the BER-A-15S in a cardboard box for transportation. Do

not drop, hit, or apply any impact to the BER-A-15S.

Do not hang the BER-A-15S by holding the cable. Always hold its main

body.

Do not drop any matters on the cable or step on the cable. Even if the

cable appearance is observed normal, conductor wires inside the cable

may be damaged.

Do not apply tension to the cable.

Do not excessively bend the cable. Take care and keep the minimum

radius of the cable curvature more than 10 cm.

Take special care for fixing and protecting the cable after installing the

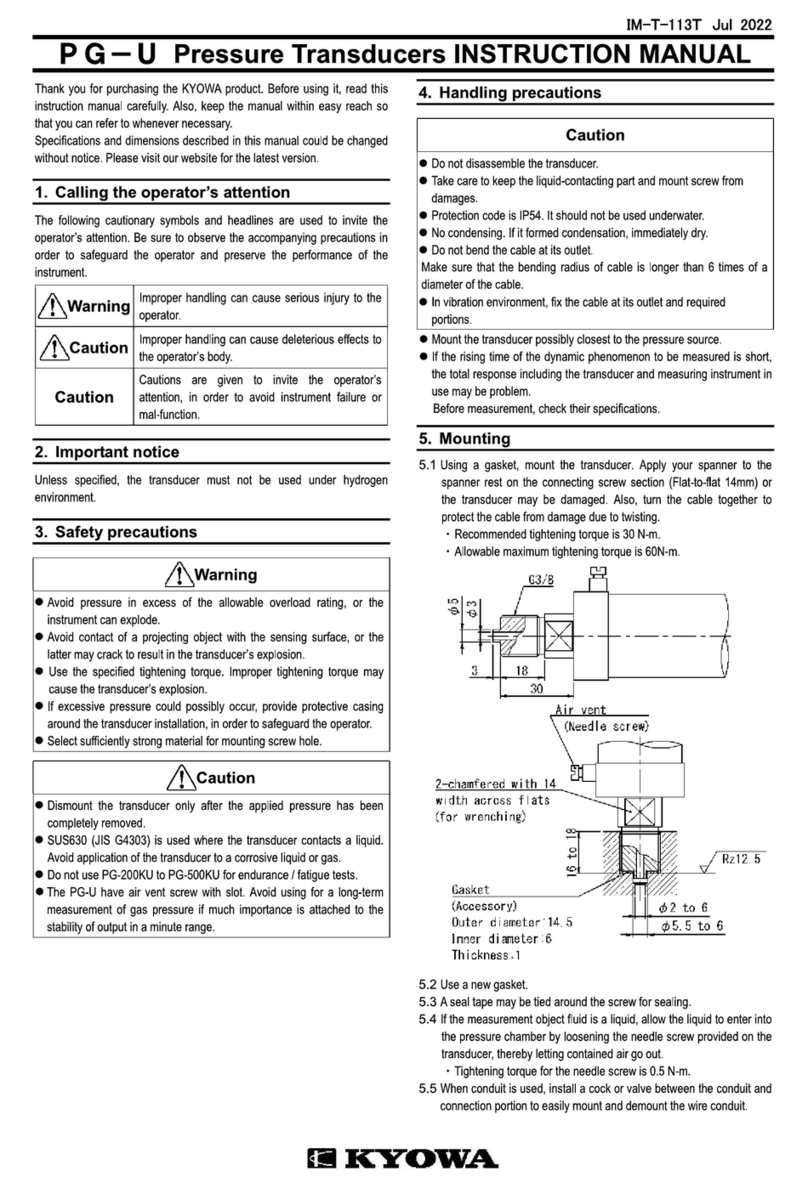

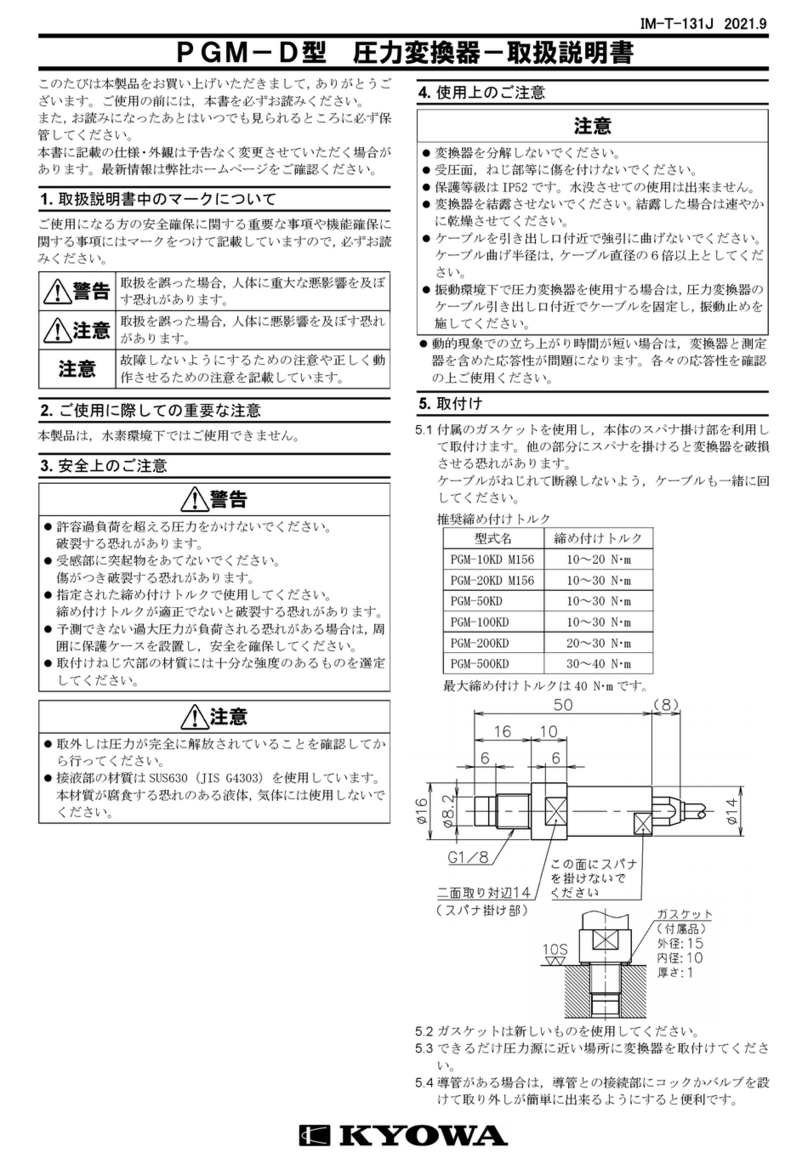

3. Mounting

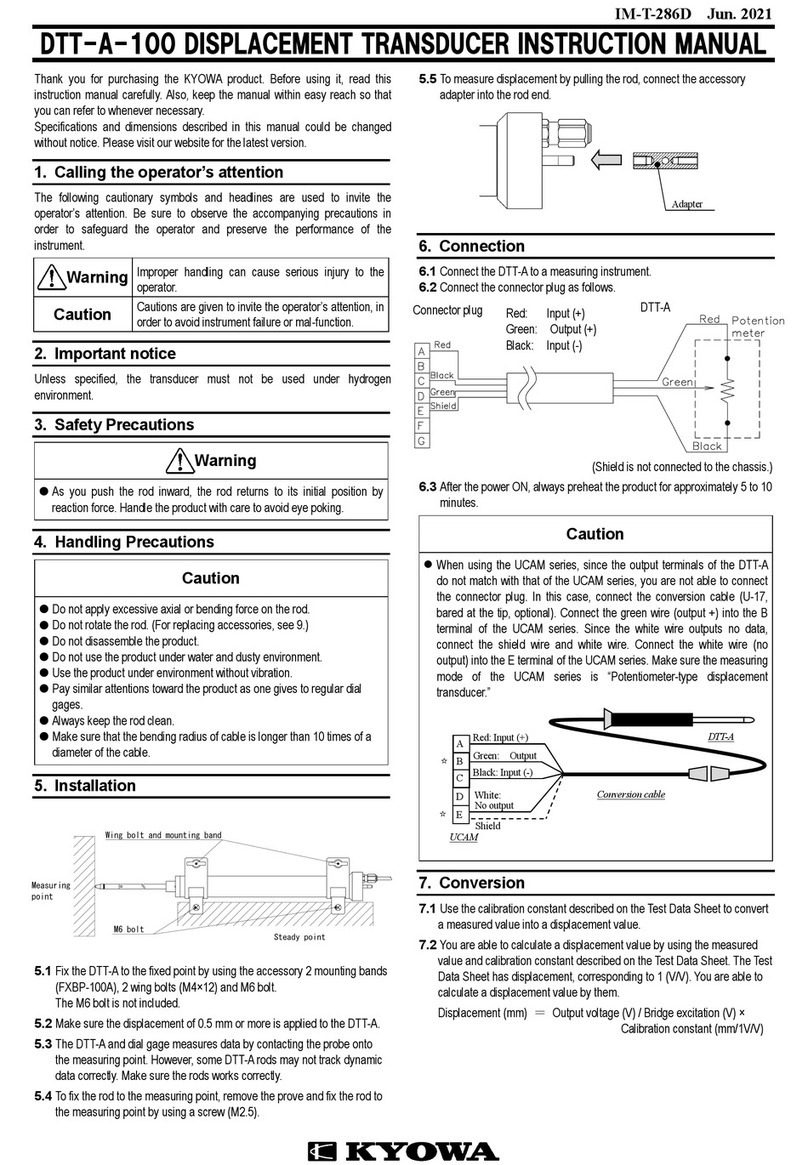

3.1 When installing the BER-A-15S, drill a hole having 30.5 mm in inner

diameter on the wall as shown in the attached 8.outside drawing.

Prepare a fixture to make the sensing diaphragm have the same level

with the mounting wall surface. Finish the surface sealed with O-ring

to have the finish level about No. ‘▽▽▽.’

3.2 Firstly, weld only the fixture to the entire periphery of the mounting wall

surface. (Sufficiently tight enough not to allow the water leak when the

water pressure is applied.) Do not weld the fixture with the BER-A-15S

mounted.

3.3 Apply the attached vacuum grease to the accessory O-ring. Install the

accessory O-ring (P-22) to the BER-A-15S. Make sure there are no

foreign objects (dust or sand) on the surface. Install them into the hole

on the wall.

3.4 Screw the screws of the mounting-fixture handle into 2 drilled holes

(1.2 mm), located around the sensing surface of the BER-A-15S.

3.5 After installing the BER-A-15S, check the zero point is stable with a

static strainmeter. Due to a temperature difference between the

ambient temperature and BER-A-15S, touched for the installation,

some BER-A-15S units are unstable. At this time, take sufficient time

for stabilization.

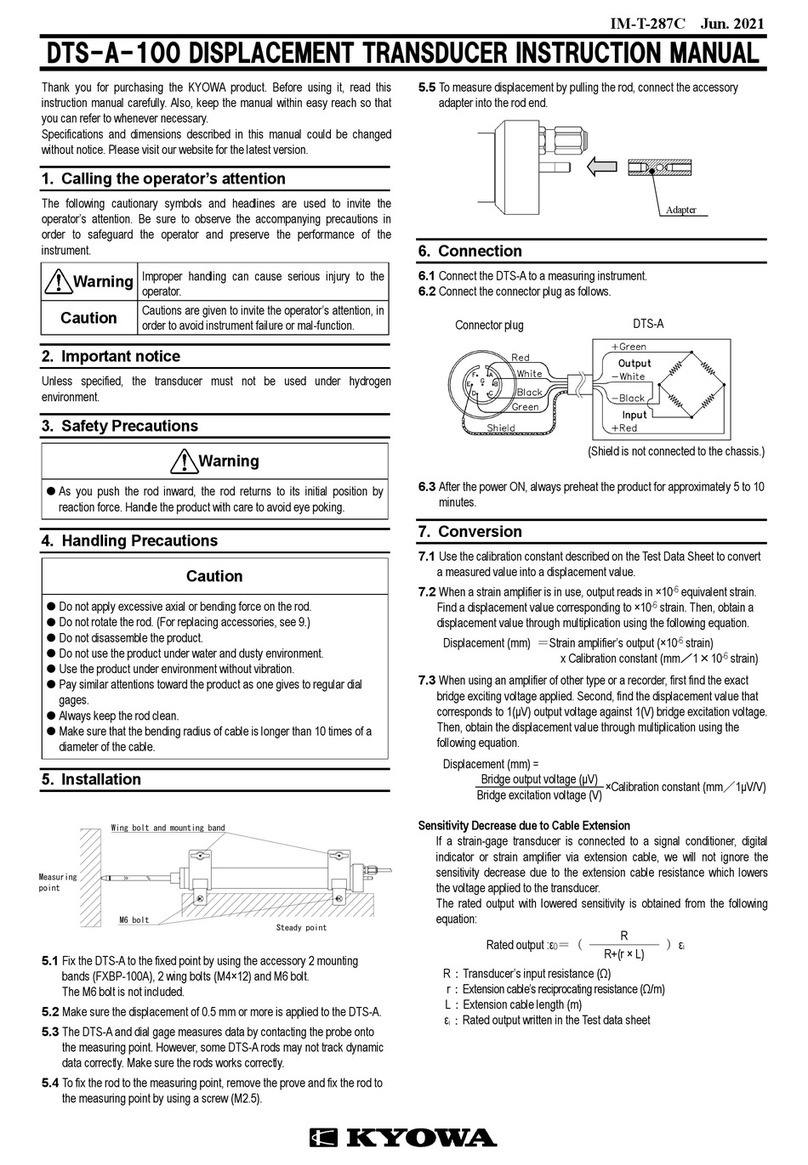

4. Connection

4.1 Connect the transducer to strain amplifier.

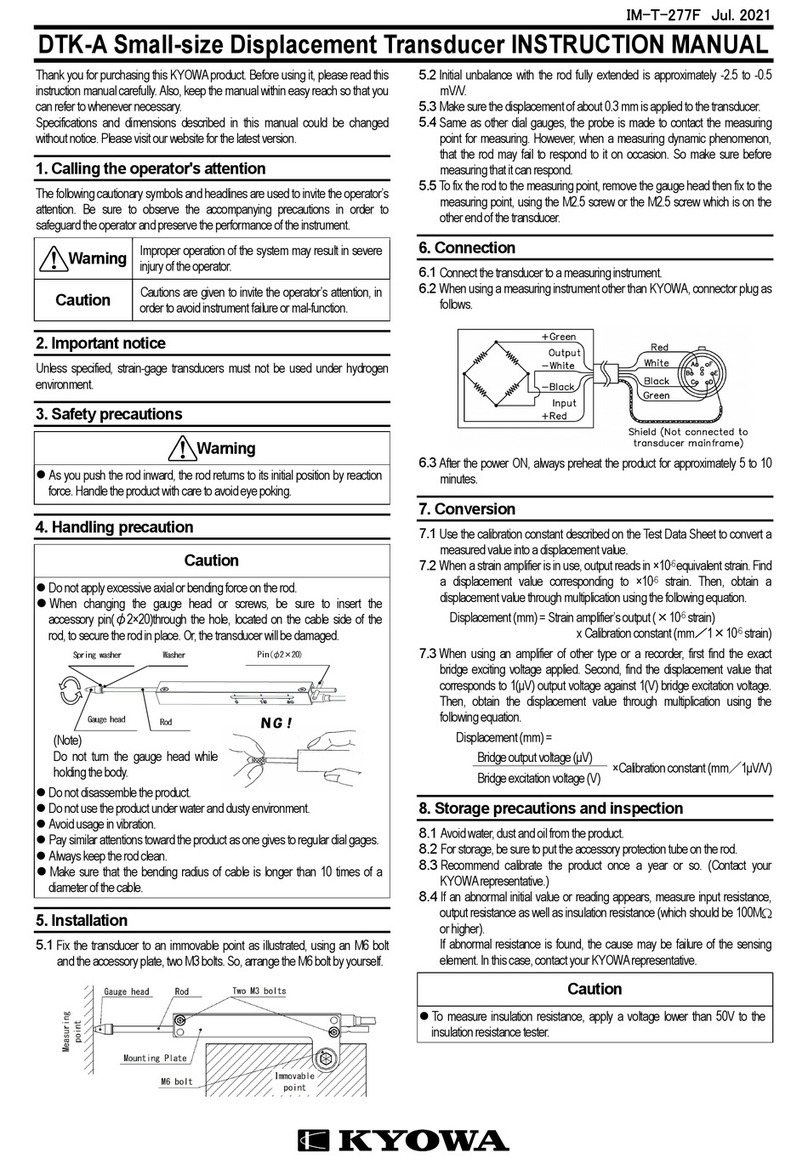

4.2 When using an NDIS connector (PRC03-12A10-7M) , perform wiring

as illustrated below.

4.3 How to connect when using KYOWA’s Bridge Box.

4.4 It is required to heat-run for 5 to 10 minutes before starting the

measurement.

4.5 A shield wire is not connected to the mainframe. If necessary, make

grounding at the amplified indicator. At this time, if inductive noise is

generated, connect an oscilloscope to the output terminal of the

amplified indicator, and while observing the waveform presented,

perform suitable grounding. Note that grounding does not always

produce a good result.

5. Conversion

5.1 Use the calibration constant described in the test data sheet to

convent a reading into pressure.

5.2 When a strain amplifier is in use, output reads in m/m equivalent

strain (×10-6 equivalent strain). Find pressure corresponding to m/m.

Then, obtain pressure through multiplication using the following

equation.

Strain amplifier's output (

×Calibration constant (MPa(kPa)/1m/m)

5.3 When using an amplifier of other type or a recorder, first find the exact

bridge exciting voltage applied. Second, find the pressure that

corresponds to 1V output voltage against 1V bridge excitation

voltage. Then, obtain the pressure through multiplication using the

following equation.

Pressure(MPa(kPa))=

Bridge excitation voltage( V)

×Calibration constant (MPa(kPa)/1V/V)

Sensitivity Decrease due to Cable Extension

If a strain gage transducer is connected to a signal conditioner, digital

indicator or strain amplifier having the bridge circuit excited on

constant voltage via extension cable, we cannot ignore the sensitivity

decrease due to the extension cable resistance which lowers the

voltage applied to the transducer.

The rated output with lowered sensitivity can be obtained through the

following equation:

True valueε0=( R )εi

R+(r×L)

Where, R:Transducer’s input resistance (Ω)

r:Extension cable’s reciprocating resistance (Ω) per meter

L:Extension cable length (m)

εi:Rated output written in the Test data sheet